Professional Documents

Culture Documents

QP-218-03 Mandatory Reporting

Uploaded by

Putu RobedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QP-218-03 Mandatory Reporting

Uploaded by

Putu RobedCopyright:

Available Formats

QUALITY PROCEDURES

QP 218-03

MANDATORY REPORTING

Originator: Quality System Auditing

Add te

12-Sep-2023

QUALITY PROCEDURES

MANDATORY REPORTING QP 218-03

RECORD OF REVISIONS

QP NO. & ISSUE REVISION DESCRIPTION OF ISSUE / DATE SUPERSEDED

REVISION

QP-218-03

0 New 01-Apr-2019 None

Issue A

• In flow process section

3.1:

1. Added QP 303-01

2. Added Safety

inspection and QSA in

PIC

• adding statement in

section 3.2.2

1. The quality inspector

will review all

customer for

QP-218-03 possibility of similar QP-218-03

1 11-Sep-23

Issue 1 occurance in order to Issue A Rev 0

prevent repetitive

incidents.

2. The inspector in

charge may request

further investigation

as necessary to

safety inspection or

QSA in accordance

with QP 303-01.

Issue: 1 Revision No.: 1 Date: 11 Sep 2023 Page 2 of 7

Form No.: GMF/Q-034 R2 CONTROLLED COPY DO NOT DUPLICATE

QUALITY PROCEDURES

MANDATORY REPORTING QP 218-03

1. GENERAL INFORMATION

1.1. Originator : General Manager Quality System & Auditing for Base Maintenance

1.2. Applicability : All Workstations

1.3. References : AMOM 2.18, MOE 2.18, RSQM 2.18, MOE CASA 2.17, SMM 1.8, CMM GA XIV.

1.4. Purpose:

To provide report of important operating defects and malfunctions found by GMF to TC

Holder, Operator, and Authority, provide reporting deficiencies caused by GMF to Operator

or Authority in the category of mandatory reporting based on authority regulation or

customer manual.

1.5. Associated procedures:

QP 218-01 Internal Occurrence Report

QP 202-01 Receiving Material inspection

QP 303-01 Investigation of Deficiency Incident or Accident

QP 601-07 Reliability Control Program

1.6. Quality Records and Forms:

Note: All current form required for the implementation of the procedures will be retrieved

from the local area network – TQ folder or intranet.

Issue: 1 Revision No.: 1 Date: 11 Sep 2023 Page 3 of 7

Form No.: GMF/Q-034 R2 CONTROLLED COPY DO NOT DUPLICATE

QUALITY PROCEDURES

MANDATORY REPORTING QP 218-03

2. DEFINITIONS

AD: Airworthiness Directive

Article: Aircraft, airframe, aircraft engine, propeller, appliance, or component part.

Authority: Means the DGCA or any other National Aviation Authority related with the A/C

registration GMF AeroAsia maintains as mentioned in this manual

Corrective Action: Actions required detecting and correcting conditions adverse to quality,

including the eliminations of the discrepancy plus establishment of controls necessary to preclude

recurrence of the condition.

Mandatory Reporting: Means any condition identified on aircraft or aircraft components that could

seriously hazard the aircraft will be mandated by reporting to the appropriate authority, the TC

Holder and the aircraft operator.

QSA: Quality System and Auditing

Issue: 1 Revision No.: 1 Date: 11 Sep 2023 Page 4 of 7

Form No.: GMF/Q-034 R2 CONTROLLED COPY DO NOT DUPLICATE

QUALITY PROCEDURES

MANDATORY REPORTING QP 218-03

3. RESPONSIBILITY AND PROCEDURES

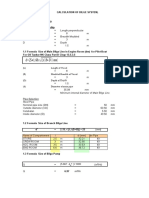

3.1 Flow Process

Mandatory Reporting

Quality Procedures Forms Responsibility

Start

Operating defects, malfunctions, and

deficiencies caused by GMF are

identified in the category of mandatory

reporting. (Section 3.2.1)

Issue Finding Inspection Report GMF/Q-161 Inspector

QSA will review and fill appropriate

form or database mandatory Quality System & Auditing

reporting ref table 1 (Section 3.2.3)

VP Quality Assurance & Safety will Correspondence VP Quality Assurance &

contact the authority as necessary Letter Safety

Internal number registration & submit Quality System

the report to the appropriate TC Documentation

Holder, Operator, and Authority (TQD-2)

Need further Yes

investigation

?

