Professional Documents

Culture Documents

Toolbox

Uploaded by

Lewis ClarkOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Toolbox

Uploaded by

Lewis ClarkCopyright:

Available Formats

PERFORMING ENGINEERING

OPERATIONS LEVEL 2

SPEO2/066A- ASSESSMENT

Date: August 2020

Version: 1

© 2020 City of Glasgow College

Charity Number: SC0 36198

Document Title

Evidence Ref No:

Candidate Name: Section:

Assessment No:

Qualification Title: Performing Engineering Operations

Evidence Route / Element :

With reference to the latest version of the drawing, the candidate has to list the planning

procedure for the component to be manufactured.

STEP No: PLANNING PROCEDURES

1 Assess the risks associated with carrying out fabrication operations

2 Gather tools / material required to complete the job

3 Gather engineering drawings to complete required tasks

4 Mark out sizes for end plates from drawings

5 Mark out body

6 Mark out lids

7 Mark out hinges

8 Mark out hasp

9 Cut and bend handles

10 Assemble

© 2020 City of Glasgow College 2

Document Title

Evidence Ref No:

Candidate Name:

Qualification Title: Performing Engineering Operations

Evidence Route / Element :

OPERATIONS SHEET

Health and Safety

This job was completed using all existing health and safety procedures, all

students were appropriately trained for all equipment and were competent with

the set tasks.

Body

The body of the toolbox was formed of 1mm galvanised steel plate, this was

sourced and checked for suitability in terms of size, smoothness and aesthetics.

Firstly, the centre line was marked for use as a datum using a scribe, steel rule

and engineers square. A line was then marked 100mm on either side of this

datum and then at 200mm. From the 200mm line on each side we marked

another line a further 10mm out. On each corner we then marked out 8mm X

20mm and this was

snipped out using either

right or left-handed snips

respectively. Each of

these folds was then bent

using the box ban folder

to 90 degrees.

End Plates

For the end plates we

© 2020 City of Glasgow College 3

Document Title

required two 177mm X 220mm plates, the centre line was then marked for use as

a datum.

The material was then marked with the material required to complete rolled

edges and the excess was then removed using the guillotine and snips. When the

flat profile of the end plate has been created fold lines marked at 4,8 & 12mm

along the top edges in order to create a rolled edge, this was created using the

techniques that have been practiced earlier on in the curriculum.

The lower flaps of the end plate were then bent to 90 degrees using the box pan

folder and joined to the folded body using 4mm rivets spaced evenly around the

ends of the body, the holes for these were drilled using a 4mm drill bit.

Hinges

For the 4 hinges we

required 8 strips of

material measuring

70mm X 50mm. We

then marked the

material as shown in

the drawing on the

left. And pre drilled the 4mm holes for the rivets

Using the techniques learnt earlier on in fabrication we created the rolled hinge

around a 4mm bar.

We then used files, snips, chisel and a hacksaw to remove the waste material.

And secured the halves together to make 4 complete hinges.

Lids

© 2020 City of Glasgow College 4

Document Title

For the lid we used two pieces of material, one sized 170mm x 410mm and the

other 150mm x 410mm. The production process was simple as the measurements

were the same for both sides with only 1 variation.

The corners were snipped with left or right-handed snips and the guillotine. The

sides were folded inwards using the box pan folder and flattened using the anvil

and nylon mallet. To achieve the specific angle for the lids we used a guide plate

that was held against the edge of the box pan folder to show how far to bend the

plates.

Hasp

© 2020 City of Glasgow College 5

Document Title

The first part of the hasp we made was the small hinge, this was rolled around a

4mm bar as was the case with the hinges for the lid. The difference being we

had to cut a slit in it to accommodate the other half of the hasp. This was

achieved by chain drilling with a 4mm drill bit and then using a chisel and files to

clean up the hole. On the other side of the hinge two rivet holes were drilled

10mm x 10mm in from the edge.

