Professional Documents

Culture Documents

Method Statement of Sliding Door

Uploaded by

arabiangulfdoorest2008Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement of Sliding Door

Uploaded by

arabiangulfdoorest2008Copyright:

Available Formats

METHOD STATEMENT

SUPPLY & INSTALLATION OF POLYCARBONATE SHUTTER

01. Objective:

Objective of this method statement is to provide details and information of

procedure, quality and control relating to the supply, and installation of

polycarbonate shutter in accordance with the standard of practice as

recommended by the manufacturers.

The Job supervisor shall be responsible to ensure quality work and finishing, as

approved by way of work-shop drawing, in according with British standards and

to co-operate and coordinate with other Civil & MEP works contractors.

02. Scope of work:

Scope of work shall be to supply and install the polycarbonate shutter.

03. Manpower:

The following members of our workforce will be deployed for the work:

For mechanical Installation

(1) Job Supervisor -1

(2) Team head (Door Technician) -1

(3) Door technician -1

(4) Skilled helper -1

04. Equipment

The following equipment’s/machines and tools will be employed in the course of

installation.

a. Hammer.

b. Tape measure, pliers

c. Electric hand Grinding/Cutting Machine

d. Vice grip, Screw drivers, nails, Rope & Fire extinguishers

05. Consumable Material:

a. Hinges, Tapping screws

b. Fixing accessories for the doors

06. Installation method/procedure:

a) Removal of old shutter top support.

b) Dismantle the shutter .

c) Removal of shutter post.

d) Installation of new shutter post.

e) Install the top support for shutter.

f) Install the polycarbonate slate bundle.

g) Connecting the motor power.

h) Finally inspect the polycarbonate shutter working condition.

Quality Control:

A) Ensuring all clearance is maintained and doors are working without

encumbrances or hurdles.

B) Ensuring that quality and installation workmanship are in accordance with the

manufacturers’ recommended procedures.

C) Completing the installation of the work good standard and order ready for

commissioning with temporary or permanent power supply

07. Inspection

a) Preliminary Inspection will be done by our own Project Engineer,

b) Clients’ Engineer will be called for inspection of completion of

installation and report the same to Architects/Consultants.

08. Safety Requirements:

a) Site will be inspected and removed for any fire hazard, cleanliness and

/ or unhealthy conditions.

b) Any accident possibility will be eliminated & safe working condition

will be organized before start of work.

c) Work – in progress will be protected from any accident.

d) Fire extinguisher will be in place for any emergency.

e) Scaffolding / ladder / raiser if used will be securely and firmly placed

to ensure accident free working.

f) Site will be cleared for any debris or any hazardous material caused by

the installation work.

10. Protection of completed work:

Installed work shall be protected by the Clients suitably for prevention of

any damage and / or accident to the installed equipment by the Clients

own working persons or of any sub-contractors and the Clients liability

will be to make the work available for handover.

The Clients or their sub-contractors with on-going jobs at the site shall not

use the equipment until final handed over to the clients.

You might also like

- RIBA Client Care Letter - Domestic TemplateDocument2 pagesRIBA Client Care Letter - Domestic Templaterowan91No ratings yet

- Method Statement of Fire Alarm SystemDocument10 pagesMethod Statement of Fire Alarm Systemmidhun murali100% (6)

- Successful Instrumentation and Control Systems Design, Second EditionFrom EverandSuccessful Instrumentation and Control Systems Design, Second EditionRating: 4.5 out of 5 stars4.5/5 (10)

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Statement For First Fixed Electrical WorkDocument8 pagesStatement For First Fixed Electrical WorkHytham El-NoubyNo ratings yet

- Method Statement For Installation of 750kva SubstationDocument3 pagesMethod Statement For Installation of 750kva SubstationKM Mehedi Hasan67% (6)

- 9 Method Statement For Wall Mounted Split AC Testing & CommissioningDocument8 pages9 Method Statement For Wall Mounted Split AC Testing & CommissioningManikandan Balasubramanian100% (1)

- Method Statement For Electrical Conduit InstallationDocument14 pagesMethod Statement For Electrical Conduit Installationshareyhou100% (1)

