Professional Documents

Culture Documents

Performance Testing of A Diesel Engine From No Load To Full Load (At Constant Speed) For A Si

Uploaded by

Navneet KumarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Testing of A Diesel Engine From No Load To Full Load (At Constant Speed) For A Si

Uploaded by

Navneet KumarCopyright:

Available Formats

BABA FARID COLLEGE OF

ENGINEERING AND TECHNOLOGY

BATHINDA

EXPERIMENT No. 12(b)

AIM: - To prepare heat balance sheet on Single-Cylinder Diesel Engine.

APPARATUS USED:- Single-Cylinder Diesel Engine (Constant Speed) Test, Rig, Stop Watch and

Digital Tachometer

THEORY:-

The thermal energy produced by the combustion of fuel in an engine is not completely utilized for the

production of the mechanical power. The thermal efficiency of I. C. Engines is about 33 %. Of the

available heat energy in the fuel, about 1/3 is lost through the exhaust system, and 1/3 is absorbed and

dissipated by the cooling system. It is the purpose of heat balance sheet to know the heat energy

distribution, that is, how and where the input energy from the fuel is is distributed.

The heat balance sheet of an I. C. Engine includes the following heat distributions:

a. Heat energy available from the fuel brunt.

b. Heat energy equivalent to output brake power.

c. Heat energy lost to engine cooling water.

d. Heat energy carried away by the exhaust gases.

e. Unaccounted heat energy loss.

FORMULE USED:-

(i) Torque, T = 9.81 x W x R Effective N-m.

; Where R Effective = (D + d)/2 or (D + tBelt)/2 m, and

W (Load) = ( S1 - S2 ) Kg,

(ii) Brake Power, B P = (2πN T) / 60, 000 KW

; Where N = rpm, T = Torque N-m,

(iii) Fuel Consumption, m f = (50 ml x 10-6 x ρ Fuel) / (t) Kg/Sec

-3 3

Here; 1 ml = 10 liters, and 1000 litres = 1 m

So 1 ml = 10-6m3

(iv)Heat energy available from the fuel brunt, Qs = mf x C. V. x 3600 KJ/hr

(v) Heat energy equivalent to output brake power, QBP = BP x 3600 KJ/hr

(vi) Heat energy lost to engine cooling water, QCW = mw x Cw (two - twi) x 3600 KJ/hr

(vii) Heat energy carried away by the exhaust gases, QEG = mfg x Cfg (tfg – tair) x 3600 KJ/hr

; Where mfg = (mf + mAir) Kg/Sec, and mAir = Cd Ao √2 g Δh ρ Air ρ Water Kg/ Sec

; Where Cd (Co-efficient of Discharge) = 0.6, ρ Air = ( Pa x 102) / ( R x Ta ) Kg/m3

Ao (Area of Orifice) = (π do2)/ 4 m , P1 = 1.01325 Bar, R = 0.287 KJ/Kg . K,

Ta = (ta + 273) K, ta = Ambient Temperature in degree centigrade

(viii) Unaccounted heat energy loss, QUnaccounted = Qs – {QBP + QCW + QEG} KJ/hr

PROCEDURE:-

1. Before starting the engine check the fuel supply, lubrication oil, and availability of cooling water.

2. Set the dynamometer to zero load and run the engine till it attain the working temperature and

steady state condition.

Dept. Of MECHANICAL ENGINEERING

BABA FARID COLLEGE OF

ENGINEERING AND TECHNOLOGY

BATHINDA

3. Note down the fuel consumption rate, Engine cooling water flow rate, inlet and outlet temperature

of the engine cooling water, Exhaust gases cooling water flow rate, Air flow rate, and Air inlet

temperature.

4. Set the dynamometer to 20 % of the full load, till it attains the steady state condition. Note down

the fuel consumption rate, Engine cooling water flow rate, inlet and outlet temperature of the engine

cooling water, Exhaust gases cooling water flow rate, Air flow rate, and Air inlet temperature.

