Professional Documents

Culture Documents

Ra - Extension Cubicees Instulation 1

Uploaded by

Ibrahim Esmat0 ratings0% found this document useful (0 votes)

3 views8 pagesOriginal Title

RA- EXTENSION CUBICEES INSTULATION 1

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views8 pagesRa - Extension Cubicees Instulation 1

Uploaded by

Ibrahim EsmatCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 8

5.

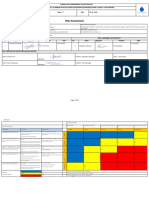

02- F01 HAZARD IDENTIFICATION & RISK

ASSESSMENT EXTENSION CUBICEES

PRE- START CHECKLIST

Date: 12-05-2023

Project Name: Sea World Abu Dhabi

Time: 8:00 AM

Description of Task / Activity: EXTENSION CUBICEES INSTULATION

Risk Assessment No: Rev No.

005 Emp No. Name

Risk Assessor: Karim MAhmoud

Construction Manager: Maruthiraj Jagadeesan

PORJECT MANGER: Hossam Hamouda

Safety Department: 516731 Johannes Olivier

Engineer: Himanshu Karayat

SUBJECT MATTER EXPERT: Joseph Xavier

1 Manpower Required for Task: EXTENSION CUBICEES INSTULATION

2 Work Notification Status:

3 Estimated / Planned Start Date: 15-05-2023

4 Duration of Activity: 7 days

5 Night work and Equipment: N/A

6 Equipment and Materials: As per MOS

7 Overhead Services / Underground: N/A

Sequence of Works Activity:

8 Subcontractors to be Used: YES

9 Interface with Public: N/A

10 Adjacent Activities & Interface with YES

other Sub Contractors:

11 Logistics, Loading, Delivery: YES

12 Specific PPE Required: As per MOS

13 Environmental: N/A

14 Elevated Positions: N/A

15 Confined Space Entry: N/A

16 Hoarding / Fencing / Barricading/ N/A

Demarcation:

17 Access / Egress: YES

18 Security Requirements: As per project main contractor requirements

19 Traffic: As per project main contractor requirements

20 Permit to Work Required Details: Mechanical Works PTW

21 Work Near Water: N/A

22 Hazardous Substances: N/A

23 Excavations: N/A

24 Lifting Equipment / Machinery: N/A

Page 1 of 9 Rev. 4 [18-Apr-2019] CRM Controlled Document

5.02- F01 HAZARD IDENTIFICATION & RISK

ASSESSMENT EXTENSION CUBICEES

Description of Task / Activity: EXTENSION CUBICEES INSTULATION

Risk Assessment No: Rev No.

25 Special Emergency Arrangements: NA

26 Additional Comments: MSRA to be communicated with all the involved persons by supervision

EXTENSION CUBICEES INSTULATION Staff

and MS & RA should be revised if work method, materials/equipment’s are

changed.

Page 2 of 9 Rev. 4 [18-Apr-2019] CRM Controlled Document

Project Name: Sea World Abu Dhabi Project Code:

Description of Task / Activity: EXTENSION CUBICEES INSTULATION

Risk Assessment No. 005 RA Rev No.

Task Site Location: Yas Island, Abu Dhabi, UAE

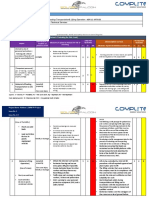

RISK/LOSS POTENTIAL ASSESSMENT MATRIX

PROBABILITY of recurrence?

Almost Certain Very Likely Likely Unlikely Very Unlikely

SEVERITY of occurrence Severity Once in a

1 or more times a Once every 10

Rating week

Once per month Once per year

years

lifetime/ 100

years

Catastrophic

Multiple Fatalities / High High High Med Low

5

Environmental release with detrimental effects requiring external emergency services/ 25 20 15 10 5

>10m AED

Major

High High High Med Low

Single Fatality/Multiple LTI’s/ Major Illness or Injury, disability/ 4

Environmental release with minimal off site impact/ 1-10m AED

20 16 12 8 4

Moderate

Single LTI/ Serious but non-permanent injury or ill health High High Med Med Low

3

Work days lost/ Restricted Workday 15 12 9 6 3

On site release requiring environmental emergency plan to be activated/ 100k-1m AED

Minor

Corrective Medical Treatment. Med Med Med Low Low

2

No work restrictions/ 10 8 6 4 2

Local on-site environmental release treated locally/ 10-100k AED

Negligible

First Aid Case/ Minor cuts & bruises or sickness/Preventive OR Diagnostic Medical Low Low Low Low Low

1

Treatment. 5 4 3 2 1

Nuisance release with no adverse impact/ 1-10k AED

Probability Rating 5 4 3 2 1

Page 4 of Rev. 4 [18-Apr- CRM Controlled

Description of Task / Activity: EXTENSION CUBICEES INSTULATION

Risk Assessment No: 005 RA Rev No.

