Professional Documents

Culture Documents

RA - Cables Pullng

Uploaded by

Ibrahim Esmat0 ratings0% found this document useful (0 votes)

3 views12 pagesOriginal Title

RA_Cables Pullng

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views12 pagesRA - Cables Pullng

Uploaded by

Ibrahim EsmatCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 12

5.

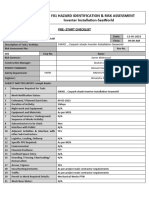

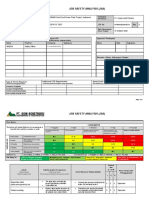

02- F01 HAZARD IDENTIFICATION & RISK ASSESSMENT

PRE- START CHECKLIST

Date: 08-05-2023

Project Name: Sea World Abu Dhabi

Time: 10:00 AM

Description of Task / Activity: AL Dahra _Cables Pulling

Risk Assessment No: Rev No.

002 Emp No. Name

Risk Assessor: Ibrahim Esmat

Construction Manager: Ibrahim Adel

PORJECT MANGER: Hossam Hamouda

Safety Department:

Engineer: Himanshu Karayat

SUBJECT MATTER EXPERT: Joseph Xavier

1 Manpower Required for Task:

Al Dahra _Cables Pulling

2 Work Notification Status:

3 Estimated / Planned Start Date: 02-09-2023

4 Duration of Activity: 1 days

5 Night work and Equipment: N/A

6 Equipment and Materials: As per MOS

7 Overhead Services / Underground: N/A

Sequence of Works Activity:

8 Subcontractors to be Used: Non

9 Interface with Public: N/A

10 Adjacent Activities & Interface with YES

other Sub Contractors:

11 Logistics, Loading, Delivery: N/A

12 Specific PPE Required: As per MOS

13 Environmental: N/A

14 Elevated Positions: yes

15 Confined Space Entry: N/A

16 Hoarding / Fencing / Barricading/ N/A

Demarcation:

17 Access / Egress: YES

18 Security Requirements: As per project main contractor requirements

19 Traffic: As per project main contractor requirements

20 Permit to Work Required Details: Mechanical Works PTW

21 Work Near Water: N/A

22 Hazardous Substances: N/A

23 Excavations: N/A

24 Lifting Equipment / Machinery: N/A

25 Special Emergency Arrangements: NA

5.02- F01 HAZARD IDENTIFICATION & RISK ASSESSMENT

Page 1 of 8 Rev. 4 [18-Apr-2019] CRM Controlled Document

Description of Task / Activity: SWAD _Cables Pulling

Risk Assessment No: Rev No.

26 Additional Comments: MSRA to be communicated with all the involved persons by supervision Staff

and MS & RA should be revised if work method, materials/equipment’s are

changed.

Page 2 of 8 Rev. 4 [18-Apr-2019] CRM Controlled Document

Project Name: Al Dahra Industerial – Khalifa/kizad_Abu Dhabi Project Code:

Description of Task / Activity: Al Dahra _Cables Pulling

Risk Assessment No. 005 RA Rev No.

Task Site Location: Yas Island, Abu Dhabi, UAE

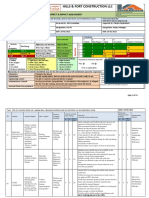

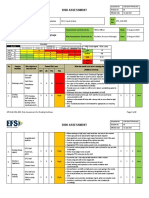

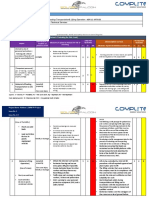

RISK/LOSS POTENTIAL ASSESSMENT MATRIX

PROBABILITY of recurrence?

