Professional Documents

Culture Documents

KIM PP Pushing Pulling

Uploaded by

Mark Philipp AbanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KIM PP Pushing Pulling

Uploaded by

Mark Philipp AbanCopyright:

Available Formats

Key Indicator Method for assessing and designing physical workloads

with respect to manual Pushing and Pulling of loads

KIM-PP

Overview of Key Indicator Methods:

Key Indicator Method for assessing and designing physical workloads ...

with respect to manual Lifting, Holding and Carrying of loads (KIM-LHC)

with respect to manual Pushing and Pulling of loads (KIM-PP)

during Manual Handling Operations (KIM-MHO)

with respect to Whole-Body Forces (KIM-BF)

with respect to Awkward Body Postures (KIM-ABP)

with respect to Body Movement (KIM-BM)

as well as the respective Extended versions in a spreadsheet program (e.g. KIM-PP-E)

Photo: U. Völkner/fox-fotos.de Photo: U. Völkner/fox-fotos.de Photo: tirc83/iStock.com

Scope of the Key Indicator Method (KIM-PP)

This Key Indicator Method serves to record and assess physical workloads resulting from moving transport

devices, overhead conveyors or overhead cranes by muscle power.

Transport devices can include one-wheel barrows, single-axle barrows, trolleys or carriages with 3 to 6 wheels

which are moved freely on the floor in all directions by muscle power only. Overhead conveyors are monorail

systems with which the load is moved on transport devices in one direction. Overhead cranes are single-girder

overhead cranes covering areas in which the load can be moved in all directions.

If no additional forces are required for material processing, this Key Indicator Method can also be used for

manually moved work equipment (e.g. colour-marking barrows, measuring rollers).

Distinction from other Key Indicator Methods

If the load is moved without using equipment (e.g. rolling rotationally symmetric objects or dragging across the

floor), the Key Indicator Method “Whole-Body Forces” (KIM-BF) must be considered.

If the load is moved using transport devices which are equipped with mechanical drives (e.g. pedestrian-operated

trucks, stair climbing carts), the Key Indicator Methods “Body Movement” (KIM-BM) and “Whole-Body Forces”

(KIM-BF) can be taken into consideration in addition.

When moving lifting aids without substantial movements (e.g. pillar crane, suction lifter), the Key Indicator Method

“Whole-Body Forces” (KIM-BF) must be taken into consideration.

If there are several different sub-activities including pushing and pulling per working day, they must be recorded

and assessed separately (e.g. using KIM-PP-E). The probability of physical overload can only be assessed if all

physical workloads occurring during a working day are assessed.

Form including brief instructions

Draft for practical testing – Version 12.5 – As of 04.2019 – © BAuA/ASER/ArbMedErgo/ebus

KIM for assessing and designing physical workloads with respect to manual Pushing and Pulling of

loads (KIM-PP)

Workplace/sub-activity:

Duration of the working day: Evaluator:

Duration of the sub-activity: Date:

1st step: Determination of time rating points (distance, duration of the PP)

Distance1) up to …m2) 40 200 400 800 1200 1800 2500 4200 6300 8400 11000 15000 20000

Duration1) up to …min2) ≤1 ≤5 ≤ 10 ≤ 20 ≤ 30 ≤ 45 ≤ 60 ≤ 100 ≤ 150 ≤ 210 ≤ 270 ≤ 360 ≤ 480

Time rating points 1 1.5 2 2.5 3 3.5 4 5 6 7 8 9 10

1) 2

An approximate walking speed of 0.7 m/s (2.5 km/h) when pushing and pulling loads is assumed. ) Per sub-activity and working day.

