Professional Documents

Culture Documents

SMI - BBSR - OPN - WI 04.02, Fixing of Copper Plate On Dummy Plate & Hammer Peening

Uploaded by

ImmalatulhusnaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SMI - BBSR - OPN - WI 04.02, Fixing of Copper Plate On Dummy Plate & Hammer Peening

Uploaded by

ImmalatulhusnaCopyright:

Available Formats

SMS GROUP

WORK INSTRUCTION

Title :Fixing of Copper Plate on Dummy plate

Doc. No : SIS/CLG/OPN/WI/05

fixture and Hammer Peening

Date : 08.05.2015 Issue : 01 Rev : 00 Rev. Date : 00 Page 1 of 2

Safety Accessories:

Safety Glass, Ear buds, Hand gloves, Nose Mask, Safety Shoe

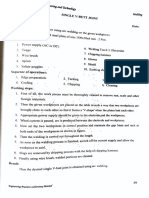

Sl. No. Activity Tools Required Responsibility Quality Standards

Fixing of Copper plate on Dummy plate fixture

1. Check thread condition of lifting holes, re-tap if required.

2. Fix lifting eye-bolts on the copper plate and lift it with EOT crane. Rotate the Copper plate

to keep the cold face on top. Synthetic slings,

3. Place the Copper plate on the rubber sheet. D-shackles, Eye bolt,

4. Bring the dummy plate fixture above the copper plate and align the dummy plate with the EOT crane, CNC

1 copper plate.

Adjustable torque Supervisor

5. Gently place the dummy plate fixture on the copper plate, with all bolts aligned with the

copper plate holes. wrench, Feeler gauge

6. Mark & tighten according to the sequence tightening sheet and tighten all the bolts with 100 (0.05 – 1.00 mm)

Nm torque in 1st step, 160 Nm torque 2nd step and 200 Nm torque 3rd step.

7. Rotate the dummy plate fixture with hot face on top and place it on a rubber sheet and check

gap with feeler gauge.

2 Hammer Peening Peening Hammer, CNC

Check for the meniscus area. Peening should not be done on meniscus area Scale, Measuring Supervisor

If the top band is in meniscus area move it below. tape, Marker

The centre line of peening should be 100 mm below the lower band of meniscus area.

Instructions:

1. Draw the centre line of the copper plate with the help of marker.

2. Draw lines 1” above & below the centre line.

3. Draw a line 9” below the top face (1” below Marked ‘DO NOT PEEN’ area on the fig

below, this is the meniscus area).

4. Draw lines 1” above & below this line.

5. Draw another line 4” above the bottom face and Draw lines 1” above & below this line.

Note: These 3 bands are our peening area (Marked as “2”WIDE PEENING AREA”)

6. Use hammer peening equipment. Hold the peening hammer straight on the copper plate and

start peening work inside these 2” wide peening bands.

7. Move the peening hammer along the marked 2” wide peening bands, at 2ft/min.

Prepared By: Approved By. Issued By Date

Signature/Date: Signature/Date:

SMS GROUP

WORK INSTRUCTION

Title :Fixing of Copper Plate on Dummy plate

Doc. No : SIS/CLG/OPN/WI/05

fixture and Hammer Peening

Date : 08.05.2015 Issue : 01 Rev : 00 Rev. Date : 00 Page 2 of 2

8. After the job is done, rotate the fixture with hot face down and place the dummy plate fixture

firmly on the rubber sheet. Re-tighten the bolts as per tightening sequence at 200 Nm torque.

9. Rotate the fixture with hot face up and place it on the rubber sheet.

FIG. MARKING FOR HAMMER PEENING

TOP

9” DO NOT PEEN (MENISCUS AREA) 8”

2” WIDE PEENING AREA 2”

2” WIDE PEENING AREA 2”

2” WIDE PEENING AREA 2”

3”

BOT

Prepared By: Approved By. Issued By Date

Signature/Date: Signature/Date:

You might also like

- Medupi Units 6 To 1 Structural Steel Daily Update.: Unit: 6Document1 pageMedupi Units 6 To 1 Structural Steel Daily Update.: Unit: 6Mbalekelwa MpembeNo ratings yet

