Professional Documents

Culture Documents

HỌC ONLINE 2022.11.12 CAP-Corrective Action Plan - Hướng Dẫn QA QC Làm Bảng Hành Động Khắc Phục Lỗi

Uploaded by

vuhien393Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HỌC ONLINE 2022.11.12 CAP-Corrective Action Plan - Hướng Dẫn QA QC Làm Bảng Hành Động Khắc Phục Lỗi

Uploaded by

vuhien393Copyright:

Available Formats

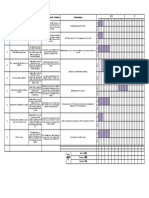

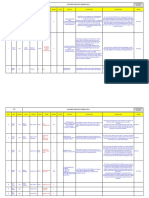

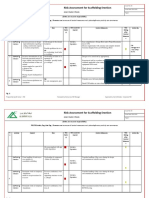

CORRECTIVE ACTION PLAN

Supplier Name Supplier No.

Factory Name Factory No.

Factory Location

Name of Factory

representative,

Phone & Email:

CAP Reviewed

1. What is

By:

Remedial Actions Date of Completion

CAP?

(To be filled by Factory) (To be filled by

Root Cause of Compliance Factory) JCP QA

Issue No. Details of compliance (To be filled by Factory)

(To be filled by Factory) Review

CAP is

mean

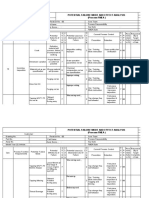

- Line leader not follow closely to quality thread

Corrective

- Worker sew armhole overlock not relaxed( 1 layer so stretch, 1

layer Action

relaxed) Plan - Line technican guide again for worker apply correct sewing end

1

2.sleeve

- Setting When ornotch mark/ chalk mark

not follow

operation, special for polyester+ spandex often to pukering.

28-Dec-18 sucking

- WrongWhy wedirection

sleeve cap

- Detail QC check step by step, once have defect sort out for

worker immediately repare before sew finished garment. machine

have to

- QC check not carefuly to mising defect.

: máy

arrange hút chỉ

bám

Armhole seam/ sleeve setting seam puckering

the CAP?

When have - Line technican guide again for worker manipulate correct

some

- Worker armhole overlock not relaxe, pull sleeve when sew.

when sew.

Fault

- Ironcomplains/ yarn/

2 Require iron worker matching sleeve open edge before iron. 28-Dec-18

part finish garment not matching sleeve edge when iron

buyer ron leader random check garment of worker after iron to

pulling

comments. guarantee quality.

3. Which yarn

departmen

t arrange Defect

3 the CAP?

- Worker cutting thread not careful then cut on the seam Line leader guide again for thread cutting worker to avoid cut on

seam.

28-Dec-18 length

CAP >5"

arrange by follow 4

factory QA point

dept. system

4.

- Worker not check 100% cutting panel before provid to line for

- must be check 100% cutting panel before bring to line to sewing.

fabric

sewing.Who/whic'

4

- QC h check not careful to mising defect.

- /Open meeting to guide again a inspection way to avoid missing

defect.

28-Dec-18

inspectio

departmen n, defect

t will point

approval will be 2

the CAP? - Require iron worker matching bottom edge before iron. points

5 the person

- Iron part finish garment not matching bottom edge when iron

- iron leader random check garment of worker after iron to

28-Dec-18

which guarantee quality.

Repair

provide by

comment replace

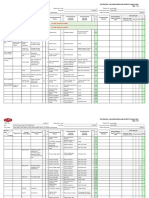

willsew coverstitch to have big raw edge when cut remove

- Worker

approval

not clean fabric. - Technican attach tool on coverstitch machine to avoid have raw sleeve

6

CAP,

- Worker cutting thread not clean

edge 28-Dec-18 panel

- Line leader Require worker cutting thread clean.

- QC normally

check not careful to mising defect.

buyer QA Front

5. what is bottom

the most hem

common poor

defect for shape/

crew out of

neck?

Wavy/ shape:

stretch at Center

neck top front

edge/ bottom

twisted hem

- How to hiking

improve? root

+ recheck cause:

the neck - poor

length

+ make the ironing

V join of - not

neck seam enough

+ If neck/ CF body

body fabric length/

by cotton, body

will adjust length

neck from

length with HPS

alittle bit

shorter - front

than neck body

body length

circumfere panel

nce. --> shorter

after since dry

joined the printing

neck will --> to

have improve:

slightly

puckering, make

it will be side

flat after seam

ironing. length

+ improve shorter

sewing within

operation. toleranc

what is sleeve

e

opening stitch Adjust

type? pattern

double needle to make

three thread cur front

cover stitch bottom

What is the hem

most

common

(2mm)

defect for Improve

hem seam sewing

allowance?

Unclean/ un- operatio

neat/ fraying/ n

too big/

uneven/

pleat/rolling. Issue no.