No

QP-303-01

Safety Inspection (TQY),

Quality System & Auditing

Stop

Issue: 1 Revision No.: 1 Date: 11 Sep 2023 Page 5 of 7

Form No.: GMF/Q-034 R2 CONTROLLED COPY DO NOT DUPLICATE

QUALITY PROCEDURES

MANDATORY REPORTING QP 218-03

3.2 REQUIREMENT

3.2.1 GENERAL

This procedure is related with:

a) Reporting important operating defects and malfunctions found by GMF AeroAsia to TC Holder,

Operator, and Authority.

b) Reporting deficiencies caused by GMF AeroAsia to Operator or Authority.

3.2.2 Finding Inspection Report

Any condition identified on aircraft or aircraft components that could seriously hazard the aircraft will

be reported to the appropriate TC Holder, Operator, and Authority. The quality inspector will create

Finding Inspection Report include chronology and pre-analysis as preliminary information. The quality

inspector will review all customer for the possibility of similar occurrences in order to prevent

repetitive incidents. The report will be send to QSA and/or related customer as necessary.

There are 2 condition since the malfunction or deficiencies detected :

1. During maintenance

2. After maintenance release performed as mentioned in part 3.2.4 of this QP.

Finding Inspection Report contains the information category of “Mandatory Report”, the inspector in

charge will determine the operating defect are suspect mandatory reporting or not based on

authority regulation or customer manual. The inspector in charge may request further investigation as

necessary to safety inspection or QSA in accordance with QP 303-01.

3.2.3 Reporting procedure during maintenance

Prior to submitting the report, the VP for Quality Assurance & Safety will contact aircraft operator or

the Authority of the A/C registration to ensure that such defect can be reported or not. The defect

may not be reported if such defect is known or it has been reported by any other organization.

Reports will be made by the VP for Quality Assurance & Safety or his delegate as soon as possible since

the defect was found, in specific manner as described in Table 1.

Table 1. Authority database for mandatory reporting & required time

Authority Reporting Required time

EASA The Report will be done through 2 ways: on-line reporting via a web-

interface www.aviationreporting.eu or off-line reporting using a pdf 72 Hours

form downloadable from the EASA portal.

CASA On a form using the following web site http://drs.casa.gov.au Two business

days

FAA On a form using the following web site http://av-info.faa.gov/sdrx

72 Hours

DGCA For DGCA Indonesia: Service Difficult Report Form No. DGCA 43-01

72 Hours

pdf downloadble through http://dkppu.id

Issue: 1 Revision No.: 1 Date: 11 Sep 2023 Page 6 of 7

Form No.: GMF/Q-034 R2 CONTROLLED COPY DO NOT DUPLICATE

QUALITY PROCEDURES

MANDATORY REPORTING QP 218-03

Other For any other Authority: As instructed by the NAA.

As instruction

authority

Customer As instructed by customer manual As instruction

3.2.4 Reporting procedure after the Release to Service is issued

The VP for Quality Assurance & Safety will determine the need to report and recall (if necessary) any

article which may subject to faults due to inappropriate process, incorrect use of material, etc. He will

inform the customer and the Authority as appropriate describing in detail the deficiency. Such

deficiencies may be identified from the following situations:

a) Records may reveal that an important maintenance task such as AD Note or defect rectification

has not been performed, or a component with improper configuration or certification has been

installed;

b) Similar maintenance tasks have resulted in deficiencies on A/C and components under

maintenance. The defects have been found by the customer during operation;

c) Any other reason that jeopardize the safety of the aircraft.

Prior to submitting the report, VP for Quality Assurance & Safety should discuss with the operator

about the possibility that an unsafe condition may exist on the aircraft. Depending on the suspected

defect, the operator may verify its existence or have GMF AeroAsia to verify and rectify the defect.

Should the suspected unsafe condition be related with an AD Note and the operator is unwilling to

cooperate for the prompt correction of the defect, the VP for Quality Assurance & Safety will inform

the Authority concerned and he will act accordingly.

