Professional Documents

Culture Documents

Full P.E.W.T

Uploaded by

Jodrish OmarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Full P.E.W.T

Uploaded by

Jodrish OmarCopyright:

Available Formats

JAAMACADA EELO JAAMACADA EELO

EELO UNIVERSITY EELO UNIVERSITY

TITLE:

CONSTRUCTION OF A CONCRETE ELEVATED WATER TANK IN GOBSHO, MUDUG,

PUNTLAND, SOMALIA

SUBTITLE:

Addressing Water Storage Needs for Sustainable Agriculture and Domestic Usage

Submitted by:

Group 3: ID: NUMBER

BISHAAR IIMAN CUMAR [3736]

ABDIKARIM ABDULLAHI MOALIM [3748]

ASAD MOHAMED HUSSEIN [3585]

YUUSUF ABDULLAHI MOALIM [3747]

SAED ABDULLAHI MOHAMED [3822]

PROJECT: ELEVATED WATER TANK ESTIMATIONS 1

DECLARATION

We hereby declare that this report isour original work and all the writings here in are our personal efforts and in

other person’s material has been dully acknowledged

PROJECT: ELEVATED WATER TANK ESTIMATIONS 2

APPROVAL

This is to certify that this piece of work was done under my supervision and that it is the original work of the

above authors.

Eng. Adifatah Mohamud Obsiiye ……………………

PROJECT: ELEVATED WATER TANK ESTIMATIONS 3

DEDICATION

We dedicate this book to Our dear parents, sisters and brothers.

PROJECT: ELEVATED WATER TANK ESTIMATIONS 4

ACKNOWLEDGEMENT

All praises to Allah the most gracious the most merciful for his showers of blessings throughout our research

successfully.

In this part I would like to thank to Eng. Abdifatah Mohamud Obsiiye who guided us from beginning to the

end. If it was not for his guidance this report wouldn’t have been completed.

Furthermore, we would like to acknowledge with much appreciation the engineers and lecturers who assisted

Us and gave me their opinions about this project.

Last but not least We thankful to Our family who supported us in every way possible.

PROJECT: ELEVATED WATER TANK ESTIMATIONS 5

CONTENTS

DECLARATION................................................................................................................................................. 2

APPROVAL......................................................................................................................................................... 3

DEDICATION..................................................................................................................................................... 4

ACKNOWLEDGEMENT.................................................................................................................................. 5

CHAPTER ONE.................................................................................................................................................. 8

Introduction:...................................................................................................................................................... 8

BACKGROUND & RATIONALE....................................................................................................................9

Introduction:.................................................................................................................................................. 9

Project Rationale:........................................................................................................................................ 9

Conclusion:.................................................................................................................................................... 9

Project Objectives & Scope of Work...............................................................................................................10

Project Objectives:...................................................................................................................................... 10

Scope of Work:............................................................................................................................................ 10

Conclusion:.................................................................................................................................................. 10

Methodology.................................................................................................................................................. 11

Introduction:.............................................................................................................................................. 11

Key Methodological Aspects:....................................................................................................................11

Conclusion:.................................................................................................................................................. 11

Significance of Project & Conclusion............................................................................................................. 12

Significance of Project:............................................................................................................................... 12

Conclusion:.................................................................................................................................................. 12

CHAPTER TWO:................................................................................................................................................13

Water tank Design in Gobsho Region..............................................................................................................13

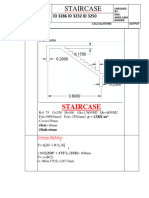

Designing Process of the tank for AutoCAD 2D with the elevations..............................................................15

Designing Process of the tank for ArchiCAD 3D with the elevations.............................................................16

CHAPTER THREE:......................................................................................................................................... 18

ESTIMATIONS:.............................................................................................................................................. 18

SITE CLEARANCE..................................................................................................................................18

LEAN CONCRETE.................................................................................................................................. 19

R.C.C FOOTING...................................................................................................................................... 20

R.C.C COLUMN....................................................................................................................................... 22

R.C.C BEAM............................................................................................................................................. 24

R.C.C SLAB............................................................................................................................................... 26

PROJECT: ELEVATED WATER TANK ESTIMATIONS 6

PLASTERING........................................................................................................................................... 28

BOQ PREPARATION...................................................................................................................................... 30

CHAPTER ONE:

Introduction:

Water scarcity in Gobsho city is a pressing concern, and addressing this challenge requires innovative solutions.

This proposal outlines a comprehensive project for the construction of a concrete elevated water tank, tailored

for sustainable agricultural practices and domestic water use. Led by Group 3, this group project aims to

implement a robust water storage system, ensuring a consistent and reliable water supply.

Key Components:

PROJECT: ELEVATED WATER TANK ESTIMATIONS 7

Aspect Details

Background & In-depth analysis of water scarcity issues, providing a rationale

Rationale for the project.

Project Clearly defined goals, including sustainable agriculture and

Objectives domestic water use.

Scope of Work Overview of the tasks and responsibilities within the project

scope.

Methodology Proposed methods for project execution, ensuring efficiency and

quality.

Significance of Discussion on the potential impact and benefits of the proposed

Project water tank.

Conclusion:

This executive summary provides a glimpse into the multifaceted aspects of the proposed project. The

subsequent sections will delve into each component, offering a thorough understanding of the project's depth

and significance.

PROJECT: ELEVATED WATER TANK ESTIMATIONS 8

BACKGROUND & RATIONALE

Introduction:

Water scarcity is a global challenge with direct implications for agriculture and daily life. We recognize the

need for a sustainable solution to address water storage deficits. The proposed concrete elevated water tank

project aims to serve as a pivotal step toward mitigating the impacts of water scarcity on agricultural activities

and domestic water needs.

Project Rationale:

The need for a concrete elevated water tank stems from the limitations of conventional water storage methods.

