Professional Documents

Culture Documents

HSE Risk Assessment For Hot Work Activity

Uploaded by

Darseen ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HSE Risk Assessment For Hot Work Activity

Uploaded by

Darseen RCopyright:

Available Formats

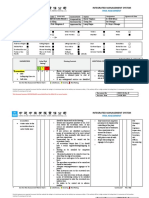

RISK ASSESSMENT

RA No: 00 Hot Work Activity

Effective Date:

Method Statement Reference: Not MS Specific

RISK MATRIX

Use the Risk Matrix to Determine the Risk Rating (Rank)

What is the PROBABILITY (P) of an occurrence? Hierarchy of Controls

What would the SEVERITY (S)

of an occurrence be? Almost

Very Unlikely Unlikely Possible Likely - Can the hazard be Eliminated or removed from the work

Certain

place?

Very High

- Can the product or process be Substituted for a less

Fatalities/Perm Total Disability

5 5 10 15 20 25 hazardous alternative?

Irreversible significant environmental impact

- Can the hazard be Engineered away with guards or barriers?

Loss more than AED 10M

- Can Administrative Controls be adopted

High (Safe Work Procedure, job rotation, warning devices, etc.)

Perm partial disability

4 4 8 12 16 20 - Can Personal Protective Equipment & Clothing be worn to

Reversible significant environmental impact safeguard against hazards?

Loss AED 5M - 10M

Medium

Injury / illness = more than 5 work day loss 16 - 25 Very High Risk Unacceptable

3 3 6 9 12 15

Reversible moderate environmental impact

Loss AED 1M – 5M

9 - 15 High Risk Undesirable

Low

Injury / illness = 1 or more day loss

2 2 4 6 8 10 5-8 Medium Risk Caution

Reversible moderate environmental impact

Loss AED100K – 1M

3-4 Low Risk Tolerable

Very Low

Injury / illness = no lost day

1 1 2 3 4 5 1-2 Very Low Risk Acceptable

Nuisance release with no adverse impact

Loss less than AED100K

1 2 3 4 5

Risk assessment developed / reviewed by team as identified on attached register.

Authorized By Designation Signature

Resi

Hazard Who/What can Risk Risk

P S Control Measures P Ri

What can cause Harm? be harmed? What can happen? Rank Ra

Page 1 of 8 Risk Assessment No: 00 (Hot Work Activity) Rev. 00 (Date :)

RISK ASSESSMENT

1.Access to Work Area

Engineering hazards Employees Injury to the Work force 3 4 12H 1. Ensure all required document approval has been 1 4L

obtained.

Unauthorized entry 2. Obtain all necessary passes to access the Airside areas for

site personal requiring to access site to complete work

required

3. Ensure work area is clear and safe.

4. Ensure all safety requirements are complied with contract

requirements.

5. Ensure all constraints on operations have been identified

and precautions are taken.

6. Employee inductions and tool Box talks for discussing risks

assessment and identification and control measures of

hazards.

2.Gas welding and Cutting works

Careless handling of a Employees Fire; Injury/Fatality and 4 4 16H 1. Wear protective clothing, gauntlets and eye protection. 1 4L

lighted blowpipe Property damage 2. Remove any combustible materials (such as flammable

resulting in burns to the Property liquids, wood, paper, textiles, packaging or plastics) away

user or others; Damage from the work area.

using the blowpipe too 3. Ventilate spaces where vapours could accumulate, such as

close to combustible vehicle pits or trenches.

material; 4. Shut off the blowpipe when not in use. Do not leave

alighted blowpipe on a bench or the floor as the force of

the flame may cause it to move.

5. Protect any combustible materials that cannot be moved,

from close contact with flame, heat, sparks or hot slag.

Use suitable guards or covers such as metal sheeting,

mineral fiber boards or fire retardant blankets.

6. Check and make sure that there are no combustible

materials hidden behind walls or partitions which could be

ignited, particularly if prolonged welding or cutting is

planned. Some wall panels contain flammable insulation

Page 2 of 8 Risk Assessment No: 00 (Hot Work Activity) Rev. 00 (Date :)

RISK ASSESSMENT

materials.