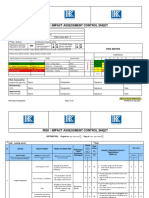

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsi

No. Consequence Details Rank Rank

Y/N ble Person

Contractor must be onboard with project WW

requirements.

Operatives must complete project HSE +WW inductions.

All should have their medical insurance cards &

Emirates ID with them.

All should enter to the site with the Mandatory & Job

specific PPEs. Refer their Mandatory PPE & Job specific

PPE in the Method statement.

DSTI to be conducted by supervisor near to the work

Hazard:

spot prior to start any activity.

Unauthorized entry

Supervisor & workers should visually inspect their work

Site / Work Not aware of Hazard /

area, equipment, plants, materials etc. prior to start

Preparatory controls.

their activity.

Works for • Slip, trip & fall

Ensure that all tools have been inspected and color

01 EXTENSION • Hit with moving 2 3 6 Y 1 3 3 CES & GFTS

coded/tagged to ensure that the plant department

CUBICEES machinery

inspected them prior to issue

INSTULATION Consequence:

Guide the movement of delivery vehicles and control

Injury from construction

operatives;

work

Unauthorized persons not allowed in work area

Barricade the work area, communicate to the nearby

activities and watch for any moving machineries at the

work spot.

Ensure safe access/egress into & out of the area

Ensure effective lighting requirements installed. Min 50

Lux

All vehicle movement in construction area either with

revolving amber light or under the control of flagman

when reversing.

Hazard General measures

Transportation

Potential for traffic accident, • • Ensure all drivers have valid driving license and fit

02 of material on 3 3 9 Y 1 3 3 CES & GFTS

Overturning Insecure material, body condition

site

Consequences

Page 5 of Rev. 4 [18-Apr- CRM Controlled

Serious personal injuries, • Establish traffic rules including care, speed limits and

property damage adhering all traffic safety rules.

• Provide information on defensively driving

• Prohibit overloading and unsecured materials

• All vehicles to be checked and be roadworthy before

entering s

• Driver to take regular breaks to prevent fatigue and

use journey planning

• Prohibition of driving under the influence of drugs

or alcohol

• Monitor vehicles and driving and take disciplinary

action as required

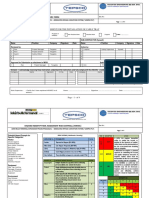

All Workers to work in compliance with the Risk

Hazard Assessment / Method Statement and apply ‘best

• Slip, trip & fall

practice’ handling techniques.

•Hit

Manual Handling Using the Fork Lift as much as possible and reducing

Consequences the daily effort of the workers

Materials of

Can cause injury Use team lifting by competent fit personnel

03 EXTENSION 2 3 6 Y 1 3 3 CES & GFTS

•musculoskeletal disorders, Supervisors and OHS team to monitor manual

CUBICEES

•Hand injuries, handling.

INSTULATION

•cut & bruises

Don't lift or handle more than can be easily managed

•Sharp edges

Move smoothly.

•Property damage

Don't flex the back any further while pulling ,lifting

General measures

Electrical supply system will be checked by competent

Hazard

electrician, follow project color coding system.

Electricity, damaged tools and

Use of Power No tampering or unauthorized modifications on

lead cable, untrained operator

tools during the electrical tools and systems — repairs will be done by

setting up an competent electricians only

Consequences

04 EXTENSION Hazards to be communicated to the workforce through Y 1 3 3 CES & GFTS

Electrical shock, electrocution,

CUBICEES DSTI and acknowledged by the workforce

burns, fire hazards personal

INSTULATION All the power tools Operatives to be trained by

injuries

manufacturer

Daily inspection by the operators

Page 6 of Rev. 4 [18-Apr- CRM Controlled

3 3 9 Send the defective power tools to quarantine zone

immediately, defective tools are not allowed to be keep

at site.

