Professional Documents

Culture Documents

01 GTSM 3

01 GTSM 3

Uploaded by

subash16880 ratings0% found this document useful (0 votes)

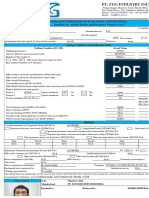

17 views1 page1) Mr. Krishnan Kutty qualified as a welder according to ASME IX standards for pipe welding.

2) He qualified to weld SA 516 Grade 70 steel plate and pipe with diameters of 24 inches and above using SMAW and GTAW processes in the 3G position with solid filler metal.

3) Visual and mechanical testing of the completed welds were satisfactory according to test reports, qualifying the welder.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document1) Mr. Krishnan Kutty qualified as a welder according to ASME IX standards for pipe welding.

2) He qualified to weld SA 516 Grade 70 steel plate and pipe with diameters of 24 inches and above using SMAW and GTAW processes in the 3G position with solid filler metal.

3) Visual and mechanical testing of the completed welds were satisfactory according to test reports, qualifying the welder.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views1 page01 GTSM 3

01 GTSM 3

Uploaded by

subash16881) Mr. Krishnan Kutty qualified as a welder according to ASME IX standards for pipe welding.

2) He qualified to weld SA 516 Grade 70 steel plate and pipe with diameters of 24 inches and above using SMAW and GTAW processes in the 3G position with solid filler metal.

3) Visual and mechanical testing of the completed welds were satisfactory according to test reports, qualifying the welder.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

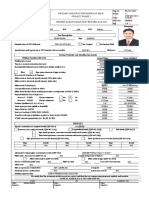

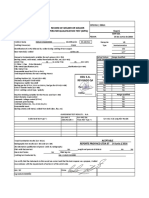

WELDER PERFORMANCE QUALIFICATION (WPQ)

In accordance with ASME IX for Pipe Welding

Welder Name: Mr. KRISHNAN KUTTY

Welder ID.No : W #01

Test Description: (Process Type: Manual)

Identification of WPS No: FFZ/WPS/ORLY/37 Rev.01

Specification of Base Metal: Overlay on SA 516 Gr. 70

Test Condition and Qualification Limits:

Welding Variables Actual Values Range Qualified

Welding Process SMAW + GTAW SMAW + GTAW

Backing With With

Base Metal: P - Number SA 516 Gr. 70 (P1) P1 TO P11, P34, P41 TO P49

F – Number F42, F34 F34, F41 TO F46

Deposited Weld Metal Thickness (2 + 2)mm Min (2 + 2)mm Min

Pipe Diameter (O.D) Plate 24’’ OD & Above

Filler Metal (GTAW) With Filler Metal With Filler Metal

Solid or flux - cored Solid Solid

Inserts No No

Position Qualified 3G FLAT & VERTICAL

Progression Uphill Uphill

Inert Backing (GTAW) NA NA

Current Polarity (GTAW) DCSP DCSP

Results:-

Visual Examination of Completed Weld: Satisfactory.

Mechanical Testing: Report # M 3599 – 3605 dated 19.08.2006 – Accepted.

We certify that the statements in this record are correct & that the test coupons were prepared, welded, and tested in

accordance with the requirements of Section IX of the ASME Boiler and Pressure Vessel Code

FOR FERROFAB (QA/QC Engineer) FOR FERROFAB (Technical Manager)

Name: Mr. V R GOMES Name: K N Murthy

Date: 20.08.2006 Date: 20.08.2006

You might also like

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit GhoshNo ratings yet

- Welder Performance Qualification (WPQ)Document1 pageWelder Performance Qualification (WPQ)JBStringerNo ratings yet

- 169 Gtaw Zug Asme (Fefri 5g) WPQDocument4 pages169 Gtaw Zug Asme (Fefri 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- WPQ FormatDocument8 pagesWPQ FormatsanjaykumarmauryaNo ratings yet