Concrete offers durability, stability, and longevity, ensuring the water tank's ability to withstand varying

environmental conditions. Additionally, the project aligns with broader sustainability goals by promoting

efficient water use and conservation.

Tables:

Water Scarcity Statistics Details

Global Water Scarcity Status [Statistics and trends related to global water scarcity.]

Regional Water Challenges [Specific challenges faced in the project region regarding

water scarcity.]

Conclusion:

Understanding the background and rationale behind the project sets the stage for a purposeful and impactful

initiative. The ensuing sections will delve into the practical aspects of the proposed concrete elevated water

tank.

PROJECT: ELEVATED WATER TANK ESTIMATIONS 9

Project Objectives & Scope of Work

Project Objectives:

The primary objectives of the concrete elevated water tank project are as follows:

1. Sustainable Agriculture: Enhance water availability for agricultural activities, promoting sustainable

farming practices.

2. Domestic Water Supply: Provide a reliable and continuous water supply for domestic usage.

3. Environmental Responsibility: Integrate eco-friendly features, such as rainwater harvesting, to align with

sustainability goals.

Scope of Work:

The scope of this project encompasses the following key tasks:

Task Responsibility

Site Assessment and Selection Project site assessment team

Design and Engineering Consultation Engineering design team

Regulatory Approvals Project regulatory compliance team

Excavation and Site Preparation Site preparation crew

Concrete WaterTankConstruction Construction team

Sealing and Interior Finishing Finishing team

Integration with Water Supply System Irrigation team

Conclusion:

Clearly defining the project objectives and the scope of work ensures a focused and systematic approach to

achieving the desired outcomes. The subsequent sections will delve into the methodology and the significance

of the proposed concrete elevated water tank.

PROJECT: ELEVATED WATER TANK ESTIMATIONS 10

Methodology

Introduction:

The methodology for the concrete elevated water tank in Gobsho project is rooted in a systematic and

collaborative approach. Leveraging the expertise of each team member, Group 3 aims to achieve the project

objectives with efficiency and precision.

Key Methodological Aspects:

1. Design Process: Collaborative efforts in designing a customized water

tank that meets the specific needs of sustainable agriculture and domestic water usage.

2. Engineering Excellence: Engaging in consultations with experts to ensure that the construction adheres to

the highest engineering standards, ensuring durability and stability.

3. Regulatory Compliance: Rigorous adherence to local regulations and obtaining necessary approvals for

seamless project execution.

4. Efficient Construction Practices: Utilizing modern construction techniques for excavation, concrete tank

construction, and finishing to ensure both speed and quality.

5. System Integration: Implementing cutting-edge technology for the seamless integration of the water tank

with the existing water supply system.

Conclusion:

A well-defined methodology is pivotal for the successful execution of the proposed concrete elevated water tank

project. The subsequent section will underscore the significance of the project, outlining the potential impact on

both the local community and the environment.

PROJECT: ELEVATED WATER TANK ESTIMATIONS 11

Significance of Project & Conclusion

Significance of Project:

The concrete water tank project holds substantial significance for various stakeholders, including the local

community, the environment, and future generations.

1. Community Impact: Reliable water supply for agriculture and domestic use improves living conditions and

enhances community resilience.

2. Environmental Contribution: Incorporating eco-friendly features, such as rainwater harvesting, reduces

reliance on external water sources, contributing to environmental sustainability.

3. Economic Boost: Increased agricultural productivity can positively impact the local economy, fostering

growth and development.

Conclusion:

In conclusion, the proposed concrete elevated water tank project is not merely a construction endeavor but a

concerted effort by Group 3 to address pressing issues related to water scarcity. We look forward to the approval

and support for this project, confident in its potential to be a beacon of sustainable water management practices.

PROJECT: ELEVATED WATER TANK ESTIMATIONS 12

CHAPTER TWO:

Water tank Design in Gobsho Region

Gobsho is small town located in Somalia, Mudug region Gobsho is 20 km away from east Galkayo

This small town consists of 150 houses and each house it’s a family of 7 member (5 children and 2 parents) and

the population will be

P = 150 x 7 = 1050 people

We plan this project for the 20 coming years. The population of the next 20 years, 2043 will be.

P2043 = Pe x (1 + IG¿n

Note the growth of Somalian is 3% per year.

P2043 = 1050 x (1 + 0.03¿20 = 1897

The population of the village will become 1897 people.

Now we find the Domestic water they use or need per day.

Domestic water L/ D / P

Dinking 4L

Cooking 10L

Pathing/clothing 15 L

School 30 L

Praying 5L

MCH 20 L

Total 84L/D/P + accessory

Total = 84 L/D/P

The charge is equal to population times percent.

Q = population x per capital

Q = 1897 x 84 = 159348 L/D

The people of this village are shepherd.

The average number of animals each family has 50 goats and the design in our tank to give a water 200 goats

per day and we know the average water needed in one goat per day is 5L.

5 x 200 = 10,000 L

The water will be.

159348 + 10000 = 169348 L/D

PROJECT: ELEVATED WATER TANK ESTIMATIONS 13

And we change this L/D into L/S

169348

=¿ 1.96 L/s

24 x 60 x 60

The charge maximum will be Q max = Q x daily max = 1.8 x 1.96 = 3.53 L/s

The next step is to find the storage and we will only store 30% of the total water

Storage = 20% x 169348 x 1.8 = 61 m3

And our tank will be rectangular.

