Professional Documents

Culture Documents

TMC423 Datasheet

Uploaded by

Marvin AguilarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TMC423 Datasheet

Uploaded by

Marvin AguilarCopyright:

Available Formats

TMC423 Data Sheet – (V1.

13 / June 20th, 2007) 1/22

TMC 423 – Datasheet

Serial Triple Incremental

Encoder Interface

EXT_RES

NSCS428

SDO428

PRA/IO

NSCS

VCCA

VCCI

NINT

GND

SDO

SCK

TCK

CLK

SDI

NC

GND COLUMN_PIN(0)

TDI COLUMN_PIN(1)

ENC1_A COLUMN_PIN(2)

ENC1_B COLUMN_PIN(3)

ENC1_N

ENC2_A

TMS GND

VCCI VKS (GND)

GND VPP (VCCA)

ENC2_B

ENC2_N SW_ROW_PIN(0)

ENC3_A SW_ROW_PIN(1)

TMC423

TRINAMIC Motion Control GmbH & Co. KG

ENC3_B SW_ROW_PIN(2)

ENC3_N

TQFP-100 Package SW_ROW_PIN(3)

Sternstrasse 67

STEP1 SW_ROW_PIN(4)

TRST SW_ROW_PIN(5)

D – 20357 Hamburg

LED_ROW_PIN(0)

DIR1 VCCI

GERMANY

VSV (VCCA)

VCCI LED_ROW_PIN(1)

STEP2 LED_ROW_PIN(2)

DIR2 LED_ROW_PIN(3)

WWW.TRINAMIC.COM

LED_ROW_PIN(4)

STEP3 LED_ROW_PIN(5)

DIR3 GND

REF(0)

REF(1)

REF(2)

STOPR(0)

STOPR(1)

STOPR(2)

PRB/IO

VCCI

TDO

SDO_D

SDI_D

SCK_D

NSCS_D

GND

NC

GND

STOPL(0)

STOPL(1)

STOPL(2)

VCCA

TMC423 Main Features

The TMC423 is a triple incremental encoder input chip, which interfaces to any SPITM compatible

controller. The TMC423 can especially be used in conjunction with the TMC428 triple stepper motor

controller to provide position verification or stabilization using some additional software. It integrates

24 bit counters for each encoder to provide a high position resolution without CPU interaction.

Further it allows dynamic resolution adaptation to allow direct comparison of encoder counters with

motors using different micro step resolution. All encoder counters can be latched synchronously, or

whenever a null channel event occurs, providing a position on strobe holding function. The TMC423

also provides a step / direction output with programmable signal shaping for the TMC428 as an

optional function. A multiplexer function is also integrated for the TMC428 reference switches.

Furthermore control and drive of a LED and switch matrix is implemented. All functions can also be

used in conjunction.

Applications

• Stepper Motor Position Verification

• Position Maintenance

• Incremental Encoder Interface Readout

• Step / Direction conversion for TMC428 systems

• Control of LED 6 x 4 Matrix and Switch 6 x 4 Matrix

Features

• Supports 2 and 3 channel incremental encoders with a wide range of resolutions

• Allows step / direction signal extraction from TMC428 output data stream

• Programmable pulse shaping for step / direction interface

• 24 bit integrated position resolution

• Programmable prescaler for Incremental Encoder Interface

• 4-times evaluation of encoder signals

• Fast 32 bit SPITM interface

• Can share SPITM interface with TMC428 and supplies separate interrupt output

• Integrates Reference Switch Multiplexers

• Package: TQ100

Note: SPI is Trademark of Motorola, Inc.

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 2/22

Revision History

Version Comment Date Name

Initial Version November 22, 2002 Technical Department

0.4 Corrected Array Switching Frequency January 23, 2003 Technical Department

0.5 First Customer Release January 24, 2003 Technical Department

0.6 Minor corrections March 11, 2003 Technical Department

Changes concerning new company TRINAMIC

0.6 Motion Control GmbH & Co. KG October 1st, 2004 Technical Department

th

0.7 Corrected Pinning: Position of CLK pin December, 15 , Technical Department

2004

Corrected Reset input in diagram, added

1.0 supply spec March, 15th, 2005 Technical Department

1.1 Added Application Environment examples March, 9th, 2007 Technical Department

1.1 Added encoder timing Apr, 4th, 2007 Dw

S/D Appl. corrected, added TMC428 SPI

1.2 datagram for S/D June 6th, 2007 HC

Figure 4 and Figure 5: TMC423 clock input

1.3 corrected; more detailed flag description June 20th, 2007 HC, Dw

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 3/22

Table of Contents

1 Pinout .............................................................................................................................................................................. 5

1.1 Pin Description .................................................................................................................................................... 6

1.2 Recommended Operating Conditions........................................................................................................... 7

1.3 Electrical Characteristics.................................................................................................................................... 7

2 Block Diagram ............................................................................................................................................................... 8

3 Application Environment ........................................................................................................................................... 9

3.1 Application Description..................................................................................................................................... 9

3.1.1 Application with TMC236 Stepper Motor Driver................................................................................... 9

3.1.2 Application with Step / Direction Power Stage ................................................................................... 9

3.2 Application Examples.......................................................................................................................................10

3.2.1 Application with TMC236 Stepper Motor Driver.................................................................................10

3.2.2 Application with Step / Direction Power Stage .................................................................................10

4 Dynamic Resolution Adaptation ............................................................................................................................11

5 Serial Peripheral Interface (SPI) with 32-bit Register .....................................................................................12

5.1 Description and Specification........................................................................................................................12

5.2 32-bit SPI Datagram Structure ......................................................................................................................13

5.3 SPI 32-bit Datagram Specification ...............................................................................................................13

5.3.1 Overview........................................................................................................................................................13

6 Incremental Encoder .................................................................................................................................................14

7 Configuration Datagrams.........................................................................................................................................15

7.1 Encoder Interface Prescaler and Null Event Configuration ..................................................................15

7.2 Encoder Interface Hold Register Operation ..............................................................................................16

7.3 Timer Logic Step Pulse Length and Delay ................................................................................................17

7.4 Control Register and Interrupt Control ......................................................................................................17

7.5 Switch Matrix Read...........................................................................................................................................17

7.6 LED Matrix Write................................................................................................................................................17

8 SPI-Protocol for Interface with 6-bit Register ...................................................................................................18

8.1 Step and Direction Pulse conversion..........................................................................................................18

9 LED and Switch Matrix..............................................................................................................................................19

10 Package dimensions..................................................................................................................................................20