SEVERITY of occurrence Severity Almost Certain Very Likely Likely Unlikely Very Unlikely

Rating 1 or more times a Once every 10 Once in a lifetime/ 100

Once per month Once per year

week years years

Catastrophic

Multiple Fatalities / Low

5 High 25 High 20 High 15 Med 10

Environmental release with detrimental effects requiring external emergency services/ 5

>10m AED

Major

Med Low

Single Fatality/Multiple LTI’s/ Major Illness or Injury, disability/ 4 High 20 High 16 High 12

Environmental release with minimal off site impact/ 1-10m AED

8 4

Moderate

Single LTI/ Serious but non-permanent injury or ill health Med Med Low

3 High 15 High 12

Work days lost/ Restricted Workday 9 6 3

On site release requiring environmental emergency plan to be activated/ 100k-1m AED

Minor

Corrective Medical Treatment. Med Med Med Low Low

2

No work restrictions/ 10 8 6 4 2

Local on-site environmental release treated locally/ 10-100k AED

Negligible

First Aid Case/ Minor cuts & bruises or sickness/Preventive OR Diagnostic Medical Low Low Low Low Low

1

Treatment. 5 4 3 2 1

Nuisance release with no adverse impact/ 1-10k AED

Probability Rating 5 4 3 2 1

Page 3 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

1 3 3

Page 4 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

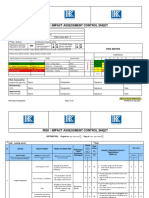

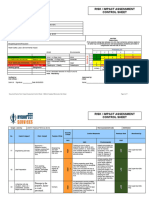

Description of Task / Activity: Al Dahra _Cables Pulling

Risk Assessment No: 005 RA Rev No. 00

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

• Contractor must be onboard with

project WW requirements.

• Operatives must complete project HSE +WW inductions.

• All should have their medical insurance cards & Emirates

ID with them.

• All should enter to the site with the Mandatory & Job

specific PPEs. Refer their Mandatory PPE & Job specific

PPE in the Method statement.

• DSTI to be conducted by supervisor near to the work spot

Hazard: prior to start any activity.

• Unauthorized entry • Supervisor & workers should visually inspect their work

Site / Work • Not aware of Hazard / area, equipment, plants, materials etc. prior to start their

Preparatory controls. activity.

Works for

• Slip, trip & fall • Hit with • Ensure that all tools have been inspected and color

01 Mobilization 2 3 6 Y 1 3 3 CES & GFTS

moving coded/tagged to ensure that the plant department

Material (Trays)

machinery inspected them prior to issue

on Car park

Consequence: • Guide the movement of delivery vehicles and control

• Injury from construction work operatives;

• Unauthorized persons not allowed in work area

• Barricade the work area, communicate to the nearby

activities and watch for any moving machineries at the

work spot.

• Ensure safe access/egress into & out of the area

• Ensure effective lighting requirements installed. Min 50

Lux

• All vehicle movement in construction area either with

revolving amber light or under the control of flagman

when reversing.

Page 5 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

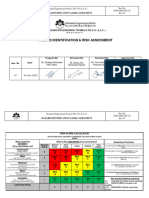

Description of Task / Activity: SWAD _Cables Pulling

Risk Assessment No: 002 RA Rev No.

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Controasures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

Page 6 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

• Establish traffic rules including care, speed limits and

adhering all traffic safety rules.

• Provide information on defensively driving

• Prohibit overloading and unsecured materials

• All vehicles to be checked and be roadworthy before

entering s

• Driver to take regular breaks to prevent fatigue and use

journey planning

• Prohibition of driving under the influence of drugs or

alcohol

• Monitor vehicles and driving and take disciplinary action as

required

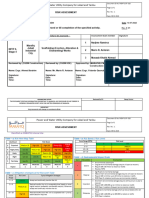

Description of Task / Activity: Al Dahra_Cables Pulling

Page 7 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

Risk Assessment No: 005 RA Rev No. 00

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

Manual Handling • Reducing the individual capacity during the process of

metarules of AC Cables drawing and tightening materials

Hazard • capability

Slip, trip & fall • Hit with moving • the nature of the load

• environmental conditions

Consequences • training

Can cause injury • work organization

• ppe

• musculoskeletal disorders,

3 3 9 • Y 1 3 3

• Hand injuries, • All Workers to work in compliance with the Risk

Assessment / Method Statement and apply ‘best

• cut & bruises

practice’ handling techniques.