- F.QC.22 Checklist Diafragma WallDocument40 pagesF.QC.22 Checklist Diafragma WallAndre SitumeangNo ratings yet

- Level 1 Deck Lifting - Lifting LugDocument20 pagesLevel 1 Deck Lifting - Lifting LugNag RajNo ratings yet

- Medupi Units 6 Shutdown Daily Update.: Unit: 6Document1 pageMedupi Units 6 Shutdown Daily Update.: Unit: 6Mbalekelwa MpembeNo ratings yet

- Manual Da Máquina Strecker Se1Document13 pagesManual Da Máquina Strecker Se1Lucas ChavesNo ratings yet

- Dynamic Behavior SMT Chip Capacitors During Solder Reflow: AbstmctDocument8 pagesDynamic Behavior SMT Chip Capacitors During Solder Reflow: AbstmctJim DotNetNo ratings yet

- Phase IV Welder Module 1.2Document15 pagesPhase IV Welder Module 1.2Magdi SiamNo ratings yet

- Assembly Manual: Table of ContentDocument23 pagesAssembly Manual: Table of ContentSigens WindestNo ratings yet

- New Operator Training ManualDocument35 pagesNew Operator Training ManualBharat ChakravartinNo ratings yet

- MCR 2606 11l+installation+manual 3Document45 pagesMCR 2606 11l+installation+manual 3Haider FaresNo ratings yet

- Team E User Manual 1Document12 pagesTeam E User Manual 1Luis IgnacoNo ratings yet

- SMR 301 WP Installation ManualDocument19 pagesSMR 301 WP Installation ManualCarlos de la VegaNo ratings yet

- Common Rail Injector Repair Tool Sets Instruction ManualDocument17 pagesCommon Rail Injector Repair Tool Sets Instruction ManualAnonymous 5tkF5bFwO100% (1)

- Methodology - Well Sinking-Foundation PDF-1Document7 pagesMethodology - Well Sinking-Foundation PDF-1Tina J100% (1)

- ASS2005002801 D Roxtec RS Ex Seal Installation Instruction enDocument4 pagesASS2005002801 D Roxtec RS Ex Seal Installation Instruction enRicardo RbNo ratings yet

- Welder Visual Inspection HandbookDocument77 pagesWelder Visual Inspection HandbookfaizalzolNo ratings yet

- GC LiSi Press Working InstructionsDocument8 pagesGC LiSi Press Working InstructionsAbdo SerboutiNo ratings yet

- Project 3 - Fabricated Mokume Band - Steven JacobDocument1 pageProject 3 - Fabricated Mokume Band - Steven Jacobmajope1966No ratings yet

- Detailed Inspection Report On 12 Inches Obigbo Sales Manifold - NGCDocument38 pagesDetailed Inspection Report On 12 Inches Obigbo Sales Manifold - NGCBethelSilasNo ratings yet

- Fabric Manu FacDocument15 pagesFabric Manu FacStudent AkashNo ratings yet

- DENSO X2 Instruction PDFDocument13 pagesDENSO X2 Instruction PDFQuy MingNo ratings yet

- DENSO X2 InstructionDocument13 pagesDENSO X2 InstructionAnonymous 5tkF5bFwO100% (3)

- CONTRACT NO.20705 Bitumen Storage Facility AT Port Khalid SharjahDocument17 pagesCONTRACT NO.20705 Bitumen Storage Facility AT Port Khalid SharjahFaruk OcalNo ratings yet

- Urea StripperDocument15 pagesUrea Strippermujahidali500100% (1)

- Ford WiringDocument6 pagesFord WiringGilberto Dipiento100% (1)

- Welders Visual Inspection Handbook-2013 WEB PDFDocument77 pagesWelders Visual Inspection Handbook-2013 WEB PDFketanNo ratings yet

- Prepared by Deepak A Vishwakarma .: Roll No L081040008 T Y B Tech ProductionDocument30 pagesPrepared by Deepak A Vishwakarma .: Roll No L081040008 T Y B Tech ProductionDIPAK VINAYAK SHIRBHATE100% (2)

- WCET FFP Challenge FactsheetDocument13 pagesWCET FFP Challenge FactsheetMohd Idris MohiuddinNo ratings yet