V=Axh

And we assume the height of our tank is 2.5 m

61 m3 = A x 2.5 m

3

61 m

A= = 24.4 m2

2.5 m

A=LxW

2

24.4 m = 6.1 m and the length and width is 4 m

The pressure of the water will be

P = 61 x 9.81 = 598.4 KN

Designing Process of the tank for AutoCAD 2D with the elevations

PROJECT: ELEVATED WATER TANK ESTIMATIONS 14

PROJECT: ELEVATED WATER TANK ESTIMATIONS 15

Designing Process of the tank for ArchiCAD 3D with the elevations

PROJECT: ELEVATED WATER TANK ESTIMATIONS 16

PROJECT: ELEVATED WATER TANK ESTIMATIONS 17

CHAPTER THREE:

ESTIMATIONS:

SITE CLEARANCE EXCAVATION OF FOOTING

Area of clearance: 6.1 x 4 = 24.4m2 Area of Excavation footing: 1.5 x 1.5 =2.25m2

1 unskilled labour = 20 m2 Volume of Excavation footing: 2.25 x 1 =

24.4 2.25m3

= 1.22 = 2 unskilled labour

20

Number of excavations: 6 x 2.25m3 = 13.5m3

2 x $8 = $16

1 unskilled can excavate = 0.5 m3 – 1.5 m3

1

One Forman = so we take one Forman So, we take 1.5 m3.

20

13.5

One Forman =$25 Number of unskilled = = 9 unskilled

1.5

Total cost of site clearance

labors

$16 + $25 = $41

Cost of labor = 9 x $8 = $72

Rate of site clearance

One Forman = $25

41

= $1.7 m2. Total cost of Excavation footing

24.4

$72 + $25 = $97

Rate of excavation footing

97

= $7.2 m3

13.5

PROJECT: ELEVATED WATER TANK ESTIMATIONS 18

LEAN CONCRETE

2

Area = 1.5mX 1.5m = 2.25m 2. Cost of labours

Volume of the lean concrete 2.25m2 x 0.2m = 3. Meson

3

0.45m3 2.7 m

1 = 5m3 , 3

=0.54=1meson

0.45 M3 X 6 = 2.7 m3 5m

Ratio of concrete we take m20, 1:1.5:3 = 5.5 Cost of meson: 1 x $16 = $16

1. Cost of materials 4. Mixers

1. Cement 1 = 3m3=¿ 2.7m3 /¿3m3= 0.9 mixers

1 0.49 Cost of mixers: 1 x $10 = $10

x 2.7=0.49= = 14.03= 14 bags

5.5 0.035 5. Unskilled

Cost of cement: 14 x $ 9 = $126 1= 0.9m3 = 2.7m3 /0.9 m3 = 3

2. Sand Cost of unskilled: 3 x $8 = $24

1, 5 0.74 Total cost of labors

x 2.7 = 0.74= =0.368=1 loads

5.5 2

• Meson = $16

Cost of sand: 1 x $25 = $25

• Mixers = $10

3. Gravel

• Unskilled = $24

3 1.47

x 2.7 = 1.47 =0.74=1 loads Total cost of labor = $50

5.5 2

Cost of gravel: 1 x $45 = $45

4. Water Total cost of a slab

14 x 100 • Total cost of material =$206.5

= 7 barriers

200 • Total cost of labor = $50

Cost of water: 7 x $1.5 = $10.5 Total cost of the lean concrete = $206.5 +

Total cost of materials $50 = $256.5

• Cement = $126

• Sand = $25 contingency 5% = $12.825+ $256.5 =

• Gravel = $45 $269.325

• Water = $10.5 269.4

= 99.75 = $100/m3

Total cost of materials =206.5 2.7

Rate of Column = $100m3

PROJECT: ELEVATED WATER TANK ESTIMATIONS 19

R.C.C FOOTING

2

Area (1.5 x 1.5) = 2.25m Vertical length of bars: 9 + 9 + 9 + 9 = 36 x 0.5

Volume of the Footing 2.25m2 x 0.5m = 1.125m3 = 18 m

1.125 M3 X 6 = 6.75 m3 Total length of bars:

Ratio of concrete we take m20, 1:1.5:3 = 5.5 488 m + 18 =506m

1. Cost of materials 506m/ 12 m = 42.16 = 43 main bars

2 2

1. Cement d 12

x L=¿ x 12=10.66 x 43 = 428.41 kg

1 1.23 162 162

x 6.75=1.23= = 35.06= 35 bags

5.5 0.035 Cost of bars: 43 x $14 = $602

Cost of cement: 35 x $ 9 = $315

2. Sand Total cost of materials

1, 5 1.84 • Cement = $315

x 6.75 = 1.84 = =0.92=1loads

5.5 2 • Sand = $25

Cost of sand: 1 x $25 = $25 • Gravel = $90

3. Gravel • Water = $27

3 3.68

x 6.75 = 3.68 =1.84=2loads • Steel bars = $602

5.5 2

Total cost of material = $1059

Cost of gravel: 2 x $45 = $90

4. Water

35 x 100

= 17.5 = 18 barrier

200

Cost of water: 18 x $1.5 = $27

5. Main bars

Distance b/w bars = 20 cm

∅ main= 12 mm, L =12m

1.5

=9 x 1.5m = 11.25m of bars

0.2

1.5

= 9 x 1.5m = 11.25m of bars

0.2

Horizontal length of bars: 122 + 122 = 244 m x2 =

488m

PROJECT: ELEVATED WATER TANK ESTIMATIONS 20

2. Cost of labours Total cost of labours

1. Steel fixers • Steel fixers = $100

1 = 100kg, 428.41 kg/100 kg = 4.28 = 5 steel fixers • Meson = $32

Cost of steel fixers: 5 x $16 = $80 • Mixers = $20

Steel fixer helper = 2 x $10 = $20. T = $100 • Unskilled = $64

2. Meson Total cost of labour = $158

3

6.75 m

1 = 5m3 , 3

=1.35=2 meson

5m Total cost of footing

Cost of meson: 2 x $16 = $32 • Total cost of material =$1059

3. Mixers • Total cost of labour = $158

3 3 3

1 = 3m =¿ 6.75m /¿3m = 2 .25 mixers Total cost of the footing = $158 + $1059 =

Cost of mixers: 2 x $10 = $20 $1218

5. Unskilled

1= 0.9m3 =6.75m3 /0.9 m3 = 7.5 contingency 10% = $121.8 + $1218 = $1339.8

Cost of unskilled: 8 x $8 = $64 1339.8 .