The other half of the hasp was created by folding a 80mm x 20mm strip of steel

in two and then using a hammer and a vice to create two small 15mm flaps

through which a 4mm hole was drilled on each side. We then used a 10mm drill

bit to make a hole through the folded section in order to make the toolbox

lockable. On corner of the folded material was filed down considerably in order

to all the hinge to pass smoothly over it.

Handles

For the toolbox handles we used 4mm steel rod, we cut two 325mm sections and

first marked the centre point. This was then lined up with the centre of the vice

and small hollow tube was used as a lever to bend the bar to 90 degrees.

We then marked 20mm from the bottom of each leg and bent that backwards by

90 degrees to create a bridge effect for a handle with clearance.

The Latches to hold the handle were made from a 20mm x 70mm strip with was

hammered around a former to create the specific shape for the 4mm bar. Two

4mm holes were them drilled in in each strip.

Assembly

After having attached the end plates to the main body earlier in the process it

© 2020 City of Glasgow College 6

Document Title

was now time to attach the lids to the body. Firstly, the hinges were attached to

the lower body 40mm in from each edge, the holes were marked using a pen and

drilled with a 4mm drill bit and then attached on with a 4mm rivet installed by a

pop rivet gun. Now the hinges are attached to the lower body we could attach

the lids, this was done by marking the hinge holes on the lid with a marker pen

and drilling through with the 4mm drill bit.

The hasp was attached by adding the hinge first and securing it with 4mm rivets,

this allowed us to find the correct position for the other half of the latch, this

was then secured with the 4mm rivets.

The handles were marked, drilled and attached by securing the small loops onto

the lids with the 4mm rivets.

© 2020 City of Glasgow College 7

Document Title

Evidence Ref No:

Candidate Name: Section

Company: Assessment No:

Qualification Title: Performing Engineering Operations

Evidence Route / Element :

Inspected Conforms to

Measuring Equipment

Drawing Dimension Size Specification

used

(Candidate) (Assessor)

Large steel rule 440mmx370mm (main body) YES / NO

Steel rule 220mmx177mm (end plates) YES / NO

Steel rule 70mmx50mm(hinges) YES / NO

Large steel rule 410mmx170mm (lids) YES / NO

Steel rule 80mmx20mm (hasp) YES / NO

Steel rule 50mmx30mm (hasp) YES / NO

Large steel rule 325mmx4mm (handles) YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

YES / NO

© 2020 City of Glasgow College 8

Document Title

Accept

Does Component

Conform to drawing YES / NO Conformity report Reject

Specification

Re-assess

Report /

Feedback:

Describe any problems you encountered.

How did you overcome these and what would you do differently next time?

Candidate Signature: Date:

Assessor Signature: Date:

Assessor No:

© 2020 City of Glasgow College 9

Document Title

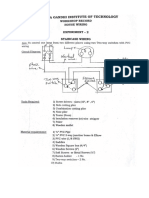

DRAWING/ CIRCUIT

© 2020 City of Glasgow College 10

You might also like

- Shop Practice No.2 Inside and Outside Caliper: Mapúa UniversityDocument12 pagesShop Practice No.2 Inside and Outside Caliper: Mapúa UniversitymarisonNo ratings yet

- Diploma I Year Workshop Practice - I Manuals MEchanical EnggDocument59 pagesDiploma I Year Workshop Practice - I Manuals MEchanical EnggKalyana Chakravarthy89% (18)

- PurifierDocument26 pagesPurifierAbhishek Kumar100% (1)

- Cat c15 Cylinder Head InstallationDocument7 pagesCat c15 Cylinder Head InstallationMUHSIN MTNo ratings yet

- Ex No - 1 RECTANGULAR TRAY MAKINGDocument5 pagesEx No - 1 RECTANGULAR TRAY MAKINGeswar kNo ratings yet

- Hammer Full ReportDocument9 pagesHammer Full ReportVince Ong100% (3)