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 4/22

List of Figures

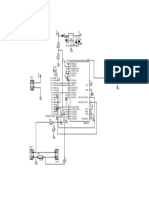

Figure 1: Pinout TMC423 5

Figure 2: Block diagram of the TMC423 8

Figure 3: Application Environment 9

Figure 4: Example for Application with TMC236 Stepper Motor Driver 10

Figure 5: Example for Application with Step / Direction Power Stage 10

Figure 6: TMC423 Application 11

Figure 7: Timing diagram of the Serial Interface 12

Figure 8: Structure 32-Bit Interface 13

Figure 9: Overview TMC423 Registers 13

Figure 10: Encoder Output and Evaluation 14

Figure 11: Crosstalk on Encoder Wire 14

Figure 12: Step Direction conversion 18

Figure 13: Connection to the matrix 19

Figure 14: 100-Pin TQFP Top View 20

Figure 15: 100-Pin TQFP Side View 20

Figure 16: 100-Pin TQFP Side View Detail A 20

List of Tables

Table 1: TMC423 Pinout 7

Table 2: Operating Conditions 7

Table 3: Operating Conditions 7

Table 4: Prescaler factors for different motors and encoders 11

Table 5: Interrupt Flags 13

Table 6: SPI Datagram Prescaler 16

Table 7: SPI Datagram Hold Register 16

Table 8: SPI Datagram Step-/Dir logic 17

Table 9: SPI Datagram Control Register 17

Table 10: Switch Matrix Read 17

Table 11: LED Matrix Write 17

Table 12: SPI Datagram Step / Direction Converter 18

Table 13: Datagram example and RAM contents for three step-direction drivers 18

Table 14: TMC423 LED Matrix Pins 19

Table 15: TQFP Dimensions 21

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 5/22

1 Pinout

EXT_RES

NSCS428

SDO428

PRA/IO

NSCS

VCCA

VCCI

NINT

GND

SDO

SCK

TCK

CLK

SDI

NC

GND COLUMN_PIN(0)

TDI COLUMN_PIN(1)

ENC1_A COLUMN_PIN(2)

ENC1_B COLUMN_PIN(3)

ENC1_N

ENC2_A

TMS GND

VCCI VKS (GND)

GND VPP (VCCA)

ENC2_B

ENC2_N SW_ROW_PIN(0)

ENC3_A SW_ROW_PIN(1)

ENC3_B

TMC423 SW_ROW_PIN(2)

ENC3_N

TQFP-100 Package SW_ROW_PIN(3)

STEP1 SW_ROW_PIN(4)

TRST SW_ROW_PIN(5)

LED_ROW_PIN(0)

DIR1 VCCI

VSV (VCCA)

VCCI LED_ROW_PIN(1)

STEP2 LED_ROW_PIN(2)

DIR2 LED_ROW_PIN(3)

LED_ROW_PIN(4)

STEP3 LED_ROW_PIN(5)

DIR3 GND

REF(0)

REF(1)

REF(2)

STOPR(0)

STOPR(1)

STOPR(2)

STOPL(0)

STOPL(1)

STOPL(2)

PRB/IO

TDO

SDO_D

SDI_D

SCK_D

NSCS_D

GND

NC

GND

VCCI

VCCA

Figure 1: Pinout TMC423

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 6/22

1.1 Pin Description

Pin Location Dir Description

GND 1, 9, 36, 39, 51, 68, In Ground

69, 91

ENC1_A 3 In Incremental Encoder Interface 1 Channel A

ENC1_B 4 In Incremental Encoder Interface 1 Channel B

ENC1_N 5 In Incremental Encoder Interface 1 Channel N

(Connect to +5V if not used)

ENC2_A 6 In Incremental Encoder Interface 2 Channel A

ENC2_B 10 In Incremental Encoder Interface 2 Channel B

ENC2_N 11 In Incremental Encoder Interface 2 Channel N

(Connect to +5V if not used)

ENC3_A 12 In Incremental Encoder Interface 3 Channel A

ENC3_B 13 In Incremental Encoder Interface 3 Channel B

ENC3_N 14 In Incremental Encoder Interface 3 Channel N

(Connect to +5V if not used)

TDI 2 Connect to Ground

TMS 7 Connect to 5 Volt via Pull-Up Resistor

TRST 16 Connect to 5 Volt via Pull-Up Resistor

TDO 49 To be left open

TCK 100 Connect to Ground

VCCI 8, 20, 44, 58, 82 In Positive Power Supply 5 Volt

VCCA 35, 57, 67, 90 In Positive Power Supply 2.5 Volt

GND 39 In Unused input: Connect to Ground

CLK 88 In System Clock 16MHz

EXT_RES 87 In External Reset Low Active

NC 37, 89 In Connect to Ground

PRA / IO 92 To be left open

PRB / IO 34 To be left open

Step 1 15 Out Step/Direction Interface – Step Output Motor 1

Dir 1 18 Out Step/Direction Interface – Direction Output Motor 1

Step 2 21 Out Step/Direction Interface – Step Output Motor 2

Dir 2 22 Out Step/Direction Interface – Direction Output Motor 2

Step 3 24 Out Step/Direction Interface – Step Output Motor 3

Dir 3 25 Out Step/Direction Interface – Direction Output Motor 3

SDO_D 26 Out Step / Direction SPI MISO

SDI_D 27 In Step / Direction SPI MOSI

SCK_D 28 In Step / Direction SPI SCK

NSCS_D 29 In Step / Direction SPI NSCS

REF0 40 Out Reference switch output 1

REF1 41 Out Reference switch output 2

REF2 42 Out Reference switch output 3

STOPR0 43 In Right Stop Switch Motor 1

STOPR1 45 In Right Stop Switch Motor 2

STOPR2 46 In Right Stop Switch Motor 3

STOPL0 47 In Left Stop Switch Motor 1

STOPL1 48 In Left Stop Switch Motor 2

STOPL2 50 In Left Stop Switch Motor 3

COLUMN_PIN0 75 Out Column Drive Pin 0

COLUMN_PIN1 74 Out Column Drive Pin 1

COLUMN_PIN2 73 Out Column Drive Pin 2

COLUMN_PIN3 72 Out Column Drive Pin 3

SW_ROW_PIN0 65 In Switch Matrix Pin 0

SW_ROW_PIN1 64 In Switch Matrix Pin 1

SW_ROW_PIN2 63 In Switch Matrix Pin 2

SW_ROW_PIN3 62 In Switch Matrix Pin 3

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 7/22

SW_ROW_PIN4 61 In Switch Matrix Pin 4

SW_ROW_PIN5 60 In Switch Matrix Pin 5

LED_ROW_PIN0 59 Out LED Matrix Drive Pin 0

LED_ROW_PIN1 56 Out LED Matrix Drive Pin 1

LED_ROW_PIN2 55 Out LED Matrix Drive Pin 2

LED_ROW_PIN3 54 Out LED Matrix Drive Pin 3

LED_ROW_PIN4 53 Out LED Matrix Drive Pin 4

LED_ROW_PIN5 52 Out LED Matrix Drive Pin 5

SDO 99 Out SPI MISO

SDI 98 In SPI MOSI

SCK 97 In SPI SCK

NSCS 96 In SPI NSCS

SDO428 95 In SPI MISO Pin of TMC428

NSCS428 94 In SPI NSCS Pin of TMC428

NINT 93 Out Interrupt Output (low active)

Table 1: TMC423 Pinout

Note: Pins which are not marked in Figure 1: Pinout TMC423 on page 5 must be left open.