= 198.5 = $200/m3

6.75

Rate of Footing = $200m3

PROJECT: ELEVATED WATER TANK ESTIMATIONS 21

R.C.C COLUMN

2

Area = 0.4mX 0.4m = 0.16m 9. Main bars

Volume of the Column 0.16m2 x 6.5m = 1.04m3 ∅ main= 12 mm, L =12m

1.04 M3 X 6 = 6.24 m3 Total length of bars: 10 x 6.5m = 65m of steel

Ratio of concrete we take m20, 1:1.5:3 = 5.5 65

= = 5.42 = 6 x 6 column = 36 main bars

12

1. Cost of materials

2 2

2. Cement d 12

x L=¿ x 12=10.66 x 36 = 383.76 kg

162 162

1 1.135

x 6.24=1.135= = 32.4= 33 bags Cost of bars: 36 x $14 = $504

5.5 0.035

Cost of cement: 33 x $ 9 = $297 10. Strippers

3. Sand ∅ main= 6 mm, L =12m

1, 5 1.7018 6.5

x 6.24 = 1.7018= =0.85=1 loads = 22 x 6 =132 of steel bar = 132 x 1.6m =

5.5 2 0.3

Cost of sand: 1 x $25 = $25 211.2 m

2 2

4. Gravel d 6

x L=¿ x 12=2.66 x 17 = 45.33 kg

162 162

3 3.403

x 6.24 = 3.403 =1.7018=2 loads

5.5 2 211.2 m of strippers. 211.2/ 12 = 17 stripper

Cost of gravel: 2 x $45 = $90 17 x $9 = $158.4

5. Water

33 x 100 Total cost of materials

= 16.5 = 17 barrier

200 • Cement = $297

Cost of water: 17 x $1.5 = $25.5 • Sand = $25

6. Frame wood • Gravel = $90

2

Area = (0.4m + 0.4m) x2 = 1.6m x 6.5 =10.4 m • Water = $25.5

2

Area of flat wood (comesato) 1.5x2 = 3m = $22 • Nails = $20

2 2

Cost of frame wood: 10.4m /3m = 3.466 = 4 x • Steel Main bars = $504

$22 = $88 • Stripper bars =$158.4

7. Supporting wood of the column(isteli) • Frame Wood = $88

48pics /16 = 3 x $20 = $60 • Support steel for slab = $60

8. Nail & wires Total cost of material = $1267.9

20kg x $1 = $20

PROJECT: ELEVATED WATER TANK ESTIMATIONS 22

2. Cost of labours Total cost of labours

1. Steel fixers • Steel fixers = $90

1 = 100kg, 429.04 kg/100 kg = 4.3 = 5 steel • Carpenters = $42

fixers • Meson = $32

Cost of steel fixers: 5 x $16 = $80 • Mixers = $20

Steel fixer helper =2 x $10 = $20. T = $90 • Unskilled = $56

2. Carpenters Total cost of labor = $240

1 = 10m2, 10.4m2/ 10m2 =1.04 = 2 carpenter

Cost of carpenters: 2 x $ 16 = $32 Total cost of a slab

Carpenter’s helper = 1 x $10 = $10. T = $42 • Total cost of material =$1267.9

4. Meson • Total cost of labour = $240

6.24 m

3

• Total cost of the slab = $1267.9 + $240 =

1 = 5m , 3

3

=1.248=2 meson

5m $1507.9

Cost of meson: 2 x $16 = $32

5. Mixers contingency 10% = $150.7 + $1507.9 = $1658.6

3 3 3

1 = 3m =¿ 6.24m /¿3m = 2.08 mixers 1658.6

= 265.8 = $266/m3

Cost of mixers: 2 x $10 = $20 6.24

6. Unskilled Rate of Column = $266m3

1= 0.9m3 =6.24m3 /0.9 m3 = 7

Cost of unskilled: 7 x $8 = $56

PROJECT: ELEVATED WATER TANK ESTIMATIONS 23

R.C.C BEAM

2

Area = 19.6mX 0.4m = 7.84m 8. Main bars

Volume of the Beam 7.84m2 x 0.3m = 2.352m3 ∅ main= 12 mm, L =12m

Ratio of concrete we take m20, 1:1.5:3 = 5.5 Total length of bars: 6 x 19.6m = 117.6m of steel