- Supply Chain Management Final Assignment: Global Production EngineeringDocument17 pagesSupply Chain Management Final Assignment: Global Production EngineeringMario EnriqueNo ratings yet

- Mechatronics Motor Sizing Using LabVIEW and SolidWorksDocument39 pagesMechatronics Motor Sizing Using LabVIEW and SolidWorksWaleed El-BadryNo ratings yet

- Workshop Practice-I ES - ME - 292 Manual MainDocument55 pagesWorkshop Practice-I ES - ME - 292 Manual MainKunal KumarNo ratings yet

- What Is Fitting Shop?Document4 pagesWhat Is Fitting Shop?Er Indraj Kumar SudiaNo ratings yet

- MFT Lab Manual 2017-18 Even UpdatedDocument63 pagesMFT Lab Manual 2017-18 Even UpdatedPrakash ThangavelNo ratings yet

- Wood Work ReportDocument10 pagesWood Work ReportHarry KirungiNo ratings yet

- Ex No - 1 RECTANGULAR TRAY MAKINGDocument5 pagesEx No - 1 RECTANGULAR TRAY MAKINGANISH PATIL (RA2111029010064)No ratings yet

- Tools You'Ll Want To Use: Workbench: PR Oject LevelDocument3 pagesTools You'Ll Want To Use: Workbench: PR Oject LevelDinesh JayasekaraNo ratings yet

- Acknowledgement: Name FacultyDocument23 pagesAcknowledgement: Name FacultySurendra JoshiNo ratings yet

- Workshop - List of Experements and Its Procedure PDFDocument29 pagesWorkshop - List of Experements and Its Procedure PDFAdhi SheshuNo ratings yet

- DJJ 10033-Chapter 1-1Document104 pagesDJJ 10033-Chapter 1-1Abbas SeuNo ratings yet

- DIY Metal Bending ToolDocument30 pagesDIY Metal Bending Toolafrica school100% (1)

- Tool Makers Clamp Write UpDocument5 pagesTool Makers Clamp Write Upmevansmetreel100% (1)

- No Worked Date Name of Shop Page No RemarkDocument8 pagesNo Worked Date Name of Shop Page No RemarkJerry CreedNo ratings yet

- Shop Exercise 5Document16 pagesShop Exercise 5Athena GrotesqueNo ratings yet

- Ex No - 3 SCOOP MAKINGDocument4 pagesEx No - 3 SCOOP MAKINGANISH PATIL (RA2111029010064)No ratings yet

- Fitting ManualDocument38 pagesFitting Manual06sureshbalaji1988_8No ratings yet

- WorkshopDocument5 pagesWorkshopJoseph NjugunaNo ratings yet

- Module 1d Rocker ArmDocument5 pagesModule 1d Rocker ArmDamien Miguel MahumotNo ratings yet

- Unit - 3 FittingDocument33 pagesUnit - 3 Fitting20BCS4054 MADHAVAN V100% (1)

- Welding DemoDocument23 pagesWelding DemoLesli Daryl Antolin SanMateoNo ratings yet

- Workshop ManualDocument41 pagesWorkshop ManualNarappaNo ratings yet

- Fitting - Fabrication Manual 2020Document14 pagesFitting - Fabrication Manual 2020Malik AbubakerNo ratings yet

- Abdi Manufacturing of StaplerDocument14 pagesAbdi Manufacturing of Staplerabdibedasa86No ratings yet

- EXP Write UpDocument28 pagesEXP Write UpSoumyajit NandiNo ratings yet

- Table Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!Document8 pagesTable Saw Sled - Taper Jig Accessory: Cut One or Many Tapers With Ease!LinNo ratings yet

- Amico Aca Serenity Panel Wall Recessed ManualDocument12 pagesAmico Aca Serenity Panel Wall Recessed ManualLuis PalaciosNo ratings yet

- Corner O Ce Desk: Step 1: PlansDocument28 pagesCorner O Ce Desk: Step 1: Plansarmando.alanisNo ratings yet

