Professional Documents

Culture Documents

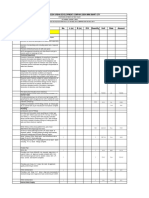

RFQ - GI & SS Pipe

Uploaded by

rkpatel400 ratings0% found this document useful (0 votes)

5 views3 pages43423223

Original Title

RFQ- GI & SS Pipe

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document43423223

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

5 views3 pagesRFQ - GI & SS Pipe

Uploaded by

rkpatel4043423223

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 3

2.

0 SOIL, WASTE & VENT PIPES & FITTINGS

2.6 Providing and fixing testing, & commissioning G.I. Pipes

complete (I:S 1239 Medium class) with G.I. Fittings e.g.elbows,

tees , reducers, unions , plugs etc. and clamps/supports and

jointing with holdtite or teflon tape including chase cutting and

making good the walls etc. wherever required for waste

connection from W.B., A.S.P, floor drain etc. including cutting

holes in RCC/ Masonry walls and floors wherever required and

making good the same. (The cost of cutting holes of all sizes in

RCC walls, slabs & beams wherever required including making

good the same with sealents as required by the engineer-in-

charge shall be included in the rate). (For Kitchen Area)

a) 32 mm nominal bore. Metre 65

b) 50 mm nominal bore. Metre 95

2.8 Painting two or more coats of Synthetic enamel paint of

approved shade and make over one coat of primer on GI/MS ,

spun cast iron/DI,soil, waste and vent pipes and fittings including

surface preparation etc. (Shade as per IS colour code) (For

Kitchen Area)

a) 100 mm dia Metre 40

2.9 Providing and painting for G.I. Pipes with two coats of

bitumastic paint, wraping with one layer of polythelene tape of

200 micron thick and applying a final coat of bitumastic paint

complete including surface preparations. (For Kitchen Area)

a) 32 mm nominal bore. Metre 65

b) 50 mm nominal bore. Metre 95

2.11 Providing and fixing 100mm dia GI Inlet Fitting approximately

450 mm long with one or more 32/40/50mm dia GI Sockets

welded and dipped in hot bitumen complete. (For Kitchen Area)

Each 91

3.0 WATER SUPPLY SYSTEM

3.2 Providing and fixing Stainless Steel Pipes of SS-304 Grade

shcedule 40 pipes complete with SS fittings i.e., tees, elbows,

bends, juctions, reducers & jointing with crimping tool as per

manufacture recommendation. (For RO water supply)

a) 15.88 mm outer dia pipe Metre 5

b) 22.22 mm outer dia pipe Metre 30

c) 28.58 mm outer dia pipe Metre 80

d) 34.00 mm outer dia pipe Metre 125

e) 42.70 mm outer dia pipe Metre 35

f) 48.60 mm outer dia pipe Metre 140

3.4 Providing, fixing and testing G.I. Pipes with zinc coating of 50

to 65 DFT (medium class) of an approved make conforming to

IS:1239 complete with malleable cast iron fittings as per IS:1879

such as tees, crosses, plugs, sockets, elbows, reducers, unions,

sleeve pieces, check nuts etc. clamps/structural steel supports

as required/directed at site including cutting and making good

the walls, floors, RCC work etc. cutting chases and filling the

same with cement concrete 1:3:6 (1 cement : 3 coarse sand : 6

graded stone aggregate 20mm nominal size) or cement mortar

1:4 (1 cement : 4 coarse sand) as required as per specifications.

(The cost of cutting holes of all sizes in RCC walls, slabs &

beams wherever required including making good the same with

sealents as required by the engineer-in-charge shall be included

in the rate). Rates shall also include cost of painting of pipes with

two coats of enamel paints over a coat of red oxide primer.

a) 65 mm nominal bore. Metre 80

b) 80 mm nominal bore. Metre 40

3.16 Providing & fixing G.I. Vent Pipe complete with 2 Nos. bends

complete with mosquito proof SS wire mesh & painting with black

bitumastic paint all complete as per drawing.

a) 100 mm dia Each 12

10.0 SUCTION AND DELIVERY PIPES AND VALVES FOR WATER

SUPPLY PUMPS

10.1 Providing, fixing, testing and commissioning G.I. suction &

delivery headers / pipes for water supply pumps (IS:1239 heavy

class) jointed with G.I. heavy class welded flanged fittings

(bends, tees, reducers, plugs, flange & blank flanges etc) and

clamps all complete. Note: All pipes & fittings in pump room will

be weldeded flanged types.