• Sharp edges • Using the Fourl Lift as much as possible and reducing

• Property damage the daily effort of the workers

• Use team lifting by competent fit personnel

• Supervisors and OHS team to monitor manual

handling.

• Don't lift or handle more than can be easily

managed

• Move smoothly.

• Don't flex the back any further while

pulling ,lifting

•

Page 8 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

• Daily DSTI briefing must be conducted to the workforce

prior to start work.

• Ensure competent workforce is assigned for the task.

• Job specific training should be conducted to the

04 Use of Hand tools Hazard 3 3 9 workforce regarding safe usage of Hand tools. Y 1 3 3 CES & GFTS

Tool fall from height, • All the tools must be tethered on rigid place while

Substandard tools, Purpose working on the roof.

made tools

• Use right tools for the right job.

• Inspect all hand tools are safe for use prior to start work.

Description of Task / Activity: SWAD _Cables Pulling

Risk Assessment No: 00 RA Rev No.

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

• Concerned work in charge should inspect all tools prior to

start the work.

Consequences

Serious injury to personnel Cuts, • Tools should be used for its proposed purpose only

bruises • Ensure appropriate PPE’s are provided (Goggles, Hand

Gloves, Ear Plugs) etc.

• Ensure protruded sharp edges are secured properly to

avoid injury

• Do not use homemade tools

• All the hand tools should be maintained in way that neat

and clean always.

• Homemade alterations or modifications of tools are not

permitted.

• Work should be performed in presence of concerned

work in charge.

• Close supervision at all times.

• Maintain proper cable management on workplace.

• Maintain proper storage for all power operated

equipment’s.

Page 9 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

• Only authorized personnel allowed in the work area

Hazard • Signage to identify and demarcate the work area must be

Adjacent work in Unauthorized personnel in area display

CES & GFTS /

05 other project 3 2 6 • Coordinate activities with adjacent work teams to prevent Y 1 2 2

ALEC

areas Consequences • Clashes in the work place

Personal injuries • Highlight adjacent teams and hazards to the work team

during DSTI

• Present a briefing talk emphasizing heat stress

Hazard management both on and off the job

Working in

Exposure to high temperatures

External • Initiate buddy system to early recognition of heat stress

07 Consequences 3 3 9 Y 1 3 3 CES & GFTS

areas/direct symptoms of co-workers and no lone working.

Heat stress and stork, dizziness,

sunlight. • Arrange for rest area that is significantly cooler (Ventilated)

Serious injuries.

than the work area

Description of Task / Activity: Al Dahra _Cables Pulling

Risk Assessment No: 005 RA Rev No. 00

Legal Additional control

SI Hazard Details Risk Risk

Task Step P S Current Control Measures Req. P S measures/Responsibl

No. Consequence Details Rank Rank

Y/N e Person

Page 10 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

• Restricted working hours in accordance with ministry of

labor requirements.

• All work is to be suspended during sandstorm or where

visibility is <5m during heavy downpour and/or strong wind

condition.

• The lifting activities to be suspended when the wind speed

is over 38km/h

• Cold drinking water to all.

• All the operatives must hold personal water bottle (project

approved) at work areas.

• Enough number of coveralls to periodically wash and use

• Cover body as much as possible from UV rays, dust etc.

• Lone working strictly prohibited at site.

Page 11 of 8 Rev. 4 [18-Apr-2019]

CRM Controlled Document

You might also like

- Soft Landscaping ROW Area Risk AssessmentDocument11 pagesSoft Landscaping ROW Area Risk AssessmentSIBIN100% (2)

- Checklist WeldingDocument5 pagesChecklist WeldingMarko RisticNo ratings yet

- Epoxy PaintingDocument4 pagesEpoxy PaintingSaleem BashaNo ratings yet

- Risk Assessment - HV 11kV Cable, Joint & TerminationDocument90 pagesRisk Assessment - HV 11kV Cable, Joint & TerminationJobish PK0% (2)

- FSCC 22000 Version 5 and Other RequirementsDocument29 pagesFSCC 22000 Version 5 and Other Requirementskrishan100% (1)