- Lab Manual Practical 1.4Document2 pagesLab Manual Practical 1.4Akanksha YadavNo ratings yet

- Machine Tools Hand Tools: Fitting ShopDocument12 pagesMachine Tools Hand Tools: Fitting ShopMadara uchihaNo ratings yet

- Job Procedure.Document2 pagesJob Procedure.Hugh G. RectionNo ratings yet

- Rectangular Tray MakingDocument6 pagesRectangular Tray MakingHell YessNo ratings yet

- EXP Write UpDocument28 pagesEXP Write UpIndrani ChakrabortyNo ratings yet

- Ex No - 2 HOPPER MAKINGDocument4 pagesEx No - 2 HOPPER MAKINGANISH PATIL (RA2111029010064)No ratings yet

- 6-String Acoustic Guitar Build-DesbloqueadoDocument359 pages6-String Acoustic Guitar Build-DesbloqueadoBenjamin Enrique HachuelNo ratings yet

- Shop Practice Number 2Document13 pagesShop Practice Number 2JantzenCaliwliwNo ratings yet

- Workshop ReportDocument8 pagesWorkshop ReportspdNo ratings yet

- Diploma Workshop Practice IDocument20 pagesDiploma Workshop Practice Ieighteen plusNo ratings yet

- 2 B.TECH EXPERIMENT'S SEM IV - Wire DrawingDocument3 pages2 B.TECH EXPERIMENT'S SEM IV - Wire DrawingNeelNo ratings yet

- DIY Router Table: InstructablesDocument18 pagesDIY Router Table: Instructablesjack100% (1)

- Department of Mechanical Engineering Ge6162 Engineering Practices Lab Laboratory RecordDocument76 pagesDepartment of Mechanical Engineering Ge6162 Engineering Practices Lab Laboratory RecordSathish KNo ratings yet

- Floor LampDocument7 pagesFloor LampSergioNo ratings yet

- MT-II LabDocument7 pagesMT-II LabAjay Vikram0% (1)

- How To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsDocument24 pagesHow To Make Your Own Six Yard Bell Target Mechanism: Glossary of TermsJose German Ojeda CruzNo ratings yet

- AutoCAD ManualDocument8 pagesAutoCAD ManualSharvaniNo ratings yet

- ME 123 L Report 5Document3 pagesME 123 L Report 5Dikimbie Aldrei GatpuNo ratings yet

- Cutter Making David CreedDocument19 pagesCutter Making David CreedBruno Delsupexhe100% (1)

- Fitting Lab ReportDocument4 pagesFitting Lab ReportEdgar ThorpeNo ratings yet

- Workshop: Name of Student:-Linda Leon Toma Energy Engineering Department First YearDocument13 pagesWorkshop: Name of Student:-Linda Leon Toma Energy Engineering Department First YearLinda Leon TomaNo ratings yet

- First Year Fall Semester 2020: Ie-115: Material Workshop Report File: Lab WorkDocument45 pagesFirst Year Fall Semester 2020: Ie-115: Material Workshop Report File: Lab WorkMuhammadtayyabaziz KhanNo ratings yet

- WorkshopDocument10 pagesWorkshophansleyNo ratings yet

- MP IIDocument9 pagesMP IIKaranbir SinghNo ratings yet

- Instruction Example 01.3. Nailing of A Tool Kit: MaterialDocument21 pagesInstruction Example 01.3. Nailing of A Tool Kit: MaterialHassan AzmiNo ratings yet

- Carpentry Job Report - Cross Lap JointDocument12 pagesCarpentry Job Report - Cross Lap JointMohammad Zahidul Karim83% (6)

- Coffee Table 3Document6 pagesCoffee Table 3- yAy3e -No ratings yet

- Valentine Project Tip 1.: This Year Give A Personalized Valentine! Step 1: Deciding What To Make?Document16 pagesValentine Project Tip 1.: This Year Give A Personalized Valentine! Step 1: Deciding What To Make?- yAy3e -No ratings yet

