Professional Documents

Culture Documents

Check List Int Dia

Uploaded by

Crazzy RamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Check List Int Dia

Uploaded by

Crazzy RamCopyright:

Available Formats

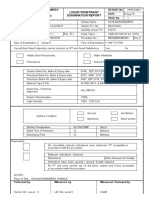

QA/C/261-A

REV 00

INTERMEDIATE DIAPHRAGM-VANES AND OTHER

Issue date: 01.10.2018

PROFILES INSPECTION REPORT

Product : COMPRESSOR W.O. No. : Part No. :

Drawing no. : Customer: Machine No .

SL NO Characteristics Requirements Remarks

1 VANE-DIRECTION

2 TOTAL NUMBER OF VANES

3 VANE HEIGHTS MAX-

MIN-

4 MAXIMUM VANE THICKNESS

5 VANE PROFILE CHECKING TEMPLATE

6 PART –A, PROFILE CHECKING TEMPLATE

Metallic template to be used

7 PART-B PROFILE CHECKING TEMPLATE

8 DETAIL-X TEMPLATE

9 DETAIL-Y TEMPLATE

10 BALL RADIUS TEMPALTE

11 SUSPENSION GUAGE TEMPLATE

12 VISUAL INSPECTION NO DENTS, STEPS & UNDERCUTS ARE NOT ALLOWED

13 SURFACE FINISH / MILLING CUTTER MARKS YES/NO

14 ID MARKS PART-A PART-B GR-

GR-

H NO- H NO-

CUSTOMER / 3rd party :

Date : . Inspected by : .

Inspector

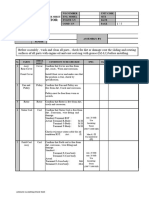

CHECK LIST FOR INSPECTION OF COMPRESSOR INTERMEDIATE DIAPHRAGM QA/C/261-B

REV 00

Issue date: 01.10.2018

CUSTOMER:TOYO ENGG INDIA.P.LIMITED. WO.NO:

VENDOR:VS ENGG WORKS Drg No:

PART NO:

SL NO DESCRIPTION: REMARKS

1. Verify drawing No against SCO and SMIV OK/NOT OK

Verify SCO NO and record:

PPMIV :

2. OK/NOT OK

GR NO:

GR NO:

3. Details of all materials including screws, nuts, taper pins OK/NOT OK

4. Surface roughness of parting plane, seal locating diameter and faces. OK/NOT OK

5. Gap between part A and B at vanes areas . OK/NOT OK

6. Rounding of vanes at inlet and outlet . OK/NOT OK

7. Parting plane gap between UH and LH. OK/NOT OK

8. Disposition of vanes w.r.t. parting plane. OK/NOT OK

9. Blue match between UH and LH to be witnessed and condition of UH parting plane to be checked OK/NOT OK

10. Checks of nuts, screws, taper pins etc before fixing. OK/NOT OK

11. All required parameters (as per CT and drawings) for fixing of parts A and B to be checked and recorded. OK/NOT OK

12. All threaded holes shall be checked for thread size and visual quality. OK/NOT OK

13. Smoothness of gas path surfaces to be checked for freedom from chatter, steps, undulations etc OK/NOT OK

14. All surfaces to be checked for any visible forging defects. OK/NOT OK

15. Lab seal Suspension thickness. OK/NOT OK

16. Preservation of machined surfaces to be checked OK/NOT OK

17. Vane milling by CNC as required by drawing to be checked. OK/NOT OK

18 Correct inlet and exit angles of the vanes w.r.t. diameters (ID or OD) to be checked. OK/NOT OK

19. Allowances on location diameter OK/NOT OK

20. Punching Identification marks on the job as per drg OK/NOT OK

You might also like

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeederDocument8 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - FeedererstendrainNo ratings yet

