Professional Documents

Culture Documents

U Through Wall 11x11

Uploaded by

Ankur ChauhanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

U Through Wall 11x11

Uploaded by

Ankur ChauhanCopyright:

Available Formats

Construction of 8-Lane Carriageway starting near Junction with Keshopura

Road to Junction with NH-11 (Km 151+840 to Km 183+000) section of

Delhi-Vadodra Greenfield Alignment(NH-148N) on EPC Mode under

Bharatmala Pariyojna in the State of Rajasthan (PKG:6)

EPC CONTRACTOR/DESIGN CONSULTANT :

KCC BUILDCON PVT. LTD.

Project Title :

0.5

Development of multi-lane carriageway from km 704.200 to km 723.000 (from Kanhan to Automotive

Square) section of urban link of Nagpur Kamptee section of Nagpur Jabalpur road of NH-44 to be

executed on EPC mode.

Client:

NATIONAL HIGHWAYS AUTHORITY OF INDIA

1.2

Contractor :

KCC BUILDCON PVT. LTD.

Title :

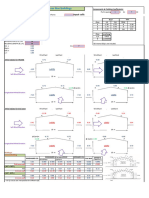

Design of U-type Retaining Wall

Factored BM at 3.3 m height from Side

Date : January, 2020

Description :

i) Design of U-type Retaining Wall 151*1.5 151 151 51.7*1.5 51.7 51.7

Prepared by Nitesh

Checked by Vikas

Approved by Rajeev

Date Revision Description Approved by

Design of U -Through for 11.0m Clear Height:

Coefficient of Active Earth Pressure 12.5

2

Sin (α + φ )

Active earth presure Ka =

2

0.47

sin(φ + δ ).sin(φ − i )

2

Sin α . sin(α − δ ). 1 + A'

sin(α − δ ).sin(α + i )

Backfill Soil Parameter 11.000 (from top)

o

φ = 30 = 0.524 Radians

o

δ = 20 = 0.349 Radians 12.2

o

δsubmerged = 10 = 0.175 Radians B'

o

ι = 0 = 0 Radians 1.2

α = 85.95 o = 1.500 Radians

3

γdry = 2 t/m 1.245 10 1.245

Ka Dry = 0.327

Total earth pressure = 1/2 Kaγh 2 = 39.567 T/m

Summery of Bending Moment at Side Wall

Force due to Factored Bending Moment at

Side wall Bottom (Tm/m) Factored BM at 3.3 m height from

Side wall Bottom (Tm/m)

DL+EP+LLS+EARTH FILL ULS SLS QP ULS SLS QP

217.5 145.0 145.0 74.7 49.8 49.8

At Side Wall Bottom:

ULS Design Bending moment = 217.500 Tm

SLS Rare Design Bending moment = 145.000 Tm

SLS QP Design Bending moment = 145.000 Tm

At 3.3 m H eig ht from Side Wall Bottom:

ULS Design Bending moment = 74.700 Tm

SLS Rare Design Bending moment = 49.800 Tm

SLS QP Design Bending moment = 49.800 Tm

Summary of Shear force

DL+EP+LLS+EARTH FILL Factored force at 3.3

Factored force at

m height from side

side wall Bottom

wall Bottom ULS Load Factor

39.600 tm/m 19.500 tm/m 1.00

2

Design Shear Force at Bottom VED = 39.600 T-m/m

2

Design SF at 2.0m height Bottom VED = 19.500 T-m/m

MATERIAL PROPERTIES :

Grade of concrete = M 30 MPa PERMISSIBLE STRESSES

fcm = 40 MPa

Grade of Reinforcement = Fe 500 MPa 1) Premissble concrete compressive stresses

fywd = 0.8 fyk = 400 MPa Load Combi Permissble Stress

Clear cover = 75 mm SLS Rare 0.48 fck = 14.4 Mpa

Modulus of Elasticity steel Es = 200000 Mpa SLS QP 0.36 fck = 10.8 Mpa

For short Term loading Ecm = 31186.6 Mpa

For long Term loading Ecm' = 12474.6 Mpa

fcteff Mean tensile strength = fctm = 2.50 Mpa 2) Permissble Tensile stress in steel = 300 Mpa

fcd = 13.40 Mpa

Creep factor φ = 1.5 3) Permissible crack width wk

εuk = 0.0045 SLS QP Load combination = 0.3 mm

εud = 0.0041

εcu2 = 0.0035

xumax/d = 0.4636

DESIGN OF SIDE WALL:

