Professional Documents

Culture Documents

Multistage Aspects and Unsteady Effects of Stator

Multistage Aspects and Unsteady Effects of Stator

Uploaded by

kanbur.191Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Multistage Aspects and Unsteady Effects of Stator

Multistage Aspects and Unsteady Effects of Stator

Uploaded by

kanbur.191Copyright:

Available Formats

See discussions, stats, and author profiles for this publication at: https://www.researchgate.

net/publication/239400275

Multistage Aspects and Unsteady Effects of Stator and Rotor Clocking in an Axial

Turbine With Low Aspect Ratio Blading

Article in Journal of Turbomachinery · January 2006

DOI: 10.1115/1.2101855

CITATIONS READS

48 457

5 authors, including:

Thomas Behr Luca Porreca

Accelleron MAN Energy Solutions

14 PUBLICATIONS 427 CITATIONS 15 PUBLICATIONS 246 CITATIONS

SEE PROFILE SEE PROFILE

Anestis Kalfas

Aristotle University of Thessaloniki

242 PUBLICATIONS 1,859 CITATIONS

SEE PROFILE

All content following this page was uploaded by Anestis Kalfas on 28 February 2014.

The user has requested enhancement of the downloaded file.

Multistage Aspects and Unsteady

Effects of Stator and Rotor

Clocking in an Axial Turbine With

T. Behr

e-mail: behr@lsm.iet.mavt.ethz.ch

Low Aspect Ratio Blading

This paper presents the outcome of a recent study in clocking-related flow features and

L. Porreca multistage effects occurring in high-pressure turbine blade geometries. The current in-

vestigation deals with an experimentally based systematic analysis of the effects of both

T. Mokulys stator-stator and rotor-rotor clocking. Due to the low aspect ratio of the turbine geom-

etry, the flow field is strongly three-dimensional and is dominated by secondary flow

A. I. Kalfas structures. The investigation aims to identify the flow interactions involved and the asso-

ciated effects on performance improvement or degradation. Consequently a three-

R. S. Abhari dimensional numerical analysis has been undertaken to provide the numerical back-

ground to the test case considered. The experimental studies were performed in a two-

Turbomachinery Laboratory,

stage axial research turbine facility. The turbine provides a realistic multi-stage

Swiss Federal Institute of Technology,

environment, in which both stator blade rows and the two rotors can be clocked relative

8092 Zurich, Switzerland

to each other. All blade rows have the same blade number count, which tends to amplify

clocking effects. Unsteady and steady measurements were obtained in the second stage

using fast response aerodynamic probes and miniature pneumatic five-hole probes. The

current comprehensive investigation has shown that multistage and unsteady flow effects

of stator and rotor clocking in low aspect ratio turbines are combined in a nonlinear

fashion caused by axial and radial redistribution of low energy fluid. The integral result

of clocking on stage efficiency is compensated by competing loss generating mechanisms

across the span. 关DOI: 10.1115/1.2101855兴

Introduction to-peak value of aerodynamic efficiency variation was determined

to be at 0.3% overall and up to 0.8% for the midspan region.

The relative clocking positions of the stator vanes and the rotor

Efficiencies of five radial positions showed differences in periodi-

blades affect the overall performance of multistage axial turbines.

cal shape, position of minimum and maximum, as well as their

An optimal clocking position of stators and rotors in a multistage

difference when plotted against the vane clocking position. Rein-

turbine aims to maximize the overall efficiency as well as to op-

möller et al. 关3兴 measured a maximum difference in relative aero-

timize the unsteady mechanical loading on the airfoils. The pre-

dynamic efficiency in a 1.5-stage turbine of 1.0% when clocking

requisite of an overall successful design are prediction tools that

the stator blade rows. Gombert et al. 关4兴 determined aerodynamic

incorporate the effects caused by clocking.

efficiency for different clocking positions of the first stator in a

Finding an optimal relative circumferential position of stators three-stage turbine with high aspect ratio blading. Although the

and rotors in a multistage axial turbine is the subject of extensive mean peak-to-peak value of the relative efficiency at different

investigations in the last decade. The prospect of increasing tur- span positions is around 1.5%, the optimum efficiency occurs at

bine efficiency by consciously positioning the blade rows drives different clocking positions.

the study of understanding the aspects of the flow physics, which The change in efficiency due to circumferential clocking of

are responsible for this effect. Thereby the main focus lies on blade rows is caused by redistributing loss areas within the blade

unsteady effects caused by the relative motion of adjacent blade passages. It was commonly found that a maximum in efficiency

rows. could be observed when the wake of an upstream stator hits the

Experimental findings could show the effect of clocking on leading edge of the subsequent stator. If the wake passes between

turbine efficiency, however the level of variation is not yet clear. two stator blades, degradation in efficiency occurs. In the refer-

Jouini et al. 关1兴 conducted a series of tests on a two-stage turbine enced test cases 关1–3兴, low aspect ratio blade rows were investi-

facility to investigate the effect of stator-stator and rotor-rotor gated. In such cases a highly three-dimensional flow field domi-

clocking on the aerodynamic efficiency. It was found that for both nated by secondary flow structures exists. Walraevens et al. 关5兴

options this efficiency revealed a sinusoidal shape with respect to gives an interpretation of the unsteady flow around a second stator

the clocking position with a peak-to-peak difference of 4% in a of a 1.5-stage turbine with low aspect ratio blading. Tiedemann et

relative basis. Spanwise variation in efficiency was detected to be al. 关6兴 investigated unsteady stator-rotor interactions in a single-

small. However, the region at 90% span showed a shift in phase stage high-pressure turbine with its effect on a downstream stator.

and higher reaction on clocking with respect to the mean due to Höhn et al. 关7兴 classifies effects in a multistage turbine that are

secondary flows offsetting the wake position. Huber et al. 关2兴 acting on a stat or wake that passes eventually through a subse-

conducted an investigation of different vane clocking positions in quent stator. In this context spanwise differences in aerodynamic

a two-stage test turbine with low aspect ratio blading. The peak- efficiency behavior as an effect of circumferential clocking might

be consequential. Corresponding phenomena, such as phase shifts

Contributed by the Turbomachinery Division of ASME for publication in the

between the optimum clocking positions, could be detected in

JOURNAL OF TURBOMACHINERY. Manuscript received by June 28, 2004; final manu- 关1–4兴.

script received June 28, 2005. Review conducted by C. Scrivener. Various numerical simulations were conducted to predict the

Journal of Turbomachinery Copyright © 2006 by ASME JANUARY 2006, Vol. 128 / 11

effects of clocking in multistage turbines. Griffin et al. 关8兴 cor-

rectly predicts the sinusoidal pattern of the efficiency at midspan

of the test case in 关2兴 using a 2D algorithm. However, the magni-

tude of the maximum efficiency change is less than in the experi-

ment 共±0.15% 兲. Differences in 2D and 3D numerical calculations

of stator-stator clocking phenomena were observed by Dorney and

Sharma 关9兴 and Dorney and Sondak 关10兴. When applying a 2D

algorithm a maximum change in efficiency of 2% was predicted,

while the 3D simulation resulted in 1%. Different opinions exist

about the effect of flow unsteadiness on the variation of efficiency

in downstream blade rows caused by stator clocking. Dorney and

Sharma 关9兴 found highest efficiency at maximum unsteadiness,

whereas Griffin et al. 关8兴 observed the opposite.

The current study intends to shed further light on the issue of

clocking by investigating the steady and unsteady effects of stator-

stator and rotor-rotor clocking in a two-stage high-pressure tur-

bine. It will focus on the effects of clocking on performance and

flow features that are especially related to the low aspect ratio of

the used blade rows.