3.2.5 Reporting procedure for Suspected Unapproved Part (SUP)

When Material Receiving Inspector identify suspected unapproved parts, the inspector will notify

Quality Assurance and Safety Department to verify. Confirmed suspected unapproved parts will be

reported to authority by completing a form in accordance with QP 202-01 Receiving Material

inspection.

Issue: 1 Revision No.: 1 Date: 11 Sep 2023 Page 7 of 7

Form No.: GMF/Q-034 R2 CONTROLLED COPY DO NOT DUPLICATE

You might also like

- The Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsFrom EverandThe Sarbanes-Oxley Section 404 Implementation Toolkit: Practice Aids for Managers and AuditorsNo ratings yet

- Testing UMTS: Assuring Conformance and Quality of UMTS User EquipmentFrom EverandTesting UMTS: Assuring Conformance and Quality of UMTS User EquipmentNo ratings yet

- WHQ SQD PR007 Controlled Shipping Level 1 and 2Document5 pagesWHQ SQD PR007 Controlled Shipping Level 1 and 2Amit DangiNo ratings yet

- Shipping LevelDocument5 pagesShipping LevelSudhagarNo ratings yet

- Approved By:: Calibration Procedure For Torque WrenchesDocument7 pagesApproved By:: Calibration Procedure For Torque Wrenchesvinsensius rasaNo ratings yet

- Grati CCPP (Peaker) Extension Project 450Mw: Pt. Perusahaan Listrik Negara (Persero)Document29 pagesGrati CCPP (Peaker) Extension Project 450Mw: Pt. Perusahaan Listrik Negara (Persero)Yurizal Firmansyah100% (1)

- Bgl-Pm-Qa-12 Control of Non Conforming OutputsDocument4 pagesBgl-Pm-Qa-12 Control of Non Conforming OutputsMohit SinghNo ratings yet

- 2.procedures Initial Supply Control UpdatedDocument3 pages2.procedures Initial Supply Control UpdatedKapil Karhana100% (1)

- Quality Control Manual of PT Sarku Enjinering Utama (ASME JR)Document110 pagesQuality Control Manual of PT Sarku Enjinering Utama (ASME JR)herlan100% (1)

- PQC-07 Rev 2 Examinacion VisualDocument6 pagesPQC-07 Rev 2 Examinacion Visualjose alberto gamiñoNo ratings yet

- AC7140 Rev CDocument73 pagesAC7140 Rev CRanga100% (1)

- AGG-ST-052 Autokiniton Process Approval Sign-Off PPAPDocument19 pagesAGG-ST-052 Autokiniton Process Approval Sign-Off PPAPRamesh DenonNo ratings yet

- General Inspection and Repair Remarks For Inspection/Repair ProceduresDocument9 pagesGeneral Inspection and Repair Remarks For Inspection/Repair ProceduresIvan MauricioNo ratings yet

- QG-QSP-08 Procedure For Control of Non-Conformance Product.Document5 pagesQG-QSP-08 Procedure For Control of Non-Conformance Product.omprakash yadavNo ratings yet

- CG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0Document30 pagesCG4338 GM 1927 03 Supplier Quality Statement of Requirements Rev 19 0masprast.devegaNo ratings yet

- Vedanta Limited: Sulphate Removal ProjectDocument7 pagesVedanta Limited: Sulphate Removal Projectsumit kumarNo ratings yet

- ISO - Control of Non-Conforming ProductsDocument5 pagesISO - Control of Non-Conforming ProductsAlmario SagunNo ratings yet

- Inspection and Test Plan (Itp) : 12", 24" and 36" Pipeline Defects RepairDocument12 pagesInspection and Test Plan (Itp) : 12", 24" and 36" Pipeline Defects RepairBestun AhmedNo ratings yet

- Kaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Document7 pagesKaizen Event Process Improvement Form - Demin - V0 - 30 Jan 23Jonas PadillaNo ratings yet

- SP 2269Document31 pagesSP 2269Vijayakumar AllimuthuNo ratings yet

- Vdocuments - MX - cg4338 GM 1927 03 Supplier Quality Statement of RequirementsDocument28 pagesVdocuments - MX - cg4338 GM 1927 03 Supplier Quality Statement of RequirementsRene Tapia100% (1)

- Control of Non ConformingDocument5 pagesControl of Non ConformingNaveenkumar R100% (1)

- Updated Closer IATFDocument8 pagesUpdated Closer IATFSandeep Verma100% (1)