A) ULS CAPACITY CHECK

Check Check Check

MRd =0.87 fyk

xu = 0.87 fyk

Ast (d-0.416

Ast / 0.362

0.87 fyk (d'-

Ast,cal =M/

Ast,provided > Ast

MED/z +∆FD

0.416 xu)

Area of steel provided

Ast Calc.<Ast

z = d- MED/z

MRD/z >

Overall

fck b

Ast, Provided

xu)

MED xmax Ast min ∆Fd 0.416 xu +∆FD MRD/z

Provided

b depth D d Dia Spacing Check

min

Load comb. Tm mm mm mm mm mm mm2 mm mm mm2 mm2 T m T Tm Tm/m

Design of Section at Bottom

ULS BM 217.50 1000 1245.0 1154.0 32 180 8936.09 534.97 357.94 UR, OK 4974.639 OK 1731.0 OK 19.80 1005.10 236.20 390.7 388.72 OK

32 180

Design of Section for 3.30 m height from bottom:

ULS BM 74.70 1000 1011.6 920.6 32 180 4468.04 426.77 178.97 UR, OK 2029.479 OK 1380.9 OK 9.75 846.15 98.03 164.5 194.36 OK

B) SLS STRESS CHECK

Rare Load combination. Formula used for calculation of stress

Ec,eq = Ecm*(MQP+MST) dc (depth of neutral axis) = -m*As + √ ( m2 * As2 + 2* m*As*b* d )

MST +(1+φ)* MQP b

MST = MRARE -MQP INA (Transformed) = b *dc3/3 + m* As *(d-dc)2

m = Es/ Ec,eq

Compressive stress in concrete σc = MRARE* dc / INA

Quasi Permanent Load Combination Tensile stress in steel σs = m* MRARE* (d - dc ) / INA

m = Es / Ecm'

Stress Check for SLS Load Combinations

M

modular N.A. Comp Tensile Max T

Check Check

Load comb. b d Ast, Provided ratio depth (dc) INA stress Max C. Stress stress Stress h k

(tm/m) mm mm mm2 mm mm4 Mpa Mpa Mpa Mpa 0 1

Section at deff from face of columne 0.3 1

SLS (R Comb.) 145.00 1000.00 1154.00 8936.08577 16.03 449.3436 1E+11 6.43 14.4 OK 161.58 300 OK 0.8 0.65

3 0.65

SLS (QP Comb.) 145.00 1000.00 1154.00 8936.08577 16.03 449.34 1E+11 6.43 10.8 OK 161.58 300 OK

Section at 2.0m height from face of columne

SLS (R Comb.) 49.80 1000.00 920.60 4468.042885 16.03 298.5336 4E+10 4.06 14.4 OK 135.74 300 OK

SLS (QP Comb.) 49.80 1000.00 920.60 4468.042885 16.03 298.53 4E+10 4.06 10.8 OK 135.74 300 OK

C) SLS CRACK WIDTH CHECK (QUASI PERMANENT LOAD COMBINATION)

1) CHECK Ast,min for crack control

b h d Act =bh/2 σs = fyk As,provide

Load mm mm mm mm2 Mpa As,min =kc k fct,eff Act / σs d

comb. mm mm mm mm2 Mpa k kc mm2 mm2 check

Section at deff from face of columne

SLS QP 1000 1245.0 1154.0 622500 500.00 0.65 0.4 809.4498867 8936.09 OK

Section at 2.0m height from face of columne

SLS QP 1000 1011.6 920.6 505800 500.00 0.65 0.4 657.702414 4468.04 OK

2) CHECK FOR MAXIMUM SPACING b/w bars.