2nd step: Determination of the rating points for other indicators

Transport device Overhead Overhead

conveyors cranes

Carriages

Load weight to only swivel with fixed castors or pedestrian-

be moved Barrows3) 4) castors lockable swivel castors controlled

including

transport device

[kg]

5) 5)

up to 50 3 2 2.5 2.5 3 1 1 1 1 2

> 50 up to 100 5 3 4 3 4 1 1 1 1 2.5

> 100 up to 200 10 6 7 4 6 2 1.5 1.5 1.5 3.5

> 200 up to 300 50 12 50 5 8 3 2 2 2 4.5

> 300 up to 400 50 7 12 4 3 2.5 2.5 6

> 400 up to 600 12 50 6 5 4 4 10

> 600 up to 800 50 10 8 7 7 15

> 800 up to 100 100 50

15 12 10 10

1000 100

100

> 1000 up to 100

50 50 50 20

1300 100

> 1300 100 100 100 50

3)

In addition to the propelling force, the load rating points also consider lifting, tilting, balancing and lowering forces. 4) Barrows with support

wheels, stair climbing carts and other special designs cannot be differentiated using the KIM-PP. 5) E.g. waste containers in outdoor areas with

simple wheel bearings, which might be exposed to the weather. Grey fields: These load weights can no longer be moved reliably.

Rating points

Driveway conditions

Carriages

Driveway completely level, smooth, solid, dry, without inclinations 0 0 0

Driveway mostly smooth and level, with small damaged spots/faults, without inclinations 0 0 1

Mixture of cobbles, concrete, asphalt, slight inclinations6), dropped kerb 0 1 2

Mixture of roughly cobbled, hard sand, slight inclinations6), small edges/sills 1 2 3

Earth or roughly cobbled driveway, potholes, heavy soiling, slight inclinations, landings, sills 3 5 6

Inclinations of 2 up to 4° (4 up to 8%) 5

Rating points

Additional points in case of Inclinations of 5 up to 10° (9 up to

10 + additional

significant inclinations or stairs 18%)

points

Stairs7), inclinations > 10° (18%) 25 Total

6) 7)

Slight inclination: up to 2° (4%) only for using stair climbing carts

Intermediate rating

Total IRP

Unfavourable working conditions (specify only where applicable) points

(max. 4)

IRP

Regularly significantly increased starting forces, because transport devices sink

3

into the ground or get wedged

Frequent stops with braking / without braking 3 / 1

Many changes of direction or curves, frequent manoeuvring 3

Load must be positioned precisely and stopped, driveway must be adhered to

1

precisely

Increased movement speed (approx. 1.0 up to 1.3 m/s) 2

None: there are no unfavourable working conditions 0

Intermediate rating

Unfavourable properties of the transport device/overhead Total IRP

points

conveyor/overhead crane (max. 4)

IRP

No suitable handles or construction parts for applying force 2

No brake when driving on inclinations > 2° (> 3%) 3

Unadjusted castors (e.g. too small on soft or uneven floor) 2

Defective castors (worn-out, rubbing, stiff, air pressure too low) 2

None: there are no unfavourable properties of the transport devices 0

Body posture / body movement 8) Rating points

Trunk upright or slightly inclined forward, no twisting

Force application height can be selected freely 3

No hindrance for the legs

Body inclined towards the direction of movement or slight twisting when

pulling the load on one side

Fixed force application height ranging from 0.9 – 1.2 m 5

No or only slight hindrance for the legs

Predominantly pulling

Awkward body postures caused by

- Fixed force application height < 0.9 or > 1.2 m

- Lateral force application on one side

- Significantly obstructed view 8

Significant hindrance for the legs

Direction of force Frequent/constant twisting and/or lateral inclination of the trunk

identifiable

8)

The typical body posture is to be taken into account. If the trunk is inclined to a greater extent when starting, braking and manoeuvring, this is

taken into account under unfavourable working conditions.

Rating

Work organisation / temporal distribution

points

Good: frequent variation of the physical workload situation due to other activities (including other types of physical

workload) / without a tight sequence of higher physical workloads within one type of physical workload during a single 0

working day.

Restricted: rare variation of the physical workload situation due to other activities (including other types of physical

workload) / occasional tight sequence of higher physical workloads within one type of physical workload during a 2

single working day.