5. Repeat the experiment at 40 %, 60 %, and 80 % of the full load at constant speed.

6. Disengage the dynamometer and stop the engine.

7. Do the necessary calculation and prepare the heat balance sheet.

OBSERVATIONS:-

Engine Speed, N = 1500 rpm

No. of Cylinders, n = Single

Calorific Value of Fuel, C.V. = 38,000 KJ/Kg

Specific Heat of Water, Cw = 4.187 KJ/Kg K

Specific Heat of Exhaust Flue Gases, Cfg = 2.1 KJ/Kg K

Gas Constant, R = 0.287 KJ/Kg K

Ambient Temperature, ta=

Atmospheric Pressure, Pa= 1.01325 Bar

Orifice Diameter, do = 25 x 10-3 m

Co-efficient of Discharge, Cd =0.6

Density of fuel (Diesel), ρ Fuel = 810 to 910 Kg/m3

Density of Water, ρWater = 1,000 Kg/m3

Brake Drum Diameter, D = 181.5 x 10-3 M

Rope Diameter, d = M

Or Belt thickness, t belt = 5.5 x 10-3M

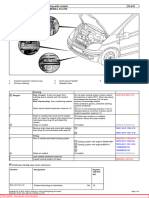

OBSERVATIONS TABLE:-

S no Engine Dynamometer Time Engine Engine Exhaust Manometer

speed Spring balance taken Cooling Cooling Gas Reading,

for 50 Water Water Temp. Temperature, Δh (m)

ml Flow TFG

S1 S2 TWI TWO

( c) ( c)

1 1500

2 1500

3 1500

4 1500

Dept. Of MECHANICAL ENGINEERING

BABA FARID COLLEGE OF

ENGINEERING AND TECHNOLOGY

BATHINDA

Result Table:

S no Engine speed Brake Fuel Air Flow Rate, Exhaust Gas

Power, BP Consumption, Mair (Kg/hr) Flow Rate,

(KW) mf (Kg/hr) Mfg

(Kg/hr)

1 1500

2 1500

3 1500

4 1500

Heat Balance sheet:

Heat Energy KJ/hr % age Heat Energy Consumed KJ/hr % age

Supplied (Distribution)

Heat energy (a) Heat energy equivalent

available to output brake power.

from the fuel

brunt

(b) Heat energy lost to

engine cooling water.

(c) Heat energy carried away

by the exhaust gases.

(d) Unaccounted heat

Energy Loss.

Total

Total 100 % 100 %

Results:

Dept. Of MECHANICAL ENGINEERING

You might also like

- Manual de SCR dd15Document190 pagesManual de SCR dd15Eduardo Villatoro81% (21)

- 3400 Cylinder Head To Block Joint Repair Procedure (1124)Document38 pages3400 Cylinder Head To Block Joint Repair Procedure (1124)A z D100% (3)

- IC Engine IES GATE IAS 20 Years Question and AnswersDocument77 pagesIC Engine IES GATE IAS 20 Years Question and AnswersSaajal Sharma96% (26)

- Thermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualFrom EverandThermodynamic Design Data for Heat Pump Systems: A Comprehensive Data Base and Design ManualNo ratings yet

- Power Plant 20 Years Gate Ies Ias Q ADocument106 pagesPower Plant 20 Years Gate Ies Ias Q ASaajal Sharma100% (12)

- Energy Audits in Thermal Power StationDocument62 pagesEnergy Audits in Thermal Power Stationfiroj_khan995% (22)

- Heat Balance Test On Diesel EngineDocument6 pagesHeat Balance Test On Diesel EngineMathew John0% (2)

- Internal Combustion Engine Lab/heat Engine Lab ExperimentsDocument19 pagesInternal Combustion Engine Lab/heat Engine Lab ExperimentsMathew John0% (2)

- US Navy Course NAVEDTRA 14093 Vol 08 - Electronics Technician-Support SystemsDocument118 pagesUS Navy Course NAVEDTRA 14093 Vol 08 - Electronics Technician-Support SystemsGeorges100% (4)

- Heller System PPT 3 Cooling SystemsDocument34 pagesHeller System PPT 3 Cooling SystemsShrey DattaNo ratings yet

- Motors MAN Part Books PDFDocument158 pagesMotors MAN Part Books PDFAli Gujir100% (3)