1. Cost of materials 117.6

= = 9.8 = 10 main bars

12

1. Cement

2 2

1 0.43 d 12

x 2.352=0.43= = 12.2 = 13 bags x L=¿ x 12=10.66 x 10 = 106.6 kg

5.5 0.035 162 162

Cost of cement: 13 x $ 9 = $11 Cost of bars: 10 x $14 = $140

2. Sand 9. Strippers

1, 5 0.64 ∅ main= 6 mm, L =12m

x 2.352 = 0.64 = =0.32=1loads

5.5 2 19..6

= 65.3 steel bar = 65 x 1.5m = 97.5 m

Cost of sand: 1 x $25 = $25 0.3

3. Gravel 98 m of strippers. 98/ 12 = 8 stripper

3 1.3 8 x $9 = $72

x 2.352 = 1.3 =0.64=1loads

5.5 2 d

2

6

2

x L=¿ x 12=2.66 x 8 = 21.28 kg

Cost of gravel: 1 x $45 = $45 162 162

4. Water

13 x 100 Total cost of materials

= 6.5 = 7 barrier

200 • Cement = $117

Cost of water: 7 x $1.5 = $10.5 • Sand = $25

5. Frame wood • Gravel = $45

Area = 19.6 x (0.4) base fr +( 0.3 + 0.3) x19.6 • Water = $10.5

2

both side fr = 19.6 m of flat wood • Nails = $20

2

Area of flat wood (comesato) 1.5x2 = 3m = $22 • Steel Main bars = $140

Cost of frame wood: 19.6m2/3m2 = 6.53 = 7 x • Stripper bars =$72

$22 = $154 • Frame Wood = $154

6. Supporting steels of the slab • Support steel for slab (rent) = $39

39 pics x $1 = $39 Total cost of material = $623

7. Nail & wires

20kg x $1 = $20

PROJECT: ELEVATED WATER TANK ESTIMATIONS 24

2. Cost of labours Total cost of labours

1. Steel fixers • Steel fixers = $42

1 = 100kg, 127.28 kg/100 kg =1.27 = 2 steel • Carpenters = $42

fixers • Meson = $16

Cost of steel fixers: 2 x $16 = $32 • Mixers = $10

Steel fixer helper = 1 x $10 = $10. T = $42 • Unskilled = $24

2. Carpenters Total cost of labour = $134

1 = 10m2, 19.6m2/ 10m2 =1.96 = 2 carpenter

Cost of carpenters: 2 x $ 16 = $32 Total cost of a slab

Carpenter’s helper = 1 x $10 = $10. T = $42 • Total cost of material =$623

3. Meson • Total cost of labour = $134

2.352m

3

• Total cost of the slab = $623 + $134 =

1 = 5m , 3

3

=0.47=1 meson

5m $757

Cost of meson: 1 x $16 = $16

4. Mixers contingency 10% = $75.7 + $757 = $832.7

3 3 3

1 = 3m =¿ 2.352m /¿3m = 0.78 mixers 832.7

= 354 = $354/m3

Cost of mixers: 1 x $10 = $10 2.352

5. Unskilled

Rate of Beam = $354m3

1= 0.9m3 =2.352m3 /0.9 m3 = 2.61

Cost of unskilled: 3 x $8 = $24

PROJECT: ELEVATED WATER TANK ESTIMATIONS 25

R.C.C SLAB

2

Area (6.1 x 4) = 24.4m 8. Nail & wires

Ly 6.1 20 kg x $1 = $20

= = 1.5 < 2 there is two-way slab

Lx 4 9. Main bars

L 610 cm Distance b/w bars = 20 cm

Thickness of the slab = = 25 cm

24 24

∅ main= 12 mm, L =12m

Volume of the slab 24.4m2 x 0.25m = 6.1m3

4

Ratio of concrete we take m20, 1:1.5:3 = 5.5 =21 x 6.1m = 128.1m of bars

0.2

1. Cost of materials 6.1

= 31.5 x 4m = 126m of bars

6. Cement 0.2

1 1.1 Total length of bars: 128 + 126 = 254m / 12 m =

x 6.1=1.1= = 31.7 = 32 bags

5.5 0.035 21 = 21 main bars

Cost of cement: 32 x $ 9 = $288 2 2

d 12

x L=¿ x 12=10.66 x 21 = 223.86 kg

7. Sand 162 162

1, 5 1.66 Cost of bars: 21 x $14 = $294

x 6.1 = 1.66 = =0.83=1loads

5.5 2

Total cost of materials

Cost of sand: 1 x $25 = $25

• Cement = $288

8. Gravel

• Sand = $25

3 3.3

x 6.1 = 3.3 =1.16=2loads • Gravel = $90

5.5 2

• Water = $24

Cost of gravel: 2 x $45 = $90

• Nails = $20

9. Water

• Steel bars = $294

32 x 100

= 16 = 16 barrier • Frame Wood = $220

200

Cost of water: 16 x $1.5 = $24 • Support steel for slab (rent) = $36

6. Frame wood Total cost of material = $997

Area = 24.4m2 + (0.25 x 4) x2 +( 0.25 x 6.1) x2 =

29.45 m2 of flat wood

Area of flat wood (comesato) 1.5x2 = 3m2 = $22

Cost of frame wood: 30m2/3m2 = 10 = 10 x $22 =

$220

7. Supporting steels of the slab

36 pics x $1 = $36

PROJECT: ELEVATED WATER TANK ESTIMATIONS 26

2. Cost of labours Total cost of labours

4. Steel fixers • Steel fixers = $58

1 = 100kg, 223.86 kg/100 kg =2.238 = 3 steel fixers • Carpenters = $58

Cost of steel fixers: 3 x $16 = $48 • Meson = $32

Steel fixer helper = 1 x $10 = $10. T = $58 • Mixers = $20

5. Carpenters • Unskilled = $56

1 = 10m2, 27m2/ 10m2 =2.7 = 3 carpenter Total cost of labour = $224

Cost of carpenters: 3 x $ 16 = $48

Carpenter’s helper = 1 x $10 = $10. T = $58 Total cost of a slab

6. Meson • Total cost of material =$975

3

6.1 m • Total cost of labour = $224

1 = 5m3 , 3

=1.22=2 meson

5m • Total cost of the slab = $997 + $224 =

Cost of meson: 2 x $16 = $32 $1221

7. Mixers

1 = 3m3=¿ 6.1m3 /¿3m3= 2 mixers contingency 10% = $122.1 + $1221 = $1343.1

Cost of mixers: 2 x $10 = $20 1343.1.

