Professional Documents

Culture Documents

A320-20 Standard Practices

Uploaded by

867189399Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

A320-20 Standard Practices

Uploaded by

867189399Copyright:

Available Formats

资料编号:GYAT/PXJC-004

云南港翊航空技术有限公司

A319/A320/A321( CFM56/V2500)

I&II Training Manual ME&AV

20 STANDARD PRACTICES

版本: V00

修订: R00

审核: 王润泽 日期: 2020.4.10

批准: 韩 序 日期: 2020.4.10

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

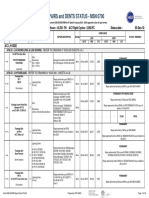

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

** ON A/C ALL

20-21-11 - TIGHTENING TORQUES FOR

STANDARD THREADED FASTENERS

20-21-11 PB 201 CONF 00 - TIGHTENING TORQUES FOR

STANDARD THREADED FASTENERS - MAINTENANCE PRACTICES

TASK 20-21-11-911-001-A

Tightening Torques for Standard Threaded Fasteners

1. Reason for the Job

This procedure gives the different tightening torques applicable to the standard screw heads and nuts.

The specific applicable torques are given in the maintenance procedure.

2 Job Set-up Information

A. Fixtures, Tools, Test and Support Equipment

REFERENCE QTY DESIGNATION

No specific Torque wrench: range to between .1 and .2 m.daN

(8.85 and 17.70 lbf.in)

B. Referenced Information

REFERENCE DESIGNATION

Ref. SRM 514900

Torque Wrench and Adapter Combination

Maximum Torque Values for Shoulder Bolts SHEET 1

Aluminum Nut SHEET 1

Bolt Assembly 1, for a Steel or CRES Nut with a Titanium or Steel or CRES Screw SHEET 1

Bolt Assembly 2, for a Steel or CRES Nut with a Titanium or Steel or CRES Screw SHEET 1

Bolt Assembly 3, for a Steel or CRES Nut with a Titanium or Steel or CRES Screw SHEET 1

Bolt Assembly 4, for a Steel or CRES Nut with a Titanium or Steel or CRES Screw SHEET 1

Bolt Assembly 5, for a Steel or CRES Nut with a Titanium or Steel or CRES Screw SHEET 1

Bolt Assembly 6, for a Steel or CRES Nut with a Titanium or Steel or CRES Screw SHEET 1

Bolt Assembly 7, for a Steel or CRES Nut with a Titanium or Steel or CRES Screw SHEET 1

Fully Threaded Screws SHEET 1

Bolt Assembly 1, for Tensile and Shear High-Strength Bolt SHEET 1

Bolt Assembly 4, for Tensile and Shear High-Strength Bolt SHEET 1

Short Threaded Screws SHEET 1

Bolt Assembly 2, for Tensile and Shear High-Strength Bolt SHEET 1

Bolt Assembly 3, for Tensile and Shear High-Strength Bolt SHEET 1

Captive Nut SHEET 1

Print Date: March 21, 2020 Page 1 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

A B

0

FACOM

BOLT AXIS

HANDLE

TYPICAL TYPICAL ADAPTER

TORQUE WRENCH

A B

0

FACOM

HANDLE

TYPICAL TYPICAL ADAPTER

TORQUE WRENCH

BOLT AXIS

N_MM_202111_2_AXM0_01_01

Figure 20-21-11-991-02000-00-A / SHEET 1/2 - Torque Wrench and Adapter Combination

** ON A/C ALL

Print Date: March 21, 2020 Page 2 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

A B

0

FACOM

HANDLE

TYPICAL ADAPTER

TYPICAL

TORQUE WRENCH

BOLT AXIS

A

0

FACOM

TYPICAL ADAPTER

HANDLE

90°

TYPICAL

TORQUE WRENCH

BOLT AXIS

ADAPTER AT RIGHT ANGLE TO THE WRENCH. NO CORRECTION NECESSARY

N_MM_202111_2_AXM0_02_00

Figure 20-21-11-991-02000-00-A / SHEET 2/2 - Torque Wrench and Adapter Combination

** ON A/C ALL

Print Date: March 21, 2020 Page 3 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

BOLT MAX-TORQUE

m.daN (lbf.in)

NSA 5042-04 1 88.5

NSA 5042-05 1 88.5

NSA 5042-06 2 177

NSA 5042-07 2 177

NSA 5042-08 2 177

NSA 5042-09 2 177

NSA 5042-10 3.5 310

NSA-5042-12 4.6 405

NSA 5042-14 8 704

NSA 5042-16 11.5 1 012

NSA 5042

NSA 5305

NSA 5060

MS 24665-153

NOTE:

THE MINIMUM TORQUE IS ABOUT 0.1 TO 0.2 m.daN TO MAKE SURE THAT THE WASHER IS NOT FREE.

N_MM_202111_2_ACM0_01_01

Figure 20-21-11-991-00500-00-A / SHEET 1/1 - Maximum Torque Values for Shoulder Bolts

** ON A/C ALL

Print Date: March 21, 2020 Page 4 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

4.16 0.15 0.18 0.21

08 01 01 01

(21/128) (13.5) (16) (18.5)

4.82 0.25 0.29 0.34 0.29

3 (3/16) (22) (25.5) (30) (25.5)

5.6 0.29 0.34 0.39 0.41

3A (7/32) (25.5) (30) (34.5) (36)

6.35 0.53 0.63 0.72 0.63

4 (1/4) (47) (56) (64) (56)

7.92 0.98 1.16 1.34 1.16

5 (5/16) (87) (102.5) (118.5) (102.5)

9.52 1.63 1.92 2.21 1.92

6 (3/8) (144) (170) (195.5) (170)

11.1 2.69 2.99 3.29 2.99

7 (7/16) (238) (264.5) (291) (264.5)

12.7 3.87 4.25 4.64 4.26

8 (1/2) (342.5) (376) (410.5) (377)

14.3 5.0 5.57 6.14 5.57

9 (9/16) (442.5) (493) (543.5) (493)

15.9 6.69 7.35 8.02 7.36

10 (5/8) (592) (650.5) (710) (651.5)

NOTE:

01 IT IS NOT RECOMMENTED TO TORQUE AGAIN. N_MM_202111_2_ABC4_01_01

Figure 20-21-11-991-04700-00-A / SHEET 1/1 - Aluminum Nut

** ON A/C ALL

Print Date: March 21, 2020 Page 5 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

3.5 0.13 0.15 0.17 0.18

06 (9/64) (11.5) (13.5) (15) (16)

4.16 0.22 0.23 0.28 0.28

08 (21/128) (19.5) (20.5) (25) (25)

4.82 0.37 0.42 0.48 0.50

3 (3/16) 01 01 01 (44.5)

(33) (37) (42.5)

5.6 0.37 0.42 0.48 0.50

3A (7/32) (33) 01 (37) 01 (42.5) 01 (44.5)

6.35 0.82 0.94 1.06 1.13

4 (1/4) (72.5) (83) (94) (100)

7.92 1.38 1.58 1.79 1.90

5 (5/16) (122) (140) (158) (168)

9.52 2.69 3.04 3.22 3.65

6 (3/8) (238) (269) (285) (323)

11.1 3.87 4.38 4.64 5.26

7 (7/16) (342.5) (387.5) (410.5) (465.5)

12.7 5.57 6.32 6.69 7.58

8 (1/2) (493) (559.5) (592) (671)

14.3 6.69 7.35 8.02 8.82

9 (9/16) (592) (650.5) (710) (780.5)

15.9 9.63 10.56 11.5 12.67

10 (5/8) (852) (934.5) (1 018) (1 121)

19.05 13.87 15.25 16.64 18.30

12 (3/4) (1 227.5) (1 349.5) (1 472.5) (1 619.5)

CAUTION:

WHEN YOU USE SCREW NAS1102 AND NUT NAS1726 TOGETHER, THE TORQUE VALUE IS ONLY APPLICABLE

FOR DASHES HIGHER THAN DASH 3.

CAUTION:

01 0.28 - 0.32 - 0.37 m.daN ONLY FOR SCREWS ABS0114 V

(25 - 28.5 - 33 lbf.in) ASNA2000 V

ASNA2001 V

ASNA2016 V N_MM_202111_2_ABA1_01_02

Figure 20-21-11-991-03600-00-A / SHEET 1/1 - Bolt Assembly 1,

for a Steel or CRES Nut with a Titanium or Steel or CRES Screw

** ON A/C ALL

Print Date: March 21, 2020 Page 6 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in.)

TIGHTENING BY NUT TIGHTENING BY SCREW

DIA

mm Min Nom Max Nom

CODE (in.)