- Maintenance Interval Schedule: Operation and Maintenance ManualDocument4 pagesMaintenance Interval Schedule: Operation and Maintenance ManualDeividas B100% (1)

- Synthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsFrom EverandSynthetic Natural Gas: From Coal, Dry Biomass, and Power-to-Gas ApplicationsTilman J. SchildhauerNo ratings yet

- TA 1499-0300 Masurari Si Setari LEANOX PDFDocument12 pagesTA 1499-0300 Masurari Si Setari LEANOX PDFPopa MihaiNo ratings yet

- Transsmission Cooling GuidelineDocument17 pagesTranssmission Cooling Guidelineamin chaabenNo ratings yet

- Manual de Partes Cat 3612 BkeDocument249 pagesManual de Partes Cat 3612 BkeJuan Carlos Valderrama100% (2)

- Sustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentFrom EverandSustainable Energy Conversion for Electricity and Coproducts: Principles, Technologies, and EquipmentNo ratings yet

- Chapter 10 - Heat Transfer in EnginesDocument35 pagesChapter 10 - Heat Transfer in EnginesB NinhNo ratings yet

- Boiler Efficiency Improvement Through Analysis of Losses PDFDocument5 pagesBoiler Efficiency Improvement Through Analysis of Losses PDFTambun BerdikariNo ratings yet

- Sebp5403 00 01 All PDFDocument797 pagesSebp5403 00 01 All PDFareef007No ratings yet

- Energy Efficiency Design Index (EEDI)Document23 pagesEnergy Efficiency Design Index (EEDI)SorinBalabanNo ratings yet

- Analysis of A 10 MW Recompression Supercritical Carbon Dioxide Cycle For Tropical Climatic Conditions Sathish Et AlDocument14 pagesAnalysis of A 10 MW Recompression Supercritical Carbon Dioxide Cycle For Tropical Climatic Conditions Sathish Et AlTanatswa MoyoNo ratings yet

- 628Document4 pages628sdiamanNo ratings yet

- Steam and Gas Tables with Computer EquationsFrom EverandSteam and Gas Tables with Computer EquationsRating: 3 out of 5 stars3/5 (2)

- Boiler Efficiency CalculationDocument5 pagesBoiler Efficiency CalculationSuparna Bhose100% (3)

- Sebp6163 00 00 Allcd PDFDocument425 pagesSebp6163 00 00 Allcd PDFMohamed Ali100% (2)

- A. B. C. D. E.: Where R (D + D) /2 or (D + T) /2 M, and W (Load) (S - S) KGDocument5 pagesA. B. C. D. E.: Where R (D + D) /2 or (D + T) /2 M, and W (Load) (S - S) KGal hasan kanonNo ratings yet

- Test On Variable Speed Petrol EngineDocument7 pagesTest On Variable Speed Petrol EngineAbhishek KhatavkarNo ratings yet

- Heat Balance Diesel Rope Brake-6Document3 pagesHeat Balance Diesel Rope Brake-6Arup NaskarNo ratings yet

- Engineering Thermodynamics Experiment: 04 Verification of First and Second Law of ThermodynamicsDocument5 pagesEngineering Thermodynamics Experiment: 04 Verification of First and Second Law of ThermodynamicsVishal DarjiNo ratings yet

- Ex - No: Date: Heat Balance Test On 4-Stroke Single Cylinder Diesel Engine AimDocument6 pagesEx - No: Date: Heat Balance Test On 4-Stroke Single Cylinder Diesel Engine AimPrashant Mansubrao JondhaleNo ratings yet

- Energy Auditing and Volumetric Efficiency of A C.I EngineDocument4 pagesEnergy Auditing and Volumetric Efficiency of A C.I EngineSIDDHARTH JAINNo ratings yet

- Experiment No: Title: Trial On Four Stroke Diesel Engine With Dynamometer. ObjectivesDocument10 pagesExperiment No: Title: Trial On Four Stroke Diesel Engine With Dynamometer. ObjectivesAl-hasanNo ratings yet