Experimental Method

Research Turbine Facility. The facility accommodates two

axial turbine stages. The air-loop is of a quasi-closed type and

includes a radial compressor, a two-stage water to air heat ex-

changer, and a calibrated venturi nozzle for mass flow measure- Fig. 1 “LISA” Two stages axial turbine facility

ments. Downstream of the turbine the air-loop is open to atmo-

spheric conditions. A dc generator absorbs the turbine power and

controls the rotational speed of the turbine. The first and the sec-

ond rotor are mechanically decoupled by a twin spool shaft de- LSM 关14,15兴. The mainstream flow field is typically measured

sign. A torque meter measures the torque of the second rotor. using a 1.8 mm tip diameter single sensor FRAP probe in virtual-

The turbine design allows quick and precise assembly and an three-sensor mode providing two-dimensional, time-resolved flow

easy access to the measurement planes. A number of different field information. The FRAP probe technology provides also tem-

intrusive and nonintrusive measurement methods can be applied. perature data at a frequency of up to 10 Hz.

The facility is equipped with a four-axis numerically controlled Clocking Test Cases. The nomenclature to identify the stator-

probe positioning system with high accuracy in every direction. stator 共SS兲 and rotor-rotor 共RR兲 clocking cases has the format

The turbine entry temperature 共TET兲 is controlled to an accuracy SSxxRRyy. The placeholder xx and yy represent the clocking po-

of 0.3% and the rpm is kept constant within ±0.5 min−1 by a dc sition as a percentage of the pitchwise chord 共Fig. 2兲.

generator. The pressure difference across the turbine is stable Two shrouded test cases 共TC1, TC2兲 with identical profile ge-

within 0.3%. The turbine is operated at constant pressure differ- ometries have been investigated during this clocking study.

ence across the stages. With this strategy even minor changes in TC1 measurements were taken in a 2 ⫻ 2 matrix containing two

mechanic efficiency due to clocking can be detected by the sys- stator-stator clocking positions 共SS00, SS50兲 and two rotor-rotor

tems high sensible torquemeters. The alternative way of operation clocking positions 共RR00, RR50兲. For all four combinations the

at constant power would not reach an equivalent level of accuracy. flow was measured in all three measurement planes with the

The interested reader can find a more detailed description of the steady technique. In addition both stator clocking positions were

research facility in Sell et al. 关11兴. A cross section of the turbine tested in all measurement planes with the unsteady technique at

module is shown in Fig. 1. The first stator blade row can be 0% rotor clocking 共RR00兲.

continuously positioned in the circumferential direction relative to In TC2 unsteady measurements were conducted in all planes for

the second stator. In addition, both rotor blade rows can be SS00RR00, SS50RR00, and SS50RR50. For a performance evalu-

clocked relatively to each other with increments of 0.25 deg. ation both rotor exit planes were tested with the coarse grid at

Key parameters of the rig are presented in Table 1. The Rey- eight different stator clocking position at RR00 and RR50.

nolds number based on axial chord is in the order of 2 ⫻ 105. The Two different measurement grids per pitch have been used dur-

blade row geometries tested for this clocking investigation are ing the campaign for the area traverses. In order to investigate a

designed to model high-pressure turbine blade geometries. In gas flow field in a measurement plane 共MP兲 a grid of 20 equidistant

turbines the effects of transition are known to be crucial for the circumferential and 30 radial positions has been used. This grid is

performance of the blades especially in low-pressure rather than the standard for the conducted measurements. A coarse grid was

high-pressure turbines 关12兴. In the current investigation, any pos-

sible effects caused by transition on the blades would apply in all

of the tested clocking positions since all Reynolds number rel-

evant parameters are kept constant. Table 1 Main parameter of “LISA” 2-stages axial turbine re-

search facility

Measurement Technology. A number of unsteady as well as

steady measurement techniques are available at the Turbomachin- Rotor speed 共RPM兲 2625

ery Laboratory 共LSM兲. Flow parameters at frequencies up to Pressure ratio 1.38

40 kHz, including total and static pressure, flow angles, velocity Mass flow 共kg/s兲 10.65

Blades 42/ 42

components, and Mach number, can be captured with fast re-

Aspect ratio 1.8

sponse pressure probes. The steady flow field is measured with Tip diameter 共mm兲 800

miniature five-hole probe with a tip diameter as small as 0.9 mm Mach number at rotor exit/stator exit 0.1/ 0.35

关13兴. The unsteady pressure measurement technology of the Fast Reynolds number based on axial chord 2 ⫻ 105

Response Aerodynamic Probes 共FRAP兲 was developed at the

12 / Vol. 128, JANUARY 2006 Transactions of the ASME

Fig. 2 Relative circumferential stator-stator „SS… and rotor-

rotor „RR… clocking positions in percent of circumferential

chord. Position of measurement planes

used once for TC2 to get sufficiently representative values of the

MP for an efficiency evaluation. This measurement grid consists Fig. 3 CFD—Mesh of “LISA” two-stage axial turbine

of 7 equidistant circumferential and 15 radial positions. configuration

All area plots shown is this paper are views in the upstream

direction and contain the area of two pitches. In there, the rota-

tional direction of the rotor blades is from the right to the left. field in this measurement plane is exposed to the potential field of

the second stator, which has a dominating influence in the follow-

Numerical Method ing flow parameters such as static pressure and flow yaw angle.

Due to the application of five-hole probes, the measurements

The 3D steady and unsteady Navier-Stokes multistage solver are pneumatically averaged and do not show pitchwise resolution

Stage3D has been derived from the original Dawes code BTOB3D of the high-frequency signal of the passing rotor blades. However,

关16兴, running a new discretization scheme from Jameson and the rotor signal is still resolved in the radial direction. This fact

Baker 关17兴. The validation on low speed turbines, comparable to allows the detection of quasi-steady flow features, which originate

LISA, has been undertaken by Emunds et al. 关18兴, where the in the first stator blade row. These features are quasi-stationary in

validity of the computational approach on low Mach number axial the absolute frame of reference, since they are not moving relative

turbines has previously been shown. The solver has an explicit to the stators, but they are modulated in time by the rotor blades.

five-step, fourth-order Runge-Kutta cycle, using three level mul- According to the relative circumferential position of the first

tigrid convergence acceleration. The spatial discretization uses a stator, the location varies, where its secondary flow structures ap-

second-order central differencing scheme. It is equipped with sev- proach the leading edge of the second stator. This dependence can

eral turbulence models, from which the one-equation of Spalart be seen in the pneumatically averaged distribution of the total

and Allmaras 关19兴 has been chosen for the investigation in this pressure coefficient Cpt downstream of the first rotor for eight

paper. When running steady state the solver uses a so-called different stator-stator clocking positions 共Fig. 4兲. The distribution

mixing-plane between rotating and nonrotating cascades, which of Cpt in the pneumatically averaged area plots shows only a

mixes out circumferential variations. The averaging for the mixing minor influence on the position of the second stators potential

planes is done, using a consistent approach from Denton 关20兴. field. Regions of higher and lower Cpt values can be observed

A nonreflective treatment of outflowing characteristics is ap- from 20% to 80% span, which are corresponding to the position of

plied, which creates a high level of independency from axial spac- the first stator. The span region from 0% to 20% is dominated by

ing between blade rows and mixing planes 关21兴. The unsteady the passing rotor hub passage vortex and the flow, which is going

treatment makes use of fourth-order-accurate sliding meshes at the into the second stators cavity. At the tip region the leakage jet

interfaces, direct periodicity at circumferential borders, as LISA is from the rotor cavity is seen as low Cpt values from 90% to 100%

of integer blade ratio nature, and dual time stepping with a span. At around 85% span, the trace of the passing rotor tip pas-

second-order time stepping scheme. sage vortex appears.