- Method Statement For Electrical Surface Conduit InstallationDocument14 pagesMethod Statement For Electrical Surface Conduit Installationshareyhou100% (1)

- Daily Hazard Reporting FormDocument1 pageDaily Hazard Reporting FormArslanNo ratings yet

- Method Statement of Rolling Shutter-04.09.2023 - Dewa Supply & InstallationDocument2 pagesMethod Statement of Rolling Shutter-04.09.2023 - Dewa Supply & Installationarabiangulfdoorest2008No ratings yet

- Method of Statement - Sapin-18-08-2023Document2 pagesMethod of Statement - Sapin-18-08-2023arabiangulfdoorest2008No ratings yet

- Method of Statement-ACC2Document2 pagesMethod of Statement-ACC2arabiangulfdoorest2008No ratings yet

- Arabica at Musherib - MOSDocument14 pagesArabica at Musherib - MOSMohd AkkiNo ratings yet

- Method Statement Atkin BostonDocument7 pagesMethod Statement Atkin BostonAbu ThahirNo ratings yet

- Method of Statement For Maintenance of Rolling Shutter - 27-10-2023Document2 pagesMethod of Statement For Maintenance of Rolling Shutter - 27-10-2023arabiangulfdoorest2008No ratings yet

- Ms-Cable Tray InstallationDocument7 pagesMs-Cable Tray InstallationVane DG100% (1)

- CCTV SystemDocument5 pagesCCTV SystemsardarmkhanNo ratings yet

- Method Statement For NocDocument8 pagesMethod Statement For Nocابو غيثNo ratings yet

- Work MethodologyDocument3 pagesWork MethodologyJohn Renzel Rivera IIINo ratings yet

- Arabica Dowtwn MosDocument13 pagesArabica Dowtwn MosMohd AkkiNo ratings yet

- MOS Installation of DampersDocument4 pagesMOS Installation of DampersSuban HariNo ratings yet

- Method Statement - CCTVDocument7 pagesMethod Statement - CCTVamenmohd100% (1)

- Installation of Climaver DuctsDocument23 pagesInstallation of Climaver DuctsvinodkumarNo ratings yet

- Table of Contents TransformerDocument14 pagesTable of Contents Transformerahmad saffafNo ratings yet

- Rev - 05 - MS - Installation of Electric PVC ConduitsDocument7 pagesRev - 05 - MS - Installation of Electric PVC Conduitsanon_534254691100% (1)

- Method Statement For Room Control UnitDocument14 pagesMethod Statement For Room Control UnitshareyhouNo ratings yet

- Standard Operating Procedure - Fibre Optic InstallationDocument17 pagesStandard Operating Procedure - Fibre Optic InstallationKaavi MaharajNo ratings yet

- Work Method Statement PranavDocument8 pagesWork Method Statement PranavpranavdoorsNo ratings yet

- 00 - MS - Devices Wires InstallationDocument8 pages00 - MS - Devices Wires Installationhossam_24_6_722542No ratings yet

- Bak El BKN CX Ms 009Document31 pagesBak El BKN CX Ms 009emreNo ratings yet

- Method Statement For Aluminium WindowDocument7 pagesMethod Statement For Aluminium WindowSagar ParabNo ratings yet

- Method Statement For Electrical ServicesDocument6 pagesMethod Statement For Electrical ServicesUmaira ZainalNo ratings yet

- Purpose: Method Statement For Fiber Optic CablingDocument18 pagesPurpose: Method Statement For Fiber Optic Cablingabd masoudNo ratings yet

- Table of Contents: Method Statement FOR Power Factor Correction Capacitors InstallationDocument8 pagesTable of Contents: Method Statement FOR Power Factor Correction Capacitors Installationanon_534254691No ratings yet

- Work Methodology FOR Chipping and Restoration Works For ElectricalDocument5 pagesWork Methodology FOR Chipping and Restoration Works For ElectricalJohn Paul Hernandez100% (1)

- MOS For Installation of DX Type UnitDocument5 pagesMOS For Installation of DX Type Unitsuban hari kumarNo ratings yet

- 00 - MS - Diesel Generator InstallationDocument8 pages00 - MS - Diesel Generator InstallationHassen LazharNo ratings yet