7. Use guards or covers to prevent hot particles passing

through openings in floors and walls (doorways, windows,

etc).

8. Maintain a continuous fire watch during the period of the

work, and for at least an hour afterwards;

9. Keep fire extinguishers nearby.

10. Keep hoses clear of sharp edges and abrasive surfaces or

where vehicles can run over them;

11. Do not allow hot metal or spatter to fall on hoses.

12. Handle cylinders carefully. Keep them in an upright

position and fasten them to prevent them from falling or

being knocked over. For example, chain them in a

wheeled trolley or against a wall.

13. Always turn the gas supply off at the cylinder when the

job is finished;

14. Regularly check all connections and equipment for faults

and leaks.

15. Always provide adequate ventilation during welding and

cutting operations.

16. Store gas cylinders outside (Shaded Area) whenever

possible or in a well-ventilated place.

17. Avoid taking gas cylinders into poorly ventilated rooms or

confined spaces.

18. Never allow oil or grease to come into contact with

oxygen valves or cylinder fittings.

19. Working pressure of the acetylene gas must never exceed

15psi.

20. Use the correct lighting up procedure. Purge the hoses

before lighting the blowpipe to remove any potentially

explosive gas mixtures. Use a spark ignitor and ignite the

gas quickly after turning it on.

Page 3 of 8 Risk Assessment No: 00 (Hot Work Activity) Rev. 00 (Date :)

RISK ASSESSMENT

21. Flash back arrestors to be fitted at both ends of the hoses.

3.Arc Welding

Careless handling of Employees Electric Shock and burns, Fire, 4 4 16H 1. Never allow any part of the body to become a part of the 1 4L

welding machine. Injury/Fatality and Property electrical circuit.

Property damage 2. Inspect cable, connections, and the amperage setting

Damage before starting the welding

3. Do not harm the welding cables, electrode holder, ground

clamp, or welding machine in any way.

4. Stand on a dry surface when welding.

5. Do not watch the electric arc without proper eye

protection.

6. In order to prevent electrical shock, radiation exposure,

and burns when welding, wear a welding face shield,

leather gloves, leather apron, cotton or wool long pants,

and long sleeved shirts.

7. Always guard your face and eyes when chipping slag.

8. Always make sure that observers are protected from the

arc.

9. Weld in well ventilated areas to avoid toxic fumes.

10. Before welding, make sure that the welding area is free of

flammable materials such as gasoline, paint, rags, and

grease.

11. Handle hot metal with pliers or tongs.

12. Prevent burns by cooling hot metal promptly, storing

metal when not in use, and never touching the electrode

or electrode holder to bare skin.

13. Do not allow the electrode to stick to the metal. If this

occurs turn off the Welding machine, allow electrode to

cool, and then break off with gloved hand.

14. Dispose of electrode stubs properly to avoid falls and

burns to feet.

15. Use both hands to avoid fatigue.

Page 4 of 8 Risk Assessment No: 00 (Hot Work Activity) Rev. 00 (Date :)

RISK ASSESSMENT

16. Secure all equipment in its proper place before leaving the

area.

4.Cutting and grinding with angle grinder

Possible eye injury to persons. 3 4 12H 1 4L

Hazards leading to eye 1. All the operators must wear eye protection.

injuries.

3 3 9M

Hand injury Possible hand injury to persons. 1. Proper PPE should be in place and MSDS to be followed.

1 3L

Only qualified and trained persons are to be allowed to

work.

Excessive noise Noise induced hearing loss from 2 3 6M 1. Regular inspection of equipment to ensure that the 1 3L

the machine and breaking equipment is in a good state of repair

process. 2. Hearing protection to be used by operator and other

workers within the noise zone.

3. Signage to be displayed that it is a temporary noise zone.

4 4 16H 1 4L

Fire hazard Injury to persons and property 1. Hot work permit should be obtained prior to start the

damage work.

