Professional Documents

Culture Documents

Piping System Assessment & Troubleshooting For 90-HRV0001 - 6 of 9

Uploaded by

Sodsai LamtharnOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Piping System Assessment & Troubleshooting For 90-HRV0001 - 6 of 9

Uploaded by

Sodsai LamtharnCopyright:

Available Formats

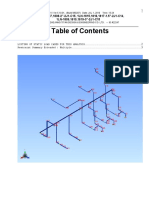

As-Designed Piping Stress Analysis-Sustained

• The original design for this piping system was based on the ASME B31.3-2004

stress allowable. For the ASTM A672, GR.B60 CL.22 material, at 370/425 °C the

Code maximum expansion Displacement stress range allowable were 199.0/191.2

MPa. and Sustained stress was 75.4 MPa.

• An as-designed piping stress analysis confirmed that the piping system design

specifications are in compliance with the ASME B31.3-2004 stress allowable for the

sustained loads, displacement load ranges, and the piping wall thickness.

• The sustained load stress contour plot for the as-designed analysis as show in

Figure 3. Based on the as-designed piping system stress analysis, the highest

sustained load stress was 54.0 MPa at the location of branch 78”x36” (node 630).

Stress Profile As-Designed

Item Load Case Type of Stress Node Allowable Stress (Mpa) Code Stress (Mpa) Ratio (%) Code Stress Check

1 10 (SUS) W+P1+H Sustain 630 75.4 54 71.6 PASSED

2 15 (EXP) L15=L4-L10 Thermal Expansion DT 560 191.2 176 92.05 PASSED

3 16 (EXP) L16=L5-L10 Thermal Expansion OT 560 199 158.6 79.70 PASSED

4 17 (OCC) L17=L10+L11 Wind +X 560 100.3 86.8 86.5 PASSED

5 18 (OCC) L18=L10+L12 Wind -X 560 100.3 99.5 99.2 PASSED

6 19 (OCC) L19=L10+L13 Wind +Z 1610 100.3 79.6 79.4 PASSED

7 20 (OCC) L20=L10+L14 Wind -Z 630 100.3 82.1 81.8 PASSED

You might also like

- Sag-Tension Calculation IEEE STD 605 2008Document10 pagesSag-Tension Calculation IEEE STD 605 2008vishnuvyasNo ratings yet

- Steel Beam DesignDocument8 pagesSteel Beam DesignKatracho2No ratings yet

- Directional Relay Sip BDocument12 pagesDirectional Relay Sip BAnonymous fU04Z4clNo ratings yet

- Newnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1From EverandNewnes Electronics Circuits Pocket Book (Linear IC): Newnes Electronics Circuits Pocket Book, Volume 1Rating: 4.5 out of 5 stars4.5/5 (3)

- Exercises in Electronics: Operational Amplifier CircuitsFrom EverandExercises in Electronics: Operational Amplifier CircuitsRating: 3 out of 5 stars3/5 (1)

- Example From Theory To Caesar IIDocument12 pagesExample From Theory To Caesar IITon Phichit100% (7)

- Handbook2 V BeltDocument5 pagesHandbook2 V Beltmehr_yazdanpanahNo ratings yet

- Location: Distribution Panel-1 (ST Stand) TPN TPN Apfcr TPN TPN TPN Distribution Panel-2 (Offices and Shops)Document35 pagesLocation: Distribution Panel-1 (ST Stand) TPN TPN Apfcr TPN TPN TPN Distribution Panel-2 (Offices and Shops)Sandeep DeodharNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- TOTAL TOWER ANALYSIS REPORT SST 150 M PDFDocument74 pagesTOTAL TOWER ANALYSIS REPORT SST 150 M PDFErpanBeanTarpoNo ratings yet

- Pipeline Design Calculations PDFDocument21 pagesPipeline Design Calculations PDFjimallen21281% (21)

- Ametank ReportDocument96 pagesAmetank ReportMiguel Angel Hernandez FloresNo ratings yet

- Calculation ResultDocument18 pagesCalculation ResultAwahida WidiNo ratings yet

- II.1 AS-shate-Jalawiyyah Line Protn Set - 1Document6 pagesII.1 AS-shate-Jalawiyyah Line Protn Set - 1Jay WinNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Example From Theory To Caesar II PDFDocument12 pagesExample From Theory To Caesar II PDFIskandar Hasibuan100% (1)

- Piping System Assessment & Troubleshooting For 90-HRV0001 - 9 of 9Document1 pagePiping System Assessment & Troubleshooting For 90-HRV0001 - 9 of 9Sodsai LamtharnNo ratings yet

- Rev01 - Report - Analysis - JK-JKB-0002 DR MAKALIWEDocument37 pagesRev01 - Report - Analysis - JK-JKB-0002 DR MAKALIWEsalman alfarisyNo ratings yet

