Professional Documents

Culture Documents

RA - Trays Installation

Uploaded by

Karimo Kilani0 ratings0% found this document useful (0 votes)

23 views11 pagesOriginal Title

RA_Trays Installation

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views11 pagesRA - Trays Installation

Uploaded by

Karimo KilaniCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 11

5.

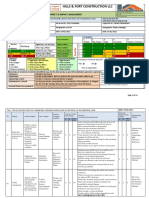

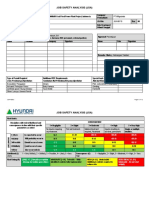

02- F01 HAZARD IDENTIFICATION & RISK ASSESSMENT

PRE- START CHECKLIST

Date: 12-05-2023

Project Name: Sea World Abu Dhabi

Time: 11:00 AM

Description of Task / Activity: SWAD _ Trays Installation

Risk Assessment No: 002 Rev No.

Emp No. Name

Risk Assessor: Karim MAhmoud

Construction Manager: Ibrahim Adel

PORJECT MANGER: Hossam Hamouda

Safety Department:

Engineer: Himanshu Karayat

SUBJECT MATTER EXPERT: Joseph Xavier

1 Manpower Required for Task:

SWAD _ Trays Installation

2 Work Notification Status:

3 Estimated / Planned Start Date: 09-05-2023

4 Duration of Activity: 7 days

5 Night work and Equipment: N/A

6 Equipment and Materials: As per MOS

7 Overhead Services / Underground: N/A

Sequence of Works Activity:

8 Subcontractors to be Used: Non

9 Interface with Public: N/A

10 Adjacent Activities & Interface with YES

other Sub Contractors:

11 Logistics, Loading, Delivery: N/A

12 Specific PPE Required: As per MOS

13 Environmental: N/A

14 Elevated Positions: yes

15 Confined Space Entry: N/A

16 Hoarding / Fencing / Barricading/ N/A

Demarcation:

17 Access / Egress: YES

18 Security Requirements: As per project main contractor requirements

19 Traffic: As per project main contractor requirements

20 Permit to Work Required Details: Mechanical Works PTW

21 Work Near Water: N/A

22 Hazardous Substances: N/A

23 Excavations: N/A

24 Lifting Equipment / Machinery: N/A

25 Special Emergency Arrangements: NA

5.02- F01 HAZARD IDENTIFICATION & RISK ASSESSMENT

Page 1 of 8 Rev. 4 [18-Apr-2019] CRM Controlled Document

Description of Task / Activity: SWAD _ Trays Installation

Risk Assessment No: Rev No.

26 Additional Comments: MSRA to be communicated with all the involved persons by supervision Staff

and MS & RA should be revised if work method, materials/equipment’s are

changed.

Page 2 of 8 Rev. 4 [18-Apr-2019] CRM Controlled Document

Project Name: Sea World Abu Dhabi Project Code:

Description of Task / Activity: SWAD _ Trays Installation

Risk Assessment No. 002 RA Rev No.

Task Site Location: Yas Island, Abu Dhabi, UAE

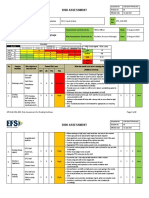

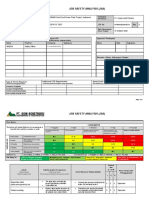

RISK/LOSS POTENTIAL ASSESSMENT MATRIX

PROBABILITY of recurrence?

SEVERITY of occurrence Severity Almost Certain Very Likely Likely Unlikely Very Unlikely

Rating 1 or more times a Once every 10 Once in a lifetime/ 100

Once per month Once per year

week years years

Catastrophic

Multiple Fatalities / Low

5 High 25 High 20 High 15 Med 10

Environmental release with detrimental effects requiring external emergency services/ 5

>10m AED

Major

Med Low

Single Fatality/Multiple LTI’s/ Major Illness or Injury, disability/ 4 High 20 High 16 High 12

Environmental release with minimal off site impact/ 1-10m AED

8 4

Moderate

Single LTI/ Serious but non-permanent injury or ill health Med Med Low

3 High 15 High 12

Work days lost/ Restricted Workday 9 6 3

On site release requiring environmental emergency plan to be activated/ 100k-1m AED

Minor

Corrective Medical Treatment. Med Med Med Low Low

2

No work restrictions/ 10 8 6 4 2

Local on-site environmental release treated locally/ 10-100k AED

Negligible

First Aid Case/ Minor cuts & bruises or sickness/Preventive OR Diagnostic Medical Low Low Low Low Low

1

Treatment. 5 4 3 2 1

Nuisance release with no adverse impact/ 1-10k AED

Probability Rating 5 4 3 2 1

1 3 3

Page 3 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

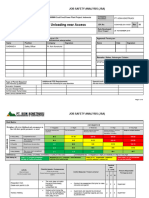

Description of Task / Activity: SWAD _ Trays Installation

Risk Assessment No: 002 RA Rev No.