2. Fire extinguisher to be kept near by the cutting area.

3. Proper housekeeping to be done and area to be free from

combustible materials.

4. Fire blankets will be used next of operational area to

prevent sparks in all direction.

5. Working in Hot Humid Climate

Heat Stress Employees Dehydration 4 4 16H 1. Provide drinking water for all work locations 1 4

Collapse 2. Provide oral rehydrating solution/electrolyte to

Fatigue compensate the loss due to sweating.

Heat Stroke 3. Provide shaded rest areas for all work locations

4. Heat stress awareness training to be conducted

5. Displaying awareness Posters

6. Regular Tool box talks on heat stress

7. Toilets to have urine colour charts posted to aid self-

assessment of dehydration levels

Page 5 of 8 Risk Assessment No: 00 (Hot Work Activity) Rev. 00 (Date :)

RISK ASSESSMENT

8. Adherence to summer working hours regulations

9. Planning of critical tasks in cooler conditions.

Risk Assessment Review (May) 2018 or following an

26-Apr-2017 1 Year Date of Next Review

Effective Date Period incident

Developed / Reviewed By: (Team shall consist of representatives with experience in the activity and of all levels where possible.)

Date Name Designation Company Signature

Page 6 of 8 Risk Assessment No: 00 (Hot Work Activity) Rev. 00 (Date :)

RISK ASSESSMENT

RISK ASSESSMENT COMMUNICATION ATTENDANCE RECORD:

Date Name Designation Company Employee Code Signature

Page 7 of 8 Risk Assessment No: 00 (Hot Work Activity) Rev. 00 (Date :)

RISK ASSESSMENT

Page 8 of 8 Risk Assessment No: 00 (Hot Work Activity) Rev. 00 (Date :)

You might also like

- Answer Key WB CHPT 2 14-17Document2 pagesAnswer Key WB CHPT 2 14-17api-26466818275% (8)

- Risk Assessment For Pools Maintenance Al Ain ZooDocument13 pagesRisk Assessment For Pools Maintenance Al Ain Zooطارق رضوان100% (1)

- 03 - Risk Assessment-Material ShiftingDocument4 pages03 - Risk Assessment-Material Shifting287No ratings yet

- FINITE ELEMENT 18ME73 ASSIGNMENTSDocument10 pagesFINITE ELEMENT 18ME73 ASSIGNMENTSFOODIE USNo ratings yet

- D2340 - 13 Standard Test Method For Peroxides in Styrene Monomer PDFDocument3 pagesD2340 - 13 Standard Test Method For Peroxides in Styrene Monomer PDFJacques BlueqNo ratings yet

- 014 - Manual HandlingDocument4 pages014 - Manual HandlingPrem ChristianNo ratings yet

- Laying of Road Crossing Duct For Irrigation WorksDocument9 pagesLaying of Road Crossing Duct For Irrigation Workssajin0% (2)

- Risk Assessment for Carpet Cleaning OperationsDocument4 pagesRisk Assessment for Carpet Cleaning Operationsmohammed ayazNo ratings yet

- Site Risk Register Summarizes Facility HazardsDocument4 pagesSite Risk Register Summarizes Facility HazardsvatasaNo ratings yet

- Personal Protective Equipment Hazard AssessmentDocument5 pagesPersonal Protective Equipment Hazard AssessmentKrsnaPentayah100% (1)

- Risk Assessment of Fabrication, Welding, Cutting WorkDocument7 pagesRisk Assessment of Fabrication, Welding, Cutting WorkAbdul MujeebNo ratings yet

- Job Risk Asessment. Excavation 8-6-22Document3 pagesJob Risk Asessment. Excavation 8-6-22Mohammed Ali Qazi100% (1)

- RISK ASESSMENT For SKYLIGHTDocument23 pagesRISK ASESSMENT For SKYLIGHTadeoye Adeyemi100% (1)

- UG RA 009 - Light Materials and Equipment Loading and UnloadingDocument6 pagesUG RA 009 - Light Materials and Equipment Loading and Unloadingshamshuddin100% (1)