- Dimensional Control ProcedureDocument22 pagesDimensional Control Proceduresilitonga3388100% (2)

- QP-304-03 Authorized Personnel QualificationDocument84 pagesQP-304-03 Authorized Personnel QualificationPutu RobedNo ratings yet

- Approved By:: Calibration Procedure For Pressure Chart RecorderDocument7 pagesApproved By:: Calibration Procedure For Pressure Chart Recordervinsensius rasaNo ratings yet

- 4100F-QAS-151 (Supplier Quality Assurance Manual)Document35 pages4100F-QAS-151 (Supplier Quality Assurance Manual)Sanjay KumarNo ratings yet

- QN-G - 01 Licensing Rev.2-04 May 2020Document19 pagesQN-G - 01 Licensing Rev.2-04 May 2020Sandy RismawanNo ratings yet

- CFU Factory Acceptance Test Procedure PDFDocument19 pagesCFU Factory Acceptance Test Procedure PDFAgung PrasetyooNo ratings yet

- Ac7126 Rev C To Be Used On or After 21-May-2017Document15 pagesAc7126 Rev C To Be Used On or After 21-May-2017unknown1711No ratings yet

- NcManagement - SA1 - 2021Document13 pagesNcManagement - SA1 - 2021Nagarajan100% (1)

- Asqr01 Form1Document17 pagesAsqr01 Form1Jim ToddNo ratings yet

- ASQR01 Rev 11 FINAL 08 - 31 - 2018Document17 pagesASQR01 Rev 11 FINAL 08 - 31 - 2018testNo ratings yet

- AQAP 2070 - 2007 NATO Mutual Government Quality Assurance ProcesDocument56 pagesAQAP 2070 - 2007 NATO Mutual Government Quality Assurance ProcesdunacoNo ratings yet

- 11-Qa - QC ProcedureDocument18 pages11-Qa - QC Procedureerwin hidayat100% (1)

- Criticality Ranking Procedure - 7200 039 700 Rev 02Document4 pagesCriticality Ranking Procedure - 7200 039 700 Rev 02Firoz HussainNo ratings yet

- GTP 127 Asdarp Engineering Development R1Document18 pagesGTP 127 Asdarp Engineering Development R1andiee traderNo ratings yet

- Quality Control Manual: Field Assembly Control 15.1. ScopeDocument4 pagesQuality Control Manual: Field Assembly Control 15.1. Scopearif rhNo ratings yet

- EC-SRC-0003 Non-Destructive Test (NDT) and Non-Destructive Evaluation (NDE) Requirements Rev 3.0Document21 pagesEC-SRC-0003 Non-Destructive Test (NDT) and Non-Destructive Evaluation (NDE) Requirements Rev 3.0Mathias NsimbeNo ratings yet

- Procedure Number: QAP-08.6 Revision: AJ Page 1 of 17 Corrective and Preventive Action Procedure 1.0 PurposeDocument17 pagesProcedure Number: QAP-08.6 Revision: AJ Page 1 of 17 Corrective and Preventive Action Procedure 1.0 PurposeGonzalo InnNo ratings yet

- DRP001 Ouf Pro Q 000 515 O1Document15 pagesDRP001 Ouf Pro Q 000 515 O1Daniel MartinezNo ratings yet

- Asme QCMDocument84 pagesAsme QCMCaptainTonies100% (2)

- NCAR 2023-027-03 Audits R0Document4 pagesNCAR 2023-027-03 Audits R0Nancy BorasoNo ratings yet

- GM Scorecard Quick Reference Guide Jan 2023 1Document3 pagesGM Scorecard Quick Reference Guide Jan 2023 1Luis AldanaNo ratings yet

- 10 603173 0000100201 Mah QMN RPT 000001 - 01Document98 pages10 603173 0000100201 Mah QMN RPT 000001 - 01Alaa MohamedNo ratings yet

- SIEMENS Corrective and Preventive ActionDocument9 pagesSIEMENS Corrective and Preventive ActionOlakunle AwoniyiNo ratings yet

- WI-TL-091 Outstation IMTE and PMI ControlDocument7 pagesWI-TL-091 Outstation IMTE and PMI ControlAzizul HakimNo ratings yet