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

• Contractor must be onboard with

project WW requirements.

• Operatives must complete project HSE +WW inductions.

• All should have their medical insurance cards & Emirates

ID with them.

• All should enter to the site with the Mandatory & Job

specific PPEs. Refer their Mandatory PPE & Job specific

PPE in the Method statement.

• DSTI to be conducted by supervisor near to the work spot

Hazard: prior to start any activity.

• Unauthorized entry • Supervisor & workers should visually inspect their work

Site / Work • Not aware of Hazard / area, equipment, plants, materials etc. prior to start their

Preparatory controls. activity.

Works for

• Slip, trip & fall • Hit with • Ensure that all tools have been inspected and color

01 INSTALLATION 2 3 6 Y 1 3 3 CES & GFTS

moving coded/tagged to ensure that the plant department

Cables Trays

machinery inspected them prior to issue

(Handling Area)

Consequence: • Guide the movement of delivery vehicles and control

• Injury from construction work operatives;

• Unauthorized persons not allowed in work area

• Barricade the work area, communicate to the nearby

activities and watch for any moving machineries at the

work spot.

• Ensure safe access/egress into & out of the area

• Ensure effective lighting requirements installed. Min 50

Lux

• All vehicle movement in construction area either with

revolving amber light or under the control of flagman

when reversing.

Lifting Cables Hazard General measures

trays Manual Handling, Proper material handling

Slip-Trip PPE’s.

3 3 9

damaged tools and Supervisors and OHS team to monitor manual handling.

Page 4 of 8 lead cable, untrained operator Rev. 4 [18-Apr-2019]

Training, Tool box talk to all operatives

CRM Controlled Document Supervisor and HSE Officer ensure The surface is dry, clean and

02 Consequences free of any materials to prevent falls and slips Y 1 3 3 CES & GFTS

personal Additional Measures

injuries , Cuts, bruises Lift any heavy equipment as much as possible using mechanical

Description of Task / Activity: SWAD _ Trays Installation

Risk Assessment No: 002 RA Rev No.

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

• No tampering or unauthorized modifications on electrical

tools and systems — repairs will be done by competent

electricians only

• Hazards to be communicated to the workforce through

DSTI and acknowledged by the workforce

• All the power tools Operatives to be trained by

manufacturer

• Daily inspection by the operators

• Send the defective power tools to quarantine zone

immediately, defective tools are not allowed to be keep at

site.

• 110 V power tools to be preferred at site using by step

down transformers, in case 220+ V power tools are chosen

30 mA RCD to be fitted on DB. Special dispensation for HV

from Main Contractor must be obtained.

• Use industrial sockets and standard cables to tap the

power

• Site DB’s to be inspected by electrician weekly and record

to be kept on DB

• All the rotating parts to be guarded Grinding /Cutting

Machine: (if required)

• Hot work permits are required for cutting and grinding

activities.

• Work area to be barricaded while the work is in progress

• Fire prevention & protection to be provided

• Fire extinguishers readily available in work locations

Page 5 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

• Competent Fire Watch available during the activity and 30

min on completion of the activity

• All combustible material must be removed or in case

immovable, covered with fire blanket.

• All task related PPE shall be worn by operatives

Description of Task / Activity: SWAD _ Trays Installation

Risk Assessment No: 002 RA Rev No.

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

Grinding /Cutting Machine: (if required)

• Hot work permits are required for cutting and grinding

activities

• Fire prevention & protection to be provided

• Fire extinguishers available

• Competent Fire Watch available during the activity and

30 min on completion of the activity

• All combustible material must be removed or in case

immovable, covered with fire blanket,

• Issue and enforce PPE for the task

03 Work at Height Hazard General Precautions: Y 1 3 3 CES & GFTS

Works for • Fall from height • Obtain PTW before starting work

INSTALLATION • Falling objects. • PPE Gloves, safety Harness, safety shoes etc..