What is hem

6: sleeve

seam hem

allowance seam

acceptable

level? allowanc

evenly 1/16 - e fraying

1/8" What is

Pls list out stitching

all kind of type of

stitch/ sleeve

seam hem?

quality 3thread

defect? overlock

- Broken +

stitch 2needle

- Run of 4 thread

stitch: cover

trượt mí/ stitch

sụp mí

- Skip

stitch: bỏ

mũi

- thread

density/

SPI =

stitch per

inch: SPI

too high =

stitch

density

too high,

thread

density/

SPI not

consistent

- Stitch

tension:

stitch too

loose/

tight, not

consistent

, not

suitable

- join

stitch

- stitch

not neat,

fraying

- under/

loop/bobin

thread

visible

- not cut

thread end

Thread

end

depend

thread

end

length to

separate

to

Minor/

Major

thread end sucking machine

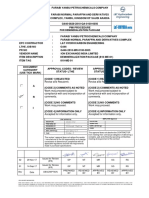

Corrective Photos

Issue No:1 Issue No:2

Corrective Photos

Issue No:3 Issue No:4

Corrective Photos

Issue No:5 Issue No:6

Corrective Photos

Corrective Photos

Corrective Photos

You might also like

- SMT Generic Control PlanDocument2 pagesSMT Generic Control Plansmtdrkd81% (21)

- TB 60 Repair Parts PDFDocument282 pagesTB 60 Repair Parts PDFvatasa100% (2)

- (Problem Books in Mathematics) Antonio Caminha Muniz Neto - An Excursion Through Elementary Mathematics, Volume III - Discrete Mathematics and Polynomial Algebra (2018, Springer)Document647 pages(Problem Books in Mathematics) Antonio Caminha Muniz Neto - An Excursion Through Elementary Mathematics, Volume III - Discrete Mathematics and Polynomial Algebra (2018, Springer)Anonymous iH6noeaX7100% (2)

- WMS 168+Installation+of+Cable+Catenary+WireDocument6 pagesWMS 168+Installation+of+Cable+Catenary+Wireozer100% (1)

- Domesticity and Power in The Early Mughal WorldDocument17 pagesDomesticity and Power in The Early Mughal WorldUjjwal Gupta100% (1)

- Guideline 4M Change MatrixDocument3 pagesGuideline 4M Change MatrixAman JasujaNo ratings yet

- Without Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Document13 pagesWithout Punch Part Mix: Customer/Supplier / in Plant Quality Problem Analysis and Countermeasure Sheet (5 - Rule)Rohtash fastnerNo ratings yet

- Daily Progress Report: Aiims BilanpurDocument2 pagesDaily Progress Report: Aiims BilanpurAnkit JainNo ratings yet

- RESP./ Date Verification (Qa Pic) Improvement Action Root Cause / Analysis Issue Detail StatusDocument2 pagesRESP./ Date Verification (Qa Pic) Improvement Action Root Cause / Analysis Issue Detail StatusSameer SaxenaNo ratings yet

- Ra - MC 9 Kiln RepairDocument4 pagesRa - MC 9 Kiln RepairalbinkhanNo ratings yet

- PTW Flow ChartDocument1 pagePTW Flow ChartRaj VeenNo ratings yet

- Discipline Prepared by Reviewed by Approved by Date (Dd-Mm-Yy) Code Lthe Approval Employer App ProvalDocument7 pagesDiscipline Prepared by Reviewed by Approved by Date (Dd-Mm-Yy) Code Lthe Approval Employer App ProvalVinay YadavNo ratings yet

- PFMEA&control Plan LinkageDocument7 pagesPFMEA&control Plan LinkageToni HimawanNo ratings yet

- Six Sigma Sample PresentationDocument25 pagesSix Sigma Sample Presentationsa_arunkumarNo ratings yet

- Process Audit Check SheetDocument5 pagesProcess Audit Check SheetaliNo ratings yet

- 2) RMC OcDocument1 page2) RMC OcJohn SiewNo ratings yet

- Mass Production Preparation Plan Specified Action PlanDocument1 pageMass Production Preparation Plan Specified Action Plan12ocaNo ratings yet

- Customer:: Potential Failure Mode and Effect Analysis (Process FMEA)Document8 pagesCustomer:: Potential Failure Mode and Effect Analysis (Process FMEA)Rajnish PotdarNo ratings yet

- JAPL-F-HE-019 Scraper CheckDocument1 pageJAPL-F-HE-019 Scraper CheckAli HassanNo ratings yet

- BP-5.1.2D OJT Effectiveness SHEET - Level-2Document1 pageBP-5.1.2D OJT Effectiveness SHEET - Level-2shinuNo ratings yet