1.2 Recommended Operating Conditions

Parameter Value Unit

Clock Frequency (1) 16 MHz

Temperature 0 … + 70 °C

2.5 V Power Supply 2.25 … 2.75 VCCA

5.0 V Power Supply 4.50 … 5.50 VCCI

Table 2: Operating Conditions

1 – slower frequencies are also supported. Please take care about the timing information in this datasheet, since they are

based on 16MHz Clock Frequency.

1.3 Electrical Characteristics

Parameter Min Max Unit

Supply Current 2.5V 100 mA

Supply Current 5.0V 10 mA

(Output current = 0)

LED driver current per pin 20 mA

Input voltage level Low 0.8 V

Input voltage level High 2.4 V

Encoder input pulse length 2 tCLK

Encoder count rate fCLK

Table 3: Operating Conditions

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 8/22

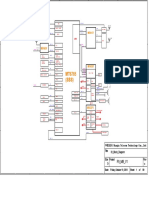

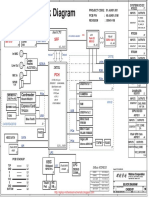

2 Block Diagram

LED SW COL EXT

5:0 5:0 3:0 RES

ENC1

A

Prescaler factor 10 bit

1/16, 2/16, ... 64

ENC1 Power On

B or 1/5, 2/5, ... 64

Reset

Matrix

prescaler+1 Control

ENC1

N

+

NSCS

ENC2

A

SCK

Encoder

ENC2 Encoder Counter SPI Interface

B signal

24+4 bit with 32 bit Reg

decoder SDI

ENC2

N M

U SDO

X

Control register

ENC3 Encoder Hold

A *Common Hold

Flag register 24 bit SDO

command 428

*Clear on N event *Interrupt enable

ENC3

B *Hold on N

NSCS

*N polarity 428

ENC3

N 3 x Encoder Interface

INT

Logik+ NINT

Latch

STEP

1

NSCS

_D

DIR1

SPI Interface

with 6 Bit reg SCK

_D

STEP

2

Timer logic

SDI

_D

DIR2 Step pulse Step pulse

length delay after dir

SDO

8 bit change 10 bit _D

STEP

3

DIR3

3 x Step / Direction converter

REF

MUX

STOP STOP STOP STOP STOP STOP

CLK VCC GND REF3 REF2 REF1

R3 R2 R1 L3 L2 L1

Figure 2: Block diagram of the TMC423

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 9/22

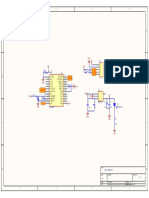

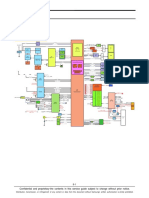

3 Application Environment

TMC423 as Incremental Encoder Interface TMC423 as Step / Direction converter

and Incremental Encoder Interface

Step/

Dir Incremental

Motor Encoder

Power

Stage

TMC Incremental

Motor Encoder

236

Step/

Dir Incremental

Motor Encoder

Power

Stage

TMC Incremental

Motor Encoder

236

Step/

Dir Incremental

Motor Encoder

Power

Stage

TMC Incremental

Motor Encoder

236 Step / Direction Interface

for up to three power stages

SPI-Interface

SPI-Interface TMC TMC

428 423

TMC TMC

428 423

SPI-Interface

SPI-Interface

µC µC

Figure 3: Application Environment

3.1 Application Description

3.1.1 Application with TMC236 Stepper Motor Driver

A complete close-loop motion control system consists of the TMC428 three-axis motion controller, the

powerful TMC236 stepper motor driver and the TMC423 Encoder Interface. The system is controlled by

an inexpensive microcontroller.

The main advantage of the system is that time critical communication to the TMC236 driver is

performed by the TMC428. The main purpose of the inexpensive microcontroller is to parameterize the

TMC428 and TMC423 and to send motion parameters like maximum speed or target position to the

TMC428. Position validation is done by reading the actual position of the TMC428 and the TMC423.

3.1.2 Application with Step / Direction Power Stage

Another possibility to built a close loop motion control system is to use the TMC423 as encoder

interface and also as a step direction converter. Thereto the TMC423 converts the SPITM datagrams

sent by the TMC428 into parameterizeable step and direction pulses. For parameterizing both the

TMC428 and TMC423 have to be connected via SPITM interface to an inexpensive microcontroller.

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 10/22

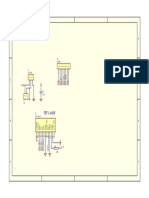

3.2 Application Examples

3.2.1 Application with TMC236 Stepper Motor Driver

This example illustrates the encoder connection and the use of reference switches with the TMC423

and additionally the SPI interface connections between TMC423, TMC428 and a microcontroller. The

communication to the drivers (e.g. TMC236) is performed via SPI by the TMC428 motion control chip.

+5V

16MHz CLK V5

+5V 16MHz CLK

REF1 REF1 V33

RESET

REF2 REF2 470nF

10k each

REF3 REF3 Test

GND

ENC1_A

SDI

ENC1_B

SCK TMC428 GND

Connect to encoders

ENC1_N

SDO

NSCS SDI_C SDI_S

ENC2_A SPI

SCK_C SCK_S

ENC2_B to

SDO428 SDO_C SDO_S

ENC2_N Drivers

NSCS428 nSCS_C nSCS_S

ENC3_A TMC423

ENC3_B +5V

ENC3_N

SS423

SS428

SCK

MISO

MOSI

+5V 10k to nSCS_D

TRST of TMC423

+2.5V VCCI1 - VCCI5 TMS

from nSCS_S µC

of TMC428 VCCA1 - VCCA4 GND1 - GND8

SDI_D SW_ROW0 - SW_ROW5

SCK_D Notes:

NSCS_D NC2

NC1

1. Application without LED and Switch matrix.

6x Reference Switch STOPR0 - STOPR2 TCK 2. If the NSCS428 pin is not in use it has to be tied to +5V.

Inputs (active high) STOPL0 - STOPL2 TDI 3. NSCS_D activates the reference switches (inputs

10k 10k STOPRx/STOPLx and outputs REFx).

GND

GND

Figure 4: Example for Application with TMC236 Stepper Motor Driver

3.2.2 Application with Step / Direction Power Stage

Additionally to the previous example the use of the TMC423 as step/direction converter is shown. The

reference switches can be used as above.