The LISA rig has been modeled in this investigation using The first stator’s secondary flow structure forms a region of low

simple straight H-meshes, without discretization of shroud leak- total pressure 共see dotted line in Fig. 4兲, which is inclined relative

ages 共see Fig. 3兲. to the radial direction. This flow structure can be viewed as a

wake-vortex secondary flow “package.” Hence, by clocking the

Results and Discussion stators relatively to each other, it cannot be achieved that all parts

The following presentation and interpretation of the measure- of the package are aligned with the second stator’s leading edge at

ment and calculation results of the flow field will refer to the three one certain clocking position. In the opinion of the authors the

measurement planes in the order as the flow passes through them. reasons for the inclination are remaining exit swirl out of the

In this context, comparisons between experimental and numerical blade rows of the first stage as well as a nonconstant spanwise

results will be commented. Effects occurring due to stator-stator loading distribution on rotor one.

and rotor-rotor clocking will be commented on in the correspond- The pneumatically averaged values of the absolute flow angles

ing sections. An evaluation of performance measurements will be downstream of the first rotor blade row reflect the position of the

given in the last part of the paper. secondary flow package that originates from the first stator. De-

pending on whether a part of the secondary flow package of the

Flow Behind First Stage (MP 1). The flow in between the first first stator hits the second stator LE or passes in between the two

and the second stage is dominated by secondary flow structures stator blades, it creates a more or less uniform flow angle distri-

created within the first rotor blade row. Remaining flow features bution across the pitch. This effect is demonstrated in Fig. 5 for

from the first stator are seen as quasi-stationary effects. The flow two exemplary span positions, 29% and 79%. The absolute flow

Journal of Turbomachinery JANUARY 2006, Vol. 128 / 13

Fig. 4 TC2—total pressure coefficient Cpt †ⴚ‡ downstream of Rotor 1 at eight

different stator-stator positions at RR00 „coarse grid measurement, pneumati-

cally averaged…. „a… SS00, „b… SS12.5, „c… SS25, „d… SS37.5, „e… SS50, „f… SS62.5,

„g… SS75, and „h… SS87.5.

angle distribution across two pitches is shown at the stator clock- four cases can be distinguished for these two span positions:

ing positions where it has its minimum and maximum amplitude. Case I—SS000: The part of the secondary flow package at 79%

The shaded area represents the variation of flow angles, which span passes in between two stator blades. A maximum peak-to-

occurs at the intermediate stator clocking positions. The following peak value of the flow yaw angle can be observed at this pitch

14 / Vol. 128, JANUARY 2006 Transactions of the ASME

Fig. 5 TC2—pitchwise distribution of absolute flow yaw angle

downstream of rotor 1 at „a… 79% and „b… 23% span „eight stator

clocking positions at RR00…

position 共⌬ = 20 deg兲.

Case II—SS250: The part of the secondary flow package at

23% span hits the LE of the second stator. The flow angle at this

span position shows the smallest variation across the pitch com- Fig. 6 TC2—time resolved pitchwise distribution of absolute

flow yaw angle downstream of rotor 1 at 79% span „a…

pared to the other clocking positions 共⌬ ⬍ 1 deg兲.

SS00RR00 and „b… SS50RR00

Case III—SS500: The part of the secondary flow package close

to the tip 共79% span兲 hits the LE of the second stator. The flow

angle at this span position shows the smallest variation across the fact, two different stator clocking cases are shown in Fig. 7, SS00

pitch compared to the other clocking positions 共⌬ = 5 deg兲. and SS50. The previously discussed span positions are marked as

Case IV—SS750: The part of the secondary flow package at dotted lines across the circumference. The minima in flow angle at

23% span passes in between two stator blades. A maximum peak- 79% span and SS00 can be located in front of the stator leading

to-peak value of the flow yaw angle can be observed at this pitch edge. If both cases are subtracted from each other, the effect of

position 共⌬ = 14 deg兲. clocking on flow yaw angles can be observed 共Fig. 8兲. Each radial

In order to verify this observation, unsteady measurement re- position shows an alternating distribution of minima and maxima

sults for cases I and III are available and presented in Fig. 6. The of flow yaw angle differences across the span. A pitchwise aver-

time-distance diagrams show the flow angle variation across two aged distribution across the span helps to evaluate the integral

stator pitches during a time of three rotor blade passing periods. effect for each span position. For this case, the 50% clocking of

Stationary flow features, i.e., a potential field around a stator LE, the stators results in an underturning at the tip region down to

will be expressed in such plots as parallel to the vertical axis. 80% span. In the midspan region, no significant change is notice-

Flow features moving with the rotor, i.e., rotor wakes, are detect- able. From 0% to 25% span an over-under-turning effect can be

able as diagonal lines oriented from the lower right to the upper observed, which results from the interaction of the rotor hub pas-

left, according to the rotational direction of the rotor. In the case sage vortex and the derivative of the shed stator hub passage

of the current geometry, one stator pitch corresponds to one blade vortex. During the time of a rotor blade passage, when these two

passing period due to an identical number of blades in the stator features interact with each other, the rotor hub passage vortex is

and rotor stages. Both unsteady plots underline the findings from weakened. The position of the second stator’s leading edge rela-

the steady measurements 共Fig. 5共a兲兲. The 50% stator clocking case tive to this interaction zone is of high importance. If the interac-

at 79% span shows much more evenly distributed flow angles tion happens in front of the leading edge, a weaker rotor hub

across the pitch compared to the 0% stator clocking case. passage vortex approaches the second stator’s leading edge.

What was explained on that exemplary span position can be Hence, the potential of loss production is reduced. If the interac-

applied to the whole pitch. Due to the inclined shape of the sec- tion occurs in the midpitch area, the rotor vortex with its full

ondary flow structure created in the first stator, it is not possible to strength approaches the leading edge of the second stator. The

have evenly distributed flow angles across the pitch at all span effect of this phenomenon can be observed in reduced perfor-

positions at one certain stator clocking position. To visualize this mance of this span region at a stator clocking position of 50%

Journal of Turbomachinery JANUARY 2006, Vol. 128 / 15

Fig. 7 Flow yaw angle distribution downstream of rotor 1 at „a… 0% and „b…

50% stator clocking „RR00…

when compared to the 0% position. difference in flow yaw angles between rotor clocking of 50% and

Resulting from this discussion it can be stated that, in the cur- 0% pitch. When the stators are aligned the rotor clocking has very

rent case, the inlet angle distribution of the second stator depends little influence on the flow angles in front of stator 2. Whereas in

especially on the position of the derivatives of the first stators the SS50 case, there are significant differences, which are ob-

passage vortices. The wake structure appears only in a very lim- served in the hub region up to 20% span, as well as close to the

ited area and has minor influence. In addition the impact of the casing endwall. However the midspan region remains unchanged.

cavity flow has to be considered when clocking the stators. This comparison leads to the conclusion that at the endwalls, the

After the potential of the stator clocking on incidences on the potential field of the downstream second rotor can have an up-

second stator has been shown, now the rotor-rotor clocking will be stream effect on the inlet flow angles of the second stator, if an

evaluated. Figure 9 shows for the SS00 and SS50 test cases the appropriate stator-stator clocking position has been chosen.

Fig. 8 Difference of flow yaw angles between 50% and 0% Stator clocking

„RR00… downstream of rotor 1. „a… Pitchwise distribution and „b… circumferen-

tially massaveraged and spanwise distribution

Fig. 9 Difference between 50% and 0% rotor clocking in flow yaw angle distri-

bution downstream of rotor 1 at „a… SS00 and „b… SS50

16 / Vol. 128, JANUARY 2006 Transactions of the ASME

Fig. 10 Spanwise total pressure distribution downstream of

rotor 1—comparison of CFD and experiment

Fig. 12 CFD—static surface pressure distribution of stator 2 at

79% span for four different stator and rotor clocking cases

In order to evaluate the accuracy of the CFD prediction for the

current case a comparison of pitchwise averaged total pressures

downstream of rotor 1 between experimental and numerical re- blade row will have an effect on the static surface pressure distri-

sults is presented in Fig. 10. The CFD model seems to predict the bution of this stage, and therefore an influence on the stator blade

midspan region from 20% to 85% span, being accurate to within loading. CFD results of the static surface pressure distribution at