Spacing b/w bars

Load comb. Bar dia cover Provided Calculated

φeq c mm mm check

Section at deff from face of column

SLS QP 32 75 180.00 455.00 OK

Section at 2.0m height from face of column

SLS QP 32 75 180.00 455.00 OK

3) CHECK FOR CRACK WIDTH

ε sm - ε cm =Max [ [ σsc -

smax =3.4c

hc,eff =Min [ 2.5 ( h ρpeff = kt fct,eff ( 1+ αe ρP,eff )

+ 0.17 φ

- d ) , ( h - x/3 ) , Aceff = As/Ac,eff αe = / ρP,eff ] /Es ,

/ρPeff

x =neutral

Load comb. h/2] hc,eff *b Asprovided σsc axis depth kt Es/Ecm' 0.6σsc/Es ] wk check

2 2

mm mm mm mm Mpa mm

Section at deff from face of columne

SLS QP 227.5 227500 8936.09 0.039 393.4946 161.58 449.34 0.5 16.03 0.00055 0.216 OK

Section at 3.3 m heightfrom face of columne

SLS QP 227.5 227500 4468.04 0.020 531.9893 135.74 298.53 0.5 16.03 0.00041 0.217 OK

D) CHECK FOR SHEAR : ( IRC 112 / clause 10.3.2 (2) )

Check of Shear Reinforcement Requirement

VRdc =Max [ ( 0.12

k (80 ρ1 fck )0.33 +

ρ1 = Min [ Asl/bw

3/2

0.15 σcp ) bw d ,

(νmin +0.15σcp )

νmin = 0.031 k

k= Min [ 1 +

√200/d , 2 ]

Check

d , 0.02 ]

bw d ]

fck1/2

Load comb. VED β βVED d bw Asl σcp

2

T T mm mm mm Mpa Tonne

At face of column

ULS 39.60 1 39.60 1154.00 1000 1.42 8936.09 0.0077 0.286 0 51.448 No Shear reinf. Required

At 2.0m height from face of column

ULS 19.50 1 19.50 920.60 1000 1.47 4468.04 0.0049 0.301 0 36.415 No Shear reinf. Required

2 2

Provide Distribution Reinforcement @ 994.928 mm per metre i.e. 12 Tor @ 100 mm C-C, thus Providing 1131 mm , Hence OK

Check for Maximum Shear Capacity :

∆Fd = 0.5 VED

2*VNS / (αcw *

θ = 0.5 sin [

bw * z * v1 *

-1

z * ν1 * fcd

αcw * bw *

Vrdmax =

θ adopted

Load comb. VED bw d z =0.9d αcw ν1 Check

/2

fcd) ]

cotθ

T mm mm mm Tonne deg deg T

At face of column

ULS 39.60 1000 1154 1038.6 1 0.6 417.52 OK 2.72 45 19.80

At 2.0m height from face of column

ULS 19.50 1000 920.6 828.54 1 0.6 333.07 OK 1.68 45 9.75

∆Fd = Additional Tensile force, to be accounted in longitudinal reinforcement

DESIGN OF BASE SLAB:

Summery of Bending Moments at Base Slab

Force due to Factored Bending Moment at

BOTTOM SLAB (Tm/m) Factored BM at mid portion of Factored BM at mid point of

Tapered portion (Tm/m) Base Slab (Tm/m)

DL+EP+LLS+EARTH FILL ULS SLS QP ULS SLS QP ULS SLS QP

253.5 169.0 169.0 0.0 0.0 0.0 80.1 59.3 59.3

At the face of Side Wall Bottom:

ULS Design Bending moment = 253.500 Tm

SLS Rare Design Bending moment = 169.000 Tm

SLS QP Design Bending moment = 169.000 Tm

At the mid point of Base Slab

ULS Design Bending moment = 80.055 Tm

SLS Rare Design Bending moment = 59.300 Tm

SLS QP Design Bending moment = 59.300 Tm

Summary of Shear force

DL+EP+LLS+EARTH FILL Factored force at

Factored force at Factored force at mid

mid point of ULS Load Factor

BOTTOM point of Base Slab

Tapered portion

19.100 tm/m 0.000 tm/m 1.600 tm/m 1.00

2

Design Shear Force at Support of Slab VED = 19.100 T-m/m

2

Design SF at tepered portion VED = 0.000 T-m/m

2

Design SF at mid of Base Slab VED = 1.600 T-m/m

A) ULS CAPACITY CHECK

Check Check Check

MRd =0.87 fyk

xu = 0.87 fyk

Ast (d-0.416

Ast / 0.362

0.87 fyk (d'-

Ast,cal =M/

Ast,provided > Ast

MED/z +∆FD

0.416 xu)

Area of steel provided

Ast Calc.<Ast

z = d- MED/z

MRD/z >

Overall

fck b

Ast, Provided

xu)