µC

SS423

SS428

MOSI

MISO

SCK

16MHz CLK

+5V

RESET NSCS TMC428 +5V

SDO

10k each SCK SCK_C V5

ENC1_A SDI SDI_C

ENC1_B CLK 16MHz

Connect to encoders

ENC1_N SDO428 SDO_C

NSCS428 nSCS_C

ENC2_A V33

ENC2_B SDI_D SDO_S 470nF

ENC2_N SCK_D SCK_S Test

SDO_D SDI_S GND

ENC3_A NSCS_D nSCS_S

GND

ENC3_B TMC423

ENC3_N

STEP1

+5V DIR1

Step/DIR

STEP2

+2.5V VCCI1 - VCCI5 to

DIR2

Drivers

VCCA1 - VCCA4 STEP3

+5V DIR3

SDI_D

SCK_D

GND1 - GND8

10k Notes:

TRST SW_ROW3 - SW_ROW5 1. Application without LED/switch matrix and

TMS reference switches.

NC2 2. If the NSCS428 pin is not in use, it has to be tied

STOPR0 - STOPR2 NC1

to +5V.

STOPL0 - STOPL2 TCK

TDI

GND

GND

Figure 5: Example for Application with Step / Direction Power Stage

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 11/22

4 Dynamic Resolution Adaptation

The dynamic resolution adaptation is needed to link stepper motors and encoders with different

resolutions. The characteristics of the connected hardware must provided to the TMC423 by sending

the corresponding SPI telegram. (See 5.3.1 Overview on page 13 in this issue). The TMC423 multiplies

the encoder counter by a user selectable value in the range 1..1024, and then divides it by 16. When

using incremental encoders with N channel it is also possible to select between different behaviors

when the N channel is triggered.

Encoder:

Resolution: e.g.: 1000 steps / rotation

Stepper

TMC423 SPI Interface

motor

TMC423:

Stepper Motor: Prescaler = 3.2 -> 1000* 4 * 3.2 = 12800

Resolution: e.g.: 12800 steps / rotation

Figure 6: TMC423 Application

Table 4 shows a number of prescaler factors for possible combinations of micro step resolution and

encoder resolution. Note: The given number of pulses have to be multiplied by four since 4-times

encoder signal evaluation is used. (See Figure 10: Encoder Output and Evaluation on page 14).

Microstep Encoder Resolution [Pulses / Rotation]

s 1024 1000 512 500 256 250 200 125 50 25

12800 3.125 3.2 6.25 6.4 12.5 12.8 16 25.6 64 ----

6400 1.5625 1.6 3.125 3.2 6.25 6.4 8 12.8 32 64

3200 ---- ---- 1.5625 1.6 3.125 3.2 4 6.4 16 32

1600 ---- ---- ---- ---- 1.5625 1.6 2 3.2 8 16

800 ---- ---- ---- ---- ---- ---- 1 1.6 4 8

400 ---- ---- ---- ---- ---- ---- ---- ---- 2 4

Table 4: Prescaler factors for different motors and encoders

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 12/22

5 Serial Peripheral Interface (SPI) with 32-bit Register

5.1 Description and Specification

Four pins named nSCS, SCK, SDI and SDO form the serial peripheral interface from a microcontroller

to the TMC423. The communication between the microcontroller and the TMC423 takes place via

datagrams with a fixed length of 32 bit. The microcontroller acts always as master and the TMC423 as

slave.

The SPITM of the TMC423 behaves like a simple 32-bit shift register. Incoming serial data at pin SDI is

shifted with the rising edge of the clock signal SCK into the 32-bit register. The content of this

register is copied after 32-bits with the rising edge of the selection signal nSCS into a buffer register

of 32-bit length. The SPITM of the TMC423 sends back data read from registers immediately via the

SDO signal. It processes serial data synchronously to the clock signal CLK.

Because of on-the-fly processing of the input data stream, the serial microcontroller interface of the

TMC423 requires the serial data clock signal SCK to have a minimum low / high time of three clock

cycles. The data signal SDI driven by the microcontroller has to be valid at the rising edge of the

serial data clock input SCK. The maximum duration of the serial data clock period is unlimited.

A complete serial datagram frame has a fixed length of 32 bit. While the data transmission from the

microcontroller to the TMC423 is idle, the low active serial chip select input nSCS and also the serial

data clock signal SCK are set to high. The serial data input SDI of the TMC428 has to be driven by the

microcontroller. Like other SPI compatible devices, the SDO signal of the TMC423 is high impedance

‘Z’ as long as nSCS is high.

The signal nSCS has to be high for at least three clock cycles before starting a datagram transmission.

To initiate a transmission, the signal nSCS has to be set to low. Three clock cycles later the serial data

clock may go low. The most significant bit (MSB) of a 32 bit wide datagram comes first and the least

significant bit (LSB) is transmitted as the last one. A data transmission is finished by setting nSCS

high for three or more CLK cycles after the last rising SCK slope. nSCS and SCK change in opposite

order from low to high at the end of a transmission as these signals change from high to low at the

beginning. The timing of the serial microcontroller interface is outlined in Figure 7: Timing diagram of

the Serial Interface.

tCLK

tDATAGRAMuC

tSUCSC tHDCSC tSCKCL tSCKCH tHDCSC tSUCSC

CLK

nSCS

SCK tSD tSD tSD

SDI sdi_bit#31 sdi_bit#30 . . . sdi_bit#1 sdi_bit#0

tPD

SDO sdo_bit#31 sdo_bit#30 ... sdo_bit#1 sdo_bit#0

tIS tSI

30 x sampled SDI_C

1 x SDI_C sampled 1 x SDI_C sampled

one full 32 bit datagram

Figure 7: Timing diagram of the Serial Interface

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 13/22

5.2 32-bit SPI Datagram Structure

Datagram from TMC423 send to µC

3 3 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1

9 8 7 6 5 4 3 2 1 0

1 0 9 8 7 6 5 4 3 2 1 0 9 8 7 6 5 4 3 2 1 0

INT 0 0 0 0 Data

Datagram from µC to TMC423

3 3 2 2 2 2 2 2 2 2 2 2 1 1 1 1 1 1 1 1 1 1

9 8 7 6 5 4 3 2 1 0

1 0 9 8 7 6 5 4 3 2 1 0 9 8 7 6 5 4 3 2 1 0

R

Address W Data

Figure 8: Structure 32-Bit Interface

Interrupt Flags [Bit] Name Description

31 INT_ext external Interrupt, e.g. TMC428

30 INT_enc1 N Signal of Encoder Interface 1 detected

29 INT_enc2 N Signal of Encoder Interface 2 detected

28 INT_enc3 N Signal of Encoder Interface 3 detected

Table 5: Interrupt Flags

5.3 SPI 32-bit Datagram Specification

5.3.1 Overview

Byte # Byte 3 Byte 2 Byte 1 Byte 0

Bit # 31 30 29 28 27 26 25 24 23 22 21 20 19 18 17 16 15 14 13 12 11 10 9 8 7 6 5 4 3 2 1 0