Cables Trays ,DC • Overhead •

Cables destitution obstruction • Tool box talk to be conducted before start the job

(use of • Fall in to sharp 3 3 9 • GFTS (HSE and supervisor) ensure that the activites is carried

Scaffolding) out properly

Consequences • (Sub con) Qualified and trained workers to work at height

Property damage, Additional Measures Scaff..

Major Injuries, Personal Injury, • Scaffolding is inspected during construction and once complete

Electrocution by an individual with a scaffolding license

• Maximum weight of scaffolding is agreed upon prior to set-up

of scaffold

Page 6 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

• Scaffolding to be secured to prevent unauthorized access

• Scaffolding is inspected for defects or damage prior to use

• Scaffolding is inspected after repairs have been made

• Scaffolding is inspected every thirty days

• Scaffolding to be erected and dismantled by a contractor with a

scaffolding licence

• Agree weight/strength specification of scaffolding with scaffolding

contractors before engaging them to erect scaffolding on site

• Maintain awareness of total weight on scaffold, Including

employees

• Under no circumstances are employees to alter scaffolding erected

by contractors

• No employees to work at height in adverse weather conditions

• Weather protection to be taken into account when selecting

• Employees to use the correct manual handling techniques at all

times

• Scaffold construction area to be isolated and cleared of all persons

• Trucks are to be escorted to the area where the scaffolding is to

be constructed

• Truck driver made aware, prior to driving into construction area,

where materials are to be placed and where the scaffold is to be

erected

• An emergency rescue plan has been established

• Close supervision of the work and maintain good

housekeeping

o Provide safe access & egress and ensure free

form overhead obstruction.

o Full body harness required on working platform.

Where primary fall protection not possible,

secondary fall protection will be applicable as

required by ensuring work at height permit, fall

arrest, fall restrain etc.

o Life lines to be erected where necessary to

maintain 100% tie off.

Page 7 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

• Daily DSTI briefing must be conducted to the workforce

prior to start work.

Use of Hand tools • Ensure competent workforce is assigned for the task.

for • Job specific training should be conducted to the

04 Hazard workforce regarding safe usage of Hand tools. CES & GFTS

INSTALLATION 2 3 6 Y 1 3 3

Tool fall from height, • All the tools must be tethered on rigid place while

Cables Trays

Substandard tools, Purpose working on the roof.

made tools

• Use right tools for the right job.

• Inspect all hand tools are safe for use prior to start work.

Description of Task / Activity: SWAD _ Trays Installation

Risk Assessment No: 002 RA Rev No.

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

• Concerned work in charge should inspect all tools prior to

2 3 6 start the work. Y 1 3 3

Consequences

Serious injury to personnel Cuts, • Tools should be used for its proposed purpose only

bruises • Ensure appropriate PPE’s are provided (Goggles, Hand

Gloves, Ear Plugs) etc.

• Ensure protruded sharp edges are secured properly to

avoid injury

• Do not use homemade tools

• All the hand tools should be maintained in way that neat

and clean always.

• Homemade alterations or modifications of tools are not

permitted.

• Work should be performed in presence of concerned

work in charge.

• Close supervision at all times.

• Maintain proper cable management on workplace.

• Maintain proper storage for all power operated

equipment’s.

Page 8 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

• Only authorized personnel allowed in the work area

Hazard • Signage to identify and demarcate the work area must be

Adjacent work in Unauthorized personnel in area display

CES & GFTS /

05 other project 3 2 6 • Coordinate activities with adjacent work teams to prevent Y 1 2 2

ALEC

areas Consequences • Clashes in the work place

Personal injuries • Highlight adjacent teams and hazards to the work team

during DSTI

General Measures

• Stop working in bad weather conditions

• Provide care facilities (drinking water and rest areas)

during high temperatures

Measures above the line

Hazard

• Before the work carried out weather monitoring should

• Height Heat

be carried out.

• Rainy

• Set the maximum safe wind speed for operation

• Windy

• Stop the work if the wind speed is above 9.8m/s .If any

Environment • Foggy

other risk is identified during lifting operation work should

condition • Dust Storme

06 2 3 6 be stopped even under lesser wind speed. y 1 3 3

Consequences

• Stopping work during the high temperature and

(Weather/climate) • (people& property)

obligatory during the summer at noon (UAE OSHAD)

• Serious injury to personnel

• Lone working strictly prohibited at site.

Cuts, bruises

• Arrange for rest area that is significantly cooler

• Heat stress and stork,

(Ventilated) than the work area

dizziness, Serious injuries

• Restricted working hours in accordance with ministry of

labor requirements.