MED xmax Ast min ∆Fd 0.416 xu +∆FD MRD/z

Provided

b depth D d Dia Spacing Check

min

Load comb. Tm mm mm mm mm mm mm2 mm mm mm2 mm2 T m T Tm Tm/m

Design of Section at bottom

ULS BM 253.50 1000 1200.0 1109.0 32 180 8936.09 514.11 357.94 UR, OK 6069.782 OK 1657.5 OK 9.55 960.10 273.59 373.2 388.72 OK

32 180

Design of Section at Mid pont of Base Slab

ULS BM 80.06 1000 1200.0 1115.0 20 100 3141.59 516.89 125.84 UR, OK 1731.842 OK 1666.5 OK 0.00 1062.65 75.34 145.2 136.659 OK

B) SLS STRESS CHECK

Rare Load combination. Formula used for calculation of stress

Ec,eq = Ecm*(MQP+MST) dc (depth of neutral axis) = -m*As + √ ( m2 * As2 + 2* m*As*b* d )

MST +(1+φ)* MQP b

MST = MRARE -MQP INA (Transformed) = b *dc3/3 + m* As *(d-dc)2

m = Es/ Ec,eq

Compressive stress in concrete σc = MRARE* dc / INA

Quasi Permanent Load Combination Tensile stress in steel σs = m* MRARE* (d - dc ) / INA

m = Es / Ecm'

Stress Check for SLS Load Combinations

M

modular N.A. Comp Tensile Max T

Check Check

Load comb. b d Ast, Provided ratio depth (dc) INA stress Max C. Stress stress Stress h k

(tm/m) mm mm mm2 mm mm4 Mpa Mpa Mpa Mpa 0 1

Section at face of side wall bottom 0.3 1

SLS (R Comb.) 169.00 1000.00 1109.00 8936.08577 16.03 438.3628 9E+10 8.01 14.4 OK 196.41 300 OK 0.8 0.65

3 0.65

SLS (QP

(Q

Section Comb.)

mid 169.00

p ) off tapered

(RatComb.)

point 1000.00

p 0.00pportion000.00 1109.00

5.00 38936.08577 16.03 #D

4 .59 654 ##### 438.36

V/0! 9E+10

#D 8.01

V/0! ##### 10.8

4.4 OK

##### 196.41

#D V/0! 300 #DOK

V/0!

Section at mid point of Base Slab

SLS (R Comb.) 59.30 1000.00 1115.00 8936.08577 16.03 439.8388 9E+10 2.78 14.4 OK 68.53 300 OK

SLS (QP Comb.) 59.30 1000.00 1115.00 8936.08577 16.03 439.84 9E+10 2.78 10.8 OK 68.53 300 OK

C) SLS CRACK WIDTH CHECK (QUASI PERMANENT LOAD COMBINATION)

1) CHECK Ast,min for crack control

b h d Act =bh/2 σs = fyk As,provide

Load mm mm mm mm2 Mpa As,min =kc k fct,eff Act / σs d

comb. mm mm mm mm2 Mpa k kc mm2 mm2 check

Section at face of side wall bottom

SLS QP 1000 1200.0 1109.0 600000 500.00 0.65 0.4 780.1926619 8936.09 OK

Section at mid point of Base Slab

SLS QP 1000 1200.0 1115.0 600000 500.00 0.65 0.4 780.1926619 3141.59 OK

2) CHECK FOR MAXIMUM SPACING b/w bars.

Spacing b/w bars

Load comb. Bar dia cover Provided Calculated

φeq c mm mm check

Section at face of side wall bottom

SLS QP 32 75 180.00 455.00 OK

Section at mid point of Base Slab

SLS QP 32 75 100.00 455.00 OK

3) CHECK FOR CRACK WIDTH

ε sm - ε cm =Max [ [ σsc -

smax =3.4c

hc,eff =Min [ 2.5 ( h ρpeff = kt fct,eff ( 1+ αe ρP,eff )

+ 0.17 φ

- d ) , ( h - x/3 ) , Aceff = As/Ac,eff αe = / ρP,eff ] /Es ,

/ρPeff

x =neutral

Load comb. h/2] hc,eff *b Asprovided σsc axis depth kt Es/Ecm' 0.6σsc/Es ] wk check

mm mm2 mm2 mm Mpa mm

Section at face of side wall bottom

SLS QP 227.5 227500 8936.09 0.039 393.4946 196.41 438.36 0.5 16.03 0.00072 0.284 OK

Section at mid point of Base Slab

SLS QP 212.5 212500 3141.59 0.015 622.9662 68.53 439.84 0.5 16.03 0.00021 0.128 OK

D) CHECK FOR SHEAR : ( IRC 112 / clause 10.3.2 (2) )