RW

Address

Control 0 0 0 0 0 0 0 1 Encoder 1 Prescaler Reserved

N Polarity

N Trigger

Direction

N Clear

N Hold

0 0 0 0 0 0 1 1 Encoder 2 Prescaler Reserved

0 0 0 0 0 1 0 1 Encoder 3 Prescaler Reserved

0 0 0 0 0 1 1 1 Encoder 1, 2, 3 Prescaler - set all commonly Reserved

Data 0 0 0 0 1 0 0 Encoder 1 Position Register

0 0 0 0 1 0 1 Encoder 2 Position Register

0 0 0 0 1 1 0 Encoder 3 Position Register

Step /Dir 0 0 0 0 1 1 1 1 Step Pulse Length Step Pulse Delay Reserved

Clear Flags

INT 0 0 0 1 0 0 0 1

Reg Hold

INT EN

Reserved

Matrix 0 0 0 1 0 0 1 0 Switch Row 3 Switch Row 2 Switch Row 1 Switch Row 0

0 0 0 1 0 1 0 1 LED Row 3 LED Row 2 LED Row 1 LED Row 0

Figure 9: Overview TMC423 Registers

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 14/22

6 Incremental Encoder

Incremental Encoders are translating the rotary motion of a shaft into a two-channel digital

quadrature output. The light emitted from a LED is focused onto a reflective code wheel. As the shaft

moves, the code wheel rotates, reflecting light from an alternating bright and dark pattern.

The TMC423 samples the incoming signals ENCx_a and ENCx_B from the incremental encoder. A

internal algorithm block counts the amount of edges generated by the encoder. A prescaler value can

be used to adapt the incremental encoder resolution to the stepper motor resolution.

For high resolution the TMC423 evaluates the encoder signals 4-times during each encoder step. This

has to kept in mind when choosing the prescaler value.

Step

Channel A

Channel B

Channel N

Evaluation

Figure 10: Encoder Output and Evaluation

Note: It is possible that the encoder signals ENCx_A, ENCx_B and ENCx_N are polluted with crosstalk

noise. Crosstalk could influence the internal logic, to overcome this problem internal filters are

applied to ensure correct functionality. Furthermore is saves the need for external analog filters.

e.g.: Figure 11: Crosstalk on Encoder Wire shows crosstalk from channel A to channel B.

Figure 11: Crosstalk on Encoder Wire

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 15/22

7 Configuration Datagrams

7.1 Encoder Interface Prescaler and Null Event

Configuration

The Encoder Interface Initialization datagram configures the parameterizeable encoder prescaler to

adapt the TMC423 for different incremental encoders. Furthermore the TMC423 behavior concerning

the N channel can be selected.

Example: A 1000 steps per rotation encoder is to connect at a stepper motor with 12800 microsteps per rotation. When the next

event at the high active N channel is found, the position register must set to zero. Only Encoder Interface 1 is connected.

The following datagram performs this task:

• Bits 31 down to 24 have to be set to 01HEX to select encoder interface 1

• The prescaler value has to set to 12800 / (1000*4) = 3.2. Therefore bits 23 down to 12 must set to 831HEX.

• The N channel is set up correctly when bits 11 down to 0 are set to A0HEX.

Bit Encoder Interface Initialization

31…28 “0000” Register Address

27…25 Interface Selection

000 = Interface 1

001 = Interface 2

010 = Interface 3

011 = Interface 1, 2 and 3

24 ‘1’

23…12 External Encoder Resolution and Corresponding Prescaler Factor

Bits 15 … 12: Fractional part of Factor. Unit: 1/16 (when bit 23 = 0) resp. 1/5 (bit 23 = 1)

Bits 22 … 16: Integer part of Factor

Bit 23: Switches Fractional part between 1/5 resolution or 1/16 resolution

Default:

(010)h (prescaler 1) (default value after power on)

Example settings:

Encoder: 1024 lines (4096 steps per rotation)

(032)h for 12800 micro steps per rotation (prescaler 3.125)

(019)h for 6400 micro steps (prescaler 1.5625)

Encoder: 1000 lines

(831) h for 12800 micro steps (prescaler 3.2)

(813)h for 6400 micro steps (prescaler 1.6)

Encoder: 512 lines

(064)h for 12800 micro steps (prescaler 6.25)

(032)h for 6400 micro steps (prescaler 3.125)

(019)h for 3200 micro steps (prescaler 1.5625)

Encoder: 500 lines

(862)h for 12800 micro steps (prescaler 6.4)

(831)h for 6400 micro steps (prescaler 3.2)

(813)h for 3200 micro steps (prescaler 1.6)

Encoder: 256 lines

(0C8)h for 12800 micro steps (prescaler 12.5)

(064)h for 6400 micro steps (prescaler 6.25)

(032)h for 3200 micro steps (prescaler 3.125)

(019)h for 1600 micro steps (prescaler 1.5625)

Encoder: 250 lines

(8C4)h for 12800 micro steps (prescaler 12.8)

(862)h for 6400 micro steps (prescaler 6.4)

(831)h for 3200 micro steps (prescaler 3.2)

(813)h for 1600 micro steps (prescaler 1.6)

Encoder: 200 lines

(100)h for 12800 micro steps (prescaler 16)

(080)h for 6400 micro steps (prescaler 8)

(040)h for 3200 micro steps (prescaler 4)

(020)h for 1600 micro steps (prescaler 2)

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 16/22

(010)h for 800 micro steps (prescaler 1)

Encoder: 125 lines

(993)h for 12800 micro steps (prescaler 25.6)

(8C4)h for 6400 micro steps (prescaler 12.8)

(862)h for 3200 micro steps (prescaler 6.4)

(831)h for 1600 micro steps (prescaler 3.2)

(813)h for 800 micro steps (prescaler 1.6)

Encoder: 50 lines (200 steps per rotation)

(400)h for 12800 micro steps (prescaler 64)

(200)h for 6400 micro steps (prescaler 32)

(100)h for 3200 micro steps (prescaler 16)

(080)h for 1600 micro steps (prescaler 8)

(040)h for 800 micro steps (prescaler 4)

(020)h for 400 micro steps (prescaler 2)

(010)h for 200 steps per rotation (prescaler 1)

11 N Polarity for Selected Interface

0 = active low (default)

1 = active high

When changing the polarity, please be aware that a single clear on N Event might be

triggered, and thus should not be initiated in the same write access.

10 Hold on N for Selected Interface

0 = no hold (default)

1 = active: Encoder counter freezes during 0 channel event.