a) 50 mm nominal bore Meter 15

b) 65 mm nominal bore Meter 10

c) 80 mm nominal bore Meter 65

d) 100 mm nominal bore Meter 20

e) 150 mm nominal bore Meter 20

f) 200 mm nominal bore Meter 10

10.2 Painting for G.I. Pipes with two or more coats of synthetic

enamel paint of approved quality and shade over a coat of

approved primer coat as directed including surface preparation

(Shade as per pipe colour code).

a) 50 mm nominal bore Meter 15

b) 65 mm nominal bore Meter 10

c) 80 mm nominal bore Meter 65

d) 100 mm nominal bore Meter 20

e) 150 mm nominal bore Meter 20

f) 200 mm nominal bore Meter 10

You might also like

- Good To Great by Jim CollinsDocument6 pagesGood To Great by Jim Collinsbubasyla33% (6)

- Service Bulletin: Fuel Injection PumpDocument15 pagesService Bulletin: Fuel Injection PumpKrunoslavNo ratings yet

- BOQ PlumbingDocument7 pagesBOQ PlumbingKing GoldNo ratings yet

- CMT1Document10 pagesCMT1Dongneu Nguyen100% (1)

- Lufthansa Technical Training Troubleshooting Fundamentals CourseDocument160 pagesLufthansa Technical Training Troubleshooting Fundamentals CourseBELISARIONo ratings yet

- Plumbing and Fire Fighting Sample BoqDocument30 pagesPlumbing and Fire Fighting Sample BoqNajeeb Ahmad Khan100% (2)

- BOQ Fire DetailDocument5 pagesBOQ Fire DetailSantanu MitraNo ratings yet

- BOQ Lotus Hotel Final 080709Document26 pagesBOQ Lotus Hotel Final 080709Jane NixonNo ratings yet

- Plumbing and Fire Fighting Sample BoqDocument30 pagesPlumbing and Fire Fighting Sample BoqNajeeb Ahmad KhanNo ratings yet

- Sugar Mommy PDF 3Document1 pageSugar Mommy PDF 3mudashiradebamiji100% (2)

- PLUMBING and FIRE FIGHTING SAMPLE BOQDocument28 pagesPLUMBING and FIRE FIGHTING SAMPLE BOQPrabhat Saxena95% (21)

- Valves Member ListDocument168 pagesValves Member Listrkpatel40No ratings yet

- Animal Feed EFFORTDocument16 pagesAnimal Feed EFFORTHaftamu Tekle100% (1)

- SIMATIC S7 + TIA Function BlocksDocument109 pagesSIMATIC S7 + TIA Function BlocksVladimirAgeevNo ratings yet

- Cadangan Membina Pondok Pengawal KeselamatanDocument9 pagesCadangan Membina Pondok Pengawal KeselamatanMohd SyahrulizamNo ratings yet

- Basic Calculus Q4 Week 2 Module 10 CathDocument12 pagesBasic Calculus Q4 Week 2 Module 10 CathLee Marck SeriosNo ratings yet

- FIRE FIGHTING WORKS (Hydrant System With Wet Riser) N.no: Description of Works QuantityDocument11 pagesFIRE FIGHTING WORKS (Hydrant System With Wet Riser) N.no: Description of Works QuantityHunkNo ratings yet

- PVC PipeDocument10 pagesPVC Piperkpatel40No ratings yet

- Rates of WATER SUPPLY AND SANITARY FITTINGSDocument14 pagesRates of WATER SUPPLY AND SANITARY FITTINGSKunal Ranjane100% (1)

- Dokumen - Tips - Boq For Fire Fighting Installation Works of Boqpdfof Electrical HydrantDocument24 pagesDokumen - Tips - Boq For Fire Fighting Installation Works of Boqpdfof Electrical HydrantJona Mae LapitanNo ratings yet

- BDVDocument14 pagesBDVabhijithavalNo ratings yet

- Boq Fire FightingDocument23 pagesBoq Fire FightingKEYSTONE INFRA PVT LTDNo ratings yet

- Bill of Quantities For Mall Total Plumbing Works Unit Qty SECTION - 1.00 A) Sanitary Fixtures and Fittings 24Document20 pagesBill of Quantities For Mall Total Plumbing Works Unit Qty SECTION - 1.00 A) Sanitary Fixtures and Fittings 24Santosh ShahNo ratings yet

- Item No. Particulars of Item Unit Quantity Rate in Fig. Rate in Words Amount (Nu) Earth WorkDocument5 pagesItem No. Particulars of Item Unit Quantity Rate in Fig. Rate in Words Amount (Nu) Earth WorkGautham GautiNo ratings yet