• All work is to be suspended during sandstorm or where

visibility is <5m during heavy downpour and/or strong wind

condition.

• Present a briefing talk emphasizing heat stress

Hazard management both on and off the job

Working in

Exposure to high temperatures

External • Initiate buddy system to early recognition of heat stress

07 Consequences 3 3 9 Y 1 3 3 CES & GFTS

areas/direct symptoms of co-workers and no lone working.

Heat stress and stork, dizziness,

sunlight. • Arrange for rest area that is significantly cooler (Ventilated)

Serious injuries.

than the work area

Page 9 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

Description of Task / Activity: SWAD _ Trays Installation

Risk Assessment No: 003 RA Rev No.

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

• Restricted working hours in accordance with ministry of

labor requirements.

• All work is to be suspended during sandstorm or where

visibility is <5m during heavy downpour and/or strong wind

condition.

• The lifting activities to be suspended when the wind speed

is over 38km/h

• Cold drinking water to all.

• All the operatives must hold personal water bottle (project

approved) at work areas.

• Enough number of coveralls to periodically wash and use

• Cover body as much as possible from UV rays, dust etc.

• Lone working strictly prohibited at site.

Page 10 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

You might also like

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- RA - Trays InstallationDocument11 pagesRA - Trays InstallationIbrahim EsmatNo ratings yet

- Introduction to Enterprise Risk Management: A Guide to Risk Analysis and Control for Small and Medium EnterprisesFrom EverandIntroduction to Enterprise Risk Management: A Guide to Risk Analysis and Control for Small and Medium EnterprisesNo ratings yet

- RA - Inverters Installation 2)Document10 pagesRA - Inverters Installation 2)Karimo KilaniNo ratings yet

- Construction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsFrom EverandConstruction Risk in Operational Hospitals: Processes to Ensure Occupant Wellbeing and Minimise DisruptionsNo ratings yet

- RA - Trays InstallationDocument12 pagesRA - Trays InstallationIbrahim EsmatNo ratings yet

- RA - Cables PullngDocument12 pagesRA - Cables PullngIbrahim EsmatNo ratings yet

- RA - PV Module Installation On ROOFDocument10 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- RA - Cables PullngDocument14 pagesRA - Cables PullngKarimo KilaniNo ratings yet

- RA - Cables PullngDocument12 pagesRA - Cables PullngIbrahim EsmatNo ratings yet

- RA - Carpark Shed Inverter Installation-Seaworld RejectedDocument9 pagesRA - Carpark Shed Inverter Installation-Seaworld RejectedIbrahim EsmatNo ratings yet

- RA - Carpark DC-AC Cables Pulling Procedure in Car Park - Seaworld RejectedDocument12 pagesRA - Carpark DC-AC Cables Pulling Procedure in Car Park - Seaworld RejectedIbrahim EsmatNo ratings yet

- RA - PV Module Installation On ROOFDocument9 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- RA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedDocument14 pagesRA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedIbrahim EsmatNo ratings yet

- RA - Carpark Cable Tray Installation & Laying of DC, AC Cables-Seaworld RejectedDocument10 pagesRA - Carpark Cable Tray Installation & Laying of DC, AC Cables-Seaworld RejectedIbrahim EsmatNo ratings yet

- Ra - Extension Cubicees Instulation 1Document8 pagesRa - Extension Cubicees Instulation 1Ibrahim EsmatNo ratings yet

- Hazard Identification and Risk Assessment HLS Ver.3Document16 pagesHazard Identification and Risk Assessment HLS Ver.3yaswanth reddy mummadi33% (3)

- RA - INSTALLATION OF FCU:AHU and FAHUDocument44 pagesRA - INSTALLATION OF FCU:AHU and FAHURAJANo ratings yet

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- Painting WorksDocument3 pagesPainting WorksSaleem Basha100% (1)

- Risk Assessment Format For SampleDocument3 pagesRisk Assessment Format For SampleSaqib RasoolNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- GS - RA Gulfstar - Environmental Aspect and ImpactDocument6 pagesGS - RA Gulfstar - Environmental Aspect and Impactsajin100% (1)

- Laying of Road Crossing Duct For Irrigation WorksDocument9 pagesLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- Hvac WorksDocument4 pagesHvac WorksSaleem BashaNo ratings yet

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocument13 pagesEMP-TR347-HFC-MES-020 Tie in ConnectionsajinNo ratings yet

- Constuction of RCC Telecom Chamber For Telecom WorksDocument14 pagesConstuction of RCC Telecom Chamber For Telecom WorkssajinNo ratings yet

