Professional Documents

Culture Documents

Structural Sub Contractor Management - Rev. 02

Structural Sub Contractor Management - Rev. 02

Uploaded by

Raja VigneshOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Structural Sub Contractor Management - Rev. 02

Structural Sub Contractor Management - Rev. 02

Uploaded by

Raja VigneshCopyright:

Available Formats

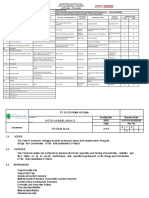

Management of Subcontractor Loose Materials

Projects Quality Sub-contractor Production

Warehouse

Control Company Team

Inspect the packing list** as per the

Start drawings and material as per the

packing list as well as per the For the material not installed

quality standards and issue IRC by subcontractor e.g. pipe

support etc., prepare indent

slip .

Prepare detailed Packing list per

Inform the Subcontractor items two weeks before the ● Receive the material and

about the loose items and shipment and submit for review to check the material

spare*** to be mentioned in Projects team physically as per the

the Packing list with

packing list

identification of loose items to

be sent to site and spare, or

● Store the material in the

to be used at ALMEM.

Inspect the material received for DEDICATED Area along To Inform warehouse if

transport damages with the identification of material to be delivered in the

project & packing list and workshop.

inform to QC for inspection

Deliver materials with segregation as

per PO with detailed packing lists,

*Consumables:

Record the material in the

● Welding Material **PACKING LIST DETAILS TO BE Material Inbound List with all the

● Tools & Equipment Checked by QC Inspector details which should include:

● Temporary beams etc. Deliver consumables* separately,

● Detailed description of each ● Material details as per the

● Cutting discs they should not be part of material

packing List

● Grinding discs item in each package to be installed packing list, instead

● Storage Area projectwise

a separate list of consumables

● Mention to the reference of ● Category identifying to be

should be submitted to the

*** Loose Items: the PO and structure part warehouse for security reasons.

used in workshop or to be Approve Subcontractors’

sent at site.

● Sheeting for roof and (e.g. Main Cold box etc.), material requisition

open areas of the ● Categorization of the items

structure, to be sent to site and the Manage consumables in

● Shim Plates, ALMEM Facility as per storage

ones going to be used at location specified by Material Issuance to production

● Support beams, ALMEM workshop. Warehouse and Subcontractor and update

● Bolts & Gaskets, ● The packing list should also Material Inbound List

● Ladder(s), refer to the drawings and

● Plate(s),

the part numbers of the Prepare Indent Slip and submit

● Insulation material such

as wire mesh. material being packed. to ALMEM production for Specify location for

approval for any material Subcontractors’ consumables.

● Additional Frames and required under the custody of

support legs etc. Warehouse.

● Pipe Support(s).

End

You might also like

- Quizzes Chapter 3 Acccounting EquationDocument7 pagesQuizzes Chapter 3 Acccounting EquationAmie Jane Miranda100% (2)

- Positive Recall ProcedureDocument6 pagesPositive Recall ProcedureSiva RamNo ratings yet

- QAP-07 Material Control Procedure PDFDocument22 pagesQAP-07 Material Control Procedure PDFnaseema1100% (9)

- SFQP-MECH With NDT-SILO-2Document8 pagesSFQP-MECH With NDT-SILO-2Dhananjay BalkiNo ratings yet

- Stores Management R1Document5 pagesStores Management R1Tarun Godiyal0% (1)

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiDocument9 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - Material Receiving STG Project 10-01759-001 EnppiTariqMalikNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials ReceivingDocument7 pagesSaudi Aramco Inspection Checklist: SAIC-J-6002 24-Jul-18 Inst General Piping and Tubing System - Materials Receivingnisha_khanNo ratings yet

- Saudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Compression Fittings and Accessories - Material Receiving SAIC-J-6005 24-Jul-18 Instnisha_khan0% (1)

- Procedure For Packing & Dispatch: Spectraa Technology Solutions LTDDocument4 pagesProcedure For Packing & Dispatch: Spectraa Technology Solutions LTDAshokkumar ThangarajNo ratings yet

- Itp WeldDocument2 pagesItp WeldHarshaVeeragandhamNo ratings yet

- Perfect Oil Seals & I.R.P.: Fifo Process FlowDocument3 pagesPerfect Oil Seals & I.R.P.: Fifo Process FlowJitendra ShindeNo ratings yet

- PIP - One Time CleansingDocument5 pagesPIP - One Time Cleansingcpscmain.supplyNo ratings yet

- Preveration Material ProcedureDocument6 pagesPreveration Material ProcedureSafety Naravisi BatamNo ratings yet

- Inspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationDocument5 pagesInspection Checklist: Analyzers / Analyzer Shelters and Racks - InstallationTariqMalik100% (1)

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Method Statement For Installation of CCTV Camera System: Join For Latest ArticlesDocument1 pageMethod Statement For Installation of CCTV Camera System: Join For Latest Articleshaytham65No ratings yet