4.82 0.28 0.32 0.37 0.38

3 (3/16) (24.5) (28.5) (33) (33.5)

5.6 0.28 0.32 0.37 0.38

3A (7/32) (25) (28.5) (33) (33.5)

6.35 0.63 0.72 0.82 0.86

4 (1/4) (56) (64) (72.5) (76)

7.92 1.06 1.22 1.38 1.46

5 (5/16) (94) (108) (122) (129)

9.52 1.79 2.01 2.24 2.41

6 (3/8) (158.5) (178) (198) (213)

11.1 2.24 2.54 2.69 3.05

7 (7/16) (198) (225) (238) (270)

12.7 3.22 3.65 3.87 4.38

8 (1/2) (285) (323) (342.5) (387.5)

14.3 3.87 4.38 4.64 5.26

9 (9/16) (342.5) (387.5) (410.5) (465.5)

15.9 4.64 5.26 5.57 6.31

10 (5/8) (410.5) (465.5) (493) (558.5)

19.05 8.02 9.09 9.63 10.91

12 (3/4) (710) (804) (852) (965.5)

N_MM_202111_2_ABA2_01_00

Figure 20-21-11-991-03700-00-A / SHEET 1/1 - Bolt Assembly 2,

for a Steel or CRES Nut with a Titanium or Steel or CRES Screw

** ON A/C ALL

Print Date: March 21, 2020 Page 7 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in.)

TIGHTENING BY NUT TIGHTENING BY SCREW

DIA

mm Min Nom Max Nom

CODE (in.)

4.82 0.13 0.15 0.17 0.18

3 (3/16) (11.5) (13.5) (15) (16)

5.6 0.13 0.15 0.17 0.18

3A (7/32) (11.5) (13.5) (15) (16)

6.35 0.28 0.32 0.37 0.38

4 (1/4) (25) (28.5) (33) (33.5)

7.92 0.63 0.72 0.82 0.86

5 (5/16) (55.5) (64) (72.5) (76)

9.52 1.06 1.22 1.38 1.46

6 (3/8) (94) (108) (122) (129)

11.1 1.38 1.58 1.79 1.90

7 (7/16) (122) (140) (158) (168)

12.7 1.79 2.01 2.24 2.41

8 (1/2) (158) (178) (198) (213)

14.3 3.22 3.65 3.87 4.38

9 (9/16) (285) (323) (342.5) (387.5)

15.9 4.64 5.26 5.57 6.31

10 (5/8) (410.5) (465.5) (492.5) (558.5)

19.05 6.69 7.58 8.02 9.10

12 (3/4) (592) (671) (709.5) (805)

N_MM_202111_2_ABA3_01_00

Figure 20-21-11-991-03800-00-A / SHEET 1/1 - Bolt Assembly 3,

for a Steel or CRES Nut with a Titanium or Steel or CRES Screw

** ON A/C ALL

Print Date: March 21, 2020 Page 8 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

4.82 0.28 0.32 0.37 0.38

3 (3/16) (25) (28.5) (33) (33.5)

5.6 0.28 0.32 0.37 0.38

3A (7/32) (25) (28.5) (33) (33.5)

6.35 0.63 0.72 0.82 0.86

4 (1/4) (56) (64) (72.5) (76)

7.92 1.38 1.58 1.79 1.90

5 (5/16) (122) (140) (158.5) (168)

9.52 1.79 2.01 2.24 2.41

6 (3/8) (158.5) (178) (198) (213)

11.1 2.69 3.04 3.22 3.65

7 (7/16) (238) (269) (285) (323)

12.7 3.87 4.38 4.64 5.26

8 (1/2) (342.5) (387.5) (410.5) (465.5)

14.3 5.57 6.32 6.69 7.58

9 (9/16) (493) (559.5) (592) (671)

15.9 6.69 7.58 8.02 9.10

10 (5/8) (592) (671) (710) (805.5)

19.05 9.63 10.87 11.5 13.04

12 (3/4) (852) (962) (1 018) (1 154)

N_MM_202111_2_ABA4_01_01

Figure 20-21-11-991-03900-00-A / SHEET 1/1 - Bolt Assembly 4,

for a Steel or CRES Nut with a Titanium or Steel or CRES Screw

** ON A/C ALL

Print Date: March 21, 2020 Page 9 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

3.5 0.13 0.15 0.17 0.18

06 (9/64) (11.5) (13.5) (15) (16)

4.16 0.22 0.25 0.28 0.30

08 (21/128) (19.5) (22) (25) (26.5)

4.82 0.37* 0.42* 0.48* 0.50

3 (3/16) (33) (37) (42.5) (44.5)

5.6 0.37* 0.42* 0.48* 0.50

3A (7/32) (33) (37) (42.5) (44.5)

6.35 0.82 0.94 1.06 1.13

4 (1/4) (72.5) (83) (94) (100)

7.92 1.38 1.58 1.79 1.90

5 (5/16) (122) (140) (158.5) (168)

9.52 2.69 2.95 3.22 3.54

6 (3/8) (238) (261) (285) (313)

11.1 3.87 4.25 4.64 5.10

7 (7/16) (342.5) (376) (410.5) (451)

12.7 5.57 6.13 6.69 7.36

8 (1/2) (493) (542.5) (592) (651.5)

14.3 6.69 7.35 8.02 8.82

9 (9/16) (592) (650.5) (710) (780.5)

15.9 9.63 10.56 11.5 12.67

10 (5/8) (852) (934.5) (1 018) (1 121)

19.05 13.87 15.25 16.64 18.30

12 (3/4) (1 227.5) (1 349.5) (1 472.5) (1 619.5)

CAUTION:

* 0.28 - 0.32 - 0.37 m.daN ONLY FOR SCREWS ASNA2001 V

(25 - 28.5 - 33 lbf.in) ABS0114V

NSA5088

N_MM_202111_2_BAM0_01_00

Figure 20-21-11-991-04900-00-A / SHEET 1/1 - Bolt Assembly 5,

for a Steel or CRES Nut with a Titanium or Steel or CRES Screw

** ON A/C ALL

Print Date: March 21, 2020 Page 10 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

4.82 0.28 0.32 0.37 0.38

3 (3/16) (25) (28.5) (33) (33.5)

5.6 0.28 0.32 0.37 0.38

3A (7/32) (25) (28.5) (33) (33.5)

6.35 0.63 0.72 0.82 0.86

4 (1/4) (56) (64) (72.5) (76)

7.92 1.06 1.22 1.38 1.46

5 (5/16) (94) (108) (122) (129)

9.52 1.79 2.01 2.24 2.41

6 (3/8) (158.5) (178) (198) (213)

11.1 2.24 2.46 2.69 2.95

7 (7/16) (198) (218) (238) (261)

12.7 3.22 3.54 3.87 4.25

8 (1/2) (285) (313) (342.5) (376)

14.3 3.87 4.25 4.64 5.10

9 (9/16) (342.5) (376) (410.5) (451)

15.9 4.64 5.1 5.57 6.12

10 (5/8) (410.5) (451) (493) (541.5)

19.05 8.02 8.82 9.63 10.58

12 (3/4) (710) (780.5) (852) (936.5)

N_MM_202111_2_BCM0_01_00

Figure 20-21-11-991-05000-00-A / SHEET 1/1 - Bolt Assembly 6,

for a Steel or CRES Nut with a Titanium or Steel or CRES Screw

** ON A/C ALL

Print Date: March 21, 2020 Page 11 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

4.82 0.28 0.32 0.37 0.38

3 (3/16) (25) (28.5) (33) (33.5)

5.6 0.28 0.32 0.37 0.38

3A (7/32) (25) (28.5) (33) (33.5)

6.35 0.63 0.73 0.82 0.88

4 (1/4) (56) (64.5) (72.5) (78)

7.92 1.38 1.58 1.79 1.90

5 (5/16) (122) (140) (158.5) (168)

9.52 1.79 2.01 2.24 2.41

6 (3/8) (158.5) (178) (198) (213)

11.1 2.69 2.95 3.22 3.54

7 (7/16) (238) (261) (285) (313)

12.7 3.87 4.25 4.64 5.10

8 (1/2) (342.5) (376) (410.5) (451)

14.3 5.57 6.13 6.69 7.36

9 (9/16) (493) (542.5) (592) (651.5)

15.9 6.69 7.35 8.02 8.82

10 (5/8) (592) (650.5) (710) (780.5)

19.05 9.63 10.56 11.5 12.67

12 (3/4) (852) (934.5) (1 018) (1 121)

N_MM_202111_2_BEM0_01_00

Figure 20-21-11-991-05100-00-A / SHEET 1/1 - Bolt Assembly 7,

for a Steel or CRES Nut with a Titanium or Steel or CRES Screw

** ON A/C ALL

Print Date: March 21, 2020 Page 12 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

3.5 0.13 0.15 0.17 0.18

06 (9/64) (11.5) (13.5) (15) (16)

4.16 0.22 0.23 0.28 0.28

08 (21/128) (19.5) (20.5) (25) (25)

4.82 0.37 0.42 0.48 0.50

3 (3/16) (33) (37) (42.5) (44.5)

6.35 0.82 0.94 1.06 1.13

4 (1/4) (72.5) (83) (94) (100)

N_MM_202111_2_ABA5_01_01

Figure 20-21-11-991-04000-00-A / SHEET 1/1 - Fully Threaded Screws

** ON A/C ALL

Print Date: March 21, 2020 Page 13 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

4.82 0.37 0.42 0.48 0.50

3 (3/16) (33) (37) (42.5) (44.5)

6.35 0.82 0.94 1.06 1.13

4 (1/4) (72.5) (83) (94) (100)

7.92 1.79 2.01 2.24 2.41

5 (5/16) (158.5) (178) (198) (213)

9.52 3.22 3.54 3.87 4.25

6 (3/8) (285) (313) (342.5) (376)

11.1 4.64 5.10 5.57 6.12

7 (7/16) (410.5) (451) (493) (541.5)

12.7 8.02 8.82 9.63 10.58

8 (1/2) (710) (780.5) (852) (936.5)

14.3 11.50 12.68 13.87 15.22

9 (9/16) (1 018) (1 122) (1 227.5) (1 347)

15.9 13.87 15.25 16.64 18.30

10 (5/8) (1 227.5) (1 349.5) (1 472.5) (1 619.5)

19.05 23.96 26.35 28.75 31.62

12 (3/4) (2 120.5) (2 332) (2 544.5) (2 798.5)

22.2 41.40 45.50 49.70 54.60

14 (7/8) (3 664) (4 027) (4 399) (4 832.5)

CAUTION:

FOR SCREW BSA228, ONLY USE THE TIGHTENING TORQUE VALUES

IF THE SCREW IS OVERSIZE. N_MM_202111_2_ABA9_01_01

Figure 20-21-11-991-04300-00-A / SHEET 1/1 - Bolt

Assembly 1, for Tensile and Shear High-Strength Bolt

** ON A/C ALL

Print Date: March 21, 2020 Page 14 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in.)