- Molex Maquina Terminales 2002181900-000Document8 pagesMolex Maquina Terminales 2002181900-000FransoloNo ratings yet

- JJJJJLKLLDocument5 pagesJJJJJLKLLsubodhasinghNo ratings yet

- Prepare Terminations-Crimping Lugs With Cable Ends: ObjectivesDocument3 pagesPrepare Terminations-Crimping Lugs With Cable Ends: ObjectivesVenkatesan SundaramNo ratings yet

- Smi Cable Gland - Better by DesignDocument2 pagesSmi Cable Gland - Better by DesignamiteshNo ratings yet

- Crack Detection & RepairDocument19 pagesCrack Detection & Repairጦቢያ TOBIYANo ratings yet

- T-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Document23 pagesT-OD-18000017A 132kV EB-A(喉箍)组装作业说明书(EN)√Abdulhanan Shaukat AliNo ratings yet

- Frame StructuresDocument10 pagesFrame StructuresPeetNo ratings yet

- Weld Cracks in An Ammonia Converter: James D. CampbellDocument6 pagesWeld Cracks in An Ammonia Converter: James D. Campbellvaratharajan g rNo ratings yet

- Hand Crimp Tool Specification Sheet: Order No. 63811-5200Document6 pagesHand Crimp Tool Specification Sheet: Order No. 63811-5200AbhinavNo ratings yet

- Conversion D Rola STD. D A P.PDDocument11 pagesConversion D Rola STD. D A P.PDOvh MaquinariasNo ratings yet

- SteelDocument55 pagesSteels170955 V. RajeshNo ratings yet

- Instruction Manual Spot Drilling CollarsDocument13 pagesInstruction Manual Spot Drilling CollarsArmando SixtoNo ratings yet

- 39 Pinhole Porosity 5 SLDocument11 pages39 Pinhole Porosity 5 SLJosé SermeñoNo ratings yet

- Student Manual of Torsional Damped & Un Damped ApparatusDocument3 pagesStudent Manual of Torsional Damped & Un Damped ApparatusaqibNo ratings yet

- Millenium Drilling Lacht Wipstock PackerDocument5 pagesMillenium Drilling Lacht Wipstock PackerErnest DelacarcovaNo ratings yet

- RDSO Maintenance Manual For G-90 BTPNDocument34 pagesRDSO Maintenance Manual For G-90 BTPNIndian RailwayNo ratings yet

- Mastering The Art of Soldering - en r03Document48 pagesMastering The Art of Soldering - en r03juanaNo ratings yet

- Procedure For Recambering of Flat Wagon Type BRN BRNA BRNAHSDocument17 pagesProcedure For Recambering of Flat Wagon Type BRN BRNA BRNAHScmpuran sseNo ratings yet

- 0 - Welding ExperimentDocument6 pages0 - Welding ExperimentSrinivas SrinivasNo ratings yet

- How To Minimize Project Cost PropertyDocument75 pagesHow To Minimize Project Cost PropertyLìññYëîkPäìñg100% (1)

- N Channel, P Channel Fabrication by School of MicroelectronicsDocument44 pagesN Channel, P Channel Fabrication by School of MicroelectronicsjouleNo ratings yet

- AEL Stope Blasting Handbook 2016Document60 pagesAEL Stope Blasting Handbook 2016DOC LAB100% (2)

- Printed in GermanyDocument8 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- DEKSTRIP Expandable Edged Flashing Product Data 661408Document2 pagesDEKSTRIP Expandable Edged Flashing Product Data 661408luisNo ratings yet

- 119118-General 09 Tool GrindersDocument217 pages119118-General 09 Tool GrindersNathan RittenhouseNo ratings yet

- 2000 2030 Maint Manual REV7 3 17Document27 pages2000 2030 Maint Manual REV7 3 17PiedmontNo ratings yet

- Phase Iv Welder Module 1.3Document15 pagesPhase Iv Welder Module 1.3Magdi SiamNo ratings yet