= 220.18 = $221/m3

10. Unskilled 6.1

1= 0.9m3 =6.1m3 /0.9 m3 = 6.8

Rate of Slab = $221m3

Cost of unskilled: 7 x $8 = $56

PROJECT: ELEVATED WATER TANK ESTIMATIONS 27

PLASTERING PAINTING

Area = 30.5+20+48.8 = 99.3m Area of the elevated tank is

1.6 x 6 = 57.6m = (2.5 x 4)x2 + (6.1 x 2.5)x2

17.08+16.8 = 33.88m 20m2 + 30.5 + (6.1 x 4 )x2

Total Area:190.75m2 20m2 +30.5 + 48.8 = 99.3m2

125 This area is the area of only tank and know we

190.75m2 x = 23.8m3

1000

find the area of beams and columns

Ratio we take: 1:6

The area o columns

1. Cost of materials

(0.4 x 6)

1. Cement

(2.4m2) x sides of the column =2.4m2 x 4

1 3.4

x 23.8=3.4= = 97.14= 97 bags 9.6m2 this is the area of one column

7 0.035

The number of columns we have is 6

Cost of cement: 97 x $ 9 = $873

6 x 9.6m2 =57.6m2

2. Sand

Area of beams

6 20.4

x 23.8 = 20.4 = =10.2=10loads

7 2 2(3.2m x 0.4) + (3.2 x 0.3)2

Cost of sand: 10 x $25 = $250 2.56m2 + 2.88 = 5.44m2

3. Water (5.44m2 + 4 beams)

97 x 100 21.76m2

= 48.5 = 49 barrier

200 The other beams are

Cost of water: 49x $1.5 = $73 (0.4 x 4) x 2 + (0.3 x 4) x 2

Labour Cost: 2 x (1.6m2) + (1.2m2)2

One man can plastering = 24m2/day 3.2m2 + 2.4m2 = 5.6m2

190.75 (5.6m2 x 4 beam)

= 7.9 = 8 skilled labours

24

22.4m2

Cost: $8 x 8 =$64

The total area is

190.75

mason 2 = 7.5 = 8 mason A= 99.3m2 + 57.6m2 + 22.4m2 + 21.m

25.6 m

Total area= 201.2m2

Cost:$18 x 8 =144

Material cost:

1. Mixers

1bag contains 35kg and coat 50m2

1 8/6 = 1.33 mixers = 2 mixers

Number of bags 201.2m2/50m2 = 4.02 =4 bags

Cost of mixers: 2 x $10 = $20

Cost: $5 X 4 = $ 20

Total cost: $1424

1424 Stucco:

= 59.8 = $60/m3

23.8 Applying two coats of external wall surface

PROJECT: ELEVATED WATER TANK ESTIMATIONS 28

Base of the building size 201.2 x 2 = 402.4m2

Description : Construction rubble stone One tin can coat = 152m2

foundation if the areas of height o=0.4m Number of tine = 402.4m2/152m2

and 0.8 width and total length of 7.6m 2.647 = 3 tin

,mixed ratio 1:6 Cost: $6 x 3 = $18

Quantity = 7.6m*0.8m*0.4m= 2.56𝑚3 Distempering: apply two coats of distempering

35% of mortar ,65% stone on external

Volume of stone = 2.43𝑚3*0.65=1.58𝑚3 201.2 x 2 = 402.4m2

We use truck load capacity of stone 2.5𝑚3 One tin can coat = 152m2

Number of loads stone = Number of tin = 402.4 m2/152m2 = 3tin

1.58𝑚3/2𝑚3=0.79 Cost: $9 x 3 = $27

1 loads Labour cost:

Cost of stone = $35*1= $35 One skilled labour: can do 50m2

mortar = 2.43𝑚3*0.35=0.85𝑚3 201.2m2/50m2 = 4.04 so is 4 skilled labours

1. Cost of materials Cost $16 x 4 = $64

1. Cement Mason: 1

1 0.14 Cost: $18 x 1 = $18

x 0.85=0.14= = 4 bags

6 0.035 Total Cost: $147

Cost of cement: 4 x $ 9 = $36 147 .

= 0.7 = $1/m2

2. Sand 201.2

6 0.72

x = 0.85 = =1=1 loads

7 2

Cost of sand: 1x $25 = $25

3. Water

4 x 100

= 2 = 2 barrier

200

Cost of water: 2 x $1.5 = $3

Unskilled labour: 4 unskilled

Cost: $8 x 4 = $32

helper labour: 2 helpers

cost: $8 x 2 = $16

mixers

1mixer $10

PROJECT: ELEVATED WATER TANK ESTIMATIONS 29

1 mason $20

Total cost:$177

Rate :$210

BOQ PREPARATION

PROJECT: ELEVATED WATER TANK ESTIMATIONS 30

You might also like

- Godey Town Water Supply: Internship Report OnDocument26 pagesGodey Town Water Supply: Internship Report Onsharmo abdirahman100% (1)

- Unit 8 (HIGHWAY DRAINAGE)Document27 pagesUnit 8 (HIGHWAY DRAINAGE)Zara Nabilah91% (22)

- Dry Fasting The AMAZING Health Benefits Everyone Should Know AboutDocument4 pagesDry Fasting The AMAZING Health Benefits Everyone Should Know AboutMariaNo ratings yet

- Material Balance 2017170615161317Document52 pagesMaterial Balance 2017170615161317etayhailuNo ratings yet

- MMS-How To Make It-By Jim HumbleDocument9 pagesMMS-How To Make It-By Jim Humblephilalethes2456No ratings yet

- MarineDocument16 pagesMarineNguyễn Thị Kim PhượngNo ratings yet

- Building Maintenance StandardsDocument15 pagesBuilding Maintenance StandardsManika KashyapNo ratings yet

- Water Treatment Plant Design ProjectDocument22 pagesWater Treatment Plant Design ProjectOzzoman Duke71% (7)

- Project Report Format22Document32 pagesProject Report Format22ashi ashiNo ratings yet

- Top Roof Rain Water Harvesting (Isa Sunasara)Document38 pagesTop Roof Rain Water Harvesting (Isa Sunasara)Isa Sunasara67% (6)

- Revised National Plumbing Code of The Philippines - 1 PDFDocument112 pagesRevised National Plumbing Code of The Philippines - 1 PDFKyra Aleson100% (1)

- Preservation Through CanningDocument6 pagesPreservation Through CanningChinmaya SahuNo ratings yet