- Qrc-Ra-001-00-Road and Footpath Modification WorksDocument27 pagesQrc-Ra-001-00-Road and Footpath Modification WorksKallem RajashekarNo ratings yet

- BSD - 019 Bulk EarthworksDocument3 pagesBSD - 019 Bulk EarthworksZakkaudin KhanNo ratings yet

- Task /activity: Installation of Abseil HooksDocument10 pagesTask /activity: Installation of Abseil HooksfrancisbautistaNo ratings yet

- RA For Snake BiteDocument5 pagesRA For Snake Biteshamroz khan100% (1)

- Temporary Fencing Risk AssessmentDocument7 pagesTemporary Fencing Risk AssessmentIrfan Prima AldiNo ratings yet

- 31.0.11 ALR - Temporary Electrical InstallationDocument3 pages31.0.11 ALR - Temporary Electrical InstallationGerritNo ratings yet

- F 5.3 C Star-Safety-Inspection-JULYDocument4 pagesF 5.3 C Star-Safety-Inspection-JULYSn Ahsan100% (1)

- Appendix 3 01 Health Safety and Fire Regulations 3rd EditionDocument168 pagesAppendix 3 01 Health Safety and Fire Regulations 3rd EditionB.Peer Muhammad NishathNo ratings yet

- QHSEDOCS-Demolition Work Activities Risk AssessmentDocument14 pagesQHSEDOCS-Demolition Work Activities Risk AssessmentLawrence adeleke OmisakinNo ratings yet

- Deep Excavation Risk AssessmentDocument12 pagesDeep Excavation Risk Assessmentdonfrancis639No ratings yet

- 31.0.10 LLA - Manual HandlingDocument4 pages31.0.10 LLA - Manual HandlingGerritNo ratings yet

- HVAC Risk AssesmentDocument8 pagesHVAC Risk Assesmentaaktgt MepNo ratings yet

- CRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardDocument4 pagesCRA - Structural Steel Staircase Fabrication Works at Leighton Plant YardRiyas Mangodan100% (1)

- Training: No Training Type To WhomDocument26 pagesTraining: No Training Type To Whomطارق رضوانNo ratings yet

- Schedule For Inspection Aug 19Document1 pageSchedule For Inspection Aug 19Siddharth RanaNo ratings yet

- Job Safety Analysis - Pipeline Bending (38 charactersDocument6 pagesJob Safety Analysis - Pipeline Bending (38 charactersMoaatazz NouisriNo ratings yet

- Risk Assessment For Disinfection - SterilizationDocument3 pagesRisk Assessment For Disinfection - Sterilizationطارق رضوان0% (1)

- Risk Assessment - Glazing PDFDocument3 pagesRisk Assessment - Glazing PDFAngel GrospeNo ratings yet

- 003 SWMS - ExcavationDocument11 pages003 SWMS - Excavationsasi kumar50% (2)

- 04 JSA - Welding WorksDocument6 pages04 JSA - Welding Workssyed khaja misbhuddinNo ratings yet

- Risk Assessment for Bodily Fluid Spillage CleaningDocument2 pagesRisk Assessment for Bodily Fluid Spillage Cleaningmohammed ayazNo ratings yet

- Boom Lift - Working FromDocument5 pagesBoom Lift - Working Fromwahyu nugrohoNo ratings yet

- Crane-Hydra-deployment For Lifting-Lowering-Risk AssessmentDocument4 pagesCrane-Hydra-deployment For Lifting-Lowering-Risk AssessmentAhmed El-sherpiniNo ratings yet

- Hot Work Safety MeasuresDocument6 pagesHot Work Safety Measurestamoor sarwarNo ratings yet

- Risk Assessment - Plumbing Pump SetDocument8 pagesRisk Assessment - Plumbing Pump SetJhOichriz Reginaldo Cuevas100% (1)

- Risk Assessment Ground Collapse 8Document5 pagesRisk Assessment Ground Collapse 8Ali Almarshad100% (1)