- PREAMBLESDocument3 pagesPREAMBLESchocostarfishNo ratings yet

- SATIP-P-104-03 Rev 7 FinalDocument3 pagesSATIP-P-104-03 Rev 7 FinalHatemS.MashaGbehNo ratings yet

- Saudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: General - Instrumentation Accessories - Material Receiving SAIC-J-6017 24-Jul-18 Instnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Turtle Diagram StoreDocument1 pageTurtle Diagram StoreRiyu Rathod0% (1)

- Saudi Aramco Inspection ChecklistDocument8 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 InstDocument4 pagesSaudi Aramco Inspection Checklist: Recorder / Indicator - Material Receiving SAIC-J-6016 24-Jul-18 Instnisha_khan0% (1)

- Standard Operation Procedure Store ProcessDocument2 pagesStandard Operation Procedure Store ProcessHarits As SiddiqNo ratings yet

- Openable Hardware Response Sheet PTB LNT CDS 1383 R01Document23 pagesOpenable Hardware Response Sheet PTB LNT CDS 1383 R01Joseph FinnyNo ratings yet

- Saudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-CommissioningDocument3 pagesSaudi Aramco Inspection Checklist: SAIC-J-6006 24-Jul-18 Inst Copper Tubing & Fittings Installation and Pre-Commissioningnisha_khan0% (1)

- AV-ST-WI-01 Material Receipt Inspection Storage Issue and Recovery Iss 1Document6 pagesAV-ST-WI-01 Material Receipt Inspection Storage Issue and Recovery Iss 1Kevin DeLimaNo ratings yet

- 3.2 Bill of QuantitiesDocument24 pages3.2 Bill of QuantitiesNazakat HussainNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Receiving Material ProcedureDocument5 pagesReceiving Material Proceduregst ajah100% (1)

- 7.ITP For Fair Face KK3 - PR - 03 - 00011Document4 pages7.ITP For Fair Face KK3 - PR - 03 - 00011Daniel SinagaNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Saudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item NoDocument7 pagesSaudi Aramco Inspection Checklist: Acceptance Criteria Reference Pass Fail N/A Re-Insp Date Item Nonisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Material Approval Document Checklist-230619Document3 pagesMaterial Approval Document Checklist-230619kennethtalacayNo ratings yet

- AV-OP-05 Goods Inwards Storage and Release Iss 1Document3 pagesAV-OP-05 Goods Inwards Storage and Release Iss 1Kevin DeLimaNo ratings yet

- Assignment On MCDDocument8 pagesAssignment On MCDshamim hossainNo ratings yet

- 3-ITP - Sample - Mechanical Installation of Compressors, Generators, PumpsDocument10 pages3-ITP - Sample - Mechanical Installation of Compressors, Generators, Pumpsumitkakca04No ratings yet

- ITP For Fire Protection System Rev. 02Document11 pagesITP For Fire Protection System Rev. 02Bibin Chacko MammenNo ratings yet

- N3 SFPI - Inventory Count Form - Facv3Document9 pagesN3 SFPI - Inventory Count Form - Facv3Alexis TiviNo ratings yet

- Chemical & Lab EquipmentDocument3 pagesChemical & Lab EquipmentsudjonoNo ratings yet

- IQC ChartDocument1 pageIQC Chartrishi gautamNo ratings yet

- 4 ASALA - Storage and Handling Pr.Document14 pages4 ASALA - Storage and Handling Pr.MohamedNo ratings yet

- 1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureDocument6 pages1000-90-0911 - 03 Fabricator Packing and Shipping ProcedureprasongNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khan0% (1)

- Building and House TrailerDocument3 pagesBuilding and House TrailersudjonoNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- 215-04a - HANDLING, STORAGE, PACKAGING, PRESERVATION AND DELIVERYDocument8 pages215-04a - HANDLING, STORAGE, PACKAGING, PRESERVATION AND DELIVERYyusuf.yuzuakNo ratings yet

- Saudi Aramco Inspection ChecklistDocument5 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Method Statement For Testing & Commissioning of Fire DetectionDocument38 pagesMethod Statement For Testing & Commissioning of Fire DetectionJaya KrishnaNo ratings yet

- Azmeel Inspection Checklist: General - Electrical Equipment, Storage, Handling & Preservation AZIC-P-3001 ElectricalDocument3 pagesAzmeel Inspection Checklist: General - Electrical Equipment, Storage, Handling & Preservation AZIC-P-3001 ElectricalVinay YadavNo ratings yet

- J910-Dh02-P10zen-040010 - (Ahf) Field Itp For Precast Box Culvert Installation Work - Rev.aDocument16 pagesJ910-Dh02-P10zen-040010 - (Ahf) Field Itp For Precast Box Culvert Installation Work - Rev.arudi sarifudinNo ratings yet

- Buildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers ADM-18Document8 pagesBuildings Department Practice Note For Authorized Persons, Registered Structural Engineers and Registered Geotechnical Engineers ADM-18Kaiser EdwardNo ratings yet

- PQ-GENR-QAC-SPC-PQC-00005-00 - H01 Traceability and Marking Requirements For Materials andDocument8 pagesPQ-GENR-QAC-SPC-PQC-00005-00 - H01 Traceability and Marking Requirements For Materials andAFQBAVQ2EFCQF31FNo ratings yet

- Saudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPDocument3 pagesSaudi Aramco Inspection Checklist: CP Accessories - Material Receiving SAIC-X-3002 CPImran khanNo ratings yet

- SACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingDocument2 pagesSACIC-T-5601 Comms Facilities - Self Supporting Communication Tower - Material ReceivingArshad ImamNo ratings yet

- Saudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 InstDocument13 pagesSaudi Aramco Inspection Checklist: Electronic Control Systems - PLC - Material Receiving SAIC-J-6803 24-Jul-18 Instnisha_khanNo ratings yet

- Material Take Off (Bulk MTO)Document6 pagesMaterial Take Off (Bulk MTO)rhomadona50% (2)

- Business Law Learning Objectives Chapter 17Document2 pagesBusiness Law Learning Objectives Chapter 17Samantha GrozaNo ratings yet

- Marketing Policy, Products & Services of Standard Chartered BankDocument19 pagesMarketing Policy, Products & Services of Standard Chartered BankMd Khurshed AlamNo ratings yet

- What Is Business RiskDocument14 pagesWhat Is Business RiskBelkacem AchourNo ratings yet

- Mepco Tender Notice National Competitive Bidding (NCB) For Procurement of Grid Station / Transmission Line Material Under Mepco'S Own ResourcesDocument1 pageMepco Tender Notice National Competitive Bidding (NCB) For Procurement of Grid Station / Transmission Line Material Under Mepco'S Own ResourceskhawarNo ratings yet

- OM With TQM (Process TechnologyDocument3 pagesOM With TQM (Process TechnologyMellanie SerranoNo ratings yet

- GDSN - Certified Data Pool List GDSN - Certified Data Pool ListDocument12 pagesGDSN - Certified Data Pool List GDSN - Certified Data Pool ListLeah WittNo ratings yet

- Bryan Basan Oliquino: Statement of AccountDocument4 pagesBryan Basan Oliquino: Statement of Accounttsung gokoNo ratings yet

- SABMiller Company ProfileDocument6 pagesSABMiller Company ProfilerejoyarchNo ratings yet

- OUCET Economics Syllabus & Exam PatternDocument1 pageOUCET Economics Syllabus & Exam PatternpavaniNo ratings yet

- Understanding Logic Behind Blue Ocean StrategyDocument2 pagesUnderstanding Logic Behind Blue Ocean StrategyImamaTariqNo ratings yet

- Annual Report 2011Document127 pagesAnnual Report 2011Nooreza PeerooNo ratings yet

- Karjat Project SummaryDocument2 pagesKarjat Project Summarysnehachandan91No ratings yet

- AT&T NegotiationDocument29 pagesAT&T NegotiationEbube Anizor100% (5)

- Basic EntryDocument7 pagesBasic EntryNaveenkumar YerawarNo ratings yet

- Câu hỏi lý thuyết TACN 2Document10 pagesCâu hỏi lý thuyết TACN 2Nguyễn Thanh NgânNo ratings yet

- (LAB) Activity - Preparation of Financial Statements Using SpreadsheetDocument3 pages(LAB) Activity - Preparation of Financial Statements Using SpreadsheetJUVEN LOGAGAY0% (1)

- What Is Franchising?: Roland G. Justo Bsbafm-3Document5 pagesWhat Is Franchising?: Roland G. Justo Bsbafm-3kim cheNo ratings yet

- Mujaya Cergas EntDocument8 pagesMujaya Cergas EntNur HaslizaNo ratings yet

- Welcome: Manual For New Staff To Understand Our Purpose and Functions of Our HR DepartmentDocument5 pagesWelcome: Manual For New Staff To Understand Our Purpose and Functions of Our HR DepartmentHieu BuiNo ratings yet

- Project Audit & ClosureDocument14 pagesProject Audit & ClosureHarshit Singh100% (1)

- 000284sidbi MatvDocument2 pages000284sidbi Matvprojects1No ratings yet

- Marketing Plan Report - IBADocument24 pagesMarketing Plan Report - IBAAamir Khan67% (3)

- Investments Chapter 1 Powerpoint SlideDocument11 pagesInvestments Chapter 1 Powerpoint SlideDénise RafaëlNo ratings yet

- Week 09 - Execise 01 (Time Value of Money Activity) - SolutionDocument4 pagesWeek 09 - Execise 01 (Time Value of Money Activity) - Solutionريم الميسريNo ratings yet

- Jep 14 4 23 PDFDocument64 pagesJep 14 4 23 PDFSang Putu NandHa SuhendRaNo ratings yet

- PDFDocument1 pagePDFJamie Roslyn YoungNo ratings yet

- Bulletin BoardDocument3 pagesBulletin BoardRoldan Arca PagaposNo ratings yet

- Icc Ncnda-BlankDocument10 pagesIcc Ncnda-BlankACCNo ratings yet

- Customer Satisfaction Towards NissanDocument43 pagesCustomer Satisfaction Towards NissanAnurag DubeyNo ratings yet