110 V power tools to be preferred at site using by step

down transformers, in case 220+ V power tools are

chosen 30 mA RCD to be fitted on DB. Special

dispensation for HV from Main Contractor must be

obtained.

Use industrial sockets and standard cables to tap the

power

Hazard

PTW to be obtained, prior to

commencing the task

Exposure to Electricity ‐

Only equipment that complies with

Use of damaged and/or

the equivalent of the UAE Standards

faulty electrical equipment

AND OSHAD FOR HSE

(Tools, Leads,

Energy Shutdown Permit ‐ an Energy

Temporary

Failure to install/use earth Shutdown Permit to work on electrical

leakage protection equipment, issued by an Authorized

devices Failure to Person before any activities

visually inspect tools / PPE personal protective equipment

equipment prior to use Supervising and alerting workers to wear

Energy 3 4 12 Y 1 4 4

Failure to conduct routine gloves and safety shoes

Shutdown FOR Identify procedure and hazards. ...

Consequences

05 EXTENSION Shut down. ...

Electrical shock, electrocution,

CUBICEES

burns, fire hazards personal Isolate machine from energy source. ...

INSTULATION

injuries Fatality & Property Apply lockout tagout devices. ...

damage, Check stored energy. ...

Verify isolation. ...

Ensure all power tools are in good condition

and appropriately maintained

Work on low voltage electrical installation

must only be done by a qualified electrician.

All electrical leads will be secured off the

ground by insulated hooks and/or lead

stands to protect against damage

The specialized electrician performs the

Page 7 of Rev. 4 [18-Apr- CRM Controlled

maintenance and verification of the

equipment

Ensure the electrical cable is not damaged

and has not been repaired with insulating

tape or unsuitable connectors.

All the power tools must be 110 volt and safe

to use

RAMS to be briefed to the operatives before

start the activity and maintain the record.

Fire extinguisher in place

Operatives should alert while using sharp

edge tools to avoid entanglement with

clothing.

ERP Plan to include site specific response

protocol for electrocution

Daily DSTI briefing must be conducted to the workforce

prior to start work.

Ensure competent workforce is assigned for the task.

Job specific training should be conducted to the

workforce regarding safe usage of Hand tools.

Hazard All the tools must be tethered on rigid place while

Tool fall from height, working leading edges, scaffold and ladders.

Substandard tools, Purpose Use right tools for the right job.

Use of Hand made tools Inspect all hand tools are safe for use prior to start work.

tools for Concerned work in charge should inspect all tools prior

Consequences

06 EXTENSION to start the work. CES & GFTS

Serious injury to personnel Cuts, 2 3 6 Y 1 3 3

CUBICEES Tools should be used for its proposed purpose only

bruises

INSTULATION Ensure appropriate PPE’s are provided (Goggles, Hand

Gloves, Ear Plugs) etc.

Ensure protruded sharp edges are secured properly to

avoid injury

Do not use homemade tools

All the hand tools should be maintained in way that

neat and clean always.

Homemade alterations or modifications of tools are not

permitted.

Page 8 of Rev. 4 [18-Apr- CRM Controlled

Work should be performed in presence of concerned

work in charge.

Close supervision at all times.

Maintain proper cable management on workplace.

Maintain proper storage for all power operated

equipment’s.

Only authorized personnel allowed in the work area

Hazard Signage to identify and demarcate the work area must be

Adjacent work in Unauthorized personnel in area display

CES & GFTS /

07 other project 3 2 6 Coordinate activities with adjacent work teams to prevent Y 1 2 2

ALEC

areas Consequences Clashes in the work place

Personal injuries Highlight adjacent teams and hazards to the work

team during DSTI

Page 9 of Rev. 4 [18-Apr- CRM Controlled

You might also like

- Triple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsFrom EverandTriple Bottom Line Risk Management: Enhancing Profit, Environmental Performance, and Community BenefitsNo ratings yet

- RA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedDocument14 pagesRA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedIbrahim EsmatNo ratings yet

- Road Map to Developing a Regional Risk Transfer Facility for CARECFrom EverandRoad Map to Developing a Regional Risk Transfer Facility for CARECNo ratings yet