- Makalah Mkdu Bahasa InggrisDocument2 pagesMakalah Mkdu Bahasa Inggrisfadhilah anggrainiNo ratings yet

- RA - Cables PullngDocument14 pagesRA - Cables PullngKarimo KilaniNo ratings yet

- RA - Cables PullngDocument12 pagesRA - Cables PullngIbrahim EsmatNo ratings yet

- RA - Trays InstallationDocument11 pagesRA - Trays InstallationKarimo KilaniNo ratings yet

- RA - Trays InstallationDocument11 pagesRA - Trays InstallationIbrahim EsmatNo ratings yet

- RA - Trays InstallationDocument12 pagesRA - Trays InstallationIbrahim EsmatNo ratings yet

- RA - Inverters Installation 2)Document10 pagesRA - Inverters Installation 2)Karimo KilaniNo ratings yet

- RA - Carpark Shed Inverter Installation-Seaworld RejectedDocument9 pagesRA - Carpark Shed Inverter Installation-Seaworld RejectedIbrahim EsmatNo ratings yet

- RA - PV Module Installation On ROOFDocument10 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- RA - Carpark DC-AC Cables Pulling Procedure in Car Park - Seaworld RejectedDocument12 pagesRA - Carpark DC-AC Cables Pulling Procedure in Car Park - Seaworld RejectedIbrahim EsmatNo ratings yet

- RA - Carpark Cable Tray Installation & Laying of DC, AC Cables-Seaworld RejectedDocument10 pagesRA - Carpark Cable Tray Installation & Laying of DC, AC Cables-Seaworld RejectedIbrahim EsmatNo ratings yet

- RA - PV Module Installation On ROOFDocument9 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- RA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedDocument14 pagesRA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedIbrahim EsmatNo ratings yet

- RA - INSTALLATION OF FCU:AHU and FAHUDocument44 pagesRA - INSTALLATION OF FCU:AHU and FAHURAJANo ratings yet

- Ra - Extension Cubicees Instulation 1Document8 pagesRa - Extension Cubicees Instulation 1Ibrahim EsmatNo ratings yet

- Hazard Identification and Risk Assessment HLS Ver.3Document16 pagesHazard Identification and Risk Assessment HLS Ver.3yaswanth reddy mummadi33% (3)

- Risk Assessment Format For SampleDocument3 pagesRisk Assessment Format For SampleSaqib RasoolNo ratings yet

- Laying of Road Crossing Duct For Irrigation WorksDocument9 pagesLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- Hvac WorksDocument4 pagesHvac WorksSaleem BashaNo ratings yet

- Risk Assessment For Runway Beams 1Document10 pagesRisk Assessment For Runway Beams 1Subbu AbuNo ratings yet

- Painting WorksDocument3 pagesPainting WorksSaleem Basha100% (1)

- Constuction of RCC Telecom Chamber For Telecom WorksDocument14 pagesConstuction of RCC Telecom Chamber For Telecom WorkssajinNo ratings yet

- EMP-TR347-HFC-MES-020 Tie in ConnectionDocument13 pagesEMP-TR347-HFC-MES-020 Tie in ConnectionsajinNo ratings yet

- GS - RA Gulfstar - Environmental Aspect and ImpactDocument6 pagesGS - RA Gulfstar - Environmental Aspect and Impactsajin100% (1)

- Electrical WorksDocument3 pagesElectrical WorksSaleem Basha50% (2)

- HSE Risk Assessment For Hot Work ActivityDocument11 pagesHSE Risk Assessment For Hot Work ActivityGokul pNo ratings yet

- SWMS 01 - Container 1 AssemblyDocument14 pagesSWMS 01 - Container 1 AssemblyAsfin HaqueNo ratings yet

- Risk / Impact Assessment Control Sheet: 000 Y N Y NDocument19 pagesRisk / Impact Assessment Control Sheet: 000 Y N Y NeDtutors. inNo ratings yet

- RA Bored Cast in Situ PileDocument38 pagesRA Bored Cast in Situ PileAnonymous zsBCtskz100% (1)