- Electrical WorksDocument3 pagesElectrical WorksSaleem Basha50% (2)

- Epoxy PaintingDocument4 pagesEpoxy PaintingSaleem BashaNo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- RA Bored Cast in Situ PileDocument38 pagesRA Bored Cast in Situ PileAnonymous zsBCtskz100% (1)

- Screeding WorksDocument2 pagesScreeding WorksSaleem Basha100% (1)

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocument2 pagesEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNo ratings yet

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- Hirac of GutDocument34 pagesHirac of GutRandy Adisyah100% (1)

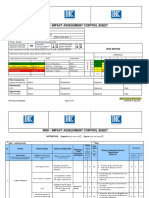

- Risk / Impact Assessment Control Sheet: 000 Y N Y NDocument19 pagesRisk / Impact Assessment Control Sheet: 000 Y N Y NeDtutors. inNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- Jsa-Wif-9 Pulling CableDocument12 pagesJsa-Wif-9 Pulling CableY a n i. A h m e dNo ratings yet

- HSE Risk Assessment For Hot Work ActivityDocument11 pagesHSE Risk Assessment For Hot Work ActivityGokul pNo ratings yet

- 9.risk Assessment - Working in PantryDocument2 pages9.risk Assessment - Working in PantryManzur AhmadNo ratings yet

- 035 Boiler Hydrostatic TestDocument7 pages035 Boiler Hydrostatic TestAngga EHSKOINNo ratings yet

- Mobile CranesDocument5 pagesMobile CranesSAYED100% (1)

- 2019-057-JSA-Loading Unloading Near Access RoadDocument8 pages2019-057-JSA-Loading Unloading Near Access RoadUD. Gunung JatiNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- Risk / Impact Assessment Control Sheet: Severity Rating: MatrixDocument7 pagesRisk / Impact Assessment Control Sheet: Severity Rating: MatrixSaim AliNo ratings yet

- Job Risk Assessment Form: Vessel: M/V Gemini 2Document1 pageJob Risk Assessment Form: Vessel: M/V Gemini 2Danilo OralNo ratings yet

- Aspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Document6 pagesAspire Logistics Safetydepartment: Ref. No. AL-SSD-SAF-FRM-02 01 Date 18.07.19 1of6Kevin ColmoNo ratings yet

- 8 Flushing and Chemical Cleaning MS-AC-08Document3 pages8 Flushing and Chemical Cleaning MS-AC-08Marwan NizarNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. Ahmad100% (1)

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- Phase 3 Hardscape RA R0Document14 pagesPhase 3 Hardscape RA R0SIBIN100% (1)

- Risk / Impact Assessment Control Sheet: MatrixDocument4 pagesRisk / Impact Assessment Control Sheet: MatrixSaim AliNo ratings yet

- SF 011 Hazard Risk AseessmentDocument3 pagesSF 011 Hazard Risk AseessmentShahid RazaNo ratings yet

- 010 - Scaffolding (Erection & Dismantling)Document6 pages010 - Scaffolding (Erection & Dismantling)Prem ChristianNo ratings yet

- Risk Assesssment-Vinyl & Tile Floor InstallationDocument2 pagesRisk Assesssment-Vinyl & Tile Floor InstallationMunaku TafadzwaNo ratings yet

- EFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & ShampooDocument4 pagesEFS-SLB-SRA-002 Risk Assessment For Carpet Cleaning Vacuum & Shampoomohammed ayazNo ratings yet

- Bwe Bypassing Bwts Aug 2020Document3 pagesBwe Bypassing Bwts Aug 2020Swapnil SheteNo ratings yet

- EFS-SLB-SRA-004 Risk Assessment For Bodily Fluid Spillage CleansDocument2 pagesEFS-SLB-SRA-004 Risk Assessment For Bodily Fluid Spillage Cleansmohammed ayazNo ratings yet

- BUS B328F Assignment 1 Lean CanvasDocument1 pageBUS B328F Assignment 1 Lean CanvasMohammed Ameer EjazNo ratings yet

- Ebacl Ips 20161130 Ips Functional Description v09 Draft PWG CleanDocument59 pagesEbacl Ips 20161130 Ips Functional Description v09 Draft PWG CleanDnyaneshwar PatilNo ratings yet

- Mechatronics SystemsDocument22 pagesMechatronics SystemsRamsai Chigurupati100% (1)