- Potential Failure Mode and Effective Analysis (Process FMEA)Document1 pagePotential Failure Mode and Effective Analysis (Process FMEA)nainarmuthuramalingamNo ratings yet

- 0718 County LineDocument8 pages0718 County LineMineral Wells Index/Weatherford DemocratNo ratings yet

- R&R EugeneDocument1 pageR&R EugenePhương Thanh TrịnhNo ratings yet

- Potential Failure Mode and Effects Analysis (Pfmea)Document3 pagesPotential Failure Mode and Effects Analysis (Pfmea)aslamNo ratings yet

- CD6 Prototype PFMEADocument4 pagesCD6 Prototype PFMEAmpedraza-1No ratings yet

- 8D Gas BoxDocument5 pages8D Gas BoxRD PlcsNo ratings yet

- FL1A SD Joblist Januari FRP 20210406Document11 pagesFL1A SD Joblist Januari FRP 20210406IR MA Al AzharNo ratings yet

- CP ProductionDocument7 pagesCP Productionsandeep.pantNo ratings yet

- 14M GREADER InspectionDocument9 pages14M GREADER Inspectionkhaled fathyNo ratings yet

- Plan de Surveillance ExempleDocument2 pagesPlan de Surveillance ExempleAudrey GavaletNo ratings yet

- Hazard Identification & Risk Assessment - Production ShopDocument1 pageHazard Identification & Risk Assessment - Production ShopDheeraj AroraNo ratings yet

- G446-0828-2810-QA-0100-0050 PMI ProcedureDocument9 pagesG446-0828-2810-QA-0100-0050 PMI ProcedureVinay Yadav100% (1)

- Problem Investigation ReportDocument2 pagesProblem Investigation ReportShaheenNo ratings yet

- CH Dilawar C.VDocument1 pageCH Dilawar C.Vwali mustafaNo ratings yet

- QAP (Honeycomb Fabric)Document4 pagesQAP (Honeycomb Fabric)Ahamed UmarNo ratings yet

- NRC Flow ProcessDocument1 pageNRC Flow ProcessSutarto SutartoNo ratings yet

- BE12 HSEQ INTERNAL AUDIT Report (2020)Document5 pagesBE12 HSEQ INTERNAL AUDIT Report (2020)sunilNo ratings yet

- Feasiblity Review 1 1 HD BucketDocument3 pagesFeasiblity Review 1 1 HD BucketSandeep KumarNo ratings yet

- Work Instruction Type RII IK-FBI-PROJ-PR-14-006 Rev.01. Englis...Document1 pageWork Instruction Type RII IK-FBI-PROJ-PR-14-006 Rev.01. Englis...Hudzaifah AbdussalamNo ratings yet

- SAMPLE - Process FlowDocument2 pagesSAMPLE - Process Flowakav123No ratings yet

- Daily Report 7 April 2023 Sent PDFDocument2 pagesDaily Report 7 April 2023 Sent PDFBambang ArdiansyahNo ratings yet

- SMT Process MapDocument1 pageSMT Process Map210151 JOSE MANUEL RAMIREZ PINEDANo ratings yet

- Pt. Prestasi Inti Rubber: Control PlanDocument1 pagePt. Prestasi Inti Rubber: Control PlanHardjonoNo ratings yet

- Quality Control Plan CoatingDocument3 pagesQuality Control Plan CoatingtonierlandaNo ratings yet

- Phalaborwa - ZBS Upgrade Project S&D ConsortiumDocument2 pagesPhalaborwa - ZBS Upgrade Project S&D Consortiumcontrax8No ratings yet

- S.P. Engineering Works: Part Inspection ReportDocument1 pageS.P. Engineering Works: Part Inspection ReportshalinmishraNo ratings yet

- Daily Report 8 April 2023 PDFDocument2 pagesDaily Report 8 April 2023 PDFBambang ArdiansyahNo ratings yet

- Phalaborwa - ZBS Upgrade ProjectDocument3 pagesPhalaborwa - ZBS Upgrade Projectcontrax8No ratings yet

- Complaint Summary All.2014Document15 pagesComplaint Summary All.2014Sameer SaxenaNo ratings yet

- Nissan Magnite - Seat Cover Inspection ReportDocument19 pagesNissan Magnite - Seat Cover Inspection ReportQuality elegantNo ratings yet

- Protection Relay Verification and Inspection Switchgear DataDocument11 pagesProtection Relay Verification and Inspection Switchgear DatamomoNo ratings yet

- Actividad de DurezaDocument7 pagesActividad de DurezaMartin Fibela EsparzaNo ratings yet

- Airend Engine AsslyDocument2 pagesAirend Engine AsslyabhijitNo ratings yet

- Repair Rate Evaluation Flow ChartDocument1 pageRepair Rate Evaluation Flow ChartjorgekarlosprNo ratings yet