- Risk Assesment Fab - Rev-07Document71 pagesRisk Assesment Fab - Rev-07Nikhil PuthiryNo ratings yet

- Screeding WorksDocument2 pagesScreeding WorksSaleem Basha100% (1)

- Jsa-Wif-9 Pulling CableDocument12 pagesJsa-Wif-9 Pulling CableY a n i. A h m e dNo ratings yet

- Workshop Risk Assessment REV II GHANADocument10 pagesWorkshop Risk Assessment REV II GHANAEmmanuel AkanvariNo ratings yet

- 035 Boiler Hydrostatic TestDocument7 pages035 Boiler Hydrostatic TestAngga EHSKOINNo ratings yet

- Mobile CranesDocument5 pagesMobile CranesSAYED100% (1)

- SWMS 01 - Container 5 AssemblyDocument23 pagesSWMS 01 - Container 5 AssemblyAsfin HaqueNo ratings yet

- Phase 3 Hardscape RA R0Document14 pagesPhase 3 Hardscape RA R0SIBIN100% (1)

- Job Risk Assessment Form: Vessel: M/V Gemini 2Document1 pageJob Risk Assessment Form: Vessel: M/V Gemini 2Danilo OralNo ratings yet

- EFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of SignagesDocument2 pagesEFS-SLB-SRA-005 Risk Assessment For Dusting Surfaces of Signagesmohammed ayazNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. Ahmad100% (1)

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- All Hira 2-1Document156 pagesAll Hira 2-1Mojib. AhmadNo ratings yet

- Transport 21 Robert Kamb PresentationDocument55 pagesTransport 21 Robert Kamb PresentationGoran JurisicNo ratings yet

- Hirac of GutDocument34 pagesHirac of GutRandy Adisyah100% (1)

- 8 Flushing and Chemical Cleaning MS-AC-08Document3 pages8 Flushing and Chemical Cleaning MS-AC-08Marwan NizarNo ratings yet

- Risk / Impact Assessment Control Sheet: Severity Rating: MatrixDocument7 pagesRisk / Impact Assessment Control Sheet: Severity Rating: MatrixSaim AliNo ratings yet

- Risk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiDocument4 pagesRisk Assessment: Chilled Water Line Chemical Flushing and Passivation DubaiSamboy Dionisio0% (1)

- HSE Risk Assessment For Hot Work ActivityDocument8 pagesHSE Risk Assessment For Hot Work ActivityDarseen RNo ratings yet

- Front Page RAMS-Loading, Unloading and Shifting of MaterialDocument7 pagesFront Page RAMS-Loading, Unloading and Shifting of MaterialEm NiaxNo ratings yet

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- 9.risk Assessment - Working in PantryDocument2 pages9.risk Assessment - Working in PantryManzur AhmadNo ratings yet

- Analysis Criteria:: Karbala Refinery ProjectDocument10 pagesAnalysis Criteria:: Karbala Refinery Projectmustafa falehNo ratings yet

- RA Existing Asphalt Milling WorksDocument8 pagesRA Existing Asphalt Milling WorksSolimanNo ratings yet

- Risk Assessment For Scaffolding Works Rev. 1Document15 pagesRisk Assessment For Scaffolding Works Rev. 1muhammad.younisNo ratings yet

- ChagTerms TBRA - Fuel Delivery To VSL - SampleDocument21 pagesChagTerms TBRA - Fuel Delivery To VSL - SampleshannonNo ratings yet

- Multihazard Risk Atlas of Maldives: Summary—Volume VFrom EverandMultihazard Risk Atlas of Maldives: Summary—Volume VNo ratings yet

- RA - PV Module Installation On ROOFDocument9 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- 45 ErtDocument2 pages45 ErtIbrahim EsmatNo ratings yet

- PPE ProcedureDocument4 pagesPPE ProcedureIbrahim EsmatNo ratings yet

- Adfi-Eme-Gfts Ces-Mos-010 - R01 - Cable Bridge InstallationDocument19 pagesAdfi-Eme-Gfts Ces-Mos-010 - R01 - Cable Bridge InstallationIbrahim EsmatNo ratings yet