Check of Shear Reinforcement Requirement

VRdc =Max [ ( 0.12

k (80 ρ1 fck )0.33 +

ρ1 = Min [ Asl/bw

3/2

0.15 σcp ) bw d ,

(νmin +0.15σcp )

νmin = 0.031 k

k= Min [ 1 +

√200/d , 2 ]

Check

d , 0.02 ]

bw d ]

fck1/2

Load comb. VED β βVED d bw Asl σcp

T T mm mm mm2 Mpa Tonne

Section at face of side wall bottom

ULS 19.10 1 19.10 1109.00 1000 1.42 8936.09 0.0081 0.289 0 50.390 No Shear reinf. Required

Section at mid point of tapered portion

ULS 0.00 1 0.00 1115.00 1000 1.42 3141.59 0.0028 0.288 0 35.789 No Shear reinf. Required

Section at mid point of Base Slab

ULS 1.60 1 1.60 1115.00 1000 1.42 3141.59 0.0028 0.288 0 35.789 No Shear reinf. Required

2 2

Provide Distribution Reinforcement @ 1213.956 mm per metre i.e. 16 Tor @ 150 mm C-C, thus Providing 1340 mm , Hence OK

Check for Maximum Shear Capacity :

∆Fd = 0.5 VED

2*VNS / (αcw *

θ = 0.5 sin [

bw * z * v1 *

-1

z * ν1 * fcd

αcw * bw *

Vrdmax =

θ adopted

Load comb. VED bw d z =0.9d αcw ν1 Check

/2

fcd) ]

cotθ

T mm mm mm Tonne deg deg T

Section at face of side wall bottom

ULS 19.10 1000 1109 998.1 1 0.6 401.24 OK 1.36 45 9.55

Section at mid point of Base Slab

ULS 1.60 1000 1115.0 1003.5 1 0.6 403.41 OK 0.11 45 0.80

∆Fd = Additional Tensile force, to be accounted in longitudinal reinforcement

Check For Base Pressure:

Safe Bearing Capacity = 15.00 T/m2

Dead Load:

Dessity of Concrete = 2.50 T/m3

Dessity of WATER = 1.00 T/m3

Cross-sectional area of U-Through = 34.03 m2

Length of U-Through = 1.00 m

Weight of U-Through = 85.09 T

Weight of Earth Fill = 89.49 T

Live Load:

40T Boggie reaction = 0.00 T

Total Weight = 174.58 T

Area of Base of U-Through = 12.50 m2

Required Base Pressure = 13.97 T/m2 OK

You might also like

- Wind Load-Gable Clad BuildingsDocument10 pagesWind Load-Gable Clad BuildingsAnkurAgarwal100% (1)

- Solution Manual for an Introduction to Equilibrium ThermodynamicsFrom EverandSolution Manual for an Introduction to Equilibrium ThermodynamicsNo ratings yet

- Annular Raft Under 1250 Cum OHRDocument1 pageAnnular Raft Under 1250 Cum OHRanirban dasNo ratings yet

- Watercolour Painting - Jean-Louis MorelleDocument128 pagesWatercolour Painting - Jean-Louis MorelleAline Fa100% (16)

- Wind LoadDocument3 pagesWind Loadvikash kumarNo ratings yet

- BS 6724 1997Document42 pagesBS 6724 1997Simon Law100% (1)

- Footing No. Fy FCK Cover Dia of Bar SBC of Soil Taken in The Design: Calculation of FoundationDocument4 pagesFooting No. Fy FCK Cover Dia of Bar SBC of Soil Taken in The Design: Calculation of FoundationIrfan ShaikhNo ratings yet

- L00004 & L00005-R001 PDFDocument1 pageL00004 & L00005-R001 PDFnagarajhebbarNo ratings yet

- Steel Pipe: C S U A Max S MaxDocument4 pagesSteel Pipe: C S U A Max S Maxankkeshmundra1No ratings yet

- Paper 1 Calvin and Hobbes Essay - Sarah Al ObaidanDocument3 pagesPaper 1 Calvin and Hobbes Essay - Sarah Al ObaidanSarah Al ObaidanNo ratings yet