70 Pa. The neighboring areas at the endwalls are affected by cav- 90% span are presented in Fig. 12. Differences between stator

ity flows and the CFD prediction is not as good. To show also the positions of 0% and 50% are noticeable, whereas rotor clocking

applicability to clocking studies, the area distribution of total pres- does not have a significant influence. While the frontloading of the

sure coefficients derived from experiments and CFD at stator stator does not change, the aft-loading increases when clocking

clocking positions 0% and 50% are shown in Fig. 11. From 0% to the stators to 50%. This difference shows an effect of the inci-

20% span the measurement detects underturned fluid coming from dence on stator 2 in this span region.

the stator 1 cavity, which propagates through the rotor. It appears The way in which a changed stator loading translates into a

as a band of low Cpt in the plot. In the tip region the cavity flow change in turning angle across this stator is demonstrated in Fig.

bypassing the blades of the first rotor can be recognized. Due to 13. Experimental and numerical results show a good agreement in

energy dissipation in the labyrinth of the shroud, the area from the midspan region from 20% to 75% span. This range has now

90% to 100% span shows Cpt values, which are 10% lower com- decreased compared to the rotor 1 exit plane, due to the added

pared to the unaffected region of this plane. rotor cavity leakage. However, both plots show strong similarities

between both rotor clocking positions of the same stator clocking

Flow of Second Stator (MP 2). The variation of inlet flow case. They agree as well in a span region 共50% to 70%兲 where the

angles in front of the second stator LE was discussed in the pre- turning angle has decreases, and a region 共20% to 40%兲 where it

vious section. The modified inlet condition of the second stator increases, with setting the stator clocking to 50% of a pitch.

Fig. 11 TC1, CFD—comparison of total pressure coefficient distribution of ex-

periment and CFD downstream of rotor 1 at RR00. „a… SS00 „Exp.…, „b… SS00

„CFD…, „c… SS50 „Exp.…, and „d… SS50 „CFD…

Journal of Turbomachinery JANUARY 2006, Vol. 128 / 17

Fig. 13 Turning angle differences ⌬ across stator 2 of four

clocking configurations „reference case is SS00RR00…: „a… Ex-

periment „TC1… and „b… CFD

The actual effect for the second rotor is expressed in the abso-

lute exit angle of the stator. The same similarities between the four

different cases as stated for the turning angle also apply here.

Figure 14 shows that at the 50% stator clocking cases the stator

exit swirl increased from 70% to 90% span, and it decreased from Fig. 15 TC2—time distance diagram of flow yaw angle down-

50% to 70%. The maximum change in these regions of 2 deg in stream of stator 2, pitchwise massaverages spanwise distribu-

absolute flow yaw angle was achieved by clocking only the stator tion versus time: „a… SS00 and „b… SS50 at RR00

50%. Additional clocking of the rotors by 50% reduced this effect.

Hence, it is possible to achieve a change in incidence on the

second rotor over a wide range of the span of up to 2 deg by

clocking the stators. clocking on the tested configuration has strong influences on cer-

The unsteady exit flow yaw angle development downstream of tain span regions, however there are others, which are much less

the second stator for two stator clocking positions is presented in affected. The modified flow conditions through the stator blade

Fig. 15. A pitchwise averaged spanwise distribution of the flow row between 0% and 50% stator clocking appear also in the en-

angle is plotted versus time, which is expressed in rotor blade tropy production of this stage.

passing periods. Due to the mass averaging, one vertical line rep- In Fig. 16 the distribution of static entropy difference across the

resents the whole effective flow field at a certain moment in time. second stator is shown for both cases. The entropy was calculated

The contained information is therefore different from regular according to Denton 关20兴. Comparing both cases, an overall in-

time-distance diagrams, which show only one pitch or span posi- crease in entropy across the span can be stated when clocking the

tion. The comparison of both clocking positions shows higher stators to 50%. At the 50% clocking case the entropy is consider-

flow yaw angles between 40% and 70% span for the 0% case. ably higher in the region from 0% to 40% span. These different

With that, the findings from the steady measurements 共Fig. 14兲 levels of entropy reflect the result of the interaction of the first

can be underlined also with the unsteady results. From the com- rotor hub passage vortex and the secondary flow structure from

parison of the two unsteady cases it becomes clear that the stator the first stator. The stator trailing edge vortex that appears in the

midspan region of the 0% clocking case seemed to have merged

with the upper stator passage vortex at the 50% clocking case.

Furthermore, the loss cores of the latter case are more detached

from the trailing edge of the stator. In the opinion of the authors

this is caused by the observed changes in incidence on the stator.

Therefore it is reasonable that they can grow in a more unob-

structed way and involve more massflow, which in the end results

in a higher entropy level.

Flow Behind Second Stage (MP 3). Unlike the case of the exit

of the first rotor, downstream of rotor 2 no potential field of a

subsequent blade row is present. The secondary flow field at this

point mainly comprises of the following three influences:

1. secondary flow generated in the second stator,

2. the secondary flow structures originated in the first rotor

blade row, and

3. cavity leakage flows of each upstream blade row.

Isolation of every single influence is difficult since they are all

interacting with each other. The impact of the secondary flows in

Fig. 14 TC1—absolute flow angle differences ⌬ of four this plane is significant. The exit plane of rotor 2 reflects the

clocking configurations „reference case: SS00RR00… at stator 2 downstream effects of the given stator clocking position. In addi-

exit: „a… experiment „TC1… and „b… CFD tion the effect of the rotor clocking becomes apparent. The super-

18 / Vol. 128, JANUARY 2006 Transactions of the ASME

Fig. 16 TC2—measured static entropy difference across the second stator of

„a… SS00 and „b… SS50 positions „both at RR00… and „c… corresponding pitch-

wise averaged spanwise distributions

position of both, the stationary and the rotating clocking of the periment at the midspan region from 25% to 75%. Out of this

two sets of blade rows, defines the flow condition of the second region the influence of the cavity flow introduces a strong devia-

rotor. Consequently the performance of the second rotor should tion between the results.

show an influence of the stator and the rotor clocking. This can be Besides the characteristic differences between the stator clock-

confirmed when evaluating the turning angles of the second rotor ing positions, the influence of the rotor clocking can be also ob-

共Fig. 17兲. served. Keeping the stator clocking position constant and varying

the rotor clocking position causes only minor changes in the shape

A strong underturning effect occurs for the 50% stator clocking and level of the flow yaw angle distribution. At SS00 an increase

cases from 40% to 75% span, which is a result of the change in in the relative turning angle of ⌬ = 1 deg can be observed from

incidence in front of the stator blade row. For the adjoining span 10% to 40% span when clocking the rotors from 0% to 50%.

regions 共80% to 100% and 20% to 40%兲 this changes into over- However, the difference in this span region at SS50 for the same

turning. However, the integral value across the span of the change

rotor clocking positions is less than ⌬ = 0.2 deg. The opposite

in turning angle is around zero. Changing the clocking position

picture appears for the span region from 70% to 90%. There the

seems to improve and reduce the performance of a stage at the

difference is in the order of ⌬ = 1.3 deg at the 50% stator clock-

same time, depending on the radial position. The comparison with

ing position, when clocking the rotors. Both span regions happen

the numerical results shows again a good agreement with the ex-

to be in the area of the rotor passage vortices. The given combi-

nation of stator and rotor clocking positions defines whether there

is an increase or decrease in performance in these regions.

Performance Evaluation

Experimental. Thermodynamic efficiencies of the three un-

steady measured clocking configurations of TC2 are presented in

Fig. 18. The graphs show the results of efficiency balances across

both stages 共turbine兲, stage 1 and stage 2. The thermodynamic

total-to-total efficiency has been calculated from

冉

th = 1 −

Tt,out

Tt,in

冊冒冋 冉 冊 册

1−

pt,out

pt,in

共−1兲/

共1兲

All three clocking cases show the difference in efficiency with

respect to the reference case at 0% stator and 0% rotor clocking.

The reference case has the highest thermodynamic efficiency of

the evaluated cases when balancing both stages together. A maxi-

mum difference in relative thermodynamic efficiency between the

clocking cases of 0.33% has been determined.