- ANEXO 10 Resumen de Esfuerzos INICIALDocument5 pagesANEXO 10 Resumen de Esfuerzos INICIALLuis Alejandro Delgado PalmaNo ratings yet

- KUS Force Transducer: ApplicationsDocument2 pagesKUS Force Transducer: ApplicationsBane RadovicNo ratings yet

- Stress SummaryDocument10 pagesStress SummaryBhaumikNo ratings yet

- MPX10DPDocument8 pagesMPX10DPsuperpuma86No ratings yet

- Geometric Design: (Two - Lane Highway)Document16 pagesGeometric Design: (Two - Lane Highway)ianiroy13No ratings yet

- TI260 - eNCODER ALTA RESOLUCIÓNDocument8 pagesTI260 - eNCODER ALTA RESOLUCIÓNJairo LugoNo ratings yet

- Summary StressDocument2 pagesSummary StressAndi HakimNo ratings yet

- Design CasingDocument10 pagesDesign CasingSelly ErlytasariNo ratings yet

- PS2815-1, PS2815-4: PhotocouplerDocument14 pagesPS2815-1, PS2815-4: PhotocouplerJuan Carlos H. SoriaNo ratings yet

- Appendix C - Stress SummaryDocument5 pagesAppendix C - Stress SummaryridwanNo ratings yet

- LTC 1052Document25 pagesLTC 1052roozbehxoxNo ratings yet

- UntitledDocument3 pagesUntitledmas muinNo ratings yet

- Heat Exchanger Network Synthesis (Pinch Analysis) : Dr. Pankaj Kalita IIT GuwahatiDocument56 pagesHeat Exchanger Network Synthesis (Pinch Analysis) : Dr. Pankaj Kalita IIT Guwahatipuja kochNo ratings yet

- Design of Square Footing (With or Without Moment)Document13 pagesDesign of Square Footing (With or Without Moment)Ella Clent moralesNo ratings yet

- UntitledDocument522 pagesUntitledmas muinNo ratings yet

- Eurobeam Steel Beam CalculationDocument3 pagesEurobeam Steel Beam CalculationnsureshbabuNo ratings yet

- Table of ContentsDocument93 pagesTable of ContentsGirlie BalabatNo ratings yet

- Anexo 13Document9 pagesAnexo 13Eusebio Castillo MejiaNo ratings yet

- LTC 6102Document20 pagesLTC 6102Martin CraysNo ratings yet

- Case Study MekanikaDocument10 pagesCase Study MekanikaOkky HeljaNo ratings yet

- Electric Power Transmission and Distribution System Engineering 2 RBCDocument17 pagesElectric Power Transmission and Distribution System Engineering 2 RBCeuler leoNo ratings yet

- SID NUMBER: 0926018 Module Code: Ed 130010SDocument38 pagesSID NUMBER: 0926018 Module Code: Ed 130010Ssamluvhouse05No ratings yet

- 2sj 598 Power Mos Dell 2407wfpbDocument8 pages2sj 598 Power Mos Dell 2407wfpbkarkeraNo ratings yet

- 60EPFxx PDFDocument8 pages60EPFxx PDFRogerio E. SantoNo ratings yet

- Annexure: Particulars Required For Overhead CrossingDocument1 pageAnnexure: Particulars Required For Overhead CrossingStephen BridgesNo ratings yet

- White Paper Guidelines For The Application of Plastic Hinges by Nigel Pritchett, M.D., Elesa UK LTDDocument3 pagesWhite Paper Guidelines For The Application of Plastic Hinges by Nigel Pritchett, M.D., Elesa UK LTDGarry TaylorNo ratings yet

- 2 Deflection Calculation (Main)Document3 pages2 Deflection Calculation (Main)OkeymanNo ratings yet

- IEEE9 Model Documentation R0Document13 pagesIEEE9 Model Documentation R0Nando LópezNo ratings yet

- Datasheet 1646Document12 pagesDatasheet 1646dandroiNo ratings yet

- Foundation Calculation Sheet: Title DescriptionDocument10 pagesFoundation Calculation Sheet: Title DescriptionrobianggaNo ratings yet

- 1LN-1806,1807,1808-2"-2J1-C15, 1LN-1815,1816,1817-1.5"-2J1-C14,1LN-1809,1810,1819-3"-2J1-C15Document7 pages1LN-1806,1807,1808-2"-2J1-C15, 1LN-1815,1816,1817-1.5"-2J1-C14,1LN-1809,1810,1819-3"-2J1-C15reza mehvariNo ratings yet

- 1LN-1806,1807,1808-2"-2J1-C15, 1LN-1815,1816,1817-1.5"-2J1-C14,1LN-1809,1810,1819-3"-2J1-C15Document7 pages1LN-1806,1807,1808-2"-2J1-C15, 1LN-1815,1816,1817-1.5"-2J1-C14,1LN-1809,1810,1819-3"-2J1-C15reza mehvariNo ratings yet