9 Clear on N Event for Selected Interface

0 = no clear (default)

1 = active

When switched to active, then it depends on bit 8, if a clear event is issued only once, or

always when the N channel becomes active.

8 N Trigger Selection

0 = only at next N signal (default)

1 = always at N signal

The clear event last until the N signal goes inactive again. If earlier termination is desired,

i.e. to preset the encoder counter to a different value, disable “Clear on N” prior to

changing the position register.

7 add or sub register for each step (CW = looking onto the axis)

0= add for CW, sub for CCW (default)

1= add for CCW, sub for CW

6…0 Reserved

Table 6: SPI Datagram Prescaler

7.2 Encoder Interface Hold Register Operation

To read the actual contents of the position register or to preset the position register the following

command is to be used:

Bit Encoder Interface Control (Read/Preload Encoder Hold Register)

31…28 “0000” Register Address

27…25 Select Encoder Hold Register

100 = Hold register in encoder interface 1

101 = Hold register in encoder interface 2

110 = Hold register in encoder interface 3

24 Read or Preload Selection

0 = Read encoder hold register

1 = Preload encoder hold register

23…0 Encoder Hold Register Data

Table 7: SPI Datagram Hold Register

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 17/22

7.3 Timer Logic Step Pulse Length and Delay

To parameterize the step length and delay the next datagram is to be used:

Bit Write Step Pulse Length / Delay

31…25 “0000111” Register Address

24 ‘1’

23…16 Step Pulse Length (default value = 48(10) after PON)

15…6 Step Pulse Delay after Direction Change (default value = 160(10) after PON)

5…0 Reserved

Table 8: SPI Datagram Step-/Dir logic

7.4 Control Register and Interrupt Control

This datagram configures the interrupt control of the TMC423. When enabled, the N channel pulse of

all encoders is fed to the NINT pin.

Bit Control Register

31…25 “0001000” Register Address

24 ‘1’

23 Set Common Hold for Encoder Hold Registers

0 = no hold (default)

1 = freeze encoder hold registers

22 Encoder Interrupt Enable, if Null signal

0 = interrupt disable (default)

1 = interrupt enable

21 Clear Interrupt Flags

0 = no clear (default)

1= clear flags

20…0 Reserved

Table 9: SPI Datagram Control Register

7.5 Switch Matrix Read

Bit Control Register

31…25 “0001001” Register Address

24 ‘0’

23…18 Switch Matrix Register Row 3

17…12 Switch Matrix Register Row 2

11…6 Switch Matrix Register Row 1

5…0 Switch Matrix Register Row 0

Table 10: Switch Matrix Read

7.6 LED Matrix Write

Bit Control Register

31…25 “0001010” Register Address

24 ‘1’

23…18 LED Matrix Register Row 3

17…12 LED Matrix Register Row 2

11…6 LED Matrix Register Row 1

5…0 LED Matrix Register Row 0

Table 11: LED Matrix Write

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 18/22

8 SPI-Protocol for Interface with 6-bit Register

The 6-bit SPI Interface is used to receive step / direction information from the TMC428. The TMC423

processes the data and issues the corresponding step / direction signals via the step / direction pins.

Bit0 (Pulse 1) have to be sent first to the TMC423.

Bit Step / Direction Converter

0 Pulse 1

1 Direction 1

2 Pulse 2

3 Direction 2

4 Pulse 3

5 Direction 3

Table 12: SPI Datagram Step / Direction Converter

The order of the control signals serially sent from the TMC428 has to be defined. This can be done by

writing so called primary signal codes into the stepper motor driver datagram configuration area of

the on-chip configuration RAM of the TMC428. This signals codes are $13 (step first) and $12

(direction). To switch to the next motor the next motor bit (NxM) has to be set.

Position within Driver/motor NxM bit TMC428 signal RAM data TMC428

datagram code mnemonic of

primary signal

0 0 $13 $13 Step

1

1 1 $12 $32 Direction

2 0 $13 $13 Step

2

3 1 $12 $32 Direction

4 0 $13 $13 Step

3

5 1 $12 $32 Direction

Table 13: Datagram example and RAM contents for three step-direction drivers

8.1 Step and Direction Pulse conversion

Step pulses can be modified in their pulse width and delayed after an direction change was done.

The corresponding datagram (See 7.3) on page 17) is used to parameterize the Step / Dir interface.

step_in step pulse length

t

step_out step pulse delay

t

dir

Figure 12: Step Direction conversion

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 19/22

9 LED and Switch Matrix

The TMC423 can be used to drive a LED matrix or to get information from a switch matrix, whether

the switches are on or off. LEDs or switches are only active when the corresponding column is

selected by setting it to zero. The switch frequency of the column pins is fixed to 500 Hz at a clock

frequency of 16MHz. The LEDs are driven with a maximum current of 20mA.

The following Table 14: TMC423 LED Matrix Pins shows how the LED Matrix Write register is mapped

to the corresponding TMC423 pins to drive the LEDs.

TMC423 Pin: COLUMN_PIN [3:0] TMC423 Pin: LED_ROW_PIN [5:0]

Bit 3 Bit 2 Bit 1 Bit 0 LED_Matrix_Write [23:0]

0 1 1 1 23 22 21 20 19 18

1 0 1 1 17 16 15 14 13 12

1 1 0 1 11 10 9 8 7 6

1 1 1 0 5 4 3 2 1 0

Table 14: TMC423 LED Matrix Pins

For correct external connection of the matrix please refer to the following Figure 13: Connection to

the matrix. If distortions causes by long PCB traces are to expect, then filter capacitors Cfilter of 100pF

have to be added.

TMC423

7407

Column Pin [3:0]

5V

10k

LED_ROW_PIN[5:0] SW_ROW_PIN [5:0]

Cfilter

(opt.)

180

Figure 13: Connection to the matrix

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 20/22

10 Package dimensions

Figure 14: 100-Pin TQFP Top View

Figure 15: 100-Pin TQFP Side View

Figure 16: 100-Pin TQFP Side View Detail A

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 21/22

JEDEC TQFP100

Equivalent MS-026 VAR BED

Dimension Min Nom Max

A 1.60

A1 0.05 0.15

A2 1.35 1.40 1.45

b 0.17 0.22 0.27

c 0.09 0.20

D/E 16.00 BSC

D1/E1 14.00 BSC

e 0.50 BSC

L 0.45 0.60 0.75

ccc 0.08

Theta 0 3.50 deg 7 deg

Table 15: TQFP Dimensions

Notes :

- all dimensions are in millimeters

- BSC Basic Spacing between Centers

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

TMC423 Data Sheet – (V1.13 / June 20th, 2007) 22/22

Life support policy

TRINAMIC Motion Control GmbH & Co. KG does not

authorize or warrant any of its products for use in life

support systems, without the specific written consent

of TRINAMIC Motion Control GmbH & Co. KG. Life

support systems are equipment intended to support

or sustain life, and whose failure to perform, when

properly used in accordance with instructions provided,

can be reasonably expected to result in personal injury

or death.