- RA - Trays InstallationDocument12 pagesRA - Trays InstallationIbrahim EsmatNo ratings yet

- RA - Cables PullngDocument12 pagesRA - Cables PullngIbrahim EsmatNo ratings yet

- RA - Cables PullngDocument14 pagesRA - Cables PullngKarimo KilaniNo ratings yet

- RA - Trays InstallationDocument11 pagesRA - Trays InstallationIbrahim EsmatNo ratings yet

- RA - Trays InstallationDocument11 pagesRA - Trays InstallationKarimo KilaniNo ratings yet

- RA - Carpark DC-AC Cables Pulling Procedure in Car Park - Seaworld RejectedDocument12 pagesRA - Carpark DC-AC Cables Pulling Procedure in Car Park - Seaworld RejectedIbrahim EsmatNo ratings yet

- RA - Inverters Installation 2)Document10 pagesRA - Inverters Installation 2)Karimo KilaniNo ratings yet

- RA - PV Module Installation On ROOFDocument10 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- RA - Cables PullngDocument12 pagesRA - Cables PullngIbrahim EsmatNo ratings yet

- Hazard Identification and Risk Assessment HLS Ver.3Document16 pagesHazard Identification and Risk Assessment HLS Ver.3yaswanth reddy mummadi33% (3)

- RA - INSTALLATION OF FCU:AHU and FAHUDocument44 pagesRA - INSTALLATION OF FCU:AHU and FAHURAJANo ratings yet

- RA - Carpark Shed Inverter Installation-Seaworld RejectedDocument9 pagesRA - Carpark Shed Inverter Installation-Seaworld RejectedIbrahim EsmatNo ratings yet

- RA - PV Module Installation On ROOFDocument9 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- RA - Carpark Cable Tray Installation & Laying of DC, AC Cables-Seaworld RejectedDocument10 pagesRA - Carpark Cable Tray Installation & Laying of DC, AC Cables-Seaworld RejectedIbrahim EsmatNo ratings yet

- 05.risk AssesmentDocument5 pages05.risk AssesmentJOSE LUIS100% (1)

- SOM 1.1 D Job - Hazard - Analysis - FormDocument3 pagesSOM 1.1 D Job - Hazard - Analysis - FormAmit BhadauriaNo ratings yet

- RA For Tiling WorkDocument12 pagesRA For Tiling WorkSaeed AhmadNo ratings yet

- Casting ConcreteDocument9 pagesCasting ConcreteNontobeko MkhizeNo ratings yet

- Mobile CranesDocument5 pagesMobile CranesSAYED100% (1)

- SWMS 01 - Container 1 AssemblyDocument14 pagesSWMS 01 - Container 1 AssemblyAsfin HaqueNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- SWMS 27 - Second Skin Wall InstallationDocument20 pagesSWMS 27 - Second Skin Wall InstallationAsfin HaqueNo ratings yet

- SWMS 01 - Container 5 AssemblyDocument23 pagesSWMS 01 - Container 5 AssemblyAsfin HaqueNo ratings yet

- 334 - Manual Handling of GRP PipingDocument7 pages334 - Manual Handling of GRP Pipingcontrax8No ratings yet

- Risk / Impact Assessment Control Sheet: 000 Y N Y NDocument19 pagesRisk / Impact Assessment Control Sheet: 000 Y N Y NeDtutors. inNo ratings yet

- JHA-scaffolding & Hot Work For TrizacDocument12 pagesJHA-scaffolding & Hot Work For Trizacsaud salemNo ratings yet

- 06.HEMP - Jet GroutingDocument3 pages06.HEMP - Jet GroutingSuhaimi ZamzarinaNo ratings yet

- DARD 16.21 - Baseline Risk AssessmentDocument46 pagesDARD 16.21 - Baseline Risk AssessmentSeeiso MasienyaneNo ratings yet

- Risk AssessmentDocument19 pagesRisk Assessmentmthokozisishangase6No ratings yet

- Hirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODDocument4 pagesHirarc Form: Task/Job Description: Method Statement For The Installation of Cable Tray VALIDITY PERIODMohd Faiz MohdNo ratings yet

- Risk Assessment For ExcavatorDocument12 pagesRisk Assessment For ExcavatorCiaraNo ratings yet