- MORSE TEST ON 4 Cylinders Petrol EngineDocument22 pagesMORSE TEST ON 4 Cylinders Petrol EngineNavneet KumarNo ratings yet

- 4paper, Part BDocument7 pages4paper, Part BAbu Hasnat Md. ShaedNo ratings yet

- Apg1000 Specs 74hc595 NXPDocument7 pagesApg1000 Specs 74hc595 NXPNatgas WebmasterNo ratings yet

- 1.trial On Diesel Engine To Determine Variable Load Performance and Energy Balance PDFDocument16 pages1.trial On Diesel Engine To Determine Variable Load Performance and Energy Balance PDFPrasad varnekarNo ratings yet

- VCR EngineDocument6 pagesVCR EngineAbNo ratings yet

- Performance Testing of Single Cylinder Four Stroke Diesel EngineDocument7 pagesPerformance Testing of Single Cylinder Four Stroke Diesel EngineDebarshi BaruahNo ratings yet

- Performance at Constant SpeedDocument6 pagesPerformance at Constant Speedpurnachand raNo ratings yet

- Thermodynamics ReportDocument6 pagesThermodynamics ReportHarsh Vora100% (1)

- 2-S Petrol EngineDocument5 pages2-S Petrol EngineAbNo ratings yet

- Exp 2 Performance Parameter of Diesel EngineDocument7 pagesExp 2 Performance Parameter of Diesel EngineShashwat JainNo ratings yet

- 7 National Certification Examination FOR Energy Auditors - Nov., 2008Document8 pages7 National Certification Examination FOR Energy Auditors - Nov., 2008venkatraman1985No ratings yet

- ThermalDocument40 pagesThermalvijayakumarNo ratings yet

- Assignment SolutionDocument3 pagesAssignment SolutionSuraj ChaudharyNo ratings yet

- Experiment No 5 Full Load CI EngineDocument3 pagesExperiment No 5 Full Load CI EngineMohamad AhmadNo ratings yet

- Diesel EngineTestingDocument5 pagesDiesel EngineTestingGorilla GrooveNo ratings yet

- ATD - I IA QP FinalDocument1 pageATD - I IA QP FinalSarita UmadiNo ratings yet

- Tata Chemical LTD., Babrala: Efficiency of GTGDocument32 pagesTata Chemical LTD., Babrala: Efficiency of GTGRishabh KumarNo ratings yet

- ECS2 Lab Report - GensetDocument7 pagesECS2 Lab Report - GensetUI Career ExpoNo ratings yet

- Section - B (Attempt All The Questions) - 50 MarksDocument2 pagesSection - B (Attempt All The Questions) - 50 MarksYash ShuklaNo ratings yet

- 1a. Ganga EngineDocument10 pages1a. Ganga EngineShreyas JusticeNo ratings yet

- Taller N1Document6 pagesTaller N1Isabella FerreiraNo ratings yet

- Gas Compressor AuditDocument28 pagesGas Compressor AuditMaxi Eureka100% (1)

- Trial On Reciprocating.Document12 pagesTrial On Reciprocating.zen tenNo ratings yet

- Lab ManualDocument31 pagesLab ManualSamuthra P TNo ratings yet

- Expt. 2A - 4-Stroke Diesel Engine-Without DataDocument6 pagesExpt. 2A - 4-Stroke Diesel Engine-Without DataZen RuNo ratings yet

- Power Plant Engineering 4Document12 pagesPower Plant Engineering 4Anushree GhoshNo ratings yet

- I.C. Engine Performance Test Single Cylinder Diesel EngineDocument6 pagesI.C. Engine Performance Test Single Cylinder Diesel EngineNavneet KumarNo ratings yet

- Thermal Lab II Manual Cycle 1Document13 pagesThermal Lab II Manual Cycle 1Rony RkzNo ratings yet

- Training Report (Kbunl) 2019 Shanu PrakashDocument33 pagesTraining Report (Kbunl) 2019 Shanu PrakashShanu PrakashNo ratings yet

- IGCC Power Plant Second Report (Repaired)Document9 pagesIGCC Power Plant Second Report (Repaired)Annas FauzyNo ratings yet