© 2004 TRINAMIC Motion Control GmbH & Co. KG

Information given in this data sheet is believed to

be accurate and reliable. However no

responsibility is assumed for the consequences

of its use nor for any infringement of patents or

other rights of third parties, which may result form

its use.

Specifications subject to change without notice.

Copyright © 2004 TRINAMIC Motion Control GmbH & Co. KG

You might also like

- SM J100M Tshoo 7 PDFDocument50 pagesSM J100M Tshoo 7 PDFRosbel HernandezNo ratings yet

- Notes:: Power Saving Reference Design Standard Reference DesignDocument1 pageNotes:: Power Saving Reference Design Standard Reference DesignAiltonDiasNo ratings yet

- ER-OLED0.96 Series InterfacingDocument1 pageER-OLED0.96 Series InterfacingBoulbeba JribiNo ratings yet

- Schematic Hand+Gesture+Car+Tx 2021-04-17Document1 pageSchematic Hand+Gesture+Car+Tx 2021-04-17ahmed mediaNo ratings yet

- SA-MAX700 Diagrama y Voltajes - 48016Document41 pagesSA-MAX700 Diagrama y Voltajes - 48016loquiNo ratings yet

- Sony Cxa3271age Fingerprint ScannerDocument16 pagesSony Cxa3271age Fingerprint ScannerPierina AstudilloNo ratings yet

- SM G3502T Tshoo 7Document39 pagesSM G3502T Tshoo 7Matheus GarciaNo ratings yet

- UM3758 Series - Z - A M - W-: I'ri-Siate Programmahle Encoder/DecoderDocument18 pagesUM3758 Series - Z - A M - W-: I'ri-Siate Programmahle Encoder/DecoderГеннадий ДармоедовNo ratings yet

- Weather Station SchematicDocument1 pageWeather Station SchematicferozaNo ratings yet

- Schematic - AVR Colour LCD Tester - LCR TC1 - 20180912214500 PDFDocument1 pageSchematic - AVR Colour LCD Tester - LCR TC1 - 20180912214500 PDFanshumantech anshumantech0% (1)

- SM G850FDocument119 pagesSM G850FErick UribeNo ratings yet

- Voltage Current MetterDocument1 pageVoltage Current MetterAYYOUB ALLAOUINo ratings yet

- Acer Aspire 4410-4410t 1 WISTRON jm41 - 08266-1Document40 pagesAcer Aspire 4410-4410t 1 WISTRON jm41 - 08266-1Maintenance broNo ratings yet

- Level 3 Repair: 8-1. Components LayoutDocument54 pagesLevel 3 Repair: 8-1. Components LayoutCarlos SilvaNo ratings yet

- ACER Aspire 7736 GM45 JV71-MV - DDR3Document62 pagesACER Aspire 7736 GM45 JV71-MV - DDR3miecho1985No ratings yet

- A351 Service ManualDocument15 pagesA351 Service ManualDark FoxNo ratings yet

- MB - Manual - B650m-Aorus-Pro - Elite - Ax - 1201 - E-1-39 (1) - 27Document1 pageMB - Manual - B650m-Aorus-Pro - Elite - Ax - 1201 - E-1-39 (1) - 27Виталий СоламанинNo ratings yet

- Reflow Control Board PDFDocument1 pageReflow Control Board PDFRafael Ruiz CabreraNo ratings yet

- Level 3 Repair: 8-1. Block DiagramDocument54 pagesLevel 3 Repair: 8-1. Block DiagramAndroid Schematics and CircuitsNo ratings yet

- MT6765 (SBS) : Project: MT6765 LPDDR3 Ref - SCH Top LevelDocument32 pagesMT6765 (SBS) : Project: MT6765 LPDDR3 Ref - SCH Top LevelMarcio PimentelNo ratings yet

- Schematic Hand+Gesture+Car+Rx 2021-04-17Document1 pageSchematic Hand+Gesture+Car+Rx 2021-04-17REGINALDO BORIKO OKOMO NGUEMANo ratings yet

- Samsung A02 SchematicsDocument30 pagesSamsung A02 SchematicsAuto repair diagnostic cars / trucksNo ratings yet

- Block DiagramDocument1 pageBlock DiagramRiza VirsadaNo ratings yet

- P5100 Troubleshooting PDFDocument72 pagesP5100 Troubleshooting PDFDaniel CekulNo ratings yet

- SM-G570F Block Diagram: ConfidentialDocument42 pagesSM-G570F Block Diagram: ConfidentialGilson PereiraNo ratings yet

- Copia de M6102 - MB - P2 - ÕăþÉåÕø - 20191125Document21 pagesCopia de M6102 - MB - P2 - ÕăþÉåÕø - 20191125juan hilarioNo ratings yet

- JM41 Block Diagram: Intel CPUDocument40 pagesJM41 Block Diagram: Intel CPUMayank Mani SinghNo ratings yet

- Lenovo TB-8506X BlockDocument1 pageLenovo TB-8506X BlockSameer varshneyNo ratings yet

- Reference DesignDocument1 pageReference Designphiu100% (1)

- CNC-fabtroller SchematicDocument1 pageCNC-fabtroller SchematicTomi OzzyNo ratings yet

- Wistron GodzillaDocument61 pagesWistron Godzillarodrigootavio5No ratings yet

- Service Manual: ChassisDocument71 pagesService Manual: Chassisshark clubNo ratings yet

- 128-Megabit 2.7-Volt Dual-Interface Dataflash At45Db1282 PreliminaryDocument35 pages128-Megabit 2.7-Volt Dual-Interface Dataflash At45Db1282 PreliminarymhasansharifiNo ratings yet

- MT6768 (SBS) : MT6177M (LWG+LTG)Document31 pagesMT6768 (SBS) : MT6177M (LWG+LTG)pc partnerNo ratings yet

- TMS370Cx0x 8-Bit Microcontroller: FZ and FN Packages (Top View)Document49 pagesTMS370Cx0x 8-Bit Microcontroller: FZ and FN Packages (Top View)Edison PerezNo ratings yet

- Oppo Realme 3 SchematicDocument37 pagesOppo Realme 3 SchematichulkNo ratings yet

- SEN0142 SCHDocument1 pageSEN0142 SCHaaiioNo ratings yet

- Miniaturowy Zasilacz 3,3 I 5 VDocument2 pagesMiniaturowy Zasilacz 3,3 I 5 VZygmunt SzaryNo ratings yet