- RST Instruments: Inclinometer Casing Repair ManualDocument4 pagesRST Instruments: Inclinometer Casing Repair ManualOscarAnibalAbantoCondoriNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- SMI - BBSR - OPN - F - 34A-F Roll Assembly Checklist (Internal)Document4 pagesSMI - BBSR - OPN - F - 34A-F Roll Assembly Checklist (Internal)ImmalatulhusnaNo ratings yet

- MTC Jfe Eh500Document2 pagesMTC Jfe Eh500ImmalatulhusnaNo ratings yet

- Your Event Guide To TAYLOR SWIFT THE ERAS TOURDocument9 pagesYour Event Guide To TAYLOR SWIFT THE ERAS TOURImmalatulhusnaNo ratings yet

- Sistim Tegangan &: Residual StressDocument52 pagesSistim Tegangan &: Residual StressImmalatulhusnaNo ratings yet

- Hydrogen Damage and EmbrittlementDocument9 pagesHydrogen Damage and EmbrittlementImmalatulhusnaNo ratings yet

- Duaplate D80 Weld Overlay: ManufactureDocument1 pageDuaplate D80 Weld Overlay: ManufactureImmalatulhusnaNo ratings yet

- Ultrasonic Flaw Detector: Sonocon ВlDocument32 pagesUltrasonic Flaw Detector: Sonocon ВlImmalatulhusnaNo ratings yet

- AWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiDocument1 pageAWS A5.9 ER310 BS EN ISO 14343-A-G (25 20) BS EN ISO 14343-B-SS310 JIS Z3321 Y310 GB/T 4241 H12Cr26Ni21SiImmalatulhusnaNo ratings yet

- Uniform CorrosionDocument33 pagesUniform CorrosionImmalatulhusnaNo ratings yet

- Welding Materials: Ultra-Precision Mold Padding WelderDocument4 pagesWelding Materials: Ultra-Precision Mold Padding WelderImmalatulhusnaNo ratings yet

- CHF101 CHW S16 PDFDocument1 pageCHF101 CHW S16 PDFImmalatulhusnaNo ratings yet

- Copper Alloys in Ingot Form: Standard Specification ForDocument12 pagesCopper Alloys in Ingot Form: Standard Specification ForImmalatulhusnaNo ratings yet

- Introduksi Analisa Kerusakan: (Introduction To Failure Analyses)Document13 pagesIntroduksi Analisa Kerusakan: (Introduction To Failure Analyses)ImmalatulhusnaNo ratings yet

- CHG 308LDocument1 pageCHG 308LImmalatulhusnaNo ratings yet

- Flux 15WDocument2 pagesFlux 15WImmalatulhusnaNo ratings yet

- Che43 PDFDocument1 pageChe43 PDFImmalatulhusnaNo ratings yet

- ZG42Cr1MoZG42CrMo Datasheet PDFDocument2 pagesZG42Cr1MoZG42CrMo Datasheet PDFImmalatulhusnaNo ratings yet

- CHM 316LDocument1 pageCHM 316LImmalatulhusnaNo ratings yet

- CHF101 CHW S12Document1 pageCHF101 CHW S12ImmalatulhusnaNo ratings yet

- Che506 PDFDocument1 pageChe506 PDFImmalatulhusnaNo ratings yet

- Abrasion and Corrosion: GB/T 984 Edzcr-B-08Document1 pageAbrasion and Corrosion: GB/T 984 Edzcr-B-08ImmalatulhusnaNo ratings yet

- CHT81 Ni 1Document1 pageCHT81 Ni 1ImmalatulhusnaNo ratings yet

- Pamphlet MG-51T PDFDocument2 pagesPamphlet MG-51T PDFImmalatulhusnaNo ratings yet

- CHG 56Document2 pagesCHG 56ImmalatulhusnaNo ratings yet

- CHR707Document1 pageCHR707ImmalatulhusnaNo ratings yet

- TDS - Nimrod C276KSDocument1 pageTDS - Nimrod C276KSImmalatulhusnaNo ratings yet

- Role of Losses in Design of DC Cable For Solar PV ApplicationsDocument5 pagesRole of Losses in Design of DC Cable For Solar PV ApplicationsMaulidia HidayahNo ratings yet

- Floating Oil Skimmer Design Using Rotary Disc MethDocument9 pagesFloating Oil Skimmer Design Using Rotary Disc MethAhmad YaniNo ratings yet