- Lockout Tagout SW-2024TrainingDocument32 pagesLockout Tagout SW-2024TrainingIbrahim EsmatNo ratings yet

- 001 Project-Risk-Register - Nyngan-Solar-Power-Station - Operations-PhaseDocument27 pages001 Project-Risk-Register - Nyngan-Solar-Power-Station - Operations-PhaseIbrahim EsmatNo ratings yet

- 46.lifting PlanDocument2 pages46.lifting PlanIbrahim EsmatNo ratings yet

- Training Matrix TemplateDocument6 pagesTraining Matrix TemplateIbrahim EsmatNo ratings yet

- OSHE-F-08, Excavation PermitDocument2 pagesOSHE-F-08, Excavation PermitIbrahim EsmatNo ratings yet

- 47.internal Audit 18001 ChecklistDocument6 pages47.internal Audit 18001 ChecklistIbrahim EsmatNo ratings yet

- OSHE-F-05, Monthly OSHE ReportDocument1 pageOSHE-F-05, Monthly OSHE ReportIbrahim EsmatNo ratings yet

- Summer Work Plan - R 0Document12 pagesSummer Work Plan - R 0Ibrahim EsmatNo ratings yet

- OSHE-F-06, OSHE Non Compliance NoticeDocument1 pageOSHE-F-06, OSHE Non Compliance NoticeIbrahim EsmatNo ratings yet

- OSHE-F-13, Near Miss ReportDocument1 pageOSHE-F-13, Near Miss ReportIbrahim EsmatNo ratings yet

- RA - 10 - For Suspended & Slab On Grade ConstructionDocument26 pagesRA - 10 - For Suspended & Slab On Grade ConstructionIbrahim EsmatNo ratings yet

- OSHE-F-09, Hotwork Permit FormDocument1 pageOSHE-F-09, Hotwork Permit FormIbrahim EsmatNo ratings yet

- OSHE-F-07 OSHE Disciplinary NoticeDocument1 pageOSHE-F-07 OSHE Disciplinary NoticeIbrahim EsmatNo ratings yet

- RA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsDocument30 pagesRA - 15 - For Production Delivery Installation of Precast Pre-Stressed ElementsIbrahim EsmatNo ratings yet

- RA - 9 - For Slab On Grade ConstructionDocument23 pagesRA - 9 - For Slab On Grade ConstructionIbrahim EsmatNo ratings yet

- RA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFDocument8 pagesRA-shifting Installation Cubical Cutout Cable Tray in LV Room (20 (2) 5 PDFIbrahim EsmatNo ratings yet

- Training Matrix Plan 2020Document1 pageTraining Matrix Plan 2020Ibrahim EsmatNo ratings yet

- RA - 14 - For Waterproofing Membrane ApplicationDocument13 pagesRA - 14 - For Waterproofing Membrane ApplicationIbrahim EsmatNo ratings yet

- RA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedDocument14 pagesRA - PV Module Installation On Carpark Shed Structure at Seaworld AD RejectedIbrahim EsmatNo ratings yet

- RA - PV Module Installation On ROOFDocument10 pagesRA - PV Module Installation On ROOFIbrahim EsmatNo ratings yet

- Iron Works and Welding CuttingDocument3 pagesIron Works and Welding CuttingIbrahim EsmatNo ratings yet

- Method Statement - Installation of Cable Tray & Laying of DC, AC CablesDocument8 pagesMethod Statement - Installation of Cable Tray & Laying of DC, AC CablesIbrahim EsmatNo ratings yet

- Risk Assessment - GFTS - Excavation Works For Solar Isolator InstallationDocument4 pagesRisk Assessment - GFTS - Excavation Works For Solar Isolator InstallationIbrahim EsmatNo ratings yet

- Risk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESDocument7 pagesRisk Assessments - Materials Offloading-Transportation& Lifting Opereation - ADFI-GFTS-CESIbrahim Esmat0% (1)