- QS-2-010, Issue 01, Procedure For Control & Handling of Non Confirming Products, Corrections, Corrective & Preventive ActionsDocument2 pagesQS-2-010, Issue 01, Procedure For Control & Handling of Non Confirming Products, Corrections, Corrective & Preventive Actionssajid waqasNo ratings yet

- A. Alan Blind: Buchanan, NY 10511Document104 pagesA. Alan Blind: Buchanan, NY 10511Agustin A.No ratings yet

- Ac7108 Rev e NadcapDocument73 pagesAc7108 Rev e NadcapJose LuisNo ratings yet

- Pa2 Ims Lof Utcl Magdalla Feb 23Document48 pagesPa2 Ims Lof Utcl Magdalla Feb 23jogender kumarNo ratings yet

- Schedule Q - Attachment VI Rev.2Document5 pagesSchedule Q - Attachment VI Rev.2dissanayake90kanishkaNo ratings yet

- Saep 381Document33 pagesSaep 381javed khanNo ratings yet

- 3.6 Initial SupplyDocument2 pages3.6 Initial SupplySunil Kumar92% (12)

- Schedule Q - Attachment VIDocument9 pagesSchedule Q - Attachment VIMuhammad AbrarNo ratings yet

- SIPAT PG TEST - Rev3Document15 pagesSIPAT PG TEST - Rev3Rohit SharmaNo ratings yet

- Itp For Field Erected Tank Rev A PDF FreeDocument9 pagesItp For Field Erected Tank Rev A PDF FreeMahmoud GaberNo ratings yet

- UGFC-PQCP-49, Rev01 March 01Document7 pagesUGFC-PQCP-49, Rev01 March 01Mahaboob PashaNo ratings yet

- HKN-PLN-QA-0001 - Rev CDocument157 pagesHKN-PLN-QA-0001 - Rev CjennyNo ratings yet

- Slide Master GMF 2024Document4 pagesSlide Master GMF 2024Putu RobedNo ratings yet

- MEL Rev.13Document1,862 pagesMEL Rev.13Putu RobedNo ratings yet

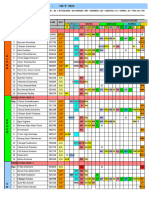

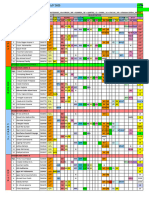

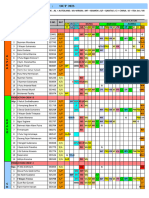

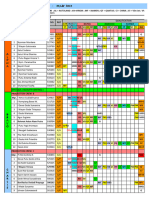

- Schedule MANPOWER TLD OCT. 2023Document59 pagesSchedule MANPOWER TLD OCT. 2023Putu RobedNo ratings yet

- A320 Circuit BreakersDocument54 pagesA320 Circuit BreakersPutu RobedNo ratings yet

- Schedule MANPOWER TLD JAN. 2023Document21 pagesSchedule MANPOWER TLD JAN. 2023Putu RobedNo ratings yet

- Schedule MANPOWER TLD OCT. 2023Document57 pagesSchedule MANPOWER TLD OCT. 2023Putu RobedNo ratings yet

- Schedule MANPOWER TLD JAN. 2023Document21 pagesSchedule MANPOWER TLD JAN. 2023Putu RobedNo ratings yet

- Schedule MANPOWER TLD MAR. 2023Document33 pagesSchedule MANPOWER TLD MAR. 2023Putu RobedNo ratings yet

- QP-304-03 Authorized Personnel QualificationDocument84 pagesQP-304-03 Authorized Personnel QualificationPutu RobedNo ratings yet

- Air Bus 330Document28 pagesAir Bus 330Putu RobedNo ratings yet

- Understanding A ConsolidationDocument2 pagesUnderstanding A Consolidationguolidong2017No ratings yet

- PP Combined PDFDocument64 pagesPP Combined PDFankitvish9No ratings yet

- Renault Ecu ManualDocument31 pagesRenault Ecu ManualDawish JallohNo ratings yet

- Crow Esr5000Document238 pagesCrow Esr5000Eldelson Baggeto100% (1)

- Operacion Terex TR100Document138 pagesOperacion Terex TR100Jose A. Basanta H.No ratings yet

- D 25+1,68 X LX (B+D) (MM) : (L) Length of VesselDocument2 pagesD 25+1,68 X LX (B+D) (MM) : (L) Length of VesselAndika SatriyaNo ratings yet