- Water Supply & Sanitry DOMBOQDocument31 pagesWater Supply & Sanitry DOMBOQajay_430No ratings yet

- CA64 B3 D0 D 01Document48 pagesCA64 B3 D0 D 01kishor.kokateNo ratings yet

- BOQ Fire Detail NetDocument10 pagesBOQ Fire Detail NetrajuNo ratings yet

- Internal PHE Works - BOQDocument2 pagesInternal PHE Works - BOQSenthilKumar RameshNo ratings yet

- Papa Document 8Document10 pagesPapa Document 8krishansoni1965No ratings yet

- Toilet Plumbing SpecDocument6 pagesToilet Plumbing SpecdhanabalNo ratings yet

- Renovation Hospital Fire ProtectionDocument7 pagesRenovation Hospital Fire ProtectionDaudMuhammadNo ratings yet

- Estimate of SBTWDocument17 pagesEstimate of SBTWSaral MajumderNo ratings yet

- Bill of QuantityDocument4 pagesBill of Quantityeng-ashraf abdullahNo ratings yet

- S.No. Description of Item No. L (M) B (M) D/H Quantity Unit Rate AmountDocument3 pagesS.No. Description of Item No. L (M) B (M) D/H Quantity Unit Rate Amountshivshankar kushwahaNo ratings yet

- Hidco Affordable Housing FIRE BOQ - (Internal & External) 04.05.2021Document23 pagesHidco Affordable Housing FIRE BOQ - (Internal & External) 04.05.2021UTTAL RAYNo ratings yet

- Work With PowerDocument6 pagesWork With PowersiamcivilengrNo ratings yet

- RANGS R.K SQUARE - BOQ - Plumbing - 140719Document18 pagesRANGS R.K SQUARE - BOQ - Plumbing - 140719Md. Mominul IslamNo ratings yet

- Dia DiaDocument1 pageDia DiasynpavanNo ratings yet

- K.S.Krishna B.W.S.S.B.Regd, Contractor: Project: Water Supply and Sanitary Works at ResidenceDocument11 pagesK.S.Krishna B.W.S.S.B.Regd, Contractor: Project: Water Supply and Sanitary Works at Residenceanon-682604No ratings yet

- S.N. Description Qty. Rate/Unit Amount. For One No. Tube Well Part A' DrillingDocument2 pagesS.N. Description Qty. Rate/Unit Amount. For One No. Tube Well Part A' Drillingmahesh579No ratings yet

- PipeworkDocument5 pagesPipeworkTAPIZ ACMVNo ratings yet

- Dharmagiri - 2 BOQDocument20 pagesDharmagiri - 2 BOQNani JupallyNo ratings yet

- BoqDocument3 pagesBoqaerorockNo ratings yet

- Sanitary Works ScheduleDocument4 pagesSanitary Works ScheduleManjunath HrmNo ratings yet

- Sample Boq For Percentage Rate Quotation Biil of Quantity (Boq)Document9 pagesSample Boq For Percentage Rate Quotation Biil of Quantity (Boq)srkali8227No ratings yet

- Chapter 30-Water Supply: NotesDocument8 pagesChapter 30-Water Supply: NotesahahNo ratings yet

- Phe Works BoqDocument10 pagesPhe Works Boqkatyayan.constructionNo ratings yet

- FIRE HYDRANT SYSTEMDocument4 pagesFIRE HYDRANT SYSTEMJoshua Gnanaraj100% (1)

- Estimate For Federation of Bus Operators Association of Tamil NaduDocument70 pagesEstimate For Federation of Bus Operators Association of Tamil Naduminit_spaasNo ratings yet

- BUET DEEP TUBE WELL INSTALLATIONDocument27 pagesBUET DEEP TUBE WELL INSTALLATIONMahfuzur RahmanNo ratings yet

- KitchenDocument39 pagesKitchenSajeshKumarNo ratings yet

- CivilDocument7 pagesCivilEnd EndNo ratings yet

- Goa LHDocument6 pagesGoa LHtnd tbecNo ratings yet

- Section 05 73 00Document5 pagesSection 05 73 00camilleNo ratings yet

- Boq 143154Document32 pagesBoq 143154Amit Kumar shuklaNo ratings yet

- BOQ Toiltes BlockDocument6 pagesBOQ Toiltes BlockIrshad KhanNo ratings yet

- Cable Tray PTC - SpecificationsDocument1 pageCable Tray PTC - SpecificationsRobert MythbustNo ratings yet