TIGHTENING BY NUT TIGHTENING BY SCREW

DIA

mm Min Nom Max Nom

CODE (in.)

4.82 0.28 0.32 0.37 0.38

3 (3/16) (25) (28.5) (33) (33.5)

6.35 0.63 0.72 0.82 0.86

4 (1/4) (56) (64) (72.5) (76)

7.92 1.38 1.58 1.79 1.90

5 (5/16) (122) (140) (158) (168)

9.52 2.24 2.46 2.69 2.95

6 (3/8) (198) (218) (238) (261)

11.1 4.64 5.10 5.57 6.12

7 (7/16) (410.5) (451) (493) (541.5)

12.7 6.69 7.35 8.02 8.82

8 (1/2) (592) (650.5) (710) (780.5)

14.3 9.63 10.56 11.50 12.67

9 (9/16) (852) (934.5) (1017.5) (1121)

15.9 13.87 15.25 16.6 18.30

10 (5/8) (1227.5) (1349.5) (1469) (1619.5)

19.05 23.96 26.35 28.75 31.62

12 (3/4) (2120.5) (2332) (2544) (2798)

22.2 41.40 45.50 49.70 54.60

14 (7/8) (3664) (4026.5) (4398) (4832)

25.4 59.64 65.60 71.57 78.72

16 (1) (5278) (5805) (6333.5) (6966.5)

N_MM_202111_2_ABC2_01_00

Figure 20-21-11-991-04600-00-A / SHEET 1/1 - Bolt

Assembly 4, for Tensile and Shear High-Strength Bolt

** ON A/C ALL

Print Date: March 21, 2020 Page 15 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

4.16 0.22 0.25 0.28 0.30

08 (21/128) (19.5) (22) (25) (26.5)

4.82 0.37 0.42 0.48 0.50

3 (3/16) (33) (37) (42.5) (44.5)

5.6 0.60 0.70 0.78 0.84

3A (7/32) (53) (62) (69) (74.5)

6.35 0.63 0.72 0.82 0.86

4 (1/4) (56) (64) (72.5) (76)

7.92 1.06 1.22 1.38 1.46

5 (5/16) (94) (108) (122) (129)

9.52 2.24 2.46 2.69 2.95

6 (3/8) (198) (218) (238) (261)

11.1 3.22 3.54 3.87 4.25

7 (7/16) (285) (313) (342.5) (376)

12.7 4.64 5.10 5.57 6.12

8 (1/2) (410.5) (451) (493) (541.5)

14.3 6.69 7.35 8.02 8.82

9 (9/16) (592) (650.5) (710) (780.5)

15.9 9.63 10.56 11.50 12.67

10 (5/8) (852) (934.5) (1 018) (1 121)

19.05 13.87 15.25 16.64 18.30

12 (3/4) (1 227.5) (1 349.5) (1 472.5) (1 619.5)

22.2 19.97 21.97 23.96 26.36

14 (7/8) (1 767.5) (1 944.5) (2 120.5) (2 333)

25.4 28.75 31.63 34.50 37.96

16 (1) (2 544.5) (2 799.5) (3 053.5) (3 359)

28.6 41.40 45.50 49.70 54.60

18 (1 1/8) (3 664) (4 027) (4 399) (4 832.5)

N_MM_202111_2_ABA7_01_01

Figure 20-21-11-991-04100-00-A / SHEET 1/1 - Short Threaded Screws

** ON A/C ALL

Print Date: March 21, 2020 Page 16 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in.)

TIGHTENING BY NUT TIGHTENING BY SCREW

DIA

mm Min Nom Max Nom

CODE (in.)

4.82 0.37 0.42 0.48 0.50

3 (3/16) (33) (37.5) (42) (44.5)

6.35 1.06 1.22 1.38 1.46

4 (1/4) (94) (108) (122) (129)

7.92 1.79 2.01 2.24 2.41

5 (5/16) (158.5) (178) (198) (213)

9.52 3.87 4.25 4.64 5.10

6 (3/8) (342.5) (376) (410.5) (451)

11.1 5.57 6.13 6.69 7.36

7 (7/16) (493) (542.5) (592) (651.5)

12.7 9.63 10.56 11.50 12.67

8 (1/2) (852) (934.5) (1017.5) (1121)

14.3 13.87 15.25 16.64 18.30

9 (9/16) (1227.5) (1349.5) (1472.5) (1619.5)

15.9 19.97 21.96 23.96 26.35

10 (5/8) (1767) (1943.5) (2120) (2332)

19.05 34.50 37.95 41.40 45.54

12 (3/4) (3053) (3358.5) (3664) (4030)

22.2 59.64 65.60 71.57 78.72

14 (7/8) (5278) (5805) (6333.5) (6966.5)

25.4 85.88 94.47 103.05 113.36

16 (1) (7600) (8360) (9119.5) (10032)

N_MM_202111_2_ABC0_01_00

Figure 20-21-11-991-04400-00-A / SHEET 1/1 - Bolt

Assembly 2, for Tensile and Shear High-Strength Bolt

** ON A/C ALL

Print Date: March 21, 2020 Page 17 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING

TIGHTENING BY NUT

BY SCREW

DIA

mm Min Nom Max Nom

CODE (in)

4.82 0.37 0.42 0.48 0.50

3 (3/16) (33) (37.5) (42) (44.5)

6.35 0.82 0.94 1.06 1.13

4 (1/4) (72.5) (83) (94) (100)

7.92 1.79 2.01 2.24 2.41

5 (5/16) (158) (178) (198) (213)

9.52 3.22 3.54 3.87 4.25

6 (3/8) (285) (313) (342.5) (376)

11.1 4.64 5.10 5.57 6.12

7 (7/16) (410.5) (451) (493) (541.5)

12.7 8.02 8.82 9.63 10.58

8 (1/2) (710) (780.5) (852) (936)

14.3 11.50 12.68 13.87 15.22

9 (9/16) (1 017.5) (1 122) (1 227.5) (1 347)

15.9 13.87 15.25 16.64 18.30

10 (5/8) (1 227.5) (1 349.5) (1 472.5) (1 619.5)

19.05 23.96 26.35 28.75 31.62

12 (3/4) (2 120.5) (2 332) (2 544) (2 798)

22.2 41.40 45.50 49.70 54.60

14 (7/8) (3 664) (4 026.5) (4 398) (4 832)

25.4 59.64 65.60 71.57 78.72

16 (1) (5 278) (5 805) (6 333.5) (6 966.5)

N_MM_202111_2_ABC1_01_01

Figure 20-21-11-991-04500-00-A / SHEET 1/1 - Bolt

Assembly 3, for Tensile and Shear High-Strength Bolt

** ON A/C ALL

Print Date: March 21, 2020 Page 18 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

TORQUE m.daN (lbf.in)

TIGHTENING BY SCREW

DIA

mm Min Nom Max

CODE (in)

3.5 0.13 0.15 0.17

06 (9/64) (11.5) (13.5) (15)

4.16 0.22 0.25 0.28

08 (21/128) (19.5) (22) (25)

4.82 0.37* 0.42* 0.48*

3 (3/16) (33) (37) (42.5)

6.35 0.82 0.94 1.06

4 (1/4) (72.5) (83) (94)

7.92 1.38 1.58 1.79

5 (5/16) (122) (140) (158.5)

9.52 2.69 2.95 3.22

6 (3/8) (238) (261) (285)

11.1 3.87 4.25 4.64

7 (7/16) (342.5) (376) (410.5)

12.7 5.57 6.13 6.69

8 (1/2) (493) (542.5) (592)

CAUTION:

* 0.28 - 0.32 - 0.37 m.daN ONLY FOR SCREWS ASNA2001 V

(25 - 28.5 - 33 lbf.in) ASNA2016 V

ASNA2000 V

ABS0114 V N_MM_202111_2_ABA8_01_01

Figure 20-21-11-991-04200-00-A / SHEET 1/1 - Captive Nut

** ON A/C ALL

Print Date: March 21, 2020 Page 19 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

3. Job Set-up

Subtask 20-21-11-911-058-A

A. Standard Threaded Fasteners - General

(1) The threaded fasteners are identified with a standard number written on the head (example: ABS, AN,

ASNA, NAS, ASN, NSA, MS). They are installed in standard conditions and lubricated.