- Family Handyman Ultimate 1 Day ProjectsFrom EverandFamily Handyman Ultimate 1 Day ProjectsRating: 5 out of 5 stars5/5 (1)

- Como Detectar Errores Relacionados Con El Transporte Antes de Que OcurranDocument5 pagesComo Detectar Errores Relacionados Con El Transporte Antes de Que OcurranVerónicaNo ratings yet

- Integrated Risk Assessment ProcessDocument63 pagesIntegrated Risk Assessment ProcessdgffasffgeNo ratings yet

- January 30, 2024 Mechanical Engineering Team Daily Report.Document4 pagesJanuary 30, 2024 Mechanical Engineering Team Daily Report.kenasa jirataNo ratings yet

- LogDocument165 pagesLogAdial WinsiNo ratings yet

- PosterDocument1 pagePosterAnjali NagarNo ratings yet

- Habtamu SerteDocument17 pagesHabtamu SerteAklilu GirmaNo ratings yet

- A10 AX3200 2200 PSU Install-20110425Document10 pagesA10 AX3200 2200 PSU Install-20110425Thuan ThaiNo ratings yet

- Penlon SP M5 Patient Monitor: Anaesthesia SolutionsDocument4 pagesPenlon SP M5 Patient Monitor: Anaesthesia SolutionsJulian GarcíaNo ratings yet

- Three Part TableDocument2 pagesThree Part Tableruben alejandro TeranNo ratings yet

- Basehor Active Transportation Public Meeting - 1!21!07 - 21Document19 pagesBasehor Active Transportation Public Meeting - 1!21!07 - 21confluencescribdNo ratings yet

- Islamia Nalsintia - 170155101029 - Jurnal PublikasiSOJDocument12 pagesIslamia Nalsintia - 170155101029 - Jurnal PublikasiSOJJung ChanwooNo ratings yet

- JDE Advanced Preferences March 9th 2011 OTV2Document29 pagesJDE Advanced Preferences March 9th 2011 OTV2chatwithgmNo ratings yet

- Nastran 2019 Doc ReleaseDocument116 pagesNastran 2019 Doc ReleaseAdamDNo ratings yet

- SPL - Capability Studies in MinitabDocument3 pagesSPL - Capability Studies in MinitabToan Pham VanNo ratings yet

- Bi 06 EtlDocument35 pagesBi 06 EtlChandra SekharNo ratings yet

- Online Java CompilerDocument3 pagesOnline Java CompilerMayank S PatelNo ratings yet

- ERP SAP HR Deviation Report Assignment Case Studies BlueprintDocument6 pagesERP SAP HR Deviation Report Assignment Case Studies BlueprintBunty JainNo ratings yet

- Io 6 HasznalatiDocument110 pagesIo 6 Hasznalatiblazee1978No ratings yet

- MS EXCEL Notes 1Document13 pagesMS EXCEL Notes 1Neha TajveNo ratings yet

- Final Paper N Simulaton FinalDocument5 pagesFinal Paper N Simulaton Finalsalman_ansari_pk4198No ratings yet

- Magellan Explorist 100 Owner S ManualDocument77 pagesMagellan Explorist 100 Owner S ManualMedina JbNo ratings yet

- Quibiztec - Proposal For GAS Conversion Plants To Lagos State Government Ver 02Document17 pagesQuibiztec - Proposal For GAS Conversion Plants To Lagos State Government Ver 02sylviaaim2No ratings yet

- Tci-378805 378905 PDFDocument6 pagesTci-378805 378905 PDFAntonio PerezNo ratings yet

- Baylon, Mark Gerald - deDocument1 pageBaylon, Mark Gerald - deraudenNo ratings yet

- Machine Room-Less (MRL)Document13 pagesMachine Room-Less (MRL)rishi070881No ratings yet

- Post Graduate Diploma in Industrial Automation (PGDIA) NewDocument4 pagesPost Graduate Diploma in Industrial Automation (PGDIA) NewSandyNo ratings yet