- FDD Form-1 MENDOZA DrillsCeremonies-30 - Aug - 20Document3 pagesFDD Form-1 MENDOZA DrillsCeremonies-30 - Aug - 20Eller-Jed Manalac MendozaNo ratings yet

- Vademecum Eiffel 2019 en PDFDocument8 pagesVademecum Eiffel 2019 en PDFMais OmarNo ratings yet

- Report #5 (Tomás Castro)Document26 pagesReport #5 (Tomás Castro)Tomas Castro D SantosNo ratings yet

- Call Letter Specimen 2021 2022Document4 pagesCall Letter Specimen 2021 2022Dr SahibaNo ratings yet

- Detection of Methicillin Resistance in Staphylococcus Species From Clinical SamplesDocument6 pagesDetection of Methicillin Resistance in Staphylococcus Species From Clinical SamplesOpenaccess Research paperNo ratings yet

- DRRM Toolkit Book - Final PDFDocument379 pagesDRRM Toolkit Book - Final PDFAnonymous JLQBb3JNo ratings yet

- Confined Space: Hole Watch TrainingDocument36 pagesConfined Space: Hole Watch TrainingMalik JunaidNo ratings yet

- Transformers Fire Protection: October 2017Document5 pagesTransformers Fire Protection: October 2017Hedi Ben MohamedNo ratings yet

- WI-962353 QEL03 Audit Plan LetterDocument3 pagesWI-962353 QEL03 Audit Plan LetterChakky DestinyNo ratings yet

- Ha NotesDocument34 pagesHa NotesLyssa KateNo ratings yet

- Statement Uni - SenithaDocument2 pagesStatement Uni - SenithaSenitha MindulaNo ratings yet

- CV of Jiaqi GaoDocument2 pagesCV of Jiaqi Gaoapi-455900676No ratings yet

- Rallygram 2022 FinalDocument4 pagesRallygram 2022 Finalapi-654829982No ratings yet

- 10 3390@pharmaceutics12020151Document19 pages10 3390@pharmaceutics12020151Faiqah Fikriyyah AhmadNo ratings yet

- SO6 - Mobilisation PlanDocument6 pagesSO6 - Mobilisation PlanMahmutDemir50% (2)

- Stress ManagementDocument106 pagesStress ManagementSanthosh SomaNo ratings yet

- Pharmaceutical Jurisprudence Sovan Sarkar 186012111012Document11 pagesPharmaceutical Jurisprudence Sovan Sarkar 186012111012Sovan SarkarNo ratings yet

- Below Are The List of Seminars Attended in The First Semester S.Y. 2020-2021Document3 pagesBelow Are The List of Seminars Attended in The First Semester S.Y. 2020-2021Jan Vincent A. LadresNo ratings yet

- Ellen Respiratory Module PortraitDocument11 pagesEllen Respiratory Module PortraitAbdelmar SusulanNo ratings yet

- Health Vocabulary ListDocument7 pagesHealth Vocabulary ListClaudia MacarieNo ratings yet

- GMP History PDFDocument49 pagesGMP History PDFSubhradipNo ratings yet

- Practice Station History Breathless 1Document8 pagesPractice Station History Breathless 1Wenbin GuoNo ratings yet

- Analysis State of The Nation Address (SONA)Document2 pagesAnalysis State of The Nation Address (SONA)K CateNo ratings yet

- United Nations For Class 8Document36 pagesUnited Nations For Class 8zeeschool25% (4)

- Jurnal Forensik 1Document7 pagesJurnal Forensik 1Rizky ErizkaNo ratings yet

- Budgeted Lesson.1st Quarter - PERDEVDocument3 pagesBudgeted Lesson.1st Quarter - PERDEVJonalyn Banez100% (1)

- Ethics, Privacy, and SecurityDocument10 pagesEthics, Privacy, and SecuritySittie Aina Munder100% (1)

- Overview of Colon Polyps - UpToDateDocument44 pagesOverview of Colon Polyps - UpToDateHartemes RosarioNo ratings yet