- CHRC SWMS Excavation Activities PDFDocument6 pagesCHRC SWMS Excavation Activities PDFBorislav VulićNo ratings yet

- CRA For Beam Stregthening WorksDocument4 pagesCRA For Beam Stregthening WorksVikki P ReddiNo ratings yet

- 10.HEMP - Mechanical Caliper CheckingDocument2 pages10.HEMP - Mechanical Caliper CheckingSuhaimi ZamzarinaNo ratings yet

- 9.risk Assessment - Working in PantryDocument2 pages9.risk Assessment - Working in PantryManzur AhmadNo ratings yet

- 06-12 RA For Discrepancy BTWN ENC Depth & Local Information SantosDocument4 pages06-12 RA For Discrepancy BTWN ENC Depth & Local Information SantosSwapnil SheteNo ratings yet

- Crane RaDocument6 pagesCrane Ramark jayson yabesNo ratings yet

- 332 - Element 5.02.75 Use of Scaffolding (EPCM)Document8 pages332 - Element 5.02.75 Use of Scaffolding (EPCM)contrax8No ratings yet

- Hvac WorksDocument4 pagesHvac WorksSaleem BashaNo ratings yet

- Bwe Bypassing Bwts Aug 2020Document3 pagesBwe Bypassing Bwts Aug 2020Swapnil SheteNo ratings yet

- HS Risk Assessment For SOAKAWAYDocument7 pagesHS Risk Assessment For SOAKAWAYpete chiz100% (1)

- Risk Assessment For Ships: A General: Soumyajit Dasgupta Marine SafetyDocument4 pagesRisk Assessment For Ships: A General: Soumyajit Dasgupta Marine Safetyjose orozcoNo ratings yet

- Epoxy PaintingDocument4 pagesEpoxy PaintingSaleem BashaNo ratings yet

- Phase 3 Hardscape RA R0Document14 pagesPhase 3 Hardscape RA R0SIBIN100% (1)

- Task Risk AssessmentDocument106 pagesTask Risk AssessmentDenis IgnatenkoNo ratings yet

- HSE Risk Assessment: Piling WorkDocument14 pagesHSE Risk Assessment: Piling WorkHamza Awam100% (1)

- 09.HEMP - Pile Construction With Plunge in ColumnDocument4 pages09.HEMP - Pile Construction With Plunge in ColumnSuhaimi ZamzarinaNo ratings yet

- Soft Landscaping ROW Area Risk AssessmentDocument11 pagesSoft Landscaping ROW Area Risk AssessmentSIBIN100% (2)

- Risk Assessment TemplateDocument3 pagesRisk Assessment TemplateAustin Akopia BoyaNo ratings yet

- Risk / Impact Assessment Control Sheet: MatrixDocument4 pagesRisk / Impact Assessment Control Sheet: MatrixSaim AliNo ratings yet

- RA Ug Fire Pipe Installation and Hyrant SystemDocument17 pagesRA Ug Fire Pipe Installation and Hyrant SystemvinayNo ratings yet

- Eepsp Ra Swro 003 - 00aDocument9 pagesEepsp Ra Swro 003 - 00afayaz5233No ratings yet

- SWMS 24 - Tractile InstallationDocument16 pagesSWMS 24 - Tractile InstallationAsfin HaqueNo ratings yet

- 02 Lifting Operations R ADocument4 pages02 Lifting Operations R ASiyadarakkalmajeed ArakkalmajeedNo ratings yet

- Plant Risk Assessment FormDocument9 pagesPlant Risk Assessment FormSufika FaniNo ratings yet

- Laying of Road Crossing Duct For Irrigation WorksDocument9 pagesLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- Painting WorksDocument3 pagesPainting WorksSaleem Basha100% (1)

- RA - PV Module Installation On ROOFDocument9 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- 45 ErtDocument2 pages45 ErtIbrahim EsmatNo ratings yet

- PPE ProcedureDocument4 pagesPPE ProcedureIbrahim EsmatNo ratings yet

- Adfi-Eme-Gfts Ces-Mos-010 - R01 - Cable Bridge InstallationDocument19 pagesAdfi-Eme-Gfts Ces-Mos-010 - R01 - Cable Bridge InstallationIbrahim EsmatNo ratings yet