(2) Before you apply a tightening torque to a fastener, make sure that you know its correct part number.

To find the correct part number of a fastener (screw, washer, nut), refer to the installation figure of the

IPC.

NOTE: It is necessary to know the fastener standard and diameter to know the correct tightening

torque.

(3) The tightening torques of the TAPERLOK, HI-LOK, and HI-LITE screws are specified in the given

procedures Ref. SRM 514900.

(4) The torque values of the nuts and the screws are given with their initial lubricants.

(5) These torque values are available for the different screw/nut diameters:

· The minimum value

· The nominal value

· The maximum value.

(6) Make sure that you get the correct part mating before you apply the maximum torque value.

Subtask 20-21-11-911-059-A

B. Used Fasteners:

(1) General

Before you use a threaded fastener again, make sure that:

· There is no deterioration of the thread of the screw and of the nut, of the mating surface of the nut

and of the recess of the screw.

· The protection of the screw and of the nut is not damaged.

NOTE: If the protection is damaged, corrosion or seizure can occur.

· The condition of the standard lubricant is correct. Apply a new layer of standard lubricant if

necessary.

NOTE: Deterioration of the lubricant decreases the preload values and can:

- Cause damage to the mating surfaces

- Decrease the torque for self-locking nuts.

· The screws and nuts are serviceable (get approval from your quality department or a qualified

mechanic).

(2) Do not use aluminum, titanium and Inconel nuts again.

(3) Do not use self-sealing nuts again.

(4) Self-locking nut (this includes castellated nuts with a nylon ring)

· Airbus does not recommend that you can use a self-locking nut again,

· If you use a self-locking nut again, make sure that the breakaway torque value is more than the

minimum breakaway-torque value.

NOTE: Refer to the nut standard to know the minimum breakaway-torque value.

NOTE: To measure the breakaway torque value, the screw end must come out of the nut.

Print Date: March 21, 2020 Page 20 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

(5) Limits for captive nuts

(a) When you install a screw in a captive nut, make sure that you feel the breakaway torque

resistance of the nut.

NOTE: After some screw removal/installation cycles, the breakaway torque value of the captive

nut can decrease and cause the screw to become loose or missing.

1 If you think that the resistance is not sufficient, Airbus recommends that you replace the nut.

2 If you are not sure that the resistance is sufficient:

· Refer to the captive nut standard to know the minimum breakaway torque value.

NOTE: If there is no minimum breakaway torque value in the standard, refer to the procure-

ment specification applicable to the captive nut.

· Make sure that the breakaway torque value is equal to or more than the specified value.

3 Replace the captive nut if necessary.

Subtask 20-21-11-911-064-A

C. Fasteners Installed on Uncured Interfay Sealant

(1) General

When the fasteners (for example, screws/nuts or TAPER-LOK fasteners) are installed on uncured

interfay sealant, their preload can decrease after curing because the sealant does not flow

immediately.

This is why it is necessary to tighten them again. Do this 30 minutes after installation of the fasteners.

If there are more than two parts assembled together, tighten again at 30-minute intervals until the

torque value stays correct.

Subtask 20-21-11-911-060-A

D. Tightening - Tools:

(1) General

(a) Before you use a tightening tool, make sure that the calibration of this tool is correct.

(b) Make sure that the torque is applied correctly.

You can apply unwanted torsion or flexion to the component if:

· The position of the wrench (or the screwdriver) is incorrect.

· You apply the tightening torque incorrectly: this can change the tightening torque and thus the

preload.

(2) Torque wrench

(a) Torque wrench range

For a given torque value, we recommend that you use a torque wrench that has a value in the

range of 30% to 80% of the full range.

NOTE: Example for a torque wrench of maximum 10 m.daN:

- Torque wrench range from 2 m.daN to 10 m.daN

- Recommended range 3 m.daN to 8 m.daN.

In the recommended range:

- only moderate force is necessary to get the correct torque,

- you can feel the force increase while you apply the torque.

(b) Torque wrench hold

The torque wrench axes must be perpendicular to the fastener axis.

Put your hand on the handle and pull it along the axis.

Print Date: March 21, 2020 Page 21 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Apply the torque value gradually and perpendicularly to the wrench.

Stop the movement when the wrench releases (or on the signal).

Do not use a torque wrench to loosen a fastener.

(3) Torque wrench adapter

(a) When you use an adapter:

(Ref. Fig. Torque Wrench and Adapter Combination)

· The value shown on the dial of the torque wrench is not the applied value.

· Make sure that the length of the torque wrench is more than the length of the adapter.

NOTE: Airbus recommends to have the torque wrench and the adapter aligned. If you cannot

align the torque wrench and the adapter (because of the fastener location), you can use

the torque wrench and the adapter not aligned.

(b) Torque-value correction applicable when the adapter is used:

NOTE: This procedure is applicable when the adapter and the torque wrench are aligned or not

aligned (Ref. Fig. Torque Wrench and Adapter Combination)

1 To pre-calibrate the torque wrench, you can use this formula to get the torque-wrench dial-

reading:

T1 x A

T2 = --------

A + B

T1: Value that you must apply on the fastener

A : Length of the torque wrench

B : Length of the adapter

T2: Torque-wrench dial-reading.

2 Calibrate the torque wrench and the adapter assembly on the torque meter.

· Adjust the T2 value until you get the T1 value on the torque meter.

· Do the tightening operations five times, one after the other to make sure that the torque

wrench and the adapter are calibrated correctly.

3 Tighten the fastener to the corrected value.

(4) Screwing machine:

When you use a screwing machine, make sure that the speed is correct to prevent too much heat on

the fasteners.

NOTE: This can cause damage to the protection and the lubricant and can cause seizing of the

fastener.

4. Procedure

Subtask 20-21-11-911-061-A

A. General

(1) Tightening for fasteners without a captive nut

(a) Install the nut manually to make sure that a minimum of one thread is engaged.

(b) In relation to the nut and screw standards and diameter, get the correct torque value.

(c) Apply the torque value on the nut:

· If you cannot tighten with the nut, apply the screw torque value.

· It is recommended to apply the nominal torque value.

· Do not apply more than the maximum torque value.

Print Date: March 21, 2020 Page 22 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

(d) Castellated nuts

1 If the torque value tolerance does not let you put a slot opposite a hole for a cotter pin, you

can do this in the sequence that follows (successively):

· Decrease the minimum torque by 10%

· Install a washer below the nut

· Replace the nut.

2 You can drill the hole during installation. If you do this:

· Make sure that you do not decrease the strength of the screw (specially for offset drilling,

the diameter of the bore must be correct, deburr lightly).

· You must prevent corrosion (put grease in the hole of the nut when you install steel bolts).

NOTE: It is recommended to use screws with their initial drill holes.

(e) Shoulder screws

1 Tighten with the nut.

The minimum torque you must apply is to between .1 and .2 m.daN

(8.85 and 17.70 lbf.in).

2 If you install a castellated nut, the tightening torque tolerance does not always let you align

the castellated nut with the hole for the cotter pin. If you cannot align the castellated nut with

the hole for the cotter pin, install a steel teflon washer NSA5325 .

3 For maximum torque values

(Ref. Fig. Maximum Torque Values for Shoulder Bolts SHEET 1)

(2) Tightening for fasteners with captive nut

(a) Make sure that the length of the screw is correct.

(b) Install the screw manually to make sure that a minimum of one thread is engaged.

(c) In relation to the nut and screw standards and diameter, get the correct torque value.

(d) Apply the tightening torque on the screw.

Subtask 20-21-11-910-050-A

B. Nut or Screw Assembly Table Instruction

(1) Get the nut and screw standards and diameter.

(2) Find the correct nut/screw assembly table.

The nut and the screw standards are given with a space between the reference standard and the last

letter.

(3) The illustrations above the related paragraph tables give the torque value for the nut/screw assembly,

for each diameter.

NOTE: To find the screw or nut standard easily in the table, you can use the Airnav "SEARCH" func-

tion as follows:

- Enter the screw and/or nut standard (with a space as separation) in the "Full text search"

line of the Airnav "Word Search" tool. If there is a letter at the end of the standard, you can

replace it with the star (*) character.

- Start the search and find the screw or nut standard in the table.

- If the search shows no result, you can replace the last one or two digit(s) of the standard

with the star (*) character and start the search again.

(4) Refer to the correct table that gives the screw-and-nut assembly. Then, refer to the related illustration

to get the related torque value.