When clocking the stators to 50% the efficiency of the first

Fig. 17 Relative turning angle differences ⌬ across rotor 2 of stage increases, while the one of the second stage drops consider-

four clocking configurations „reference case is SS00RR00…: „a… ably. The first stage reveals a relative increase in efficiency of

experiment „TC1… and „b… CFD 0.32%, whereas the second stage decreases by 1.3%. This trade-

Journal of Turbomachinery JANUARY 2006, Vol. 128 / 19

Fig. 19 TC2—spanwise distribution of turbine relative thermo-

dynamic efficiency difference to the reference case of three

characteristic clocking configurations

measure rig operation parameters, such as the torque of the second

stage and massflow. This allows the calculation of mechanic effi-

ciency. The integral character of this value does not resolve any

spanwise efficiency distribution. It is defined as the ratio of spe-

cific shaft power over the enthalpy difference of the isentropic

Fig. 18 TC2, CFD—relative thermodynamic efficiency differ-

expansion:

冉 冊 冒 冋 冉 冉 冊 冊册

ence to the reference case of three characteristic clocking con-

共−1兲/

figurations: „a… stage 1, „b… stage 2, and „c… turbine ·M pt,out

m = c pTin 1 − 共2兲

ṁ pt,in

off between efficiency gain in one stage and efficiency loss in the The resulting values are plotted for comparison as the ratio of

冋 冒 冉 兺 冊册

other stage reveals the multistage effect of the clocking. It shows the actual value over the average of all values from a data set:

that it cannot be assumed that clocking has only an efficiency n

1

effect on downstream stages. In the present case the flow has a ⌬m,rel = m m,i −1 共3兲

highly subsonic character, which increases the potential for flow n i=1

effects to be transmitted upstream. This kind of phenomena was The differences from the mean are plotted in Fig. 20. From the

also observed by Haldeman et al. 关22兴 when clocking a low- variation of the efficiencies versus clocking positions no system-

pressure turbine vane in a 1.5-stage transonic turbine. atic change can be observed. The maximum peak-to-peak varia-

If in addition the rotors are also clocked to 50%, the efficiencies tion is in the order of 0.3%. This magnitude of changes in me-

of both stages again come closer to the one of the SS00RR00 chanic efficiency is within the relative accuracy of the test facility.

position. This counterbalancing effect due to the clocking of the Reasons for these minor changes are suspected to be the strong

rotors compensates in the present case to a certain extent the nega- three-dimensional character of the flow at each clocking position.

tive effect of the stator clocking. Especially the second stage receives a highly complex flow field,

The observed effects of the experiments on relative efficiency containing secondary flow features from the upstream blade rows.

between the clocking cases can also be seen in the numerical The mixture of positive and negative effects of the current clock-

results. The CFD model shows the same trend, however it the ing position across the span results in a rather small change in

underpredicts the effect of clocking on the efficiency of both mechanical efficiency.

stages, due to the insufficient modeling of endwall flows and nu-

merical diffusion. Numerical. A series of 2D and 3D unsteady computations was

The radial distribution of thermodynamic efficiency balanced performed for the different clocking cases 共SS-RR: 0-0, 50-0,

across both stages 共Fig. 19兲 shows which span regions are affected 0-50, 50-50兲. The 2D calculation considered only the midspan

most by the clocking. The plot shows the difference from the position, whereas the 3D method evaluates the whole span. In

reference case SS00RR00. The regions where vortical structures

were identified, 0% to 40% span and 80% to 100% span, show

locally significant relative changes in thermodynamic efficiency

up to −0.7%. The integral change in efficiency across the span

corresponds with the values presented in Fig. 18共c兲. The higher

overall efficiency of the SS50RR50 case compared to the

SS50RR00 case comes due to a higher efficiency value close to

the endwalls. Haldeman et al. 关22兴 reported as well significant

spanwise differences in the effect of clocking based on static pres-

sure measurements. They have found the effect of clocking at

10% span to be most apparent.

The error analysis 关23兴 shows that the relative uncertainty in

efficiency between different test cases is in the order of 0.3%. The

relative uncertainty between clocking cases of the same measure-

ment campaign will be even less, since identical test and measure-

ment conditions apply. Fig. 20 TC2—total-to-total mechanic efficiency of the second

Due to the instrumentation of the test facility it is possible to stage at eight stator and two rotor clocking positions

20 / Vol. 128, JANUARY 2006 Transactions of the ASME

clocking appears since vortices are not existent in the model. The

more realistic result comes therefore again from the 3D calcula-

tion, where the influence of the clocking on the vortex propaga-

tion is also taken into account. The second stage shows generally

a higher reaction on clocking than the first one and has also the

bigger contribution to the overall losses. It can be concluded from

the 3D numerical results that the rotor clocking, compared to the

stator clocking, has only low impact on the stator losses. How-

ever, the relatively high loss generation of the second rotor for all

clocking cases seems to indicate that the loss of rotor 2 depends

Fig. 21 CFD—overall aerodynamic loss deviation from refer- on the same order of magnitude on two influences: 共1兲 the relative

ence case SS00 RR00 position of rotor 2 to the first rotor’s secondary flow remainders

and 共2兲 changes in loading of the second stator due to the clocking

of the stators.

contrast to the 2D, which only accounts for profile losses, the 3D The second rotor seems to be the weakest part in the develop-

calculation realizes the full modeling of secondary flow propaga- ment of losses, as it can suffer under its own clocking position as

tion through the engine and the influences due to wall friction. well as ill-conditioned inflow characteristics from previous stator

In Figs. 21 and 22 the results of both kinds of calculations are rows.

presented. All plots show difference values of the aerodynamic Observed efficiency changes are in the order of −0.35% from

loss compared to the reference case of 0% stator clocking and 0% the reference case for the stator clocking and about −0.32% for

rotor clocking. The direct comparison shows several systematic the rotor clocking, while the combined case 50-50 differs in the

differences, which illustrates the insufficiency of the 2D algo- order of −0.25%.

rithms for the current low aspect ratio application.

In Fig. 21 the differences in aerodynamic loss are presented for

each clocking case. The 2D results show a variation of the losses

Conclusions

at midspan only in the order one-tenth of what has been calculated Stator-stator as well as rotor-rotor clocking effects have been

with the 3D algorithm. The reason for this is the strong influence investigated in a comprehensive experimental and numerical ef-

of vortical structures in the flow field. Hence, the losses due to fort. The test case was a two-stage low aspect ratio axial turbine.

vortices and endwalls have a predominant character over losses Thus, a combined view on the flow field and the performance of

created by wakes, which makes the midspan region not represen- blade rows and turbine was achieved. In addition, a 2D and 3D

tative for the overall flow. However, in both calculations the ref- numerical study was performed to study the numerical effects of

erence case 0-0 has the lowest losses compared to the clocking the current clocking case.

positions. A closer look at the development of losses per row is An overall change of relative mechanical efficiency of ±0.15%

given in Fig. 22. The most significant difference between the 2D was experimentally determined. The maximum relative change in

and 3D methods appears in the losses of the second stator. An thermodynamic efficiency between two oppositional stator clock-

opposite result has been derived for this blade row with the two ing positions was in the order of 0.3%.

methods. There at the midspan, only the influence of the wake Evaluating the applied measurement techniques it was found

that steady, pneumatically averaged five-hole probe measurements

are sufficient to derive overall performance values of turbine

stages. In order to understand the influence of clocking on the

interaction of flow features between neighboring blade rows,

highly resolved unsteady measurements of the related flow fields

are necessary.

The application of numerical methods for clocking investiga-

tions on turbines with low aspect ratio blading requires the use of

3D unsteady algorithms with a full nonlinear treatment. It allows

correct modeling of secondary flow propagation through different

blade rows and accurate prediction of flow angles. In 2D ap-

proaches the use of mixing algorithms between blade rows pre-

vents the modeling of convective flow features that are dominant

in such kinds of geometries. In the current case, the region from

0% to 40% span behind the first rotor is clearly dominated by a

strong vortical structure, which is a combination of cavity leakage

from the first stator and vortices of the first rotor.