- Lockout Tagout SW-2024TrainingDocument32 pagesLockout Tagout SW-2024TrainingIbrahim EsmatNo ratings yet

- 001 Project-Risk-Register - Nyngan-Solar-Power-Station - Operations-PhaseDocument27 pages001 Project-Risk-Register - Nyngan-Solar-Power-Station - Operations-PhaseIbrahim EsmatNo ratings yet

- 46.lifting PlanDocument2 pages46.lifting PlanIbrahim EsmatNo ratings yet

- Training Matrix TemplateDocument6 pagesTraining Matrix TemplateIbrahim EsmatNo ratings yet

- OSHE-F-08, Excavation PermitDocument2 pagesOSHE-F-08, Excavation PermitIbrahim EsmatNo ratings yet

- 47.internal Audit 18001 ChecklistDocument6 pages47.internal Audit 18001 ChecklistIbrahim EsmatNo ratings yet

- OSHE-F-05, Monthly OSHE ReportDocument1 pageOSHE-F-05, Monthly OSHE ReportIbrahim EsmatNo ratings yet

- Summer Work Plan - R 0Document12 pagesSummer Work Plan - R 0Ibrahim EsmatNo ratings yet

- OSHE-F-06, OSHE Non Compliance NoticeDocument1 pageOSHE-F-06, OSHE Non Compliance NoticeIbrahim EsmatNo ratings yet

- OSHE-F-13, Near Miss ReportDocument1 pageOSHE-F-13, Near Miss ReportIbrahim EsmatNo ratings yet

- RA - 10 - For Suspended & Slab On Grade ConstructionDocument26 pagesRA - 10 - For Suspended & Slab On Grade ConstructionIbrahim EsmatNo ratings yet

- OSHE-F-09, Hotwork Permit FormDocument1 pageOSHE-F-09, Hotwork Permit FormIbrahim EsmatNo ratings yet

- OSHE-F-07 OSHE Disciplinary NoticeDocument1 pageOSHE-F-07 OSHE Disciplinary NoticeIbrahim EsmatNo ratings yet

- RA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsDocument30 pagesRA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsIbrahim EsmatNo ratings yet

- RA - 9 - For Slab On Grade ConstructionDocument23 pagesRA - 9 - For Slab On Grade ConstructionIbrahim EsmatNo ratings yet

- RA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFDocument8 pagesRA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFIbrahim EsmatNo ratings yet

- Training Matrix Plan 2020Document1 pageTraining Matrix Plan 2020Ibrahim EsmatNo ratings yet

- RA - 14 - For Waterproofing Membrane ApplicationDocument13 pagesRA - 14 - For Waterproofing Membrane ApplicationIbrahim EsmatNo ratings yet

- RA - PV Module Installation On ROOFDocument10 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- Iron Works and Welding CuttingDocument3 pagesIron Works and Welding CuttingIbrahim EsmatNo ratings yet

- Method Statement - Installation of Cable Tray & Laying of DC, AC CablesDocument8 pagesMethod Statement - Installation of Cable Tray & Laying of DC, AC CablesIbrahim EsmatNo ratings yet

- Risk Assessment - GFTS - Excavation Works For Solar Isolator InstallationDocument4 pagesRisk Assessment - GFTS - Excavation Works For Solar Isolator InstallationIbrahim EsmatNo ratings yet

- Risk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESDocument7 pagesRisk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESIbrahim Esmat0% (1)

- Small Animal Emergency and Critical Care MedicineDocument193 pagesSmall Animal Emergency and Critical Care MedicineYaiza Garcia CasadoNo ratings yet

- Brief Trauma Questionnaire (BTQ) : Version Date: 1999 Reference: Schnurr, P., Vielhauer, M., Weathers, F.Document4 pagesBrief Trauma Questionnaire (BTQ) : Version Date: 1999 Reference: Schnurr, P., Vielhauer, M., Weathers, F.Mirjana StevanovicNo ratings yet

- FlexibilityDocument10 pagesFlexibilityAudrey silalahi100% (1)

- Ultrasound-Guided Nerve Blocks in The Head and Neck For Chronic Pain Management - The Anatomy, Sonoanatomy, and ProcedureDocument16 pagesUltrasound-Guided Nerve Blocks in The Head and Neck For Chronic Pain Management - The Anatomy, Sonoanatomy, and Proceduremarcus moraisNo ratings yet