Print Date: March 21, 2020 Page 23 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Subtask 20-21-11-911-062-A

C. Non-Captive Nut and Screw Assembly Tables

(1) Anodized Aluminum Nut

(Ref. Fig. Aluminum Nut SHEET 1)

Group of Nuts Group of Screws Group of Screws

ASNA2528 ABS0559 ABS0876 K

ASNA2529 ABS0560 VBV ABS0876 L

ASNA2537 ABS0810 VHK ABS0907 K

ABS0812 VHK ABS0925 K

ABS0997 K ASNA2026 T

ABS0997 L ASNA2026 V

ASNA2026 ASNA2027

ASNA2026 K ASNA2027 K

ASNA2027 T EN6114

ASNA2027 V EN6114 K

ASNA2352 T EN6114 L

ASNA2657 V EN6114 M

EN6114 T EN6115 L

EN6114 V EN6115 M

EN6115 EN6115 V

EN6115 K

(2) Steel Nut

(a) With a Titanium or Steel or CRES Screw

1 Bolt Assembly 1

(Ref. Fig. Bolt Assembly 1, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Group of Nuts Group of Screws Group of Screws

NSA5050 ABS0114 T ASNA2000 V

NSA5050 P ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS1131 to 1138

NAS1101 NAS1131 E to 1138 E

NAS1101 E NAS1151 to 1158

NAS1102 NAS1151 E to 1158 E

NAS1102 E NAS600 to 604

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502 NSA5089 V

NAS7503 to 7516

NSA5088 V

NSA5089

MS21042 ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS1131 to 1138

Print Date: March 21, 2020 Page 24 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Group of Nuts Group of Screws Group of Screws

NAS1101 NAS1131 E to 1138 E

NAS1101 E NAS1151 to 1158

NAS1102 NAS1151 E to 1158 E

NAS1102 E NAS600 to 604

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502

NAS7503 to 7516

NSA5088 V

NSA5089

NSA5089 V

NSA5457 E ABS0114 T ASNA2000 V

NSA5457 PE ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS1131 to 1138

NAS1101 NAS1131 E to 1138 E

NAS1101 E NAS1151 to 1158

NAS1102 NAS1151 E to 1158 E

NAS1102 E NAS600 to 604

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502

NAS7503 to 7516

NSA5089

NSA5089 V

NAS1726 E ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS1131 to 1138

NAS1101 NAS1131 E to 1138 E

NAS1101 E NAS1151 to 1158

NAS1102 NAS1151 E to 1158 E

NAS1102 E NAS600 to 604

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502 NSA5089

NAS7503 to 7516 NSA5089 V

NSA5042

NSA5042 C

NAS1727 E ABS0114 T ASNA2000 V

NAS1727 AE ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS600 to 604 NAS1131 E to 1138 E

NAS1100 NAS1151 to 1158

NAS1101 NAS1151 E to 1158 E

NAS1101 E NAS1307

NAS1102 NAS6603 to 6612

Print Date: March 21, 2020 Page 25 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Group of Nuts Group of Screws Group of Screws

NAS1102 E NAS6703 to 6712

NAS1131 to 1138 NAS7500 to 7502

NAS1151 to 1158 NAS7503 to 7516

NAS1303 to 1312 NSA5089 V

NAS1635

NAS1802

NAS6303 to 6312

NSA5089

ASNA2532 ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 V

ABS0559 VBV ASNA2016 V

ASNA2000 T NAS1101

NAS600 to 604 NAS1131 E to 1138 E

NAS1100 NAS1151 to 1158

NAS1101 E NAS1151 E to 1158 E

NAS1102 NAS1303 to 1312

NAS1102 E NAS6303 to 6312

NAS1131 to 1138 NAS6603 to 6612

NAS1307 NAS6703 to 6712

NAS1635 NAS7500 to 7502

NAS1802

NAS7503 to 7516

NSA5089

NSA5089 V

2 Bolt Assembly 2

(Ref. Fig. Bolt Assembly 2, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Group of Screws Group of Screws

NAS509 ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS600 to 604

NAS1101 NAS1131 to 1138

NAS1101 E NAS1131 E to 1138 E

NAS1102 NAS1151 to 1158

NAS1102 E NAS1151 E to 1158 E

NAS1303 to 1312 NAS6303 to 6312

NAS1307 NAS6603 to 6612

NAS1635 NAS6703 to 6712

NAS1802 NSA5088 V

NAS7500 to 7502 NSA5089

NAS7503 to 7516 NSA5089 V

NSA5042

NSA5042 C

3 Bolt Assembly 3

(Ref. Fig. Bolt Assembly 3, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Print Date: March 21, 2020 Page 26 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Nut Group of Screws Group of Screws

NSA5059 ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS600 to 604

NAS1101 NAS1131 to 1138

NAS1101 E NAS1131 E to 1138 E

NAS1102 NAS1151 to 1158

NAS1102 E NAS1151 E to 1158 E

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1790 NAS6703 to 6712

NAS1802 NSA5089

NAS7500 to 7502 NSA5089 V

NAS7503 to 7516

NSA5042

NSA5042 C

4 Bolt Assembly 4

(Ref. Fig. Bolt Assembly 4, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Group of Screws Group of Screws

NSA5060 ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS600 to 604

NAS1101 NAS1131 to 1138

NAS1101 E NAS1131 E to 1138 E

NAS1102 NAS1151 to 1158

NAS1102 E NAS1151 E to 1158 E

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502 NSA5089

NAS7503 to 7516 NSA5089 V

NSA5042

NSA5042 C

5 Bolt Assembly 5

(Ref. Fig. Bolt Assembly 5, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Screw

NAS1726 E NAS1790

6 Bolt Assembly 6

(Ref. Fig. Bolt Assembly 6, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Print Date: March 21, 2020 Page 27 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Nut Screw

NAS509 NAS1790

7 Bolt Assembly 7

(Ref. Fig. Bolt Assembly 7, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Screw

NSA5060 NAS1790

(b) With a Fully Threaded Screw

(Ref. Fig. Fully Threaded Screws SHEET 1)

Group of Nuts Group of Screws

MS21042 NAS514 P

MS35650 NAS1096

NAS509 NAS1801

NAS1726 E NSA5191

NSA5050

NSA5050 P

(c) With a Tensile and Shear High-Strength Bolt

1 Bolt Assembly 1

(Ref. Fig. Bolt Assembly 1, for Tensile and Shear High-Strength Bolt SHEET 1)

Nut Group of Screws

NSA5057 BSA228

MS21250

2 Bolt Assembly 4

(Ref. Fig. Bolt Assembly 4, for Tensile and Shear High-Strength Bolt SHEET 1)

Group of Nuts Group of Screws Group of Screws

NAS1726 E ASNA0092 ASNA0124

NAS1727 E ASNA0093

NAS1727 AE ASNA0092 P

NSA5050 ASNA0093 P

NSA5050 P ASNA0123

(d) With a Short Threaded Screw

(Ref. Fig. Short Threaded Screws SHEET 1)

Group of Nuts Group of Screws Group of Screws

ASNA2531 ABS0559 ABS0876 K

ASNA2532 ABS0560 VBV ABS0876 L

ABS0810 VHK ABS0907 K

ABS0812 VHK ABS0925 K

ABS0997 K ASNA2026 K

ABS0997 L ASNA2026 T

ASNA2001 T ASNA2026 V

ASNA2026 ASNA2027

Print Date: March 21, 2020 Page 28 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Group of Nuts Group of Screws Group of Screws

ASNA2027 K EN6114

ASNA2027 T EN6114 K

ASNA2027 V EN6114 L

ASNA2352 T EN6115 K

EN6114 M EN6115 L

EN6114 T EN6115 M

EN6114 V EN6115 V

EN6115

(3) CRES Nut

(a) With a Titanium or Steel or CRES Screw

1 Bolt Assembly 1

(Ref. Fig. Bolt Assembly 1, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Group of Nuts Group of Screws Group of Screws

NAS1291 C ABS0114 T ASNA2000 V

NAS5457 CPE ABS0114 V ASNA2001 T

NSA5050 C ABS0559 VBV ASNA2001 V

MS21043 ASNA2000 T ASNA2016 V

NAS1100 NAS600 to 604

NAS1101 NAS1131 to 1138

NAS1101 E NAS1131 E to 1138 E

NAS1102 NAS1151 to 1158

NAS1102 E NAS1151 E to 1158 E

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502 NSA5089 V

NAS7503 to 7516

NSA5088 V

NSA5089

ASNA2021 CE ABS0114 T ASNA2000 V

NAS1726 CPE ABS0114 V ASNA2001 T

NAS1726 CSE ABS0559 VBV ASNA2001 V

NAS1727 CE ASNA2000 T ASNA2016 V

NAS1727 KE NAS1100 NAS600 to 604

NAS1101 NAS1131 to 1138

NAS1101 E NAS1131 E to 1138 E

NAS1102 NAS1151 to 1158

NAS1102 E NAS1151 E to 1158 E

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502 NSA5088 V

NAS7503 to 7516 NSA5089

NSA5042 NSA5089 V

NSA5042 C

2 Bolt Assembly 2

Print Date: March 21, 2020 Page 29 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

(Ref. Fig. Bolt Assembly 2, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Group of Screws Group of Screws

NAS509 C ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS600 to 604

NAS1101 NAS1131 to 1138

NAS1101 E NAS1131 E to 1138 E

NAS1102 NAS1151 to 1158

NAS1102 E NAS1151E to 1158E

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502 NSA5088 V

NAS7503 to 7516 NSA5089

NSA5042 NSA5089 V

NSA5042 C

3 Bolt Assembly 3

(Ref. Fig. Bolt Assembly 3, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Group of Screws Group of Screws

NAS5059 C ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

NAS1100 NAS600 to 604

NAS1101 NAS1131 to 1138

NAS1101 E NAS1131 E to 1138 E

NAS1102 NAS1151 to 1158

NAS1102 E NAS1151 E to 1158 E

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1790 NAS6703 to 6712

NAS1802 NSA5088 V

NAS7500 to 7502 NSA5089

NAS7503 to 7516 NSA5089 V

NSA5042

NSA5042 C

4 Bolt Assembly 4

(Ref. Fig. Bolt Assembly 4, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Group of Screws Group of Screws