- Technical Data:: Load Center C / SEC TUNNEL-C130/C13O Basement 2 Sec TunnelDocument3 pagesTechnical Data:: Load Center C / SEC TUNNEL-C130/C13O Basement 2 Sec Tunneleswaran005100% (1)

- BBP CBF - Function TestDocument21 pagesBBP CBF - Function TestAmr ElkadyNo ratings yet

- LCC Bus Section - Functional TestDocument10 pagesLCC Bus Section - Functional TestAmr ElkadyNo ratings yet

- SECL-CV210-A4 Pre-Pouring InspectionDocument1 pageSECL-CV210-A4 Pre-Pouring InspectionhadefNo ratings yet

- Commissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDocument6 pagesCommissioning Service Department Commissioning Standard Test Formats Description: Functional Test - Bus EarthingDinesh PitchaivelNo ratings yet

- LCC Bus Coupler - Functional TestDocument7 pagesLCC Bus Coupler - Functional TestAmr ElkadyNo ratings yet

- 7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDDocument8 pages7SR102 Rho-MOTOR PROTECTION RELAY-UPDATEDAnonymous dH3DIEtzNo ratings yet

- L.P.T Reports.Document12 pagesL.P.T Reports.Shaikh AdilNo ratings yet

- As Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedDocument12 pagesAs Per The Schematic Drawings The Contents in This Test Format Can Be ModifiedAlexNo ratings yet

- SACEP - RTCC - Delivery #0971558-12Document16 pagesSACEP - RTCC - Delivery #0971558-12Ryan condeNo ratings yet

- Cur Soar Condicion A Do AutoDocument37 pagesCur Soar Condicion A Do AutoFabio Adriana FláviaNo ratings yet

- Field Inspection ReportDocument14 pagesField Inspection ReportRanjit SinghNo ratings yet

- Check ListDocument19 pagesCheck ListPanruti S SathiyavendhanNo ratings yet

- SACEP - RTCC - Delivery #0971542-11Document16 pagesSACEP - RTCC - Delivery #0971542-11Ryan condeNo ratings yet

- Structural Damage Report Form: SDR NoDocument2 pagesStructural Damage Report Form: SDR NoDewin SilvaNo ratings yet

- Checklist For Water TestDocument2 pagesChecklist For Water TestBluebay TeamNo ratings yet

- Tz.O.R.C R.O. Project: Liquid Penetrant Inspection Quality Control FormDocument2 pagesTz.O.R.C R.O. Project: Liquid Penetrant Inspection Quality Control Formbehzad mohammadiNo ratings yet

- Qap Reciever TanksDocument6 pagesQap Reciever Tanksyamunaengg2011No ratings yet

- WELDING MACHINE ChecklistDocument1 pageWELDING MACHINE Checklistsakthi venkatNo ratings yet

- SA 980 P 11433 CS Plug Valve Rev T02Document3 pagesSA 980 P 11433 CS Plug Valve Rev T02altipatlarNo ratings yet

- Annexure To Start-Up & Commissioning of Fire Water PumpsDocument5 pagesAnnexure To Start-Up & Commissioning of Fire Water PumpsMina KhalilNo ratings yet

- Circuit Breaker - For SwitchayrdDocument9 pagesCircuit Breaker - For SwitchayrdSindhuKumarNo ratings yet

- Commissioning of Electrical SystemsDocument14 pagesCommissioning of Electrical SystemsRatheesh Kumar100% (1)

- Alternator Assembling Check Sheet3Document5 pagesAlternator Assembling Check Sheet3Erik dwi KurniawanNo ratings yet

- SA 980 P 11432 CS Globe Valve Rev T02Document3 pagesSA 980 P 11432 CS Globe Valve Rev T02altipatlarNo ratings yet

- Final Report - 1721-V-0905 BDocument5 pagesFinal Report - 1721-V-0905 BvivekNo ratings yet

- Cupiagua CPF: UPS Inverter and Static Switch Function Test CertificateDocument1 pageCupiagua CPF: UPS Inverter and Static Switch Function Test CertificateKhaled FatnassiNo ratings yet