- P342 343 Generators ProtectionsDocument16 pagesP342 343 Generators ProtectionshieudaininhNo ratings yet

- Cyber Seurity 1Document118 pagesCyber Seurity 1suhailwilliamsonugca16No ratings yet

- Sales and MarketingDocument13 pagesSales and MarketingSupriyadiNo ratings yet

- Ga Z77X D3H R101 PDFDocument41 pagesGa Z77X D3H R101 PDFTANo ratings yet

- Acer Aspire One 522 AO522 - COMPAL LA-7072P - REV 1.0sec PDFDocument36 pagesAcer Aspire One 522 AO522 - COMPAL LA-7072P - REV 1.0sec PDFMcgregori AndradeNo ratings yet

- Automation and Control EngineeringDocument246 pagesAutomation and Control EngineeringB J ISAC ABRAHAM PAULNo ratings yet

- Course Content: SAP Fiori Implementation (SAPX03)Document3 pagesCourse Content: SAP Fiori Implementation (SAPX03)Jathin Varma KanumuriNo ratings yet

- Install Firefox in Redhat 8 PDFDocument3 pagesInstall Firefox in Redhat 8 PDFzenithNo ratings yet

- Breezeaccess II Instruction ManualDocument346 pagesBreezeaccess II Instruction ManualMikhail YarovNo ratings yet

- OpenText Document Management EDOCS DM 5 3 1 Suite Patch 6 Release NotesDocument49 pagesOpenText Document Management EDOCS DM 5 3 1 Suite Patch 6 Release NotesaminymohammedNo ratings yet

- Software Requirement Specification: Employee Tracking SystemDocument14 pagesSoftware Requirement Specification: Employee Tracking SystemBerker Güngör50% (4)

- Singly Reinforced Beam NSCP 2015Document5 pagesSingly Reinforced Beam NSCP 2015Harambe GorillaNo ratings yet

- HTC Gene Service Manual - Rev A08Document53 pagesHTC Gene Service Manual - Rev A08arryscompNo ratings yet

- QAQC Terms & DefinitionsDocument5 pagesQAQC Terms & DefinitionsSalman HameedNo ratings yet

- Unit 3 Routing Algorithms Computer NetworksDocument78 pagesUnit 3 Routing Algorithms Computer NetworksSAUMIL SHAHNo ratings yet

- Higher Education Students' Financing Board List of Succeesful Undergraduate Loan Beneficiaries For The Academic Year 2017/17Document18 pagesHigher Education Students' Financing Board List of Succeesful Undergraduate Loan Beneficiaries For The Academic Year 2017/17The Campus TimesNo ratings yet

- CTFL-AuT 2018 Sample Exam A v2.1 Questions PDFDocument17 pagesCTFL-AuT 2018 Sample Exam A v2.1 Questions PDFMartin DeusNo ratings yet

- Trina Solar 375W Allmax PDFDocument2 pagesTrina Solar 375W Allmax PDFDiego PulidoNo ratings yet

- Series: High Performance High Rigidity Vertical Machining CenterDocument12 pagesSeries: High Performance High Rigidity Vertical Machining CenterAbhishek VelagaNo ratings yet

- Business English - Departments in A Company - Learn EnglishDocument3 pagesBusiness English - Departments in A Company - Learn EnglishRobert Delgado MontesinosNo ratings yet

- Pyramid - Adventurous Occupations - Computer Expert (For Gurps 4e)Document5 pagesPyramid - Adventurous Occupations - Computer Expert (For Gurps 4e)answeringthecalNo ratings yet

- Using The KneeboardDocument2 pagesUsing The KneeboardDenis CostaNo ratings yet

- Light Current Systems Course: Eng.: Rizk MagdyDocument16 pagesLight Current Systems Course: Eng.: Rizk MagdyIslamNo ratings yet

- BPS Impounded Vehicles List For Official Gazette November 2022Document3 pagesBPS Impounded Vehicles List For Official Gazette November 2022Anonymous UpWci5No ratings yet

- Scada Compone NTS: Prepared By:-Animesh Ghosh Roll No - 4 M.Tech (EE)Document28 pagesScada Compone NTS: Prepared By:-Animesh Ghosh Roll No - 4 M.Tech (EE)Animesh GhoshNo ratings yet

- Question Bank Unit 2 SepmDocument2 pagesQuestion Bank Unit 2 SepmAKASH V (RA2111003040108)No ratings yet

- Nolans Resume 1 3 23Document1 pageNolans Resume 1 3 23api-490401336No ratings yet