- 457Document117 pages457Rajesh ChowhanNo ratings yet

- BOQ For Repair Work of 40'X20' Building at A/Selesthimaduwa VidyalayaDocument9 pagesBOQ For Repair Work of 40'X20' Building at A/Selesthimaduwa VidyalayaAnuranga SahampathNo ratings yet

- Borewell WorkDocument2 pagesBorewell WorkAMIT KUMARNo ratings yet

- MG Road - PHE BOQ-ESTIMATES For QuoteDocument8 pagesMG Road - PHE BOQ-ESTIMATES For QuoteSachin KothvalNo ratings yet

- GR02 Boq 08 2023-24Document10 pagesGR02 Boq 08 2023-24kamilaaNo ratings yet

- Road furniture unit rates and specificationsDocument16 pagesRoad furniture unit rates and specificationsAnirudh Sarkar100% (1)

- P.W.D Electrical SR 10-11Document60 pagesP.W.D Electrical SR 10-11uday.sachin PandithNo ratings yet

- 2a Annexure - II-IMTECH-NEW ITEMS Draft-16.01.2016Document12 pages2a Annexure - II-IMTECH-NEW ITEMS Draft-16.01.2016Amit SinghNo ratings yet

- SCDA Building Electrical Assesment As Per Work Order.Document5 pagesSCDA Building Electrical Assesment As Per Work Order.sourendra prasad karanNo ratings yet

- Effluent Treatment Plants: The PrincipleDocument15 pagesEffluent Treatment Plants: The Principlerkpatel40No ratings yet

- Adad of GJDF ldfdf9-8-2023Document1 pageAdad of GJDF ldfdf9-8-2023rkpatel40No ratings yet

- BLANK FINAL BOQ PHOENIX ELV Wkad 16.12.2021Document21 pagesBLANK FINAL BOQ PHOENIX ELV Wkad 16.12.2021rkpatel40No ratings yet

- Water Recycling PlantDocument59 pagesWater Recycling Plantrkpatel40No ratings yet

- S.N Earthing Catalog 2 5e2c47750177cd0001cb1f59Document4 pagesS.N Earthing Catalog 2 5e2c47750177cd0001cb1f59rkpatel40No ratings yet

- Enquiry - Floor Boxes Switch SocketsDocument4 pagesEnquiry - Floor Boxes Switch Socketsrkpatel40No ratings yet

- ELECTRICDocument113 pagesELECTRICrkpatel40No ratings yet

- 03 - Make List Electrical-ELVDocument3 pages03 - Make List Electrical-ELVrkpatel40No ratings yet

- Enquiry - GeyserDocument2 pagesEnquiry - Geyserrkpatel40No ratings yet

- GeedyDocument4 pagesGeedyrkpatel40No ratings yet

- Enquiry - Sanitary FixtureDocument9 pagesEnquiry - Sanitary Fixturerkpatel40No ratings yet

- Urinal With Top SensorDocument5 pagesUrinal With Top Sensorrkpatel40No ratings yet

- 01.1 - ELV TDS For Fire Alarm Cable (MasterFlexo Make)Document2 pages01.1 - ELV TDS For Fire Alarm Cable (MasterFlexo Make)rkpatel40No ratings yet

- PHOENIX MALL - IBMS TECHNICAL SPECIFICATION - 2020.11.24 FinalDocument63 pagesPHOENIX MALL - IBMS TECHNICAL SPECIFICATION - 2020.11.24 Finalrkpatel40No ratings yet

- ValvesDocument12 pagesValvesrkpatel40No ratings yet

- Intimation of Inclusion of Company in The List of RDSO VendorsDocument3 pagesIntimation of Inclusion of Company in The List of RDSO Vendorsrkpatel40No ratings yet

- 638442031459211118Document5 pages638442031459211118rkpatel40No ratings yet

- Valves - SantDocument5 pagesValves - Santrkpatel40No ratings yet

- Enquiry - CCTV - DelhiDocument1 pageEnquiry - CCTV - Delhirkpatel40No ratings yet

- Vedant Rate BOQ WiseDocument22 pagesVedant Rate BOQ Wiserkpatel40No ratings yet

- Enquiry - DG Set Shardaben HospitalDocument1 pageEnquiry - DG Set Shardaben Hospitalrkpatel40No ratings yet

- Anchor Fastner SupportDocument1 pageAnchor Fastner Supportrkpatel40No ratings yet