NSA5060 C ABS0114 T ASNA2000 V

ABS0114 V ASNA2001 T

ABS0559 VBV ASNA2001 V

ASNA2000 T ASNA2016 V

Print Date: March 21, 2020 Page 30 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Nut Group of Screws Group of Screws

NAS1100 NAS1131 to 1138

NAS1101 NAS1131 E to 1138 E

NAS1101 E NAS1151 to 1158

NAS1102 NAS1151 E to 1158 E

NAS1102 E NAS600 to 604

NAS1303 to 1312 NAS6303 to 6312

NAS1635 NAS6603 to 6612

NAS1802 NAS6703 to 6712

NAS7500 to 7502 NSA5088 V

NAS7503 to 7516 NSA5089

NSA5042 NSA5089 V

NSA5042 C

5 Bolt Assembly 5

(Ref. Fig. Bolt Assembly 5, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Group of Nuts Screw

ASNA2021 CE NAS1790

NAS1726 CPE

NAS1726 CSE

NAS1727 CE

NAS1727 KE

NSA5050 C

6 Bolt Assembly 6

(Ref. Fig. Bolt Assembly 6, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Screw

NAS509 C NAS1790

7 Bolt Assembly 7

(Ref. Fig. Bolt Assembly 7, for a Steel or CRES Nut with a Titanium or Steel or CRES

Screw SHEET 1)

Nut Screw

NAS5060 C NAS1790

(b) With a Fully Threaded Screw

(Ref. Fig. Fully Threaded Screws SHEET 1)

Group of Nuts Group of Screws

MS21043 NAS514 P

NAS509 C NAS1096

NAS1291 C NAS1801

NAS1726 CPE NSA5191

NAS1726 CSE

(c) With a Tensile and Shear High-Strength Bolt

Print Date: March 21, 2020 Page 31 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

(Ref. Fig. Bolt Assembly 4, for Tensile and Shear High-Strength Bolt SHEET 1)

Group of Nuts Group of Screws Group of Screws

NAS1726 CPE ASNA0092 ASNA0123

NAS1726 CSE ASNA0092 P ASNA0124

NAS1727 CPE ASNA0093

NSA5050 C ASNA0093 P

ASNA2021 CE ASNA0123

ASNA0124

(d) With a Short Threaded Screw

(Ref. Fig. Short Threaded Screws SHEET 1)

Group of Nuts Group of Screws Group of Screws

ASNA2536 ABS0559 ABS0876 K

ASNA2536 P ABS0560 VBV ABS0876 L

ASNA2538 ABS0810 VHK ABS0907 K

ASNA2538 P ABS0812 VHK ABS0925 K

ABS0997 K ASNA2026 T

ABS0997 L ASNA2026 V

ASNA2026 ASNA2027

ASNA2026 K ASNA2027 K

ASNA2027 T EN6114

ASNA2027 V EN6114 K

ASNA2352 T EN6114 L

EN6114 T EN6114 M

EN6114 V EN6115 L

EN6115 EN6115 M

EN6115 K EN6115 V

(4) Inconel Nut

(a) With a Tensile and Shear High-Strength Bolt

1 Bolt Assembly 2

(Ref. Fig. Bolt Assembly 2, for Tensile and Shear High-Strength Bolt SHEET 1)

Group of Nuts Group of Screws

ASNA0094 NSA5378

ASNA0094 N NSA5378 A

NSA5373

2 Bolt Assembly 3

(Ref. Fig. Bolt Assembly 3, for Tensile and Shear High-Strength Bolt SHEET 1)

Group of Nuts Group of Screws

ASNA0094 ASNA0122 A

ASNA0094 N ASNA0122 P

NSA5373 ASNA0143 A

ASNA0143 P

Subtask 20-21-11-911-063-A

D. Captive nut with screw assembly tables

Print Date: March 21, 2020 Page 32 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

(1) Steel Captive Nut

(Ref. Fig. Captive Nut SHEET 1)

Group of Nuts Group of Screws Group of Screws

NSA5147 ABS0114 T ABS0950 T

ABS0114 V ASNA2000 T

ABS0376 ASNA2000 V

ABS0559 VBV ASNA2001 T

ASNA2001 V NAS1100

ASNA2016 V NAS1101

ASNA2358 T NAS1101 E

NAS514 P NAS1102

NAS600 to 604 NAS1102 E

NAS1096 NAS1303 to 1312

NAS1131 to 1138 NAS1351

NAS1131 E to 1138 E NAS1352

NAS1151 to 1158 NAS1635

NAS1151 E to 1158 E NAS6303 to 6312

NAS1801 NAS6303 to 6320

NAS1802 NAS6603 to 6612

NSA5088 V NAS6703 to 6720

NSA5089 V

ABS0365 B ABS0114 T NAS514 P

ABS0804 ABS0114 V NAS600 to 604

NAS577 BA ABS0376 NAS1131 to 1138

NAS1068 A ABS0559 VBV NAS1131 E to 1138 E

NAS1473 A ABS0950 T NAS1151 to 1158

NAS1474 A ASNA2000 T NAS1151 E to 1158 E

NAS1791 A ASNA2000 V NAS1303 to 1312

NAS1792 A ASNA2001 T NAS1351

NAS1870 ASNA2001 V NAS1351 C

NSA5051 ASNA2016 V NAS1352

NSA5055 ASNA2358 T NAS1352 C

NSA5066 NAS1096 NAS1635

NSA5067 NAS1100 NAS1801

NSA5078 NAS1101 NAS1802

NSA5084 NAS1101 E NAS6303 to 6320

NSA5456 NAS1102 NAS6603 to 6612

MS21047* NAS1102 E NAS6703 to 6720

MS21049* NSA5089

MS21051* NSA5089 V

MS21053* NSA5191

MS21055*

MS21057*

MS21059*

MS21061*

MS21063*

MS21069*

MS21071*

MS21073*

MS21075*

MS21086*

* See NOTE

Print Date: March 21, 2020 Page 33 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

NOTE: The "MS21XXX" standard can have the name "NASMS21XXX".

(2) CRES captive nut

(Ref. Fig. Captive Nut SHEET 1)

Group of Nuts Group of Screws Group of Screws

NSA5067 C ABS0114 T ABS0950 T

ABS0114 V ASNA2000 T

ABS0376 ASNA2000 V

ABS0559 VBV ASNA2001 T

ASNA2001 V NAS514 P

ASNA2016 V NAS600 to 604

ASNA2358 T NAS1100

NAS1096 NAS1101

NAS1131 to 1138 NAS1101 E

NAS1131 E to 1138 E NAS1102

NAS1151 to 1158 NAS1102 E

NAS1151 E to 1158 E NAS1303 to 1312

NAS1352 NAS1351

NAS1352 C NAS1351 C

NAS1635 NAS1802

NAS1801 NAS6303 to 6320

NAS6603 to 6612 NSA5089 V

NAS6703 to 6720 NSA5191

NSA5088 V

NSA5089

MS21048* ABS0114 T NAS514 P

MS21050* ABS0114 V NAS600 to 604

MS21052* ABS0376 NAS1131 to 1138

MS21054* ABS0559 VBV NAS1131 E to 1138 E

MS21056* ABS0950 T NAS1151 to 1158

MS21058* ASNA2000 T NAS1151 E to 1158 E

MS21060* ASNA2000 V NAS1303 to 1312

MS21062* ASNA2001 T NAS1351

MS21070* ASNA2001 V NAS1351 C

MS21072* ASNA2016 V NAS1352

MS21074* ASNA2358 T NAS1352 C

MS21076* NAS1096 NAS1635

MS21087* NAS1100 NAS1801

* See NOTE NAS1101 NAS1802

NAS1474 C NAS1101 E NAS6303 to 6320

NAS1102 NAS6603 to 6612

NAS1102 E NAS6703 to 6720

NSA5088 V

NSA5089 V

NSA5191

NSA5147 C ABS0114 T ABS0950 T

ABS0114 V ASNA2000 T

ABS0376 ASNA2000 V

ABS0559 VBV ASNA2001 T

ASNA2001 V NAS1100

ASNA2016 V NAS1101

ASNA2358 T NAS1101 E

Print Date: March 21, 2020 Page 34 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

Group of Nuts Group of Screws Group of Screws

NAS1096 NAS1102

NAS1131 to 1138 NAS1102 E

NAS1131 E to 1138 E NAS1303 to 1312

NAS1151 to 1158 NAS1635

NAS1151 E to 1158 E NAS1801

NAS514 P NAS1802

NAS600 to 604 NSA5088 V

NAS6303 to 6312 NSA5089 V

NAS6603 to 6612

NAS1068 CM ABS0114 T ABS0950 T

ABS0114 V ASNA2000 T

ABS0376 ASNA2000 V

ABS0559 VBV ASNA2001 T

ASNA2001 V NAS514 P

ASNA2016 V NAS600 to 604

ASNA2358 T NAS1100

NAS1096 NAS1101

NAS1131 to 1138 NAS1101 E

NAS1131 E to 1138 E NAS1102

NAS1151 to 1158 NAS1102 E

NAS1151 E to 1158 E NAS1303 to 1312

NAS1352 NAS1307

NAS1352 C NAS1351

NAS1635 NAS1351 C

NAS1801 NAS1802

NAS6603 to 6612 NAS6303 to 6320

NAS6703 to 6720 NSA5089 V

NSA5088 V NSA5191

NSA5089

NAS1473 F ABS0114 T ABS0950 T

NAS1474 F ABS0114 V ASNA2000 T

NAS1791 C ABS0376 ASNA2000 V

NAS1792 C ABS0559 VBV ASNA2001 T

ASNA2001 V NAS514 P

ASNA2016 V NAS600 to 604

ASNA2358 T NAS1100

NAS1096 NAS1101

NAS1131 to 1138 NAS1101 E

NAS1131 E to 1138 E NAS1102

NAS1151 to 1158 NAS1102 E

NAS1151 E to 1158 E NAS1303 to 1312

NAS1352 NAS1351

NAS1352 C NAS1351 C

NAS1635 NAS1802

NAS1801 NAS6303 to 6320

NAS6603 to 6612 NSA5089 V

NAS6703 to 6720 NSA5191

NSA5088 V

NSA5089

NOTE: The "MS21XXX" standard can have the name "NASMS21XXX".