- Boiler PerformanceDocument20 pagesBoiler Performancesameer betalNo ratings yet

- I.C. Engine Performance Test Single Cylinder Diesel EngineDocument5 pagesI.C. Engine Performance Test Single Cylinder Diesel EngineNavneet KumarNo ratings yet

- Assignment No. - 1Document4 pagesAssignment No. - 1Vedant KarnatakNo ratings yet

- At MST 2Document1 pageAt MST 2Navneet KumarNo ratings yet

- Experiment List of Mechanical LabDocument6 pagesExperiment List of Mechanical LabNavneet KumarNo ratings yet

- Faculty Wise 04.03.2024Document54 pagesFaculty Wise 04.03.2024Navneet KumarNo ratings yet

- Answer Key To The Post(s) of Information Technology Specialist, Screening Test Held On 29.02.2024Document2 pagesAnswer Key To The Post(s) of Information Technology Specialist, Screening Test Held On 29.02.2024Navneet KumarNo ratings yet

- MORSE TEST ON 4 Cylinders Petrol EngineDocument22 pagesMORSE TEST ON 4 Cylinders Petrol EngineNavneet KumarNo ratings yet

- PERFORMANCE TEST ON CompressorsDocument5 pagesPERFORMANCE TEST ON CompressorsNavneet KumarNo ratings yet

- M .Tech Thermal SyllabusDocument19 pagesM .Tech Thermal SyllabusNavneet KumarNo ratings yet

- A Project Report On CadburyDocument77 pagesA Project Report On CadburyNavneet KumarNo ratings yet

- ThermalDocument48 pagesThermalNavneet KumarNo ratings yet

- Curriculam Vitae: Career ObjectiveDocument3 pagesCurriculam Vitae: Career ObjectiveNavneet KumarNo ratings yet

- Arni University::: B.Tech Mechanical II SEMESTERDocument3 pagesArni University::: B.Tech Mechanical II SEMESTERNavneet KumarNo ratings yet

- H.B.MDocument7 pagesH.B.MNavneet KumarNo ratings yet

- Degree FormDocument4 pagesDegree FormNavneet Kumar80% (5)

- Degree FormDocument4 pagesDegree FormNavneet Kumar80% (5)

- RefrigeranteDocument7 pagesRefrigeranteDiasarmaNo ratings yet

- GRUNDFOS Product LineDocument40 pagesGRUNDFOS Product LinezaidosamaNo ratings yet

- Int Coolling SystemDocument29 pagesInt Coolling SystemChandra SekharNo ratings yet

- MeyleCat TruckAll en b3449Document868 pagesMeyleCat TruckAll en b3449SpicNo ratings yet

- Yang 2021Document29 pagesYang 2021Mohan KumarNo ratings yet

- Draining - Filling With CoolantDocument3 pagesDraining - Filling With CoolantatelierautogordonNo ratings yet

- Raw Water Cooling System: Schematic DiagramsDocument4 pagesRaw Water Cooling System: Schematic DiagramshamidrezachamaniNo ratings yet

- Maintenance Interval Schedule 938HDocument4 pagesMaintenance Interval Schedule 938HForesight MisrNo ratings yet

- Lli Ip: Downloaded From Manuals Search EngineDocument144 pagesLli Ip: Downloaded From Manuals Search EngineEduardo ArrietaNo ratings yet

- Operation and Maintenance ManualDocument12 pagesOperation and Maintenance ManualpussykhanNo ratings yet

- Deutz 912 Construction Engine Spec SheetDocument6 pagesDeutz 912 Construction Engine Spec SheetAbdelrahmanNo ratings yet

- Acteon (2) .PDF Versión 1Document215 pagesActeon (2) .PDF Versión 1quepex76No ratings yet

- AttachmentDocument58 pagesAttachmentAman Sharma0% (1)

- Sebu8605 05Document130 pagesSebu8605 05MirekNo ratings yet

- Mxu 500-05-06Document40 pagesMxu 500-05-06alexander ortizNo ratings yet

- Internship Report PDFDocument53 pagesInternship Report PDFSurabhi SharmaNo ratings yet