- 001 Energy Conservation and Ea PGDCDocument157 pages001 Energy Conservation and Ea PGDCsaiNo ratings yet

- Project Report On Forced Convection Solar DehydratorDocument52 pagesProject Report On Forced Convection Solar DehydratorPradnesh Mokal100% (1)

- BQS667 - Task 3 - Project Report PM-03 CaaDocument76 pagesBQS667 - Task 3 - Project Report PM-03 CaaSiti Aisyah IleyesNo ratings yet

- Design of Sewage Treatment Plant For Saraswati Hi Tech City PrayagrajDocument38 pagesDesign of Sewage Treatment Plant For Saraswati Hi Tech City PrayagrajB Baboo B100% (3)

- Effect of Duration of Curing On Compressive Strength of ConcreeeteDocument50 pagesEffect of Duration of Curing On Compressive Strength of ConcreeetealexomputuNo ratings yet

- LET Reviewer 4Document84 pagesLET Reviewer 4jovan amihanNo ratings yet

- Heap Leach DesignDocument10 pagesHeap Leach DesignustavNo ratings yet

- Diffusion Through A Membrane LabDocument5 pagesDiffusion Through A Membrane LabKasey FullerNo ratings yet

- Bahar Dar ProjectDocument87 pagesBahar Dar Projectmulalem baheruNo ratings yet

- Arjo Rport PDFDocument41 pagesArjo Rport PDFrahel abrahamNo ratings yet

- Group 9 Final ReportDocument7 pagesGroup 9 Final Reportziziphomkosana2003No ratings yet

- ThesisDocument34 pagesThesisFacts fidaNo ratings yet

- Fabrication of Mini Refrigerator For Life Protecting ContainerDocument43 pagesFabrication of Mini Refrigerator For Life Protecting Containerashok kumar KNo ratings yet

- Integrate Project FinalDocument129 pagesIntegrate Project FinalNaafNo ratings yet

- DIPLOMA ProjectDocument25 pagesDIPLOMA ProjectMahir aliNo ratings yet

- EWB 28 - Design Proposal - Rev 01Document5 pagesEWB 28 - Design Proposal - Rev 01TIAN VAN WYKNo ratings yet

- Woliso Town WSS DesignDocument87 pagesWoliso Town WSS DesignAbdulbasit Aba Biya100% (1)

- Trade Project KevinDocument21 pagesTrade Project Kevinakinyisheril36No ratings yet

- Free Energy WaterpumpDocument38 pagesFree Energy WaterpumpDanial FitriNo ratings yet

- Cubaan Dengan TemplateDocument26 pagesCubaan Dengan TemplateFarhanaNo ratings yet

- Feb 540: Engineering Design Project 2015/2016 ACADEMIC YEAR: Department of Environmental and Biosystems EngineeringDocument75 pagesFeb 540: Engineering Design Project 2015/2016 ACADEMIC YEAR: Department of Environmental and Biosystems Engineeringmacklyn tyanNo ratings yet

- CE MoskovDocument62 pagesCE Moskov886sbNo ratings yet

- Efficiency For Access Design ChallengeDocument19 pagesEfficiency For Access Design ChallengeAlexNo ratings yet

- SewerageDocument47 pagesSewerageB SRINIVASNo ratings yet

- University of Nairobi: Feb 540: Engineering Project-Report 2017/2018Document62 pagesUniversity of Nairobi: Feb 540: Engineering Project-Report 2017/2018macklyn tyanNo ratings yet

- Research Proposal LastDocument35 pagesResearch Proposal LastGada MitikuNo ratings yet

- DoiAndrew 2000 MRM272Document109 pagesDoiAndrew 2000 MRM27221131A04J2 NUTULAPATI NAGA SRIPADA VALLABHA ABHIRAMNo ratings yet

- Sustainability Assessment of Hydropower ProjectsDocument14 pagesSustainability Assessment of Hydropower ProjectsHaposanNo ratings yet

- 1 Shor Small Scale Irrigation Project Finished End LastDocument119 pages1 Shor Small Scale Irrigation Project Finished End LastOtoma OrkaidoNo ratings yet

- Lrs Project Group 13Document55 pagesLrs Project Group 13Gabriel ChingarandeNo ratings yet

- AREPORTOnE WastemanagementDocument17 pagesAREPORTOnE WastemanagementKholoud RedaNo ratings yet

- 2013-Design and Development of Solar Dryer FoDocument47 pages2013-Design and Development of Solar Dryer FoK. VenkyNo ratings yet

- Main ReportDocument31 pagesMain ReportSandeep PandeyNo ratings yet

- Border Hydropower Project 3rd EditionDocument173 pagesBorder Hydropower Project 3rd Editionyared sitotawNo ratings yet

- Border Hydropower Project 3rd Edition PDFDocument171 pagesBorder Hydropower Project 3rd Edition PDFyared sitotawNo ratings yet

- Group 15 Lrs Compiled Project0001Document73 pagesGroup 15 Lrs Compiled Project0001Gabriel ChingarandeNo ratings yet

- Design and Development of Solar Dryer For Fruit Chips: Technical ReportDocument47 pagesDesign and Development of Solar Dryer For Fruit Chips: Technical ReportBicaaqaa M. AbdiisaaNo ratings yet

- Development of A Leakage Target Setting Approach For South Korea Based On Economic Level of LeakageDocument96 pagesDevelopment of A Leakage Target Setting Approach For South Korea Based On Economic Level of Leakagetomi wirawanNo ratings yet

- UG Sewer Class ProjectDocument34 pagesUG Sewer Class ProjectOliver BrownNo ratings yet

- Drainage Master Plan For NCT of Delhi: Draft Final ReportDocument138 pagesDrainage Master Plan For NCT of Delhi: Draft Final ReportRudra Pratap SinghNo ratings yet