Unfavourable: no/hardly any variation of the physical workload situation due to other activities (including other types

of physical workload) / frequent tight sequence of higher physical workloads within one type of physical workload 4

during a single working day with concurrent high load peaks.

3rd step: Evaluation and assessment

Load weight / transport device

Driveway conditions +

Unfavourable working conditions (∑ IRP) +

Properties of transport device (∑ IRP) +

Body posture +

In case of female

Work organisation / temporal distribution + employees:

Time rating Total of

x indicator rating points:

= x 1.3 =

points Result

Pushing and Pulling in pairs: x 0.7

The risk score calculated and the table below can be used as the basis for a rough evaluation:

Intensity of a) Probability of physical overload

Risk Risk range Measures

load* b) Possible health consequences

< 20 a) Physical overload is unlikely.

1 low None

points b) No health risk is to be expected.

a) Physical overload is possible for less resilient persons. For less resilient persons, workplace

20 - < 50 slightly

2 b) Fatigue, low-grade adaptation problems redesign and other prevention

points increased

which can be compensated for during leisure time measures may be helpful.

a) Physical overload is also possible for normally resilient

Workplace redesign and other

50 - < 100 substantially persons.

3 prevention measures should be

points increased b) Disorders (pain), possibly including dysfunctions, reversible

considered.

in most cases, without morphological manifestation

a) Physical overload is likely. Workplace redesign measures are

≥ 100

4 high b) More pronounced disorders and/or dysfunctions, structural necessary. Other prevention

points

damage with pathological significance measures should be considered.

*)

The boundaries between the risk ranges are fluid because of the individual working techniques and performance conditions. The classification

may therefore only be regarded as an orientation aid. Basically, it must be assumed that the probability of physical overload will increase as the

risk scores rise.

Guideline for the Key Indicator Method for assessing and designing physical

workloads with respect to manual Pushing and Pulling of loads

KIM-PP

Objective of the Key Indicator Method:

The objective of the KIMs is to document the main physical workload indicators as easily as possible, make correlations clear to the

user and allow for a rough assessment of the probability of physical overload. Possible consequences for health as well as the

resulting need for action may be derived from that.

Please note:

This method serves to assess the working conditions with respect to pushing and pulling loads on transport devices/overhead

conveyors/single-girder overhead cranes for orientation purposes. When determining the time rating points as well as assigning the

rating points for the key indicators (type of the transport device/load weight, driveway conditions, working conditions, properties and

condition of the transport device and body posture),sound knowledge of the sub-activity being assessed is nevertheless an absolute

prerequisite. Without such knowledge, it is not permitted to conduct an assessment. Rough estimates or assumptions lead to false

results.

Procedure:

If there are several different sub-activities including pushing and pulling per working day, they must be recorded and assessed

separately where applicable. The probability of physical overload can only be assessed if all physical workloads occurring during a

working day are assessed. They can be assessed using KIM-PP-E, for example. In case of overlaps with other types of physical

workload, it is to be examined whether other KIMs must also be used as an alternative (in this respect, see

https://www.baua.de/EN/Topics/Work-design/Physical-workload/Key-indicator-method/Key-indicator-method_node.html).

The assessment requires 3 steps to be carried out:

1. Determination of time rating points

2. Determination of the rating points for key indicators and

3. Evaluation/assessment. As a result, it may be

4. necessary to carry out a step which includes the derivation and implementation of workplace redesign measures.

It is generally allowed to form useful intermediate steps (interpolation) when determining the rating points.

Time rating points < 1 may not be assigned, as the time rating point is always at least 1!

Carrying out the documentation and evaluation/assessment:

1st step: Determination of time rating points

The time rating points are determined on the basis of the table. The basis is the whole distance or total duration in the sub-activity

per working day, which is covered using the transport device, both loaded and empty.

2nd step: Determination of the rating points for other indicators

The rating points for the type of the transport device/load weight, driveway conditions, working conditions, properties and condition

of the transport device and body posture are determined according to the indicators and scales described in the respective tables.