- Risk Assessment Erection of Scaff. UnisteelDocument10 pagesRisk Assessment Erection of Scaff. UnisteelshafiqNo ratings yet

- CAPA Incomplete Part MixDocument16 pagesCAPA Incomplete Part MixRohtash fastnerNo ratings yet

- Edoc Corrective Action Plan 2016Document2 pagesEdoc Corrective Action Plan 2016musewejamesoumaNo ratings yet

- Ec CompoDocument18 pagesEc CompoashokvannanubNo ratings yet

- Standard Operation ProcedureDocument3 pagesStandard Operation ProcedureAnand KesarkarNo ratings yet

- Production Study Sheet: Effective Non Effective ActivitiesDocument3 pagesProduction Study Sheet: Effective Non Effective Activitieslodestar ieNo ratings yet

- Production Flow ChartDocument1 pageProduction Flow ChartAmeer uddinNo ratings yet

- Organogram of WashingDocument1 pageOrganogram of WashingReazus SalehinNo ratings yet

- Makalah Bahasa Inggris TranslateDocument14 pagesMakalah Bahasa Inggris TranslatevikaseptideyaniNo ratings yet

- Electronics 11 02566Document13 pagesElectronics 11 02566卓七越No ratings yet

- Citibank CaseDocument6 pagesCitibank CaseLalatendu Das0% (1)

- Army Aviation Digest - Apr 1971Document68 pagesArmy Aviation Digest - Apr 1971Aviation/Space History LibraryNo ratings yet

- Corelink Mmu600ae TRM 101412 0100 00 enDocument194 pagesCorelink Mmu600ae TRM 101412 0100 00 enLv DanielNo ratings yet

- Kortz Center GTA Wiki FandomDocument1 pageKortz Center GTA Wiki FandomsamNo ratings yet

- Managing Errors and ExceptionDocument12 pagesManaging Errors and ExceptionShanmuka Sreenivas100% (1)

- Population Second TermDocument2 pagesPopulation Second Termlubna imranNo ratings yet

- Retail Branding and Store Loyalty - Analysis in The Context of Reciprocity, Store Accessibility, and Retail Formats (PDFDrive)Document197 pagesRetail Branding and Store Loyalty - Analysis in The Context of Reciprocity, Store Accessibility, and Retail Formats (PDFDrive)Refu Se ShitNo ratings yet

- Outlook of PonDocument12 pagesOutlook of Ponty nguyenNo ratings yet

- Kallatam of Kallatar (In Tamil Script Tscii Format)Document78 pagesKallatam of Kallatar (In Tamil Script Tscii Format)rprabhuNo ratings yet

- Standard BMW PDFDocument19 pagesStandard BMW PDFIna IoanaNo ratings yet

- Landscape ArchitectureDocument9 pagesLandscape Architecturelisan2053No ratings yet

- City Limits Magazine, December 1981 IssueDocument28 pagesCity Limits Magazine, December 1981 IssueCity Limits (New York)No ratings yet

- SHS G11 Reading and Writing Q3 Week 1 2 V1Document15 pagesSHS G11 Reading and Writing Q3 Week 1 2 V1Romeo Espinosa Carmona JrNo ratings yet

- Study and Interpretation of The ScoreDocument10 pagesStudy and Interpretation of The ScoreDwightPile-GrayNo ratings yet

- Monitor 14sepDocument2 pagesMonitor 14sepabhaymvyas1144No ratings yet

- Current Harmonics: Electric Power System Power QualityDocument3 pagesCurrent Harmonics: Electric Power System Power QualityAlliver SapitulaNo ratings yet

- Lecture 19 Code Standards and ReviewDocument27 pagesLecture 19 Code Standards and ReviewAdhil Ashik vNo ratings yet

- Ode To The West WindDocument4 pagesOde To The West WindCharis Mae DimaculanganNo ratings yet

- 6int 2008 Dec ADocument6 pages6int 2008 Dec ACharles_Leong_3417No ratings yet

- Chapter 30 - HypertensionDocument70 pagesChapter 30 - HypertensionSakaC.TanayaNo ratings yet

- Caroline Coady: EducationDocument3 pagesCaroline Coady: Educationapi-491896852No ratings yet

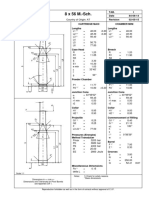

- 8 X 56 M.-SCH.: Country of Origin: ATDocument1 page8 X 56 M.-SCH.: Country of Origin: ATMohammed SirelkhatimNo ratings yet

- Music Production EngineeringDocument1 pageMusic Production EngineeringSteffano RebolledoNo ratings yet

- Microsoft Powerpoint BasicsDocument20 pagesMicrosoft Powerpoint BasicsJonathan LocsinNo ratings yet

- Solutions DPP 2Document3 pagesSolutions DPP 2Tech. VideciousNo ratings yet