- 016Document6 pages016Moinullah Khan AteeqNo ratings yet

- Site Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)Document3 pagesSite Inspection and Test Record: Al - Babtain S/S 8715 (132/13.8 KV)m khNo ratings yet

- General Format For Girder Fabrication Check ListDocument4 pagesGeneral Format For Girder Fabrication Check ListBhanu Pratap ChoudhuryNo ratings yet

- SACEP - RTCC - Delivery #0971407-05Document12 pagesSACEP - RTCC - Delivery #0971407-05Ryan condeNo ratings yet

- SWGR Feeder - Functional TestDocument13 pagesSWGR Feeder - Functional TestChheng KimhokNo ratings yet

- Saudi Aramco Pre-Commissioning Form: Instrument TransformersDocument4 pagesSaudi Aramco Pre-Commissioning Form: Instrument TransformersJithuRaj0% (1)

- Inspection Test Plan PV Nozzle Modification/AlterationDocument4 pagesInspection Test Plan PV Nozzle Modification/AlterationMohd Shafuaaz KassimNo ratings yet

- Acdb - Function TestDocument4 pagesAcdb - Function TestDinesh Pitchaivel0% (1)

- FRM2-007 Rev03 (Material Testing Consignment Note) WQT PAMMEKDocument1 pageFRM2-007 Rev03 (Material Testing Consignment Note) WQT PAMMEKHazizul Hanafiah BgracingekzosysNo ratings yet

- HOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)Document3 pagesHOANG TRUNG KIEN - 6G GTAW + SMAW (Duplex, T 18.26mm)TuTuy AnNo ratings yet

- Manual de Bop Doble RamDocument30 pagesManual de Bop Doble RamAndres Paul (paultgt)No ratings yet

- 1721-V-0905 A - MergedDocument5 pages1721-V-0905 A - MergedvivekNo ratings yet

- Daily Painting Inspection Report 08Document2 pagesDaily Painting Inspection Report 08Oussama Ben AbbesNo ratings yet

- Reactor - For SwitchayrdDocument10 pagesReactor - For SwitchayrdSindhuKumarNo ratings yet

- Checklist Fire StopDocument9 pagesChecklist Fire StopAnonymous DMdGdsOENo ratings yet

- Procedure D'inspectionDocument9 pagesProcedure D'inspectionsalahjallali100% (2)

- SA 980 P 11430 CS FGD Ball Valve Rev T02Document3 pagesSA 980 P 11430 CS FGD Ball Valve Rev T02altipatlarNo ratings yet

- APT001-D-DWG-ME-003 - Drawing Water Coalescer Tank (T-106A-B) - 0 - IFBDocument2 pagesAPT001-D-DWG-ME-003 - Drawing Water Coalescer Tank (T-106A-B) - 0 - IFBRoy RahadianNo ratings yet

- DCDB - Function TestDocument5 pagesDCDB - Function TestAmr ElkadyNo ratings yet

- Inspection Job Plan (Ijp)Document1 pageInspection Job Plan (Ijp)hammad100% (1)

- Sa 980 P 11434 Cs Swing Check Valve Rev. t02Document3 pagesSa 980 P 11434 Cs Swing Check Valve Rev. t02altipatlar100% (1)

- Saudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Inspect Repairs of Weld Overlay & Restored Cladding SAIC-W-2024 24-Mar-16 WeldRijwan MohammadNo ratings yet

- SA-P-011 Instrument TransformerDocument4 pagesSA-P-011 Instrument TransformerSathiya SeelanNo ratings yet

- SA-P-050 - Dry Type Power TransformersDocument4 pagesSA-P-050 - Dry Type Power TransformersUET MAINNo ratings yet

- Impressed Current CP Quality Control and Inspection Report FormDocument1 pageImpressed Current CP Quality Control and Inspection Report FormBiswasNo ratings yet