3rd step: Evaluation and assessment

Each sub-activity is evaluated on the basis of a sub-activity-related risk score (calculated by adding the rating points for the key

indicators and multiplying this by the time rating points). This risk score can be assigned to a risk range relating to this sub-activity

and, based on this, the probability of physical overload and possible consequences for health as well as the need for action

resulting from that can be derived. If women carry out this sub-activity, the risk score is to be multiplied by the factor 1.3. This takes

into account that women have on average about 2/3 of the physical capacity of men.

4th step: Workplace redesign and preventive occupational medical care

In addition to the prevention measures derived on the basis of the risk assessment, the following applies:

From risk range 3 “substantially increased”, workplace redesign measures as well as further collective and individual

prevention measures are usually necessary. In Germany, preventative occupational medical care in accordance with

ArbMedVV [German Ordinance on Occupational Health Care] is to be offered *).

Workplace redesign and prevention measures for groups of particularly vulnerable employees (e.g. young people or people

with altered performance) must be considered irrespective of the intensity of load and on a case-by-case basis where

appropriate, e.g. if employees demand preventive occupational medical care.

By examining the highest risk scores of the key indicators, the causes of increased physical workloads can be identified and

changes initiated. The need for a redesign should also be considered if individual indicators reach the maximum rating points.

Where appropriate, indications to restrictions of the feasibility with respect to the rating points for individual indicators must be

considered.

*) ArbMedVV [German Ordinance on Occupational Health Care] as of June 2019

You might also like

- Types - of - TransportationDocument8 pagesTypes - of - TransportationParvathaneni KarishmaNo ratings yet

- TM RM CH 9 TADocument12 pagesTM RM CH 9 TAPw SajanNo ratings yet

- 321DLCR#209Document1 page321DLCR#209Kyaw Thet AungNo ratings yet

- EL Topic1 - APSDocument4 pagesEL Topic1 - APSSrinivasan SNo ratings yet

- OhmmeterDocument33 pagesOhmmetermardyNo ratings yet

- BD-XDUO288-EN-WW 160810 Original 76740Document4 pagesBD-XDUO288-EN-WW 160810 Original 76740Juan Jose Palacios BecerraNo ratings yet

- 321DLCR#209Document1 page321DLCR#209Kyaw Thet AungNo ratings yet

- I Answer All The Questions. Each Question Carries 2 Marks (2 X 5 10)Document4 pagesI Answer All The Questions. Each Question Carries 2 Marks (2 X 5 10)Jayasurya GottapuNo ratings yet

- Mekano Channel Selection Guide - 11.2018 PDFDocument2 pagesMekano Channel Selection Guide - 11.2018 PDFvuhalamNo ratings yet

- C1 Resmat 232663 166251Document19 pagesC1 Resmat 232663 166251thianaNo ratings yet

- L2b - (Live) Graphs and Equations of MotionDocument16 pagesL2b - (Live) Graphs and Equations of MotionGGNo ratings yet

- Freight Transport SystemsDocument34 pagesFreight Transport SystemspeanakyNo ratings yet

- Ingersoll Rand Herculink Bop Hoist ManualDocument4 pagesIngersoll Rand Herculink Bop Hoist Manualjohn_192775339No ratings yet

- Handout Plaxis Introduction Course - Session 3Document46 pagesHandout Plaxis Introduction Course - Session 3Mehdi.Most0% (1)

- Belt Tension and Power FormulasDocument1 pageBelt Tension and Power FormulasBarry ChungNo ratings yet

- Aaff Mue Idm Test A4 - en LowDocument20 pagesAaff Mue Idm Test A4 - en LowAfzal SarfarazNo ratings yet

- Method Pile Load Test Using Kentledge MethodDocument6 pagesMethod Pile Load Test Using Kentledge MethodAndhika HerdiawanNo ratings yet