- Fundamental Metallurgy of Niobium in SteelDocument74 pagesFundamental Metallurgy of Niobium in SteelCarlos Viana100% (1)

- Student Assessment: Sitxccs008 Develop & Manage Quality Customer Service PracticesDocument51 pagesStudent Assessment: Sitxccs008 Develop & Manage Quality Customer Service PracticesJB Nery Dela Cruz80% (5)

- Reading and Writing Skills PRETESTDocument4 pagesReading and Writing Skills PRETESTREZITTE MABLES100% (1)

- Fore Kazık HesabıDocument62 pagesFore Kazık HesabıEkrem BakırNo ratings yet

- Elastomercic Bearing DN (14+872 MNB)Document19 pagesElastomercic Bearing DN (14+872 MNB)Ankur ChauhanNo ratings yet

- Exame 2020Document8 pagesExame 2020Tiago MotaNo ratings yet

- Wind Caribbean - Winds - NHC (Edit)Document28 pagesWind Caribbean - Winds - NHC (Edit)chrisNo ratings yet

- ImpactDocument1 pageImpactNikodem GorskiNo ratings yet

- Ce226 Q6 Corpuz J 3cegDocument12 pagesCe226 Q6 Corpuz J 3cegJermaine CorpuzNo ratings yet

- DN - PCC Toe Wall - 01 - R1Document9 pagesDN - PCC Toe Wall - 01 - R1ShivamKumarNo ratings yet

- Stor: SuperficieDocument2 pagesStor: SuperficieAlejandro Álvarez CastroNo ratings yet

- Calculation Sheet-Footing of SCM-160Document16 pagesCalculation Sheet-Footing of SCM-160กิตติชัย โยธาภักดีNo ratings yet

- Untitled NotebookDocument3 pagesUntitled Notebookalyaqeenalkalbani16No ratings yet

- Applied Calculus Quiz 2 SolutionsDocument2 pagesApplied Calculus Quiz 2 SolutionsAndrew EwersNo ratings yet

- Pembahasan Tutorial Fisika Dasar IIA - Kuis 3Document5 pagesPembahasan Tutorial Fisika Dasar IIA - Kuis 3Salma AzzahraNo ratings yet

- Electricity and Magnetism 8Document1 pageElectricity and Magnetism 8Julia KarakiNo ratings yet

- Short Circuit Calculation (MDP) A. I : Riser Diagram (Green Tower Zone A) Schedule of LoadsDocument1 pageShort Circuit Calculation (MDP) A. I : Riser Diagram (Green Tower Zone A) Schedule of Loadsadrian karl bonaNo ratings yet

- Modulo IIIDocument8 pagesModulo IIIjose antonio manchaNo ratings yet

- SSE Sheet Pile Analysis Sheet v1.09Document3 pagesSSE Sheet Pile Analysis Sheet v1.09SES DESIGNNo ratings yet

- The If: FingersDocument12 pagesThe If: FingersRiddhi SheteNo ratings yet

- F-Riviera: AlishaDocument5 pagesF-Riviera: AlishaFalisha RivienaNo ratings yet

- Semiconductor KDS226: Technical DataDocument2 pagesSemiconductor KDS226: Technical DataMuhajir BusraNo ratings yet

- Pile Capacity Comp./UpliftDocument2 pagesPile Capacity Comp./UpliftPankaj Sherwal100% (1)

- Meyerhof PDFDocument1 pageMeyerhof PDFAhmet DemirNo ratings yet

- Axial and Lateral Load Piles (Fem)Document61 pagesAxial and Lateral Load Piles (Fem)Wahyudi EffendiNo ratings yet

- Wind CalculationsDocument4 pagesWind CalculationsTrinh Hong VINo ratings yet

- Kn2222as SDocument3 pagesKn2222as SHero A. AcevedoNo ratings yet

- Semiconductor 2N3906S: Technical DataDocument4 pagesSemiconductor 2N3906S: Technical DatabedusmadeNo ratings yet

- Feeder Pillar 9 - Agro PalmDocument5 pagesFeeder Pillar 9 - Agro PalmapihmarcNo ratings yet

- Forum 12 - Herdi Nur Fauzi41418310089Document1 pageForum 12 - Herdi Nur Fauzi41418310089herdinurNo ratings yet

- Semiconductor KTC3200: Technical DataDocument2 pagesSemiconductor KTC3200: Technical DataBuitinės Technikos RemontasNo ratings yet