- Oneysubc19958700 447Document2 pagesOneysubc19958700 447Hanif Abdillah RahmanNo ratings yet

- JLG 600A Articulating Boom Lift Manual PDFDocument148 pagesJLG 600A Articulating Boom Lift Manual PDFbabaNo ratings yet

- The Conoco Weather ClauseDocument10 pagesThe Conoco Weather ClauseJayakumar SankaranNo ratings yet

- 2022-06-27 FY22 SGR Project ManualDocument259 pages2022-06-27 FY22 SGR Project ManualMuhammad SulemanNo ratings yet

- Acknowledgement: Induction Training Report - Naa Koshie LampteyDocument21 pagesAcknowledgement: Induction Training Report - Naa Koshie LampteyasamselaseNo ratings yet

- Review On Effect of Anti-Stripping Agent and Cement On Indirect Tensile Strength of DBMDocument7 pagesReview On Effect of Anti-Stripping Agent and Cement On Indirect Tensile Strength of DBMIJRASETPublicationsNo ratings yet

- Parts Manual Mitsubishi Engine 6D24 TUM For Mitsubishi MG560 98160 43930Document222 pagesParts Manual Mitsubishi Engine 6D24 TUM For Mitsubishi MG560 98160 43930Iginio Malaver VargasNo ratings yet

- Amicable Settlement SampleDocument2 pagesAmicable Settlement SampleRey Janolino Jr80% (20)

- Doosan DX140LC-3 Excavator Parts ManualDocument778 pagesDoosan DX140LC-3 Excavator Parts ManualDjalmaNo ratings yet

- Illustrated Parts List: Spicer Drive SystemDocument48 pagesIllustrated Parts List: Spicer Drive SystemSIMON BOLIVARNo ratings yet

- GoibiboDocument2 pagesGoibiboVenkatesh Surampally100% (1)

- Nebraska Tractor Test 1834A John Deere 7820 Autoquad-Plus Diesel 20 Speed (EU Version - 6.8L Engine)Document2 pagesNebraska Tractor Test 1834A John Deere 7820 Autoquad-Plus Diesel 20 Speed (EU Version - 6.8L Engine)Колки АвтосервісNo ratings yet

- A-Pillar Structure For An Automotive VehicleDocument6 pagesA-Pillar Structure For An Automotive VehiclesopanNo ratings yet

- Warehouse 1 of 9: List of Pre-Owned Vehicles For SaleDocument9 pagesWarehouse 1 of 9: List of Pre-Owned Vehicles For SaleRaymart S. IringanNo ratings yet

- Parclick Voucher V9NR6W0Document1 pageParclick Voucher V9NR6W0Nelly Sabry SabryNo ratings yet

- 2018 - Dry Docks - Overview of Design and ConstructionDocument12 pages2018 - Dry Docks - Overview of Design and Constructionran2315570No ratings yet

- Pilatus PC-12 NGX Specifications, Cabin Dimensions, PerformanceDocument1 pagePilatus PC-12 NGX Specifications, Cabin Dimensions, PerformanceAndres LealNo ratings yet

- Course To Work in The AirportDocument6 pagesCourse To Work in The Airportafiwhhioa100% (1)

- Aci 230.1R - 1997 PDFDocument23 pagesAci 230.1R - 1997 PDFBhavanishankar ShettyNo ratings yet

- RT440B ENG Rev.01 - 2007 (1) (001-099)Document99 pagesRT440B ENG Rev.01 - 2007 (1) (001-099)Valmaq Prestação Serviço Lda100% (1)

- UDCPR Presentaion Training Marale Sir 8-11Document40 pagesUDCPR Presentaion Training Marale Sir 8-11Abhilash ParlikarNo ratings yet

- PCM Products GeneralDocument6 pagesPCM Products Generalvenugopalan srinivasanNo ratings yet

- 69 Mustang Wiring Diagram (Colorized)Document1 page69 Mustang Wiring Diagram (Colorized)1piotr1No ratings yet

- Comparing The Costs To Transport Liquids Using Pipelines, Truck and ShipsDocument4 pagesComparing The Costs To Transport Liquids Using Pipelines, Truck and ShipsPedro GelsonNo ratings yet