- Lateral Pile Load Test For PilesDocument8 pagesLateral Pile Load Test For PilesSubrahmanaya S Murthy TATA100% (3)

- Critical Lift Plan - Gen Set RoomDocument4 pagesCritical Lift Plan - Gen Set RoomKachi NixonNo ratings yet

- Crane How+to+Use+Load+ChartDocument7 pagesCrane How+to+Use+Load+ChartAnonymous d2wsnS9UkNo ratings yet

- TRAFFIC ANALYSIS REPORTDocument6 pagesTRAFFIC ANALYSIS REPORTBipin Gyawali0% (1)

- Universal Testing Machines - Model: UTE: FeaturesDocument6 pagesUniversal Testing Machines - Model: UTE: FeaturesEr Hemant Kumar SahNo ratings yet

- Spearman's Rank: A Guide ToDocument4 pagesSpearman's Rank: A Guide TonugrohoNo ratings yet

- Exp 1Document6 pagesExp 1Muhammad Moin KhanNo ratings yet

- MC104 Mini Crane Delivers 0.995 Ton Capacity in Compact 5.5m PackageDocument4 pagesMC104 Mini Crane Delivers 0.995 Ton Capacity in Compact 5.5m PackageCamilo Corrales M.No ratings yet

- KKKH 4543: Urban Transport Planning: Name: Aini Hazwani Binti Shahrir Matric No.: A155202Document4 pagesKKKH 4543: Urban Transport Planning: Name: Aini Hazwani Binti Shahrir Matric No.: A155202Muhammad BilalNo ratings yet

- MPFM Handbook Program Version 1Document20 pagesMPFM Handbook Program Version 1Olusegun OyebanjiNo ratings yet

- Hiab Knuckle Boom Cranes Spec 09d776 122Document2 pagesHiab Knuckle Boom Cranes Spec 09d776 122LitsaNo ratings yet

- Bangunan & Stabilitas UAD Naskah 1Document6 pagesBangunan & Stabilitas UAD Naskah 1Iskandar ZulkarnainNo ratings yet

- MPFM Handbook Program Version 1Document20 pagesMPFM Handbook Program Version 1AliNo ratings yet

- Design guidelines for acceleration and deceleration lanesDocument2 pagesDesign guidelines for acceleration and deceleration lanesezarul321100% (1)

- Well data analysisDocument20 pagesWell data analysisAhmedNo ratings yet

- Exp 4 AdpDocument4 pagesExp 4 AdpAditya kumar GuptaNo ratings yet

- C 1005 Â " 99 QZEWMDUTUKVEDocument4 pagesC 1005 Â " 99 QZEWMDUTUKVEMichael Bogantes JimenezNo ratings yet

- CVEN 2401 Workshop Wk2 SolutionDocument8 pagesCVEN 2401 Workshop Wk2 SolutionMichael BoutsalisNo ratings yet

- Measuring column height over timeDocument4 pagesMeasuring column height over timeTaslinNo ratings yet

- BUS473: Supply Chain Management Unit 4.1: Type of FacilitiesDocument22 pagesBUS473: Supply Chain Management Unit 4.1: Type of FacilitiesMoiz MunisNo ratings yet

- Whitepaper Tobii Pro I-VT Fixation FilterDocument21 pagesWhitepaper Tobii Pro I-VT Fixation FilterAlexOO7No ratings yet

- Sieve Analysis of AggregatesDocument6 pagesSieve Analysis of AggregatesShahbaz WaraichNo ratings yet

- Belt Bucket Elevator - Mechanical Engineer PartnershipDocument6 pagesBelt Bucket Elevator - Mechanical Engineer PartnershipDeo Warren SilangNo ratings yet

- Propuesta de EJERC Rayleigh WavesDocument3 pagesPropuesta de EJERC Rayleigh WavesJose Alejandro Benites CruzNo ratings yet

- Elevator & Hoist Modeling, Simulation & Speed ControlDocument39 pagesElevator & Hoist Modeling, Simulation & Speed ControlRui Miguel Salvador100% (1)