The current study has demonstrated that the evaluation of over-

all performance of a certain clocking position requires the consid-

eration of all stages. The performance of a downstream stage is set

by its relative clocking position with respect to the preceding

stage. However, in the upstream direction an effect influencing

efficiency was detected. In the current test case the change from

0% to 50% stator clocking position caused a relative degradation

of thermodynamic efficiency of the second stage by 1.3%. This

was accompanied by an efficiency increase in the first stage of the

order of 0.3%. The applied numerical methods show the same

trend. However, due to insufficient modeling of cavity leakage

flows involved in the experiment as well as numerical diffusion,

this effect is underpredicted. At this point it has to be pointed out

again that this rather small effect on efficiency is characteristic for

Fig. 22 CFD—aerodynamic loss deviation from reference case the tested geometry. It must not lead to a general conclusion, that

0-0 clocking for each blade row: „a…… 2D and „b… 3D clocking has a minor influence on efficiency.

Journal of Turbomachinery JANUARY 2006, Vol. 128 / 21

In the flow field of the investigated low aspect ratio blading Subscripts

vortex, interaction and propagation are more important than the t ⫽ total

influence of wakes. Vortices close to the endwalls are enhanced by th ⫽ thermal

leakage flows from the cavities. The wakes of the stators and the rel ⫽ relative frame of reference

rotors are strongly affected by their adjoining vortical structures. m ⫽ Mechanical

Due to the resulting deformation of the wakes they cannot be 0 ⫽ turbine inlet

clearly distinguished anymore in the flow field. Therefore an 1 ⫽ measurement plane 1

alignment of wakes relative to the leading edges of a subsequent 2 ⫽ measurement plane 2

bladerow is not as important as it is in high aspect ratio geom- 3 ⫽ measurement plane 3

etries.

Vortical structures can be seen as the instrument of redistribut- Superscripts

⫺

ing low energy fluid in the radial direction. The convection and ⫽ circumferentially averaged

⫽

interaction of secondary flow structures results in local variations ⫽ average across the pitch area

of flow angles, incidences, and loading. Therefore, clocking is

affecting the performance characteristic of each radial position

References

differently. The combination of the resultant performance charac-

关1兴 Jouini, D. B. M., Little, D., Bancalari, E., Dunn, M., Haldeman, C., and

teristics across the span causes a nonlinear behavior of the overall Johnson, P. D., 2003, “Experimental Investigation of Airfoil Wake Clocking

stage. In order to have an overall efficiency benefit due to clock- Impacts on Aerodynamic Performance in a Two Stage Turbine Test Rig,”

ing, the blade design has to ensure that an efficiency increase can ASME Paper No. GT-2003–38872.

be achieved on the majority of the span by setting up a certain 关2兴 Huber, F. W., Johnson, P. D., Sharma, O. P., Staubach, J. B., and Gaddis, S. W.,

1996, “Performance Improvement Through Indexing of Turbine Airfoiles: Part

clocking position. 1—Experimental Investigation,” J. Turbomach., 118, pp. 630–635.

关3兴 Reinmöller, U., Stephan, B., Schmidt, S., and Niehuis, R., 2002, “Clocking

Acknowledgment Effects in a 1.5 Stage Axial Turbine—Steady and Unsteady Experimental In-

vestigations Supported by Numerical Simulations,” J. Turbomach., 124, pp.

The authors gratefully acknowledge the support and the pre- 52–60.

cious suggestions of Dr. Pfau and Dr. Schlienger. The geometries 关4兴 Gombert, R., and Höhn, W., 2001, “Unsteady Aero-dynamical Blade Row

of the blades used in this investigation were developed during the Interactions in a New Multistage Research Turbine—Part I: Experimental In-

vestigation,” ASME Paper No. 2001-GT-0306.

course of the AG-Turbo project “500 MW auf einer Welle” 关5兴 Walraevens, R. E., Gallus, H. E., Jung, A. R., Mayer, J. F., and Stetter, H.,

funded by the German Federal Ministry of Economy 共BMWI兲 1998, “Experimental and Computational Study of the Unsteady Flow in a 1.5

under File Nos. 0327060D and 0327060F. In particular, Dr. E. Stage Axial Turbine with Emphasis on the Secondary Flow in the Second

Janke, Dr. H.-P. Schiffer, and Dr. H. Richter of Rolls-Royce Deut- Stator,” ASME Paper No. 98-GT-254.

关6兴 Tiedemann, M., and Kost, F., 2001, “Some Aspects of Wake-Wake Interactions

schland are acknowledged for their continuous support and kind Regarding Turbine Stator Clocking,” J. Turbomach., 123, pp. 526–533.

permission to publish the results presented in this paper. 关7兴 Höhn, W., and Heinig, K., 2000, “Numerical and Experimental Investigation

of Unsteady Flow Interaction in a Low-Pressure Multistage Turbine,” J. Tur-

bomach., 122, pp. 628–633.

Nomenclature 关8兴 Griffin, L. W., Huber, F. W., and Sharma, O. P., 1996, “Performance Improve-

c p ⫽ Specific heat capacity at constant pressure, ment Through Indexing of Turbine Airfoiles: Part II—Numerical Simulation,”

J/kg K J. Turbomach., 118, pp. 636–642.

关9兴 Dorney, D. J., and Sharma, O. P., 1996, “A Study of Turbine Performance

cv ⫽ Specific heat capacity at constant volume, Increase Through Airfoil Clocking,” AIAA Paper No. 96–2816.

J/kg K 关10兴 Dorney, D. J., and Sondak, D. L., 1996, “Three-Dimensional Simulation of

Cps ⫽ Static pressure coefficient, Cps = 共p − p3兲 / 共pt0 Airfoil Clocking in a 1–1/2 Stage Turbine,” AIAA Paper No. 96–2816.

− p 3兲 关11兴 Sell, M., Schlienger, J., Pfau, A., Treiber, M., and Abhari, R. S., 2001, “The

2-stage Axial Turbine Test Facility LISA,” ASME Paper No. 2001-GT-0492.

Cpt ⫽ total pressure coefficient, Cpt = 共pt − p3兲 / 共pt0 关12兴 Hourmouziadis, J., 1989, “Aerodynamic Design of Low Pressure Turbines,”

− p 3兲 Lecture 8, AGARD LS-167.

关13兴 Treiber, M., Kupferschmied, P., and Gyarmathy, G., 1998, “Analysis of the

ṁ ⫽ massflow, kg/s Error Propagation Arising from the Measurements with a Miniature Pneumatic

M ⫽ torque, N m 5-hole Probe,” XIVth Symposium on Measuring Techniques for Transonic and

P ⫽ pressure, Pa Supersonic Flows in Cascades and Turbomachines, Limerck.

关14兴 Kupferschmied, P., Köppel, O., Gizzi, W. P., and Gyarmathy, G., 2000, “Time

R ⫽ perfect gas constant, J/kg K Resolved Flow Measurements with Fast Aerodynamic Probes in Turbomachin-

R ⫽ radius, m ery,” Meas. Sci. Technol., 11, pp. 1036–1054.

S ⫽ specific entropy, J/kg K 关15兴 Pfau, A., Schlienger, J., Kalfas, A. I., and Abhari, R. S., 2002, “Virtual Four

T ⫽ temperature, K Sensor Fast Response Aerodynamic Probe 共FRAP兲,” Proceedings of the XVIth

Bi-Annual Symposium on Measuring Techniques in Transonic and Supersonic

Greek Flows in Cascades and Turbomachines, Cambridge, UK, September 23–24.

关16兴 Dawes, W. N., BT0B3D, 1991, “A Computer Program for the Analysis of

⫽ turning angle, deg Three-Dimensional Viscous Compressible Flow in Tubomachinery Blade

⫽ flow yaw angle, deg Rows,” Manual for BT0B3D.