- Isolator & Earth Switch - For SwitchayrdDocument6 pagesIsolator & Earth Switch - For SwitchayrdGopal KrishnanNo ratings yet

- WPS PQR FormulirDocument2 pagesWPS PQR FormulirAZaiNo ratings yet

- Cupiagua CPF: Power Transformers Function Test CertificateDocument1 pageCupiagua CPF: Power Transformers Function Test CertificateKhaled FatnassiNo ratings yet

- Saudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldDocument3 pagesSaudi Aramco Inspection Checklist: Final Welding Insp - Weld Overlay & Cladding Rest. SAIC-W-2023 24-Mar-16 WeldRijwan MohammadNo ratings yet

- C15 Additional Part Bushing Cam ShaftDocument7 pagesC15 Additional Part Bushing Cam ShaftYeremiaNo ratings yet

- ALL Checklist - FinalDocument33 pagesALL Checklist - FinalKaran KumarNo ratings yet

- Milk Basket 2Document1 pageMilk Basket 2Crazzy RamNo ratings yet

- Class 8 Friction.Document3 pagesClass 8 Friction.Crazzy RamNo ratings yet

- Class 9 - MotionDocument6 pagesClass 9 - MotionCrazzy RamNo ratings yet

- Milk Basket 1Document1 pageMilk Basket 1Crazzy RamNo ratings yet

- Class 7 Acids and BasesDocument3 pagesClass 7 Acids and BasesCrazzy RamNo ratings yet

- Class 6 Measurements Ad MotionDocument3 pagesClass 6 Measurements Ad MotionCrazzy RamNo ratings yet

- Class 7 Light and It's PhenomenaDocument3 pagesClass 7 Light and It's PhenomenaCrazzy RamNo ratings yet

- Heat EnergyDocument18 pagesHeat EnergyCrazzy RamNo ratings yet

- Class 8 Combustion and Flame.Document4 pagesClass 8 Combustion and Flame.Crazzy RamNo ratings yet

- GSTCHANGEDocument1 pageGSTCHANGECrazzy RamNo ratings yet

- 11 Atoms and NucleiDocument13 pages11 Atoms and NucleiHimanshu GuptaNo ratings yet

- Crazzy Rams Magnetic Field Due To A Circular LoopDocument3 pagesCrazzy Rams Magnetic Field Due To A Circular LoopCrazzy RamNo ratings yet

- Parents' Handbook of Careers After SchoolDocument32 pagesParents' Handbook of Careers After Schoolraj50% (4)

- AttachmentDocument41 pagesAttachmentCrazzy RamNo ratings yet

- Import An atDocument1 pageImport An atCrazzy RamNo ratings yet

- Recomendaciones para ReclusosDocument4 pagesRecomendaciones para ReclusosRadha K dasNo ratings yet

- Sri Krishna ChaitanyaDocument1 pageSri Krishna ChaitanyaCrazzy RamNo ratings yet

- Haree Krishnaa Haree RamDocument1 pageHaree Krishnaa Haree RamCrazzy RamNo ratings yet

- ImportantDocument1 pageImportantCrazzy RamNo ratings yet

- NPPTDSFGDocument1 pageNPPTDSFGCrazzy RamNo ratings yet

- Mechatronics Basic IntroductionDocument104 pagesMechatronics Basic IntroductionRahul100% (4)

- WCM OPC Pillar: Grand Prix of Excellence - NSADocument51 pagesWCM OPC Pillar: Grand Prix of Excellence - NSATadeu granatoNo ratings yet

- Budget: Project Plant Pals Operations & Training: TotalDocument3 pagesBudget: Project Plant Pals Operations & Training: Totalbrasilrules100% (1)

- ch6 - Business StrategyDocument34 pagesch6 - Business StrategyFarah Farah Essam Abbas HamisaNo ratings yet

- Operating and Cash Conversion CyclesDocument4 pagesOperating and Cash Conversion CyclesChristoper SalvinoNo ratings yet