- 1LN-1806,1807,1808-2"-2J1-C15, 1LN-1815,1816,1817-1.5"-2J1-C14,1LN-1809,1810,1819-3"-2J1-C15Document7 pages1LN-1806,1807,1808-2"-2J1-C15, 1LN-1815,1816,1817-1.5"-2J1-C14,1LN-1809,1810,1819-3"-2J1-C15reza mehvariNo ratings yet

- Final Revised TP 17 Pile Layout IsolatedDocument42 pagesFinal Revised TP 17 Pile Layout IsolatedSahil OzaNo ratings yet

- Portal Frame Analysis Using Finite Element Method: Input Data & SummaryDocument1 pagePortal Frame Analysis Using Finite Element Method: Input Data & SummaryHarjasa AdhiNo ratings yet

- Perhitungan SaggingDocument3 pagesPerhitungan Saggingwiizt0% (1)

- Sag Tension-ACSR FinchDocument5 pagesSag Tension-ACSR FinchPower Transmission Solution Ltd.No ratings yet

- Synchronous Buck Converter LAB-2: Power Electronics (ECEN405)Document5 pagesSynchronous Buck Converter LAB-2: Power Electronics (ECEN405)Jafar SadiqNo ratings yet

- 2MX-1710-2690-33-20.5i-M Model: AMB452000: Antenna SpecificationsDocument2 pages2MX-1710-2690-33-20.5i-M Model: AMB452000: Antenna SpecificationsЕлена ПотоковауыяNo ratings yet

- SME-Total Service Solution For Dynamic-Vibration-Static Pipe Stress & Piping Failure Analysis and TroubleshootingDocument1 pageSME-Total Service Solution For Dynamic-Vibration-Static Pipe Stress & Piping Failure Analysis and TroubleshootingSodsai LamtharnNo ratings yet

- Opportunity Identification Framework-11Document1 pageOpportunity Identification Framework-11Sodsai LamtharnNo ratings yet

- Piping System Assessment & Troubleshooting For 90-HRV0001 - 2 of 9Document1 pagePiping System Assessment & Troubleshooting For 90-HRV0001 - 2 of 9Sodsai LamtharnNo ratings yet

- Piping System Assessment & Troubleshooting For 90-HRV0001 - 7 of 9Document1 pagePiping System Assessment & Troubleshooting For 90-HRV0001 - 7 of 9Sodsai LamtharnNo ratings yet

- Opportunity Identification Framework-10Document10 pagesOpportunity Identification Framework-10Sodsai LamtharnNo ratings yet

- Opportunity Identification Framework-5Document1 pageOpportunity Identification Framework-5Sodsai LamtharnNo ratings yet

- Stress TeeDocument16 pagesStress TeeSodsai LamtharnNo ratings yet

- Question 8 ASME B31.3Document1 pageQuestion 8 ASME B31.3Sodsai LamtharnNo ratings yet

- Opportunity Identification Framework-4Document1 pageOpportunity Identification Framework-4Sodsai LamtharnNo ratings yet

- Question 9 ASME B31.3Document1 pageQuestion 9 ASME B31.3Sodsai LamtharnNo ratings yet

- Thermal Stress Analysis of Beam Subjected To Fire: Hemangi K. Patade, Dr. M. A. ChakrabartiDocument5 pagesThermal Stress Analysis of Beam Subjected To Fire: Hemangi K. Patade, Dr. M. A. ChakrabartiSodsai LamtharnNo ratings yet

- Discussion: Stresses and Deflections of Three-Dimensional Pipe BendsDocument3 pagesDiscussion: Stresses and Deflections of Three-Dimensional Pipe BendsSodsai LamtharnNo ratings yet

- Question 1 ASME B31.3Document1 pageQuestion 1 ASME B31.3Sodsai LamtharnNo ratings yet

- Surge Screening Step-By-Step.: เพจ หมอท่อ Dr. PipexDocument1 pageSurge Screening Step-By-Step.: เพจ หมอท่อ Dr. PipexSodsai LamtharnNo ratings yet

- Tresca Vs Von Mises 1626508549Document8 pagesTresca Vs Von Mises 1626508549Sodsai LamtharnNo ratings yet

- Surge Screening Step-By-Step.: เพจ หมอท่อ Dr. PipexDocument1 pageSurge Screening Step-By-Step.: เพจ หมอท่อ Dr. PipexSodsai LamtharnNo ratings yet

- Example Surge Screening: Step AnalysisDocument1 pageExample Surge Screening: Step AnalysisSodsai LamtharnNo ratings yet

- Example: Piping Vibration Caused by Gas-Liquid Two-Phase Flow: - Calculation For Flow Patterns MapDocument1 pageExample: Piping Vibration Caused by Gas-Liquid Two-Phase Flow: - Calculation For Flow Patterns MapSodsai LamtharnNo ratings yet