⫽ isentropic coefficient, = c p / cv, 关17兴 Jameson, A., and Baker, T. J., 1984, “Multigrid Solutions of the Euler Equa-

tions for Aircraft Configurations,” AIAA Paper No. 84–0093.

⫽ rotational velocity, 1 / s 关18兴 Emunds, R., Jennions, I. K., Bohn, D., and Gier, J., 1997, “The Computation

of Adjacent Blade-Row Effects in a 1.5 Stage Axial Flow Turbine,” ASME

Abbreviations Paper No. 97-GT-81.

5HP ⫽ five-hole probe 关19兴 Spalart, P. R., and Allmaras, S. R., 1992, “A One-Equation Turbulence Model

CFD ⫽ computational fluid dynamics for Aerodynamic Flows,” AIAA Report 92–0439.

FRAP ⫽ fast response aerodynamic probe 关20兴 Denton, J. D., 1993, “Loss Mechanisms in Turbomachines,” ASME J. Tur-

bomach., 115, pp. 621–656.

LE ⫽ leading edge 关21兴 Saxer, A. P., and Giles, M. B., 1993, “Quasi-Three-Dimensional Nonreflecting

MP ⫽ measurement plane Boundary Conditions for Euler Equations Calculations,” J. Propul. Power,

RR ⫽ relative rotor-rotor clocking position 9共2兲, pp. 263–271.

SS ⫽ relative stator-stator clocking position 关22兴 Haldeman, C., Dunn, M. G., J., Barter, J. W., Green, B. R., and Bergholz, R.

F., 2004, “Experimental Investigation of Vane Clocking in a One and 1 / 2

TC ⫽ test case Stage High Pressure Turbine,” ASME Paper No. GT2004–53477.

TE ⫽ trailing edge 关23兴 Pfau, A., 2003, “Loss Mechanisms in Labyrinth Seals of Shrouded Axial Tur-

TET ⫽ turbine entry temperature bines.” ETH Ph.D. dissertation no. 15226.

22 / Vol. 128, JANUARY 2006 Transactions of the ASME

View publication stats

You might also like

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Performance of A High-Solidity Wells Turbine For An OWC Wave Power PlantDocument6 pagesPerformance of A High-Solidity Wells Turbine For An OWC Wave Power PlantAna Elisa Rodrigues do CoutoNo ratings yet

- Friction Factors For Large Conduits Flowing FullDocument77 pagesFriction Factors For Large Conduits Flowing FullJean BattellNo ratings yet

- 2021 ASME JOT Flow Reconstruction Part 1Document10 pages2021 ASME JOT Flow Reconstruction Part 1JUN LAINo ratings yet

- General Disclaimer One or More of The Following Statements May Affect This DocumentDocument14 pagesGeneral Disclaimer One or More of The Following Statements May Affect This DocumentUmair MunirNo ratings yet

- Simulacion NumericaDocument7 pagesSimulacion Numericajohansarache1986No ratings yet

- .0 .0 GAP - AXIAL.1-s2.0-S1000936117302200-mainDocument13 pages.0 .0 GAP - AXIAL.1-s2.0-S1000936117302200-mainRabei RomulusNo ratings yet

- Numerical Simulation of Six Jet Pelton Turbine Model GRUPO 2Document9 pagesNumerical Simulation of Six Jet Pelton Turbine Model GRUPO 2Cristian Polo VallejosNo ratings yet

- Floquet Modal Analysis of A Teetered-Rotor Wind Turbine: Karl StolDocument8 pagesFloquet Modal Analysis of A Teetered-Rotor Wind Turbine: Karl StolAnonymous UoHUagNo ratings yet

- CFD Analysis of Compressor Blade Stalling (2376)Document37 pagesCFD Analysis of Compressor Blade Stalling (2376)032Apoorva patelNo ratings yet

- Uma Investigação Experimental Sobre A Influência Do Vento Instável No Desempenho de Uma Turbina Eólica de Eixo VerticalDocument9 pagesUma Investigação Experimental Sobre A Influência Do Vento Instável No Desempenho de Uma Turbina Eólica de Eixo VerticalEMMANUELLE CARNEIRO DE MESQUITANo ratings yet

- Numerical Simulation Analysis of Flow Characteristics in The Cavity of The Rotor Stator SystemDocument14 pagesNumerical Simulation Analysis of Flow Characteristics in The Cavity of The Rotor Stator System孟卫帅No ratings yet

- Computational Flow Field Analysis of A Vertical Axis Wind TurbineDocument6 pagesComputational Flow Field Analysis of A Vertical Axis Wind TurbineAnonymous ITnkbIEFNo ratings yet

- Vortex Transport and Blade Interactions in High Pressure TurbinesDocument11 pagesVortex Transport and Blade Interactions in High Pressure Turbinesapi-19772009100% (1)

- Measurements of The Near Wake of A Rotor in Forward Flight: AIAA 98-0692Document10 pagesMeasurements of The Near Wake of A Rotor in Forward Flight: AIAA 98-0692Naveen NaviNo ratings yet

- 13 - Chapter 7 PDFDocument33 pages13 - Chapter 7 PDFArul PrakashNo ratings yet

- Modelling and Simulation Offlow Induced Vibrations in Vertical Axis Wind Turbine BladeDocument11 pagesModelling and Simulation Offlow Induced Vibrations in Vertical Axis Wind Turbine BladeElena VlangarNo ratings yet

- ArticleJEPS Ravelet 3 PDFDocument10 pagesArticleJEPS Ravelet 3 PDFNaveen Suresh KumarNo ratings yet

- Blade Row Interaction in A High-Pressure Steam Turbine: V. S. P. Chaluvadi A. I. Kalfas H. P. HodsonDocument11 pagesBlade Row Interaction in A High-Pressure Steam Turbine: V. S. P. Chaluvadi A. I. Kalfas H. P. Hodsonapi-19772009No ratings yet

- 1996-Review of Contra Rotating Axial CompressorDocument10 pages1996-Review of Contra Rotating Axial CompressorLakshya KumarNo ratings yet

- PadovaDocument12 pagesPadovaSAGI RATHNA PRASAD me14d210No ratings yet

- Wind Tunnel Testing and Numerical Simulation On Aerodynamic Performance of A Three-Bladed Savonius Wind TurbineDocument14 pagesWind Tunnel Testing and Numerical Simulation On Aerodynamic Performance of A Three-Bladed Savonius Wind TurbineARIANNE PALOMINO CAMACNo ratings yet

- 3-JournalofEnergyResourcesTechnology 2020 Impact 2.903Document12 pages3-JournalofEnergyResourcesTechnology 2020 Impact 2.903Sajad MostafaviNo ratings yet

- NCCS-2019-1009 Sensitivity Studies On The Effect of Axial Clearances On The Turbine EfficiencyDocument5 pagesNCCS-2019-1009 Sensitivity Studies On The Effect of Axial Clearances On The Turbine EfficiencySiddharth BehalNo ratings yet

- Idei Principale Articole Si TezeDocument4 pagesIdei Principale Articole Si TezeRazvan RomanNo ratings yet

- AkbariNalimMueller JGTP2006 aReviewOfWaveRotorTechnologyAndApplicationsDocument19 pagesAkbariNalimMueller JGTP2006 aReviewOfWaveRotorTechnologyAndApplicationsAvinash SneharaviNo ratings yet

- Renewable Energy: Keum Soo Jeon, Jun Ik Jeong, Jae-Kyung Pan, Ki-Wahn RyuDocument10 pagesRenewable Energy: Keum Soo Jeon, Jun Ik Jeong, Jae-Kyung Pan, Ki-Wahn Ryuhasybi abiNo ratings yet

- Renewable Energy: Guanghui Bai, Jun Li, Pengfei Fan, Guojun LiDocument7 pagesRenewable Energy: Guanghui Bai, Jun Li, Pengfei Fan, Guojun LiNasteho DjamaNo ratings yet