- Pawan Singh Resume PlanningDocument2 pagesPawan Singh Resume Planningarchit gargNo ratings yet

- Amity MBA CRM Module 1Document102 pagesAmity MBA CRM Module 1vikrant100% (1)

- IT-Operation-Sytem-Project ManagementDocument12 pagesIT-Operation-Sytem-Project ManagementAbdulNo ratings yet

- Contineous Assessment 2 Group BDocument11 pagesContineous Assessment 2 Group BMasnoon MidhatNo ratings yet

- Responsibility Matrix PDFDocument1 pageResponsibility Matrix PDFNour MerjaniNo ratings yet

- How To Enable A Six Sigma Methodology With SAP For Quality Management, Projects and AnalyticsDocument11 pagesHow To Enable A Six Sigma Methodology With SAP For Quality Management, Projects and AnalyticsMarco Aurélio De Araujo BuenoNo ratings yet

- Installed Base ComponentsDocument4 pagesInstalled Base ComponentsSyed Faisal JavedNo ratings yet

- Blueprint Procedures - Tool-Kit - V3Document67 pagesBlueprint Procedures - Tool-Kit - V3Srinivas N GowdaNo ratings yet

- Procurement AssignmentDocument2 pagesProcurement AssignmentJun LengNo ratings yet

- Oracle India Localization PDFDocument156 pagesOracle India Localization PDFLaxmidhara NayakNo ratings yet

- Welding Program Quality Assurance GuideDocument19 pagesWelding Program Quality Assurance GuideDonald ray100% (1)

- Mid Career Resume ExampleDocument2 pagesMid Career Resume ExampleSenthil KumarNo ratings yet

- Tle6 Q3 Summative Test#1Document5 pagesTle6 Q3 Summative Test#1rona sumodio100% (2)

- Microeconomics Cha 4Document8 pagesMicroeconomics Cha 4haile GetachewuNo ratings yet

- Sandvik Steel - Case StudyDocument2 pagesSandvik Steel - Case StudynileshNo ratings yet

- Burden PreparationDocument14 pagesBurden PreparationAkarshit NandeshwarNo ratings yet

- A Genetic Programming Approach To Record DeduplicationDocument45 pagesA Genetic Programming Approach To Record DeduplicationRamesh KumarNo ratings yet

- Client Analysis: Grainger and Bosch CapstoneDocument25 pagesClient Analysis: Grainger and Bosch CapstoneKazi Shadid RaiyanNo ratings yet

- Almighty Containers Freight Stations Pvt. Ltd. (C.F.S: Ghavan Phata, Village Wahal Tal. Uran, Dist. Raigadh - Mumbai)Document12 pagesAlmighty Containers Freight Stations Pvt. Ltd. (C.F.S: Ghavan Phata, Village Wahal Tal. Uran, Dist. Raigadh - Mumbai)Harsh AgrawalNo ratings yet

- Product Offer For TelecommunicationsDocument84 pagesProduct Offer For TelecommunicationsisfaroNo ratings yet

- Con8522 - Casey-Fdmee Epm and Erp Integration Con8522Document41 pagesCon8522 - Casey-Fdmee Epm and Erp Integration Con8522parmitchoudhuryNo ratings yet

- IBM Insurance IAA Warehouse GIMv85Document23 pagesIBM Insurance IAA Warehouse GIMv85Matthew ReachNo ratings yet

- Case Study1Document17 pagesCase Study1Christine Alderama MurilloNo ratings yet

- 200120-NSH AMC CONTRACT ConceptDocument22 pages200120-NSH AMC CONTRACT ConceptSaurabh YadavNo ratings yet

- 31.10.2023 - EYP Pernod Ricard Vs DiageoDocument27 pages31.10.2023 - EYP Pernod Ricard Vs Diageoneptune flagNo ratings yet

- B2B Assignment 2Document11 pagesB2B Assignment 2DeepakNo ratings yet