- Semiconductor KTA1266: Technical DataDocument2 pagesSemiconductor KTA1266: Technical DataAlex Hernandez VasquezNo ratings yet

- Semiconductor KTA1266: Technical DataDocument2 pagesSemiconductor KTA1266: Technical Dataserrano.flia.coNo ratings yet

- Semiconductor KTA1266: Technical DataDocument3 pagesSemiconductor KTA1266: Technical DataBarron Bin ShorehNo ratings yet

- Elevator DSA OSHPDDocument2 pagesElevator DSA OSHPDjorge01No ratings yet

- Semiconductor 2N7000: Technical DataDocument4 pagesSemiconductor 2N7000: Technical DataFrancisco RodriguesNo ratings yet

- KTN2222 KecDocument5 pagesKTN2222 KecПетро ДуманськийNo ratings yet

- KTN2222ASDocument5 pagesKTN2222ASclivaldoNo ratings yet

- F1 Construction of Community Hall at Konaraopet.: Design of Footing: ProjectDocument2 pagesF1 Construction of Community Hall at Konaraopet.: Design of Footing: ProjectBIGG BOSSNo ratings yet

- Proposed Recharging Well RBF - DrawingDocument7 pagesProposed Recharging Well RBF - Drawingdwiyatno1302No ratings yet

- Física RepasosDocument3 pagesFísica RepasosGabriela TorresNo ratings yet

- Semiconductor KRC110 KRC114: Technical DataDocument4 pagesSemiconductor KRC110 KRC114: Technical DataDabro FabioNo ratings yet

- KTN2222 A PDFDocument6 pagesKTN2222 A PDFKatherine EsperillaNo ratings yet

- 6 Verification On Loading: References CalculationsDocument1 page6 Verification On Loading: References CalculationsAzahar Bin HashimNo ratings yet

- One-Way Slab DesignDocument4 pagesOne-Way Slab DesignChristoper Dela CruzNo ratings yet

- Semiconductor KTA1241: Technical DataDocument2 pagesSemiconductor KTA1241: Technical DataDeilyn RivasNo ratings yet

- Diseño Muro Nº1Document22 pagesDiseño Muro Nº1FREDY HUMBERTO TACCA MAMANINo ratings yet

- Lambda - Introduction To ANSYS Electromagnetic SolutionsDocument102 pagesLambda - Introduction To ANSYS Electromagnetic SolutionsLAMBDA INDIANo ratings yet

- Solution: WL WL WLDocument6 pagesSolution: WL WL WLJohn Resty RamosNo ratings yet

- Truss Calculation ReportDocument2 pagesTruss Calculation Reportjonathan chandaNo ratings yet

- Sta 1+600Document24 pagesSta 1+600rismanNo ratings yet

- KN2222 A PDFDocument4 pagesKN2222 A PDFRONIBAEL CORDOVANo ratings yet

- NBC 105-2020 Base Shear CalculationDocument3 pagesNBC 105-2020 Base Shear CalculationPrakash Singh RawalNo ratings yet

- Appendix A: Pipe and Duct SystemsDocument25 pagesAppendix A: Pipe and Duct SystemsUM'mer FarooqNo ratings yet

- 1.825 X 2.05 M Spread Footing (CKE 10+010, 6+820)Document11 pages1.825 X 2.05 M Spread Footing (CKE 10+010, 6+820)UmesgNo ratings yet

- Datasheet PDFDocument3 pagesDatasheet PDFJoan CruzNo ratings yet

- Compliance To Comments Recieved On The Drawings On 05th Februrary, 2020Document2 pagesCompliance To Comments Recieved On The Drawings On 05th Februrary, 2020Ankur ChauhanNo ratings yet

- 04-Layout MCW 80 To EndDocument1 page04-Layout MCW 80 To EndAnkur ChauhanNo ratings yet

- Compliance To Comments Recieved On The Drawings On 05th Februrary, 2020 SvupDocument2 pagesCompliance To Comments Recieved On The Drawings On 05th Februrary, 2020 SvupAnkur ChauhanNo ratings yet

- Safety Observations For Drain P6Document1 pageSafety Observations For Drain P6Ankur ChauhanNo ratings yet

- Quotation Topo Jhosimath-TESDocument3 pagesQuotation Topo Jhosimath-TESAnkur Chauhan50% (2)