- Belt Conveyor CalculationDocument45 pagesBelt Conveyor CalculationAnkurNo ratings yet

- Effect of Truck PayloadDocument28 pagesEffect of Truck Payloadernesto gil huiñocanaNo ratings yet

- Truck-Mounted UNIC Crane V550K-TH Series Lifts Up To 5050kgDocument4 pagesTruck-Mounted UNIC Crane V550K-TH Series Lifts Up To 5050kgRestie TeanoNo ratings yet

- Crane Barge Stability Criteriariver-Rules-Jan22Document5 pagesCrane Barge Stability Criteriariver-Rules-Jan22Prakash MohanNo ratings yet

- Assignment OverheadsDocument33 pagesAssignment OverheadsBishnu Ram GhimireNo ratings yet

- E Line Info enDocument29 pagesE Line Info enmarchentoNo ratings yet

- Temp4 Design ProceduresDocument23 pagesTemp4 Design ProceduresAhmed AdelNo ratings yet

- Shop Manual: WA65-3 WA65-3 Parallel Lift WA75-3 WA85-3 WA90-3 WA95-3Document422 pagesShop Manual: WA65-3 WA65-3 Parallel Lift WA75-3 WA85-3 WA90-3 WA95-3Thein Htoon lwin100% (3)

- Material Handling System Homework Group Project AnalysisDocument3 pagesMaterial Handling System Homework Group Project AnalysisKhiêm GiaNo ratings yet

- Terminologies Maintained Load Test Constant Rate of Penetration TestDocument10 pagesTerminologies Maintained Load Test Constant Rate of Penetration TestRajput Ayush ThakurNo ratings yet

- Types of Pile Load Test PDFDocument10 pagesTypes of Pile Load Test PDFRajesh KhadkaNo ratings yet

- Haulage Trucks 953Document7 pagesHaulage Trucks 953Muhammad Syukri YusaNo ratings yet

- ImpactDocument7 pagesImpactpdiconpNo ratings yet

- Mechanical Aptitude & Spatial Relations Practice QuestionsFrom EverandMechanical Aptitude & Spatial Relations Practice QuestionsNo ratings yet

- A Student’s Guide for a Medical Mission-trip-guideDocument57 pagesA Student’s Guide for a Medical Mission-trip-guideMark Philipp AbanNo ratings yet

- Industrial - Ergo - Screening StanfordDocument2 pagesIndustrial - Ergo - Screening StanfordMark Philipp AbanNo ratings yet

- Breast Screening Guide For GPsDocument1 pageBreast Screening Guide For GPsMark Philipp AbanNo ratings yet

- Tips for Promoting School Employee Wellness CDCDocument2 pagesTips for Promoting School Employee Wellness CDCMark Philipp AbanNo ratings yet

- American Diabetes Assn-EmployerPlaybookDocument12 pagesAmerican Diabetes Assn-EmployerPlaybookMark Philipp AbanNo ratings yet

- WHO Basic Emergency CareDocument70 pagesWHO Basic Emergency CareMark Philipp AbanNo ratings yet

- Checklist For Best Practices For Vaccination Clinics Held at Satellite, Temporary, or Off-Site LocationsDocument6 pagesChecklist For Best Practices For Vaccination Clinics Held at Satellite, Temporary, or Off-Site LocationsMark Philipp AbanNo ratings yet

- Checklist For Best Practices For Vaccination Clinics Held at Satellite, Temporary, or Off-Site LocationsDocument6 pagesChecklist For Best Practices For Vaccination Clinics Held at Satellite, Temporary, or Off-Site LocationsMark Philipp AbanNo ratings yet

- Church Mobilization FlyerDocument1 pageChurch Mobilization FlyerMark Philipp AbanNo ratings yet

- Chapter5 Quality in Production & Operations Management QuestionsDocument4 pagesChapter5 Quality in Production & Operations Management QuestionsMark Philipp AbanNo ratings yet