- RA Underground Fire Pipe Installation Work R02Document15 pagesRA Underground Fire Pipe Installation Work R02vinayNo ratings yet

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- Risk Assessment - Hand ToolsDocument2 pagesRisk Assessment - Hand ToolsRoy Chandra Sekar JeyapaulNo ratings yet

- JSA for Pipeline Crossing WorksDocument6 pagesJSA for Pipeline Crossing WorksMajdiSahnounNo ratings yet

- Risk Assessment of Trees MaintenanceDocument9 pagesRisk Assessment of Trees Maintenanceطارق رضوان100% (1)

- Job Safety Analysis (Jsa) N2.Document5 pagesJob Safety Analysis (Jsa) N2.Joseph Paul IlaganNo ratings yet

- RA - (LPG System)Document26 pagesRA - (LPG System)Md ShahinNo ratings yet

- HSE RA 032 Diesel Storage Rev 0Document11 pagesHSE RA 032 Diesel Storage Rev 0عمروNo ratings yet

- RA For Builders Work A59Document11 pagesRA For Builders Work A59Sajid ShahNo ratings yet

- Updated - Risk Assessment - Preventive Maintenance at REMELT AREADocument13 pagesUpdated - Risk Assessment - Preventive Maintenance at REMELT AREAKareem MohamedNo ratings yet

- 7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineDocument5 pages7.OHS-PR-09-03-F02 HIRA - 30 Hydro Testing of Gas PipelineabbasNo ratings yet

- Hazard Identification & Risk Assessment FormDocument3 pagesHazard Identification & Risk Assessment FormChandra Shekar EmaniNo ratings yet

- SCP109 - Risk Assessment For Glass Partition EditedDocument4 pagesSCP109 - Risk Assessment For Glass Partition EditedamenmohdNo ratings yet

- Brazing (Oxygen and Acetylene)Document6 pagesBrazing (Oxygen and Acetylene)My Zain100% (1)

- HSE-RA-007 Crane Usage - Rev 0Document13 pagesHSE-RA-007 Crane Usage - Rev 0عمروNo ratings yet

- Visitors HSES InductionDocument30 pagesVisitors HSES InductionPradeep KunduNo ratings yet

- Risk Assessment - Concrete PouringDocument6 pagesRisk Assessment - Concrete Pouringabdullah ashrafNo ratings yet

- Risk Assessment For Coring WorksDocument5 pagesRisk Assessment For Coring WorksFaizan Tanveer100% (1)

- Water Proofing JSADocument9 pagesWater Proofing JSARamNo ratings yet

- HSE Inspection Report SummaryDocument5 pagesHSE Inspection Report SummaryAnonymous kWfNFb100% (1)

- HSE-RA-023 Site Establishment - Rev 0Document17 pagesHSE-RA-023 Site Establishment - Rev 0عمروNo ratings yet

- CSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Document12 pagesCSCEC HSE-F-01 Risk Assessment Form - Excavation& Backfilling - RA-02Dan SarmientoNo ratings yet

- HSE Risk Assessment For Hot Work ActivityDocument11 pagesHSE Risk Assessment For Hot Work ActivityGokul pNo ratings yet

- Task Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Document3 pagesTask Risk Assessment Enter Company Name AMG: Risk Evaluation (Refer To Evaluation Form)Faizan ShabbirNo ratings yet

- Window Fixing JSA HSE ProfessionalsDocument2 pagesWindow Fixing JSA HSE ProfessionalsDarseen RNo ratings yet

- Structural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDocument2 pagesStructural Fabrication & Erection by Using Hydra or Farana JSA HSE ProfessionalsDarseen RNo ratings yet

- ConfinedspaceDocument54 pagesConfinedspaceAlonso Olaya RuizNo ratings yet

- MirrorDocument2 pagesMirrorDarseen RNo ratings yet

- Utility FogDocument33 pagesUtility Fogarjun c chandrathil50% (2)