- Enquiry - Valve PlumbingDocument15 pagesEnquiry - Valve Plumbingrkpatel40No ratings yet

- Enquiry - Boom Barrier & Baggage Scanner & Metal DetectorDocument1 pageEnquiry - Boom Barrier & Baggage Scanner & Metal Detectorrkpatel40No ratings yet

- Enquiry - ValvesDocument6 pagesEnquiry - Valvesrkpatel40No ratings yet

- Vithalpur Project Pump STPDocument3 pagesVithalpur Project Pump STPrkpatel40No ratings yet

- Electric Fire PumpDocument8 pagesElectric Fire Pumprkpatel40No ratings yet

- Enquiry - Passive Fire Protection SystemDocument6 pagesEnquiry - Passive Fire Protection Systemrkpatel40No ratings yet

- Enquiry - Fire ExtinguisherDocument2 pagesEnquiry - Fire Extinguisherrkpatel40No ratings yet

- ZXUN USPP Load BalancingDocument69 pagesZXUN USPP Load BalancingTawhid AlamNo ratings yet

- KTU S7 Elective: CST433 Security in ComputingDocument8 pagesKTU S7 Elective: CST433 Security in ComputingJishnu ManikkothNo ratings yet

- S&T Achievements from Marcos to PresentDocument9 pagesS&T Achievements from Marcos to PresentNICOLE IRISH CABUNILASNo ratings yet

- Oferta Bodor: Model (E) Pret ( Fara TVA) Garantie Modele CO2Document3 pagesOferta Bodor: Model (E) Pret ( Fara TVA) Garantie Modele CO2Librarie PapetarieNo ratings yet

- Volume II - PEFA Assessment Fieldguide (Second Edition) - Public Expenditure and Financial Accountability (PEFA)Document3 pagesVolume II - PEFA Assessment Fieldguide (Second Edition) - Public Expenditure and Financial Accountability (PEFA)Thomas nyadeNo ratings yet

- 55174A92 QS II Basic Model With ADSU (Diktron) User Manual ENDocument28 pages55174A92 QS II Basic Model With ADSU (Diktron) User Manual ENSorin MilicaNo ratings yet

- CH62 Lighting SystemDocument94 pagesCH62 Lighting SystemYaQodNo ratings yet

- Kalibrr Brochure 2020 PDFDocument12 pagesKalibrr Brochure 2020 PDFSuryadi YadiNo ratings yet

- Gas Turbine Tooling List TTS - Oi - 037Document9 pagesGas Turbine Tooling List TTS - Oi - 037rana usmanNo ratings yet

- Array in C++Document19 pagesArray in C++Shweta ShahNo ratings yet

- Basic Firefighting LectureDocument88 pagesBasic Firefighting LectureBfp Region Vii SanJoseNo ratings yet

- Cryptography - Lucee DocumentationDocument2 pagesCryptography - Lucee Documentationrangel.sardinhaNo ratings yet

- Stat Lesson 1 PDFDocument19 pagesStat Lesson 1 PDFCharles Contridas100% (1)

- 2 CEMEX Synhelion CemNet Webinar VFDocument15 pages2 CEMEX Synhelion CemNet Webinar VFChophel TashiNo ratings yet

- It Sem-Vi PDFDocument50 pagesIt Sem-Vi PDFEr Touhid AlamNo ratings yet

- Lubricated Plug Valves: Price List #3119 - Effective: 3/1/19Document16 pagesLubricated Plug Valves: Price List #3119 - Effective: 3/1/19nurhadiNo ratings yet

- M5A78L-M PLUS-USB3 Devices ReportDocument21 pagesM5A78L-M PLUS-USB3 Devices ReportDante MoretaNo ratings yet

- EagleBurgmann - PDGS Dry Gas Seal Upgrade For Australian LNG ProjectDocument2 pagesEagleBurgmann - PDGS Dry Gas Seal Upgrade For Australian LNG Projectsudhindra_tiwariNo ratings yet

- EFI FLash Tool - HowToDocument15 pagesEFI FLash Tool - HowToJasonNo ratings yet

- MKT V-5esc Installation GuideDocument31 pagesMKT V-5esc Installation GuidePrudzNo ratings yet

- Smart HelmetDocument11 pagesSmart HelmetsarangNo ratings yet

- SSP G7 Release NotesDocument8 pagesSSP G7 Release Notesalmoez JbeliNo ratings yet

- Electrical Codes and StandardsDocument21 pagesElectrical Codes and StandardsVirgilioNo ratings yet