- Key Plan (Chittoor To Thatchur)Document1 pageKey Plan (Chittoor To Thatchur)Ankur ChauhanNo ratings yet

- Key Plan (Walajahpet To Arakkonamr)Document1 pageKey Plan (Walajahpet To Arakkonamr)Ankur ChauhanNo ratings yet

- Winstar Display Co., LTD: SpecificationDocument24 pagesWinstar Display Co., LTD: SpecificationElvis SilvaNo ratings yet

- Ajuy MHPP Revision - 26 March 2021Document21 pagesAjuy MHPP Revision - 26 March 2021Jocelyn TordaNo ratings yet

- Reading Material Lecture 04Document12 pagesReading Material Lecture 04Muqeem MahmoodNo ratings yet

- Entry-Level Firefighter Test: Study GuideDocument16 pagesEntry-Level Firefighter Test: Study GuideArun Chand C VNo ratings yet

- English Language: 8700/1 Paper 1 Explorations in Creative Reading and Writing Mark SchemeDocument21 pagesEnglish Language: 8700/1 Paper 1 Explorations in Creative Reading and Writing Mark SchemeT SolomonNo ratings yet

- Rulebook Newton PDFDocument16 pagesRulebook Newton PDFvaggos1988No ratings yet

- Contrastive Linguistics - D2019 (Ms. Yen)Document134 pagesContrastive Linguistics - D2019 (Ms. Yen)Lan Anh ChuNo ratings yet

- Midea Modularni Cilleri MGB-service ManualDocument119 pagesMidea Modularni Cilleri MGB-service ManualGermánCastiglioniNo ratings yet

- Automated Blood Culture SystemDocument2 pagesAutomated Blood Culture SystemAltruist AcharyaNo ratings yet

- English HistoryDocument7 pagesEnglish HistorySam FoxNo ratings yet

- Journal of Drug Delivery and TherapeuticsDocument7 pagesJournal of Drug Delivery and TherapeuticsNisa SasaNo ratings yet

- 3D Bio Printing TechnologyDocument2 pages3D Bio Printing Technologykummetha vanithaNo ratings yet

- Hán Công Đỉnh 20195767Document46 pagesHán Công Đỉnh 20195767Hán Công ĐỉnhNo ratings yet

- Review of Available Experimental Data and Models For The Transport Properties of CO - Mixtures Relevant For CO Capture, Transport and StorageDocument36 pagesReview of Available Experimental Data and Models For The Transport Properties of CO - Mixtures Relevant For CO Capture, Transport and StorageF SedighiNo ratings yet

- MBEH'S - Final - Work (1) 27Document72 pagesMBEH'S - Final - Work (1) 27Fon Palverd Brent BridenNo ratings yet

- Journal of King Saud University - Science: Naziya N. Mohammad Aziz Rehman, Prashant P. DixitDocument8 pagesJournal of King Saud University - Science: Naziya N. Mohammad Aziz Rehman, Prashant P. DixitMrmc CovidNo ratings yet

- Science Quarter 1 Week 8: Learner's Activity and Assessment SheetsDocument6 pagesScience Quarter 1 Week 8: Learner's Activity and Assessment SheetsLo RaineNo ratings yet

- EIU Dropbox WFH Executive SummaryDocument19 pagesEIU Dropbox WFH Executive SummaryЮрий БагничNo ratings yet

- Formula B2 - Unit 7a PhotocopiableDocument1 pageFormula B2 - Unit 7a PhotocopiablePolina GeorgievaNo ratings yet

- Required: If Green Machine Company Used The FIFO and The Weighted Average Methods ofDocument6 pagesRequired: If Green Machine Company Used The FIFO and The Weighted Average Methods ofrook semayNo ratings yet

- Cambridge IGCSE™: Biology 0610/62Document10 pagesCambridge IGCSE™: Biology 0610/62manar mohamedNo ratings yet

- Making A Mirror Grinding Tool by Allen MalsburryDocument14 pagesMaking A Mirror Grinding Tool by Allen MalsburrymohamadazareshNo ratings yet

- SOAL + JAWAB BHS Inggris HAL 1-15Document15 pagesSOAL + JAWAB BHS Inggris HAL 1-15Nor JanahNo ratings yet

- Sample Lesson Plan Format (7es)Document5 pagesSample Lesson Plan Format (7es)Kenyl Vincent BundaNo ratings yet