- Oracle - Prep4sure.1z0 068.v2016!07!12.by - Lana.60qDocument49 pagesOracle - Prep4sure.1z0 068.v2016!07!12.by - Lana.60qLuis AlfredoNo ratings yet

- Monkey Says, Monkey Does Security andDocument11 pagesMonkey Says, Monkey Does Security andNudeNo ratings yet

- Unit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptDocument6 pagesUnit 7: Anthropology: Q2e Listening & Speaking 4: Audio ScriptĐại học Bạc Liêu Truyền thông100% (1)

- IKEA SHANGHAI Case StudyDocument5 pagesIKEA SHANGHAI Case StudyXimo NetteNo ratings yet

- Principals' Leadership Styles and Student Academic Performance in Secondary Schools in Ekiti State, NigeriaDocument12 pagesPrincipals' Leadership Styles and Student Academic Performance in Secondary Schools in Ekiti State, NigeriaiqraNo ratings yet

- Assessment of Students' Oral Communication in English ClassDocument10 pagesAssessment of Students' Oral Communication in English ClassKeebeek S ArbasNo ratings yet

- Stress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingDocument9 pagesStress-Strain Modelfor Grade275 Reinforcingsteel With Cyclic LoadingRory Cristian Cordero RojoNo ratings yet

- Fusion Implementing Offerings Using Functional Setup Manager PDFDocument51 pagesFusion Implementing Offerings Using Functional Setup Manager PDFSrinivasa Rao Asuru0% (1)

- Chapter 13 Exercises With AnswerDocument5 pagesChapter 13 Exercises With AnswerTabitha HowardNo ratings yet

- Lecture 4 ENGR 243 DynamicsDocument45 pagesLecture 4 ENGR 243 DynamicsRobby RebolledoNo ratings yet

- Product CatalogsDocument12 pagesProduct Catalogscab666No ratings yet

- Test Your Knowledge - Study Session 1Document4 pagesTest Your Knowledge - Study Session 1My KhanhNo ratings yet

- Excon2019 ShowPreview02122019 PDFDocument492 pagesExcon2019 ShowPreview02122019 PDFSanjay KherNo ratings yet

- Retailing in IndiaDocument11 pagesRetailing in IndiaVinod MalkarNo ratings yet

- Project ManagementDocument11 pagesProject ManagementBonaventure NzeyimanaNo ratings yet

- E0 UoE Unit 7Document16 pagesE0 UoE Unit 7Patrick GutierrezNo ratings yet

- Android Developer PDFDocument2 pagesAndroid Developer PDFDarshan ChakrasaliNo ratings yet

- Vendor Information Sheet - LFPR-F-002b Rev. 04Document6 pagesVendor Information Sheet - LFPR-F-002b Rev. 04Chelsea EsparagozaNo ratings yet

- Checklist & Guideline ISO 22000Document14 pagesChecklist & Guideline ISO 22000Documentos Tecnicos75% (4)

- Hima OPC Server ManualDocument36 pagesHima OPC Server ManualAshkan Khajouie100% (3)

- Aleksandrov I Dis 1-50.ru - enDocument50 pagesAleksandrov I Dis 1-50.ru - enNabeel AdilNo ratings yet

- Tplink Eap110 Qig EngDocument20 pagesTplink Eap110 Qig EngMaciejNo ratings yet

- B.SC BOTANY Semester 5-6 Syllabus June 2013Document33 pagesB.SC BOTANY Semester 5-6 Syllabus June 2013Barnali DuttaNo ratings yet

- Traveling Salesman ProblemDocument11 pagesTraveling Salesman ProblemdeardestinyNo ratings yet

- Nutrition and CKDDocument20 pagesNutrition and CKDElisa SalakayNo ratings yet

- A Case Study Puga Geothermal System,: OF IndiaDocument7 pagesA Case Study Puga Geothermal System,: OF IndiaPERIKALA TARUNNo ratings yet

- Chapter 2 ProblemsDocument6 pagesChapter 2 ProblemsYour MaterialsNo ratings yet

- Agnes de MilleDocument3 pagesAgnes de MilleMarie-Maxence De RouckNo ratings yet