- Method Statement DraftDocument9 pagesMethod Statement DraftJAMES neelNo ratings yet

- Applicable Projects Specification: Materials: Materials Used Will Be As Per The Material SubmittalDocument3 pagesApplicable Projects Specification: Materials: Materials Used Will Be As Per The Material SubmittalRICHARDSIBANDANo ratings yet

- Erection of LV Switchgears (PCC, MCC, Aux PDB'S)Document6 pagesErection of LV Switchgears (PCC, MCC, Aux PDB'S)Sutanu BiswasNo ratings yet

- Manzo - Typical Pipe Support Installation Rev 1Document4 pagesManzo - Typical Pipe Support Installation Rev 1Senzo NkwanyanaNo ratings yet

- Method Statment CEB BUILDINGDocument7 pagesMethod Statment CEB BUILDINGUpali KarunarathneNo ratings yet

- Method StatementDocument9 pagesMethod Statementtmopeli3130No ratings yet

- Method StatementDocument4 pagesMethod StatementshyankaranNo ratings yet

- Installation of GI Duct, Volume Dampers and Access DoorDocument20 pagesInstallation of GI Duct, Volume Dampers and Access DoorvinodkumarNo ratings yet

- Method Statement For Installation of Electric PVC Conduits and AccessoriesDocument6 pagesMethod Statement For Installation of Electric PVC Conduits and Accessoriesmidhun murali100% (1)

- 00 - MS - Electrical PanelBoards InstallationDocument8 pages00 - MS - Electrical PanelBoards Installationanon_534254691No ratings yet

- Risk Assessment Method Statement Documents: April 2007Document11 pagesRisk Assessment Method Statement Documents: April 2007Tamilchelvam MurogayahNo ratings yet

- Method Statement For Installation of Diesel Generator SetDocument7 pagesMethod Statement For Installation of Diesel Generator SetAnonymous 8xHUWB100% (5)

- Rev - 03 - Ms - Installation of Cable Tray or Trunking SystemDocument7 pagesRev - 03 - Ms - Installation of Cable Tray or Trunking Systemanon_534254691No ratings yet

- Rev - 10 - Ms - Installation of Lighting Control PanelDocument8 pagesRev - 10 - Ms - Installation of Lighting Control Panelanon_534254691No ratings yet

- 00 - MS - Transformer InstallationDocument8 pages00 - MS - Transformer InstallationMohd AliNo ratings yet

- Method Statement PVC Conduit InstallationDocument8 pagesMethod Statement PVC Conduit InstallationAzree Mohd Noor67% (3)

- Standard Operating Procedure - Civil WorksDocument7 pagesStandard Operating Procedure - Civil WorksKaavi Maharaj100% (1)

- Method Statement Gypsum BoardDocument6 pagesMethod Statement Gypsum Boardsajin100% (1)

- Wire and Cable InstallationDocument9 pagesWire and Cable InstallationqaqcmepteamNo ratings yet

- Method Statement For Installation of GRE PipingDocument11 pagesMethod Statement For Installation of GRE Pipingmichaelnicodemus93No ratings yet

- 00 - MS - MV Cable Pulling and InstallationDocument9 pages00 - MS - MV Cable Pulling and Installationanon_534254691100% (1)

- Methodology - LAISAMIS WATER PROJECTDocument4 pagesMethodology - LAISAMIS WATER PROJECTsatejaNo ratings yet

- MOS Installation of GI DuctDocument5 pagesMOS Installation of GI DuctSuban Hari100% (1)

- Procedure For ExcavationDocument9 pagesProcedure For ExcavationBhargav Bbvs100% (1)

- 01a CAPEX Overview - Basic (LH)Document25 pages01a CAPEX Overview - Basic (LH)herman rinaldiNo ratings yet

- Sol. Man. - Chapter 15 - Ppe Part 1 - Ia Part 1BDocument5 pagesSol. Man. - Chapter 15 - Ppe Part 1 - Ia Part 1BMahasia MANDIGANNo ratings yet

- Especificación QC2 - Martin InglésDocument2 pagesEspecificación QC2 - Martin InglésAntonio Mena MiñoNo ratings yet