- XT2097-x (Malta Lite) - Schematics - L3 Repair PDFDocument21 pagesXT2097-x (Malta Lite) - Schematics - L3 Repair PDFWALTER CABRERANo ratings yet

- Eizo l367 Fa-1568 LCD Monitor SCHDocument9 pagesEizo l367 Fa-1568 LCD Monitor SCHVladimirNo ratings yet

- Troubleshooting PDFDocument42 pagesTroubleshooting PDFKiris Santacruz100% (1)

- SM-J260 Core 2Document22 pagesSM-J260 Core 2lfismael95No ratings yet

- Redmi 6a Schematic DiagramDocument34 pagesRedmi 6a Schematic DiagramKaran Matale80% (5)

- HP Pavilion dv2000 Intel 945 Akita 05232 Rev SD SchematicsDocument39 pagesHP Pavilion dv2000 Intel 945 Akita 05232 Rev SD SchematicsGyan PrakashNo ratings yet

- Monkmakesduino Arduino Compatible Board SchematicDocument1 pageMonkmakesduino Arduino Compatible Board SchematicWagner Gómez100% (1)

- SM-A260F Common Tshoo 7 PDFDocument24 pagesSM-A260F Common Tshoo 7 PDFRamíro ChocotecóNo ratings yet

- 1.44 TFT LCD SchematicDocument1 page1.44 TFT LCD SchematicerickNo ratings yet

- MT6572 SchematicDocument19 pagesMT6572 SchematicdomisoftNo ratings yet

- Acer - Travelmate 2423 (Ag1-910) PDFDocument40 pagesAcer - Travelmate 2423 (Ag1-910) PDFLos QuilmesNo ratings yet

- Sony Mbx-229 - Wistron Cadiz-Cp - Rev - 1mDocument57 pagesSony Mbx-229 - Wistron Cadiz-Cp - Rev - 1mLeandro SilvaNo ratings yet

- CADIZ-CP Block Diagram: Intel CPUDocument57 pagesCADIZ-CP Block Diagram: Intel CPUvnenovNo ratings yet

- SN 74 HC 166Document35 pagesSN 74 HC 166Carlos OrtegaNo ratings yet

- MX88V44 MxicDocument63 pagesMX88V44 MxicmirandowebsNo ratings yet

- Troubleshooting1 PDFDocument68 pagesTroubleshooting1 PDFanonymus algorithmNo ratings yet

- Marco Vardaro - PHD Thesis - 2018 01 14 (104-108)Document5 pagesMarco Vardaro - PHD Thesis - 2018 01 14 (104-108)mjd rNo ratings yet

- Road To VlsiDocument8 pagesRoad To VlsiAbhinandan GhosalNo ratings yet

- Lastexception 63820220204Document13 pagesLastexception 63820220204Matías FigueroaNo ratings yet

- FEM-9 221 EnglischDocument9 pagesFEM-9 221 EnglischxgclNo ratings yet

- Big Data For Open Innovation in SMEs and Large CorporationsDocument17 pagesBig Data For Open Innovation in SMEs and Large CorporationsJuan Carlos Álvarez SalazarNo ratings yet

- Uber Partner Agreement November 10 2014Document19 pagesUber Partner Agreement November 10 2014Prasad ShriyanNo ratings yet

- BABOK - Techniques by KADocument1 pageBABOK - Techniques by KABenhar Masahod BLM-VLOGNo ratings yet

- Data Sheet: FeaturesDocument8 pagesData Sheet: FeatureschristianNo ratings yet

- Allplan 2014 SBS SysadmNetworkDocument157 pagesAllplan 2014 SBS SysadmNetworkcan canNo ratings yet

- Ils Z Rwy10 CatDocument1 pageIls Z Rwy10 CatDante RussiaNo ratings yet

- Vapor-Logic 6 V V: Installation and Operation Manual N O in ODocument108 pagesVapor-Logic 6 V V: Installation and Operation Manual N O in OLeo ReyesNo ratings yet

- A Dynamic Route Guidance System Based On Real Traffic Data 2001 European Journal of Operational ResearchDocument7 pagesA Dynamic Route Guidance System Based On Real Traffic Data 2001 European Journal of Operational ResearchMarcoLuisDoradoPinedaNo ratings yet

- CSL5404 CompilerDesignLabDocument2 pagesCSL5404 CompilerDesignLabAyeshaNo ratings yet

- DFA AssessmentDocument328 pagesDFA AssessmentMALOTH BABU RAO76% (42)

- 07-08-2023 G-Tel Upadte T ListDocument23 pages07-08-2023 G-Tel Upadte T ListtelecommahadevNo ratings yet

- MikroTik Wireless Wire nRAYDocument3 pagesMikroTik Wireless Wire nRAYddddNo ratings yet

- Vinafix - VN - Tra Ma IC Richtek 1Document42 pagesVinafix - VN - Tra Ma IC Richtek 1jjoaquimmartinsNo ratings yet

- Coa Lab 4Document6 pagesCoa Lab 405raiuttuNo ratings yet

- Guidance For Industry - Part 11, Electronic Records Electronic Signatures - Scope and ApplicationDocument12 pagesGuidance For Industry - Part 11, Electronic Records Electronic Signatures - Scope and ApplicationSandeep KumarNo ratings yet

- Commit Log v1.0bDocument3 pagesCommit Log v1.0bcory ahumadaNo ratings yet

- Pandas PD: File PD Read - CSV File HeadDocument10 pagesPandas PD: File PD Read - CSV File HeadAbhijeet DubeyNo ratings yet

- Five Rules For Creating Great PresentationsDocument56 pagesFive Rules For Creating Great PresentationsAJier CHukyNo ratings yet

- Endoscopic Flushing Pump and AccessoriesDocument5 pagesEndoscopic Flushing Pump and AccessoriesЭнхЗаяаNo ratings yet

- Lom LogDocument2 pagesLom LogVilma CuculNo ratings yet

- Maybank2U Biz / Maybank Autocredit Application FormDocument4 pagesMaybank2U Biz / Maybank Autocredit Application Formmk100% (1)

- PWC Healthcare ReportDocument13 pagesPWC Healthcare ReportDark KnightNo ratings yet

- HotelDocument8 pagesHoteldhiren swainNo ratings yet

- Python Inheritance - Is It Necessary To Explicitly Call The Parents Constructor and Destructor - Stack OverflowDocument2 pagesPython Inheritance - Is It Necessary To Explicitly Call The Parents Constructor and Destructor - Stack OverflowvaskoreNo ratings yet

- User Manual (89v51rd2)Document4 pagesUser Manual (89v51rd2)rahul_kumbhar05No ratings yet

- Blood Count TrackerDocument8 pagesBlood Count TrackerSrinivasan .DNo ratings yet

- ALD Management (SRAN18.1 02)Document239 pagesALD Management (SRAN18.1 02)VVL1959No ratings yet