- SampleDocument5 pagesSample이훈No ratings yet

- Cert Piping W54.5Document2 pagesCert Piping W54.5SANU0% (1)

- Welder Certificate UpdatedDocument25 pagesWelder Certificate Updatedm.aljhany18No ratings yet

- Val Caraig WPQTDocument1 pageVal Caraig WPQTMark Jason M. BrualNo ratings yet

- 170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQDocument4 pages170 Gtaw&Smaw Zug Asme (Afri S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- PWPS CS To SS446-3Document5 pagesPWPS CS To SS446-3BIIS QAQC Babu SivaNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- WQR V01 PLT 012-ComDocument3 pagesWQR V01 PLT 012-Comhaim timorNo ratings yet

- Welder Test Certificate - CSDocument1 pageWelder Test Certificate - CSPrathamesh Omtech100% (4)

- WPQ Formats NEWDocument4 pagesWPQ Formats NEWMANABENDRA MAITRANo ratings yet

- Wip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreDocument3 pagesWip Site, Igcar, Kalpakkam: Vacuum Techniques PVT LTD BanagloreVijayabaraniNo ratings yet

- WPQ WeldCanada PDFDocument1 pageWPQ WeldCanada PDFAhmad DanielNo ratings yet

- Sample Welder ID As Per ASME Section IXDocument99 pagesSample Welder ID As Per ASME Section IXVivek Jadhav100% (1)

- A-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Rev A Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- A-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessDocument4 pagesA-Mtl-Pro-730-38931 Pwps For Column Pipe To Column Pipe and 10 Inch Dia. Pipe To Pipe Welding With Gtaw + Smaw ProcessRamzi ZoghlamiNo ratings yet

- Slamet WPQRDocument1 pageSlamet WPQRChandra Bintang W.PNo ratings yet

- Procedure Qualification RecordDocument6 pagesProcedure Qualification RecordGaurang PandyaNo ratings yet

- QW 482 WPS (Gtaw+smaw) 04.01.2015Document8 pagesQW 482 WPS (Gtaw+smaw) 04.01.2015Srikant GanjiNo ratings yet

- Wps For Butt Weld Qualification 4 Inch Cs Pipe To Cs Pipe - p0Document3 pagesWps For Butt Weld Qualification 4 Inch Cs Pipe To Cs Pipe - p0YokeshAnandNo ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- KKJV WPS PP01Document2 pagesKKJV WPS PP01serbay tuncaNo ratings yet

- WA-AEI-001 Some Comments AddressedDocument2 pagesWA-AEI-001 Some Comments AddressedMulPXNo ratings yet

- GCB WPS Tsila 012Document19 pagesGCB WPS Tsila 012AslaouiNo ratings yet

- Wqt-Suria Engineering-M.waqasDocument1 pageWqt-Suria Engineering-M.waqassuria qaqcNo ratings yet

- Tecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)Document2 pagesTecnicas Reunidas S.A: Proposed Welding Procedure Specification (PWPS)BIIS QAQC Babu SivaNo ratings yet

- QW - 482 Welding Procedure Specification (WPS)Document5 pagesQW - 482 Welding Procedure Specification (WPS)Arijit GhoshNo ratings yet

- QW 483 - PQR (Gtaw+smaw) 04.01.17Document8 pagesQW 483 - PQR (Gtaw+smaw) 04.01.17Srikant GanjiNo ratings yet

- Rep WPS 02Document2 pagesRep WPS 02shaniraj BirajdarNo ratings yet

- WQTDocument1 pageWQTRamkunwar YadavNo ratings yet

- NYX Ndustries ZC: Welder Performance Qualification RecordDocument1 pageNYX Ndustries ZC: Welder Performance Qualification RecordanoopkumarNo ratings yet

- Pt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionDocument1 pagePt. Vista Bangun Utama: in Accordance With Section IX, ASME Boiler and Pressure Vessel Code 2013 EditionHaryanto RNo ratings yet