- The Diagnosis and Management of Soft Tissue Knee Injuries - Internal Derangements, New Zeeland Guideline Group, 2003Document104 pagesThe Diagnosis and Management of Soft Tissue Knee Injuries - Internal Derangements, New Zeeland Guideline Group, 2003Pedro FonsecaNo ratings yet

- Causes of Sports InjuriesDocument13 pagesCauses of Sports InjuriesRasell de LunaNo ratings yet

- Introduction To NeuroimagingDocument84 pagesIntroduction To NeuroimagingLiezty VioLen'sNo ratings yet

- People vs. VillacortaDocument2 pagesPeople vs. VillacortaRain CoNo ratings yet

- Head and Neck: Openings in The Base of The Skull and The Structures That Pass Through ThemDocument11 pagesHead and Neck: Openings in The Base of The Skull and The Structures That Pass Through ThemcathdelosoNo ratings yet

- ADM 4th Quarter EIM Week 1 4Document32 pagesADM 4th Quarter EIM Week 1 4ARLENE GRACE AVENUENo ratings yet

- Cold Laser Technology & Frequency HealingDocument330 pagesCold Laser Technology & Frequency HealingM.I.S.No ratings yet

- Introduction To TCCC: Tactical Combat Casualty Care For All Combatants August 2017Document36 pagesIntroduction To TCCC: Tactical Combat Casualty Care For All Combatants August 2017INSTRUCTOR INTERNACIONAL ANTONIO RAMIREZNo ratings yet

- CAX InstallationDocument50 pagesCAX InstallationashukbashaNo ratings yet

- Cópia de Current Concepts - The Kinetic Chain Hip Core and Its Relation To The Overhead Athlete (Jones 2023)Document23 pagesCópia de Current Concepts - The Kinetic Chain Hip Core and Its Relation To The Overhead Athlete (Jones 2023)GuilhermeNo ratings yet

- Critical Care - Criteria For Admission & Role of NurseDocument64 pagesCritical Care - Criteria For Admission & Role of NurseProf. Ramsharan MehtaNo ratings yet

- Service Manual: WarningDocument70 pagesService Manual: WarningMATHALINNo ratings yet

- Type of Joints: Group MembersDocument21 pagesType of Joints: Group MembersBeni Ram RawalNo ratings yet

- Flexion: To Improve Movement of The PivotalDocument3 pagesFlexion: To Improve Movement of The PivotalKelsey MacaraigNo ratings yet

- Overgeared Volume 20 (901-950)Document396 pagesOvergeared Volume 20 (901-950)Evgeni IvanovNo ratings yet

- Competitive 2 WsDocument29 pagesCompetitive 2 WsAASHNA JHAWARNo ratings yet

- Toe and Foot ConditionsDocument14 pagesToe and Foot ConditionsNur InsyirahNo ratings yet

- P.E. 10 - Q1 - Module1bDocument17 pagesP.E. 10 - Q1 - Module1bJaspher PayagNo ratings yet

- Lateral - Ankle Reconstruction ProtocolDocument5 pagesLateral - Ankle Reconstruction ProtocolNovaria PuspitaNo ratings yet

- 5 - EIB Tasks CurrentDocument2 pages5 - EIB Tasks Currentsmith.kevin1420344No ratings yet

- Biceps Tenotomy Vs Tenodesis in Patients Younger Than 50, Systematic ReviewDocument6 pagesBiceps Tenotomy Vs Tenodesis in Patients Younger Than 50, Systematic ReviewIJRASETPublicationsNo ratings yet

- Nervous System ANAPHY NotesDocument10 pagesNervous System ANAPHY NotesAlloiza CaguiclaNo ratings yet

- Case Presentation - Garcia, NKVDocument12 pagesCase Presentation - Garcia, NKVNika GarciaNo ratings yet

- Firearm Injuries: Forensic MedicineDocument71 pagesFirearm Injuries: Forensic MedicineHamzaNo ratings yet

- (CC) Malpresentation and DeliveryDocument6 pages(CC) Malpresentation and DeliveryDaryl Gay NanoNo ratings yet

- Hira Gaurd HouseDocument14 pagesHira Gaurd HouseNagadevan GovindanNo ratings yet