Print Date: March 21, 2020 Page 35 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

Customer : CHH Manual : AMM

Type : A318/A319/A320/A321 Selected applicability : 003-003

Rev. Date : Feb 01, 2020

20-21-11 - TIGHTENING TORQUES FOR STANDARD THREADED FASTENERS

DO NOT USE AFTER 7 DAYS

(3) Inconel Captive Nut

(Ref. Fig. Captive Nut SHEET 1)

Group of Nuts Group of Screws Group of Screws

NAS577 CD ABS0114 T ABS0950 T

NAS577 CGX ABS0114 V ASNA2000 T

ABS0376 ASNA2000 V

ABS0559 VBV ASNA2001 T

ASNA2001 V NAS514 P

ASNA2016 V NAS600 to 604

ASNA2358 T NAS1100

NAS1096 NAS1101

NAS1131 to 1138 NAS1101 E

NAS1131 E to 1138 E NAS1102

NAS1151 to 1158 NAS1102 E

NAS1151 E to 1158 E NAS1303 to 1312

NAS1352 NAS1351

NAS1352 C NAS1351 C

NAS1635 NAS1802

NAS1801 NAS6303 to 6320

NAS6603 to 6612 NSA5089 V

NAS6703 to 6720 NSA5191

NSA5088 V

NSA5089

Figure 20-21-11-991-00500-00-A / SHEET 1/1 - Maximum Torque Values for Shoulder Bolts

Figure 20-21-11-991-02000-00-A / SHEET 1/2 - Torque Wrench and Adapter Combination

Figure 20-21-11-991-02000-00-A / SHEET 2/2 - Torque Wrench and Adapter Combination

Figure 20-21-11-991-03600-00-A / SHEET 1/1 - Bolt Assembly 1, for a Steel or CRES Nut with a Titanium or Steel

or CRES Screw

Figure 20-21-11-991-03700-00-A / SHEET 1/1 - Bolt Assembly 2, for a Steel or CRES Nut with a Titanium or Steel

or CRES Screw

Figure 20-21-11-991-03800-00-A / SHEET 1/1 - Bolt Assembly 3, for a Steel or CRES Nut with a Titanium or Steel

or CRES Screw

Figure 20-21-11-991-03900-00-A / SHEET 1/1 - Bolt Assembly 4, for a Steel or CRES Nut with a Titanium or Steel

or CRES Screw

Figure 20-21-11-991-04900-00-A / SHEET 1/1 - Bolt Assembly 5, for a Steel or CRES Nut with a Titanium or Steel

or CRES Screw

Figure 20-21-11-991-05000-00-A / SHEET 1/1 - Bolt Assembly 6, for a Steel or CRES Nut with a Titanium or Steel

or CRES Screw

Figure 20-21-11-991-05100-00-A / SHEET 1/1 - Bolt Assembly 7, for a Steel or CRES Nut with a Titanium or Steel

or CRES Screw

Figure 20-21-11-991-04000-00-A / SHEET 1/1 - Fully Threaded Screws

Figure 20-21-11-991-04100-00-A / SHEET 1/1 - Short Threaded Screws

Figure 20-21-11-991-04200-00-A / SHEET 1/1 - Captive Nut

Figure 20-21-11-991-04300-00-A / SHEET 1/1 - Bolt Assembly 1, for Tensile and Shear High-Strength Bolt

Figure 20-21-11-991-04400-00-A / SHEET 1/1 - Bolt Assembly 2, for Tensile and Shear High-Strength Bolt

Figure 20-21-11-991-04500-00-A / SHEET 1/1 - Bolt Assembly 3, for Tensile and Shear High-Strength Bolt

Figure 20-21-11-991-04600-00-A / SHEET 1/1 - Bolt Assembly 4, for Tensile and Shear High-Strength Bolt

Figure 20-21-11-991-04700-00-A / SHEET 1/1 - Aluminum Nut

End of document

Print Date: March 21, 2020 Page 36 of 36

© AIRBUS S.A.S. ALL RIGHTS RESERVED. CONFIDENTIAL AND PROPRIETARY DOCUMENT.

You might also like

- JCB380 Parts Manual PDFDocument254 pagesJCB380 Parts Manual PDFSRINIVASA RAO MARTURINo ratings yet

- TASK 71-00-00-000-042-A Removal of The Power PlantDocument24 pagesTASK 71-00-00-000-042-A Removal of The Power PlantVijai PrakashNo ratings yet

- Adjust and correct Z and Y vibrationsDocument19 pagesAdjust and correct Z and Y vibrationsFábio HenriqueNo ratings yet

- LENGTH .010 D E: Bombardier Standards ManualDocument4 pagesLENGTH .010 D E: Bombardier Standards ManualJohn CollinsNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- A320 Tasksharing for New ChecklistsDocument39 pagesA320 Tasksharing for New ChecklistsallenNo ratings yet

- Plane Link ListDocument2 pagesPlane Link Listthe breycot50% (2)

- HPT Shroud and LPT NozzleDocument27 pagesHPT Shroud and LPT Nozzlekien Duy PhanNo ratings yet

- Bscu FCNDocument161 pagesBscu FCNWaleed HassanNo ratings yet

- ON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty DesignationDocument27 pagesON A/C 001-150, 301-350, 504-504, 550-550, 601-850: Reference Qty Designationkien Duy PhanNo ratings yet

- 9820 - 1015P - 3DX Super Parts Manual From 1855501-2583230Document445 pages9820 - 1015P - 3DX Super Parts Manual From 1855501-2583230Moussa HamzaNo ratings yet

- Inspt of The Combustion Chamber and HPT NozzleDocument9 pagesInspt of The Combustion Chamber and HPT NozzleSuman BajracharyaNo ratings yet

- On Shot Fan Blade Balancing Leap 1aDocument7 pagesOn Shot Fan Blade Balancing Leap 1aAbhishekprasad royNo ratings yet

- Intls of NLGDocument11 pagesIntls of NLGje_carD23No ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- HPT RotorDocument46 pagesHPT Rotorkien Duy PhanNo ratings yet

- Packing List SamplerDocument2 pagesPacking List SamplerJuan Jose Coila P.No ratings yet

- Connector: 3.5mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsDocument2 pagesConnector: 3.5mm Pitch/disconnectable Crimp Style Wire-To-Wire ConnectorsJamesNo ratings yet

- LF45/55 Technical Data GuideDocument84 pagesLF45/55 Technical Data GuideANDREI26No ratings yet

- 606nct en Fm1Document199 pages606nct en Fm1Coil98No ratings yet

- Advance Trim Balance LEAP 1ADocument7 pagesAdvance Trim Balance LEAP 1AAbhishekprasad royNo ratings yet

- Ds-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Document2 pagesDs-Me-0018 - Mechanical Data Sheet For Overfill Prevention Valve (Rev.0)Panisa BanimaNo ratings yet

- Swivel JointDocument8 pagesSwivel JointSuman BajracharyaNo ratings yet

- 78 36 00 410 040 BDocument5 pages78 36 00 410 040 BRohan SinghNo ratings yet

- 04 - Panel Dpc-Panel LayoutDocument1 page04 - Panel Dpc-Panel LayoutJohan IgnacioNo ratings yet

- Caution / Notice / HintDocument15 pagesCaution / Notice / HintZouhair WahbiNo ratings yet

- Calcu Nozzle NeckDocument15 pagesCalcu Nozzle Necksachmaya0% (1)

- AMM - 01-Aug-2019 - 79-21-10-400-004-A - Installation of The Lubrication UnitDocument11 pagesAMM - 01-Aug-2019 - 79-21-10-400-004-A - Installation of The Lubrication UnitIrfan05No ratings yet

- C Max Tightening Torque Admissible Side Load Est'd Weight ClipsDocument2 pagesC Max Tightening Torque Admissible Side Load Est'd Weight ClipsTowerNo ratings yet

- Aquachill: Air Cooled Scroll Water ChillersDocument48 pagesAquachill: Air Cooled Scroll Water ChillersLee BroNo ratings yet