- Event Details Letter Vaccinology Workshop - June23Document1 pageEvent Details Letter Vaccinology Workshop - June23Mark Philipp AbanNo ratings yet

- START Emergency TriageDocument12 pagesSTART Emergency TriageMark Philipp AbanNo ratings yet

- Operations Management BabDocument109 pagesOperations Management BabBenjamin Adelwini BugriNo ratings yet

- Bites and Sting Presentation Lesson Plan ResourceDocument5 pagesBites and Sting Presentation Lesson Plan ResourceMark Philipp AbanNo ratings yet

- Chapter5 Total Quality Management NotesDocument4 pagesChapter5 Total Quality Management NotesMark Philipp AbanNo ratings yet

- Chapter5 Statistical Process Control QuestionsDocument3 pagesChapter5 Statistical Process Control QuestionsMark Philipp AbanNo ratings yet

- Chapter5 Total Quality Management QuestionsDocument2 pagesChapter5 Total Quality Management QuestionsMark Philipp AbanNo ratings yet

- A Cross-Sectional Study of Viral Hepatitis Perception Among Residents From Southeast and North Regions of BrazilDocument11 pagesA Cross-Sectional Study of Viral Hepatitis Perception Among Residents From Southeast and North Regions of BrazilMark Philipp AbanNo ratings yet

- Chapter5 QMS and ISO Standards QuestionsDocument3 pagesChapter5 QMS and ISO Standards QuestionsMark Philipp AbanNo ratings yet

- POM COURSE GUIDEDocument8 pagesPOM COURSE GUIDEMark Philipp AbanNo ratings yet

- Chapter5 Quality in Production & Operations Management NotesDocument12 pagesChapter5 Quality in Production & Operations Management NotesMark Philipp AbanNo ratings yet

- DOH Training On Water Safety PlanDocument19 pagesDOH Training On Water Safety PlanMark Philipp AbanNo ratings yet

- Chapter5 Quality Assurance NotesDocument4 pagesChapter5 Quality Assurance NotesMark Philipp AbanNo ratings yet

- Tuberculosis (TB) Spreads Through The Air From One Person To AnotherDocument1 pageTuberculosis (TB) Spreads Through The Air From One Person To AnotherMark Philipp AbanNo ratings yet

- Addressing Myths and Misconceptions About Hepatitis B Among African Immigrant CommunitiesDocument13 pagesAddressing Myths and Misconceptions About Hepatitis B Among African Immigrant CommunitiesMark Philipp AbanNo ratings yet

- Sex and Hepatitis B Factsheet - 030816Document2 pagesSex and Hepatitis B Factsheet - 030816Mark Philipp AbanNo ratings yet

- How To Protect Ourselves From TBDocument8 pagesHow To Protect Ourselves From TBMark Philipp AbanNo ratings yet

- Knowledge of Hepatitis B Virus Infection Among Traders: Original ArticleDocument6 pagesKnowledge of Hepatitis B Virus Infection Among Traders: Original ArticleMark Philipp AbanNo ratings yet

- Adapt NTP to COVID-19Document42 pagesAdapt NTP to COVID-19Julius Dominique Lagtapon AnjaoNo ratings yet

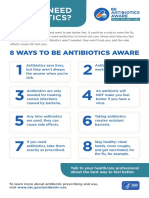

- Cdc-Antibiotic Use-Wait-Room-Poster-11x17-PDocument1 pageCdc-Antibiotic Use-Wait-Room-Poster-11x17-PMark Philipp AbanNo ratings yet

- Macho Drum Winches Data v1.4Document2 pagesMacho Drum Winches Data v1.4AdrianSomoiagNo ratings yet

- Inverse Trigo and Functions BansalDocument28 pagesInverse Trigo and Functions BansalYagyank ChadhaNo ratings yet

- Pr2-Chapter3 Mao MN Guto JoDocument5 pagesPr2-Chapter3 Mao MN Guto JoAnaroseNo ratings yet