- Welding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001Document2 pagesWelding Procedure Specifications (WPS) : NMDC Nagarnar 2 MTPA Pellet Plant, Jagdalpur - 494001neerajNo ratings yet

- DGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)Document4 pagesDGCL-IBFPL-WPS-05 Station Piping (2 Inch & Below)সীমান্ত ছাড়িয়ে - Shemanto ChariyeNo ratings yet

- Wqt-Suria Engineering-M.rashidDocument1 pageWqt-Suria Engineering-M.rashidsuria qaqcNo ratings yet

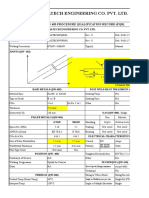

- Diamond Engineering (Chennai) PVT LTD.,: Welder Qualification Test RecordDocument1 pageDiamond Engineering (Chennai) PVT LTD.,: Welder Qualification Test Recordmangalraj900No ratings yet

- Tecnicas Reunidas S.A: Welding Procedure Specification (WPS)Document2 pagesTecnicas Reunidas S.A: Welding Procedure Specification (WPS)BIIS QAQC Babu SivaNo ratings yet

- Abdul Muhid WPQRDocument1 pageAbdul Muhid WPQRChandra Bintang W.PNo ratings yet

- Rep WPQ 02Document1 pageRep WPQ 02shaniraj BirajdarNo ratings yet

- WQT-SURIA ENGINEERING - Naveed WelderDocument1 pageWQT-SURIA ENGINEERING - Naveed Weldersuria qaqcNo ratings yet

- Wps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Document4 pagesWps No Ltbf/Capfims/Sswps-11: - Contractor Revision No: - Welding Process (Es)Nilotpal Kumar RaiNo ratings yet

- WPQ 양식 김정균 (DSHI Rev.0)Document5 pagesWPQ 양식 김정균 (DSHI Rev.0)이훈No ratings yet

- Welding Procedure Specification (WPS) : Supporting PQR 01Document2 pagesWelding Procedure Specification (WPS) : Supporting PQR 01duyanhNo ratings yet

- Calificación Termotecnica CoindustrialDocument1 pageCalificación Termotecnica CoindustrialTato VargasNo ratings yet

- Toaz - Info Welding Procedure Specification Format PRDocument3 pagesToaz - Info Welding Procedure Specification Format PRKarim ZahranNo ratings yet

- Welding Procedure Specification FormatDocument3 pagesWelding Procedure Specification FormatAnonymous 4e7GNjzGW100% (1)

- 180-Smaw-Zug-Asme (Andhika Rolando-3g) - WPQDocument4 pages180-Smaw-Zug-Asme (Andhika Rolando-3g) - WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- 165 Gmaw Zug Asme (Imam Mustofa 3g) WPQDocument4 pages165 Gmaw Zug Asme (Imam Mustofa 3g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- Eslam Abdelhameed Asme Ix IdDocument1 pageEslam Abdelhameed Asme Ix Idel_sharkawy2011No ratings yet

- WPQ Is 2062 Angad Chauhan W3 - 1GDocument2 pagesWPQ Is 2062 Angad Chauhan W3 - 1Gprod4150% (1)

- WQT Form (ASME) 04-23Document1 pageWQT Form (ASME) 04-23hanz bermejoNo ratings yet

- Qw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)Document2 pagesQw-482 Welding Procedure Specification (WPS) : (Automatic, Manual, Machine or Semi-Auto)BalasahebNo ratings yet

- WPS Vessel 1Document4 pagesWPS Vessel 1Naqqash SajidNo ratings yet

- PQR (52a) ModelDocument1 pagePQR (52a) ModelSIDDHARTH BEHERAYNo ratings yet

- Welder'S Qualification Test Certificate: (As Per Asme Sec Ix)Document2 pagesWelder'S Qualification Test Certificate: (As Per Asme Sec Ix)vijay100% (1)

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)