- The Impact of Construction Waste To The PDFDocument9 pagesThe Impact of Construction Waste To The PDFIslamNo ratings yet

- 2010.06.09 Microsoft Word - Mechanical Particular Spec V2Document26 pages2010.06.09 Microsoft Word - Mechanical Particular Spec V2samanNo ratings yet

- Global Electric Service Provider: TBEA Shandong Luneng Taishan Cable Co., LTDDocument32 pagesGlobal Electric Service Provider: TBEA Shandong Luneng Taishan Cable Co., LTDmd saikotNo ratings yet

- Construction Management Manual - TH CSEDP - Ver 2 Rev 2 - June 5 - Eng - Cẩm nang quản lý thi côngDocument30 pagesConstruction Management Manual - TH CSEDP - Ver 2 Rev 2 - June 5 - Eng - Cẩm nang quản lý thi côngLe GiangNo ratings yet

- Real Estate Development Process and PrinciplesDocument6 pagesReal Estate Development Process and PrinciplesAbicha AlemayehuNo ratings yet

- Process Flow Diagrams (PFDS) Piping and Instrumentation Diagram (P&Id)Document6 pagesProcess Flow Diagrams (PFDS) Piping and Instrumentation Diagram (P&Id)Mateus Chingore ZindimoNo ratings yet

- Chew 2021Document22 pagesChew 2021Pedro Hygor100% (1)

- Sapients 2020 ProfileDocument7 pagesSapients 2020 ProfileVaradaraj CkNo ratings yet

- Repair and Replace Support LCP at CB3 Area 4BDocument23 pagesRepair and Replace Support LCP at CB3 Area 4BMUHAMAD ROZEE MAT AZMINo ratings yet

- Catalogo Adaptadores HidraulicosDocument97 pagesCatalogo Adaptadores HidraulicosGonzalo Villalobos SanchezNo ratings yet

- Liebherr - WikipediaDocument23 pagesLiebherr - WikipediaNUTHI SIVA SANTHANNo ratings yet

- Customised Service and Individual Solutions: Welcome To EMSTECDocument23 pagesCustomised Service and Individual Solutions: Welcome To EMSTEClpczyfansNo ratings yet

- Form CPTDocument4 pagesForm CPTUrhiel JuwehlekhNo ratings yet

- 01 2023 MR Wilson Contreras ResumeDocument14 pages01 2023 MR Wilson Contreras ResumeWily ContrerasNo ratings yet

- GDC LAYOUT UpdatedDocument1 pageGDC LAYOUT UpdatedPradneshNo ratings yet

- Portakabin 03 S033Document12 pagesPortakabin 03 S033AaronNo ratings yet

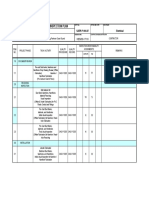

- Annex 2 Preliminary BOQ Package 40 Crew 2Document58 pagesAnnex 2 Preliminary BOQ Package 40 Crew 2GenetNo ratings yet

- PRK 9-Gravelling PowDocument16 pagesPRK 9-Gravelling PowDarwinlye GravinoNo ratings yet

- (Iss-00878) Afncvil048Document2 pages(Iss-00878) Afncvil048layaljamal2No ratings yet

- Ppe BuildingDocument7 pagesPpe BuildingHappyPurpleNo ratings yet

- SATIP-P-104-07 Rev 8 Final Bel Grade Conduit and Dduct Bank PDFDocument2 pagesSATIP-P-104-07 Rev 8 Final Bel Grade Conduit and Dduct Bank PDFSabheeh AliNo ratings yet

- NR-L3-CIV-006-07B - Handbook For Examination of Structures - BuildingsDocument16 pagesNR-L3-CIV-006-07B - Handbook For Examination of Structures - BuildingsnigelNo ratings yet

- CEA Report 2023 Final Download 3Document24 pagesCEA Report 2023 Final Download 3DuyNo ratings yet

- Study and Analysis of Low Cost Housing BDocument3 pagesStudy and Analysis of Low Cost Housing BPATRICE NICOLE TRINIDADNo ratings yet