- BCS - SS-CRM 460 - 2 Jun2019Document2 pagesBCS - SS-CRM 460 - 2 Jun2019Peterson SudlabNo ratings yet

- NRD Idg Gy Fiyf FofkDocument7 pagesNRD Idg Gy Fiyf FofkMERA MENTALNo ratings yet

- 2011 2012 Machinery SubsidyDocument130 pages2011 2012 Machinery SubsidyanbugobiNo ratings yet

- Chapter 3 PPTDocument41 pagesChapter 3 PPTidNo ratings yet

- How Society Is Organized Chapter 5Document18 pagesHow Society Is Organized Chapter 5Anne MoralesNo ratings yet

- Van Inwagen's Treatment of The Problem of The ManyDocument13 pagesVan Inwagen's Treatment of The Problem of The ManyHershy FishmanNo ratings yet

- Negasi Aregawi PpintDocument16 pagesNegasi Aregawi PpintMilkias MenaNo ratings yet

- Republic of The Philippines: Libon Community CollegeDocument2 pagesRepublic of The Philippines: Libon Community Collegepayno gelacioNo ratings yet

- En 10305-4Document21 pagesEn 10305-4lorenzinho290100% (1)

- Concepts - Essential Elements of Theories PDFDocument5 pagesConcepts - Essential Elements of Theories PDFKarlHeinrichNo ratings yet

- ASCO Switch CatalogDocument38 pagesASCO Switch Catalogjohnnie0% (1)

- Axiatonal Lines Connection IntroductionDocument9 pagesAxiatonal Lines Connection IntroductionDavid Lopes100% (1)

- Analysis of Salem PossessedDocument4 pagesAnalysis of Salem PossessedCharity BurgessNo ratings yet

- Pitch Angle Control For A Small-Scale Darrieus VAWTDocument11 pagesPitch Angle Control For A Small-Scale Darrieus VAWThuy4ngooNo ratings yet

- Department of Education: Republic of The PhilippinesDocument4 pagesDepartment of Education: Republic of The PhilippinesEllen Cabatian BanaguasNo ratings yet

- 4.3.c-Technology and IndustrializationDocument23 pages4.3.c-Technology and Industrializationjjamppong09No ratings yet

- Factors Affecting Online Grocery Shopping Experience: Dhinda Siti Mustikasari, Rifelly Dewi AstutiDocument7 pagesFactors Affecting Online Grocery Shopping Experience: Dhinda Siti Mustikasari, Rifelly Dewi AstutiSiddharth Singh TomarNo ratings yet

- Science 7 Q4 FinalDocument38 pagesScience 7 Q4 FinalJavier August100% (1)

- Vasos Amortiguadores - Sedical PDFDocument1 pageVasos Amortiguadores - Sedical PDFLuis DomdNo ratings yet

- The Trouble With UV LightDocument3 pagesThe Trouble With UV LightSàkâtã ÁbéŕàNo ratings yet

- From The Conventional Total Station To The Prospective Image Assisted Photogrammetric Scanning Total Station: Comprehensive ReviewDocument7 pagesFrom The Conventional Total Station To The Prospective Image Assisted Photogrammetric Scanning Total Station: Comprehensive ReviewLeroy Lionel SonfackNo ratings yet

- Pathway 4 Unit 2Document9 pagesPathway 4 Unit 2Andrea ParedesNo ratings yet

- 10 819 Astro Express LF Valve IODocument2 pages10 819 Astro Express LF Valve IOHary FadlyNo ratings yet

- TX AsiaDemandForecast 2018Document12 pagesTX AsiaDemandForecast 2018Muhammad AsadNo ratings yet

- 151430X PDFDocument5 pages151430X PDFIndra RosadiNo ratings yet

- How you seize the space between next and nowDocument11 pagesHow you seize the space between next and nowMathan J RNo ratings yet

- Ogp1 Pintura PDFDocument19 pagesOgp1 Pintura PDFEl_memito100% (1)