- Desalination Solar Powered ThesisDocument209 pagesDesalination Solar Powered ThesisEdison ChandraseelanNo ratings yet

- 2013-Design and Development of Solar Dryer FoDocument47 pages2013-Design and Development of Solar Dryer FosanjuNo ratings yet

- B.Tech Civil Project Report SEM VIIIDocument107 pagesB.Tech Civil Project Report SEM VIIIsreshanthgundu123No ratings yet

- DasuHydropowerProject ReportDocument33 pagesDasuHydropowerProject ReportAbdul QadeerNo ratings yet

- Design of RCC Gravity Dam and FEM Modelling in GeoStudioDocument125 pagesDesign of RCC Gravity Dam and FEM Modelling in GeoStudiolorenzojovanot100% (1)

- GreenBuilding For Energy Management, Conservation and Sustainability ReportDocument154 pagesGreenBuilding For Energy Management, Conservation and Sustainability ReportSyed Maarij ShoaibNo ratings yet

- PRPOSAL ON HydropowerDocument19 pagesPRPOSAL ON HydropowerSudip ShresthaNo ratings yet

- Wire Final Project Design Group Iv (2022.GC.)Document74 pagesWire Final Project Design Group Iv (2022.GC.)Ochan Kuach ochan KuachNo ratings yet

- Gilgel Abay Medium Hydro Power Design EtDocument181 pagesGilgel Abay Medium Hydro Power Design Etashenafi negusNo ratings yet

- PHE Micro ProjectDocument35 pagesPHE Micro ProjectBhushanDabholkarNo ratings yet

- Selamawit WorkinehDocument131 pagesSelamawit WorkinehDebergeNo ratings yet

- Project Water-Al RashidiyaDocument33 pagesProject Water-Al Rashidiya4tbvy4hr65No ratings yet

- Kathmandu UniversityDocument32 pagesKathmandu UniversityAnup Gautam100% (1)

- 3D Numerical Moedlong Settling Basin NTNUDocument162 pages3D Numerical Moedlong Settling Basin NTNUSDNo ratings yet

- Performance Assessment of Solid Waste Collection System in New Juaben South DistrictDocument145 pagesPerformance Assessment of Solid Waste Collection System in New Juaben South Districtbenjamin kwasi boatengNo ratings yet

- Fresh Water: Using The Sun To GenerateDocument20 pagesFresh Water: Using The Sun To GeneraterakeshNo ratings yet

- Hoteldesign F.G.M 1Document22 pagesHoteldesign F.G.M 1Jodrish OmarNo ratings yet

- Evolution of Transboundary Politics in The EuphratDocument28 pagesEvolution of Transboundary Politics in The EuphratJodrish OmarNo ratings yet

- STAIRCASEDocument8 pagesSTAIRCASEJodrish OmarNo ratings yet

- Elevated Steel Water TankDocument8 pagesElevated Steel Water TankJodrish OmarNo ratings yet

- Water For Growth and DevelopmentDocument55 pagesWater For Growth and DevelopmentLTE002No ratings yet

- Potential Use of Solar Energy PDFDocument360 pagesPotential Use of Solar Energy PDFcamulNo ratings yet

- SPE 81457 Strategies To Mitigate Corrosion Caused Due To H S in Wells and Well Fluid Lines of Mumbai Offshore, IndiaDocument6 pagesSPE 81457 Strategies To Mitigate Corrosion Caused Due To H S in Wells and Well Fluid Lines of Mumbai Offshore, IndiaWaleed Barakat MariaNo ratings yet

- Hydraulic Design AspectsDocument60 pagesHydraulic Design AspectsSivaramakrishnanNo ratings yet

- Phchem 1a - Activity #2 - Pharmaceutical Aids and Necessities (Summer 2022)Document3 pagesPhchem 1a - Activity #2 - Pharmaceutical Aids and Necessities (Summer 2022)Shopifyy ClothingNo ratings yet

- Sound ObservationDocument25 pagesSound ObservationXis Yàh James RobinsonNo ratings yet

- Grade 6 Agriculture T2 2020Document6 pagesGrade 6 Agriculture T2 2020MuramCoNo ratings yet

- General To Specific Pattern of Idea DevelopmentDocument39 pagesGeneral To Specific Pattern of Idea DevelopmentAnn GaniaNo ratings yet

- ISU - Weather Unit: Due Date: Jan 18, 2018Document6 pagesISU - Weather Unit: Due Date: Jan 18, 2018sasada asdaNo ratings yet

- PROJECT TECH SPECIFICATION - Chemical TreatmentDocument11 pagesPROJECT TECH SPECIFICATION - Chemical TreatmentNAHASALI11No ratings yet

- Guia 1 FisicoquimicaDocument4 pagesGuia 1 FisicoquimicaRhooZhii AgueroNo ratings yet

- Tray DryerDocument22 pagesTray DryerHari KishoreNo ratings yet

- BS 7874Document11 pagesBS 7874Fenner ElectromechanicalNo ratings yet

- Rate Consumption (CUBIC) Charge 0.180 2.110 0.66 00.770 0 2: Water Service FeesDocument1 pageRate Consumption (CUBIC) Charge 0.180 2.110 0.66 00.770 0 2: Water Service FeesRiyyaz HussainNo ratings yet

- Factors Affecting Steam Turbine Performance-MergedDocument26 pagesFactors Affecting Steam Turbine Performance-MergedrahulNo ratings yet

- Boiler's EfficiencyDocument11 pagesBoiler's Efficiencymaw222No ratings yet

- Hydrologic Engineering Center (Ceiwr-Hec) Mission, Roles, & ResponsibilitiesDocument2 pagesHydrologic Engineering Center (Ceiwr-Hec) Mission, Roles, & ResponsibilitieselfatihsalimNo ratings yet

- 2016 1 CE11 Syllabus-1Document2 pages2016 1 CE11 Syllabus-1Cole FargoNo ratings yet