- Piping Materials Match Chart (ASTM) - ProjectmaterialsDocument14 pagesPiping Materials Match Chart (ASTM) - ProjectmaterialsdhurjatibhuteshNo ratings yet

- Heavy Duty Pavement Design Guide 1Document94 pagesHeavy Duty Pavement Design Guide 1askarahNo ratings yet

- Pages From LBS - RCF4 - DFAC Cabling - Additional Submittals - 03JAN23 - Red SizeDocument7 pagesPages From LBS - RCF4 - DFAC Cabling - Additional Submittals - 03JAN23 - Red Sizemohammed mustafaNo ratings yet

- Electrochemical TechniquesDocument35 pagesElectrochemical Techniquesfatema100% (1)

- Synthesis and Characterization of Schiff Base Ligands and Their Metal ComplexesDocument9 pagesSynthesis and Characterization of Schiff Base Ligands and Their Metal Complexesmaryam Saket OsgoueiNo ratings yet

- Ignition Characteristics of Cracked JP-7 FuelDocument4 pagesIgnition Characteristics of Cracked JP-7 Fuelfahrul3xNo ratings yet

- PDF ST PROLITE Vertrieb en 3 2020.en - UndefinedDocument6 pagesPDF ST PROLITE Vertrieb en 3 2020.en - UndefinedArgenis Emmanuel Rodriguez MarianoNo ratings yet

- 1 s2.0 S1359431123015909 MainDocument33 pages1 s2.0 S1359431123015909 Mainfabio1199No ratings yet

- 3751 QD Almagard®Vari PurposeLubricant3751Document4 pages3751 QD Almagard®Vari PurposeLubricant3751Celular Oil Control 05No ratings yet

- ASTM A615 Physical TestDocument44 pagesASTM A615 Physical TestSasha BrausNo ratings yet

- Chemistry in Your Cupboard: GavisconDocument16 pagesChemistry in Your Cupboard: Gavisconarnold espinaNo ratings yet

- Sikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemDocument5 pagesSikadur - 42 MP Normal HC: 3-Part, Multi Purpose Epoxy Grouting SystemJay PadamaNo ratings yet

- Sandfilter - Lenntech PDFDocument2 pagesSandfilter - Lenntech PDFargaNo ratings yet

- Nuodex BroschüreDocument4 pagesNuodex BroschüreviettaNo ratings yet

- Fermi World Fermi Material 2022Document42 pagesFermi World Fermi Material 2022MishaNo ratings yet

- Chemical Reaction Unit Test - QuizizzDocument4 pagesChemical Reaction Unit Test - QuizizzAngkita KiranaNo ratings yet

- Engineering Geology: Katsuo Sasahara, Naoki SakaiDocument9 pagesEngineering Geology: Katsuo Sasahara, Naoki SakaiRehan HakroNo ratings yet

- Shell Moulding Production ProcessDocument21 pagesShell Moulding Production ProcessUzair AzziNo ratings yet

- Dulux Weather Shield Sealer A93118177Document3 pagesDulux Weather Shield Sealer A93118177zorozulNo ratings yet

- ESA SyllabusDocument2 pagesESA SyllabusAshish VajirNo ratings yet

- Tribological Behavior of UHMWPE Reinforced with Graphene Oxide NanosheetsDocument10 pagesTribological Behavior of UHMWPE Reinforced with Graphene Oxide NanosheetsA P BNo ratings yet

- Dispensing Non-Bulk Ingredients/Additive SDocument19 pagesDispensing Non-Bulk Ingredients/Additive SRoma Diane AvigueteroNo ratings yet

- Experiment On Single PieceDocument3 pagesExperiment On Single PieceZatchBell100% (4)

- Fatai Kolawole Ikumapayi Lic2010Document182 pagesFatai Kolawole Ikumapayi Lic2010Gaurav MeshramNo ratings yet

- Packing and GasketsDocument59 pagesPacking and GasketsSteve WanNo ratings yet

- TOT Nevastane XSH 220 2018 - SDSDocument8 pagesTOT Nevastane XSH 220 2018 - SDSHENDRA TNo ratings yet