- Rod, Cable, and SW Wind BracingDocument19 pagesRod, Cable, and SW Wind BracingNyein ZawNo ratings yet

- V (V) I (Ma) V (V) at +25°C I (Ua) at +25°C: Surface Mount Schottky Barrier DiodeDocument5 pagesV (V) I (Ma) V (V) at +25°C I (Ua) at +25°C: Surface Mount Schottky Barrier DiodetusharNo ratings yet

- Fine Adjust Crimp ApplicatorDocument5 pagesFine Adjust Crimp ApplicatorAmine MaaouiNo ratings yet

- Cimechel-Kptl (JV) : SHEET No: 23Document1 pageCimechel-Kptl (JV) : SHEET No: 23Anubhav Hem Kumar JainNo ratings yet

- Van FlapDocument133 pagesVan FlapthanhNo ratings yet

- CW Series Air Compressor Parts List and ManualDocument17 pagesCW Series Air Compressor Parts List and ManualrobertNo ratings yet

- Eo A320 009.16 Engine Change Rev. 04Document30 pagesEo A320 009.16 Engine Change Rev. 04likephungproNo ratings yet

- 625 24 Unef 2aDocument1 page625 24 Unef 2amacsen.malacaiNo ratings yet

- Mecss - Bracket Design LoadDocument1 pageMecss - Bracket Design LoadVíctor CasadoNo ratings yet

- Catalog Ass en - Produse NoiDocument28 pagesCatalog Ass en - Produse NoiBirciu ValiNo ratings yet

- AMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitDocument10 pagesAMM - 01-Aug-2019 - 79-21-10-000-004-A - Removal of The Lubrication UnitIrfan05100% (1)

- Wheel InspectionDocument36 pagesWheel InspectionRemoNo ratings yet

- InstallationDocument12 pagesInstallationhammad ahmedNo ratings yet

- Flexible Hoses: ACETILENE 25 BUNDLE: Domains of ApplicationsDocument3 pagesFlexible Hoses: ACETILENE 25 BUNDLE: Domains of ApplicationsAbdullah FazilNo ratings yet

- HPT NozzleDocument19 pagesHPT Nozzlekien Duy PhanNo ratings yet

- RAP - Panel SDP-1Document1 pageRAP - Panel SDP-1Hellen EnggalaNo ratings yet

- AMM August 2020 12-13-79-610-003-C - Oil Tank DrainingDocument5 pagesAMM August 2020 12-13-79-610-003-C - Oil Tank DrainingIrfan05No ratings yet

- TCE Anchor Bolt Schedule User InstructionsDocument19 pagesTCE Anchor Bolt Schedule User InstructionsneerajNo ratings yet

- Ds-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Document2 pagesDs-pp-0016 - Data Sheet For Flexible Joint (Rev.0)Panisa BanimaNo ratings yet

- OFC-VILLA 2015 General CatalogueDocument256 pagesOFC-VILLA 2015 General CatalogueМихаилNo ratings yet

- 51-10-08 - Hfec Inspection For Surface Breacking Cracks in Aluminum or Titanium Alloy MaterialsDocument32 pages51-10-08 - Hfec Inspection For Surface Breacking Cracks in Aluminum or Titanium Alloy Materialskien Duy PhanNo ratings yet

- J3295-W-047 C Temporary Bollard DesignDocument19 pagesJ3295-W-047 C Temporary Bollard DesignKelvin TsoiNo ratings yet

- VXN155 Vixion R Electrical 1Document1 pageVXN155 Vixion R Electrical 1smksteknologiNo ratings yet

- 750 24 Uns 2aDocument1 page750 24 Uns 2amacsen.malacaiNo ratings yet

- Ash 13.8 em 411B - AsbuiltDocument25 pagesAsh 13.8 em 411B - AsbuiltMr IlchamNo ratings yet

- HPT Stage 1 Blades and Duct SegmentsDocument28 pagesHPT Stage 1 Blades and Duct SegmentsArabyAbdel Hamed SadekNo ratings yet

- Avk Handwheel 08Document2 pagesAvk Handwheel 08Popescu OctavianNo ratings yet

- Pressure DefuelDocument14 pagesPressure DefuelIvan KryskoNo ratings yet

- Alert Service Bulletin UH-1H-17-19: ASB UH-1H-17-19 Page 1 of 8 Approved For Public ReleaseDocument8 pagesAlert Service Bulletin UH-1H-17-19: ASB UH-1H-17-19 Page 1 of 8 Approved For Public Releasesebastian eduardoNo ratings yet

- ESR - 2948 FisherDocument14 pagesESR - 2948 FisherReinel OrjuelaNo ratings yet

- Volvo construction equipment sales bulletin on bronze wearing stripsDocument1 pageVolvo construction equipment sales bulletin on bronze wearing stripsBilal VURALNo ratings yet

- Notes CC GEO 4Document10 pagesNotes CC GEO 4Delor FoyetNo ratings yet

- A320 A330 A340 Families - Cabin CrewDocument33 pagesA320 A330 A340 Families - Cabin CrewDefinal ChaniagoNo ratings yet

- Airbus Aircraft Family Figures Brochure - June 2017Document13 pagesAirbus Aircraft Family Figures Brochure - June 2017SoulFalconNo ratings yet

- Aircraft Recognition PowerPoint PDFDocument11 pagesAircraft Recognition PowerPoint PDFNick TsangNo ratings yet

- 72 00-00-200 025 A01 Over Serviceable Limit ExtensionsDocument79 pages72 00-00-200 025 A01 Over Serviceable Limit ExtensionsmailtoshiyasNo ratings yet

- Flex and Derate Takeoff and ClimbDocument32 pagesFlex and Derate Takeoff and Climbhdrabs100% (4)

- Easa Pad 19-209 1Document4 pagesEasa Pad 19-209 1cf34No ratings yet

- GOW - A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 12-15-38-613-001-A - Fill The Potable Water Tank System (Aircraft Electrical Power Available)Document6 pagesGOW - A318 - A319 - A320 - A321 - AMM - 01-Feb-2020 - 12-15-38-613-001-A - Fill The Potable Water Tank System (Aircraft Electrical Power Available)nazia0% (1)

- Easa Pad 22-169 1Document10 pagesEasa Pad 22-169 1emad24No ratings yet

- AFM Airbus 320Document8 pagesAFM Airbus 320Dan AndreiNo ratings yet

- Figure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Document1 pageFigure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaNo ratings yet

- How To Handle Different Class Fault MessagesDocument7 pagesHow To Handle Different Class Fault MessagesSuman BajracharyaNo ratings yet

- A318/A319/A320/A321: Service BulletinDocument23 pagesA318/A319/A320/A321: Service BulletinPradeep K sNo ratings yet

- FOT-999-0130!16!00 Incorrect Characteristic Speeds Computation Due To Absence of The ZFWCG ValueDocument3 pagesFOT-999-0130!16!00 Incorrect Characteristic Speeds Computation Due To Absence of The ZFWCG ValueGermanTobonNo ratings yet

- Apu Bottle Discharge IndicatorDocument4 pagesApu Bottle Discharge IndicatorsummerstoryNo ratings yet

- Vdu Lift Stair Tower 302 - Structure - Part List - IfcDocument130 pagesVdu Lift Stair Tower 302 - Structure - Part List - IfcDarshan PanchalNo ratings yet

- Administration of Flight Ops Manuals For Flight Ops Engineers - XG10 - 27032024Document3 pagesAdministration of Flight Ops Manuals For Flight Ops Engineers - XG10 - 27032024steve yangNo ratings yet

- Binder 3 of 4 Dec-2018Document1,169 pagesBinder 3 of 4 Dec-2018Anonymous OEmUQuNo ratings yet

- A320 CEO (Current Engine Option) SpecsDocument6 pagesA320 CEO (Current Engine Option) SpecsGustavo GómezNo ratings yet

- SpecificationDocument3 pagesSpecificationMessala YoveraNo ratings yet

- AIFPCfg Aig Britishairways Summer 2018 TfsDocument6 pagesAIFPCfg Aig Britishairways Summer 2018 TfsHT RepaintsNo ratings yet

- Steel Grades For GB Standard JIS Standard ASTM Standard DIN Standard PDFDocument8 pagesSteel Grades For GB Standard JIS Standard ASTM Standard DIN Standard PDFsenthilkumar100% (1)

- vEZY Policies Guide 2022Document3 pagesvEZY Policies Guide 2022Maurício BrentanoNo ratings yet

- CAR147 approved organisations for aircraft engine trainingDocument13 pagesCAR147 approved organisations for aircraft engine trainingKaren NoronhaNo ratings yet

- Title: Flight Controls - Spoiler and Elevator Computer - Install Sec 125 Hardware B'Document83 pagesTitle: Flight Controls - Spoiler and Elevator Computer - Install Sec 125 Hardware B'omidNo ratings yet

- Airbus SB A320-31-1583 R05 Dated 09.apr.2021Document240 pagesAirbus SB A320-31-1583 R05 Dated 09.apr.2021Pradeep K sNo ratings yet

- AIrbus Tires InfoDocument19 pagesAIrbus Tires Infotayo_b100% (4)

- Introduction To A350 and A380 New FeaturesDocument23 pagesIntroduction To A350 and A380 New FeaturesMarian Rotaru86% (7)