- Analysis of The Furling Behavior of Small Wind Turbines 2010 Applied EnergyDocument15 pagesAnalysis of The Furling Behavior of Small Wind Turbines 2010 Applied EnergygeoNo ratings yet

- Three-Dimensionality of The Wake Recovery Behind A Vertical Axis Turbine PDFDocument12 pagesThree-Dimensionality of The Wake Recovery Behind A Vertical Axis Turbine PDFJiyong LeeNo ratings yet

- Renewable Energy: A. Mahboubidoust, A. RamiarDocument18 pagesRenewable Energy: A. Mahboubidoust, A. RamiarAlmir RodriguesNo ratings yet

- Numerical investigation of model Francis turbine for performance enhancement with geometrical modificationDocument15 pagesNumerical investigation of model Francis turbine for performance enhancement with geometrical modificationRodolfo Paze C. DiasNo ratings yet

- Articulo 3Document14 pagesArticulo 3Angel RodriguezNo ratings yet

- Fractal Impeller Amol KulkarniDocument10 pagesFractal Impeller Amol KulkarniTej ChoksiNo ratings yet

- Multistage CompressorDocument12 pagesMultistage CompressorFahmi AliNo ratings yet

- Energy: Abbas Ebrahimi, Mahmood SekandariDocument15 pagesEnergy: Abbas Ebrahimi, Mahmood Sekandarimohdsolihat1No ratings yet

- Renewable Energy: Paresh Halder, Abdus Samad, Dominique TH EveninDocument13 pagesRenewable Energy: Paresh Halder, Abdus Samad, Dominique TH EveninAlmir RodriguesNo ratings yet

- Curvature and Twist of VAWTDocument16 pagesCurvature and Twist of VAWTBattle SagaNo ratings yet

- Increase Savonius Rotor EfficiencyDocument11 pagesIncrease Savonius Rotor EfficiencyAndri Jaya WardanaNo ratings yet

- Aerodynamic Characteristics of Rigid Coaxial Rotor by Wind Tunnel Test and Numerical CalculationDocument9 pagesAerodynamic Characteristics of Rigid Coaxial Rotor by Wind Tunnel Test and Numerical CalculationAngel RodriguezNo ratings yet

- Vol1no1-6 GovardhanMDocument14 pagesVol1no1-6 GovardhanMSandra PowersNo ratings yet

- ASME Journal Leakage Control Akturk CamciDocument37 pagesASME Journal Leakage Control Akturk CamciLiang Chung Tan100% (1)

- Numerical Investigation On The Performance of Wells Turbine With Non-Uniform Tip Clearance For Wave Energy Conversion - Artigo - TahaDocument11 pagesNumerical Investigation On The Performance of Wells Turbine With Non-Uniform Tip Clearance For Wave Energy Conversion - Artigo - TahaAdson Santos Silva Jr.No ratings yet

- Effect of Rotor Profiles On The Torque of A Switched ReluctaDocument6 pagesEffect of Rotor Profiles On The Torque of A Switched Reluctaapi-19827661No ratings yet

- Turbine Blade Tip Leakage Flow Control by Unsteady Periodic Wakes of Upstream Blade RowDocument14 pagesTurbine Blade Tip Leakage Flow Control by Unsteady Periodic Wakes of Upstream Blade RowJavier Alejandro RodriguezNo ratings yet

- Choudhry 2013Document14 pagesChoudhry 2013Andri YansyahNo ratings yet

- Advanced Control Algorithms For Reduction of Wind Turbine 2015 Renewable enDocument14 pagesAdvanced Control Algorithms For Reduction of Wind Turbine 2015 Renewable enclaralisieNo ratings yet

- 1 s2.0 S1876610217301637 MainDocument8 pages1 s2.0 S1876610217301637 MainEngineer BoyNo ratings yet

- Kumashiro 2019 IOP Conf. Ser. Earth Environ. Sci. 240 072006Document10 pagesKumashiro 2019 IOP Conf. Ser. Earth Environ. Sci. 240 072006emerson william vidalNo ratings yet

- Research Article Axial Spacing Effects On Rotor-Rotor Interaction Noise and Vibration in A Contra-Rotating FanDocument16 pagesResearch Article Axial Spacing Effects On Rotor-Rotor Interaction Noise and Vibration in A Contra-Rotating Fancepheid_luNo ratings yet

- Experimental Investigation of Characteristics ofDocument16 pagesExperimental Investigation of Characteristics ofShivani SNo ratings yet

- Wind Dfig Paper PDFDocument10 pagesWind Dfig Paper PDFShraddha VardikarNo ratings yet

- Permanent Magnet Bias, Homopolar Magnetic Bearings For A 130 KW-HR Composite FlywheelDocument8 pagesPermanent Magnet Bias, Homopolar Magnetic Bearings For A 130 KW-HR Composite FlywheelAnonymous f3oWRCJNo ratings yet

- Influenceof Blade Overlapand Blade Angleonthe Aerodynamic Coefficientsin Vertical Axis Swirlingtype Savonius Wind TurbineDocument5 pagesInfluenceof Blade Overlapand Blade Angleonthe Aerodynamic Coefficientsin Vertical Axis Swirlingtype Savonius Wind TurbineAbdullah KhanNo ratings yet

- 2D Numerical Simulations of Blade-Vortex Interaction in A Darrieus TurbineDocument15 pages2D Numerical Simulations of Blade-Vortex Interaction in A Darrieus Turbinealentan_774042No ratings yet

- Experimental Study of Stator Clocking Effects in An Axial CompressorDocument8 pagesExperimental Study of Stator Clocking Effects in An Axial CompressorUmair MunirNo ratings yet

- Balancing Rotating Machines: Future DevelopmentsDocument2 pagesBalancing Rotating Machines: Future DevelopmentsJessica SandersNo ratings yet

- Tidal TurbineDocument10 pagesTidal TurbineAdson Santos Silva Jr.No ratings yet

- Interaction of Turbomachinery ComponentsDocument7 pagesInteraction of Turbomachinery ComponentsPedro LeyvaNo ratings yet

- Chemical Engineering Science: Chiara Galletti, Elisabetta BrunazziDocument12 pagesChemical Engineering Science: Chiara Galletti, Elisabetta BrunazziAngghisna Richard N.H.PNo ratings yet

- Synopsis TH 2113 - 166103030Document8 pagesSynopsis TH 2113 - 166103030Aaradhya YadavNo ratings yet

- Two-Phase Micro-Channel Heat Sinks: Theory, Applications and LimitationsDocument32 pagesTwo-Phase Micro-Channel Heat Sinks: Theory, Applications and Limitationskanbur.191No ratings yet

- Aerospace 08 00271 v3Document25 pagesAerospace 08 00271 v3kanbur.191No ratings yet

- ChanaSinghPoveyASME GT 2004 53951 FinalDocument9 pagesChanaSinghPoveyASME GT 2004 53951 Finalkanbur.191No ratings yet

- Efficient BEM Modeling of The Heat Transfer in TheDocument18 pagesEfficient BEM Modeling of The Heat Transfer in Thekanbur.191No ratings yet

- The Number of Subgrain Boundaries in The AirfoilsDocument16 pagesThe Number of Subgrain Boundaries in The Airfoilskanbur.191No ratings yet

- Technical Note: Nasa TN D-1046Document48 pagesTechnical Note: Nasa TN D-1046kanbur.191No ratings yet

- MTT1806 A207Document8 pagesMTT1806 A207kanbur.191No ratings yet

- Mathematics 09 00627Document21 pagesMathematics 09 00627kanbur.191No ratings yet

- Study of Entropy Generation in Secondary Flows in The T106A Low Pressure Axial Turbine CascadeDocument8 pagesStudy of Entropy Generation in Secondary Flows in The T106A Low Pressure Axial Turbine Cascadekanbur.191No ratings yet

- 2001 Caf Turbine Blade FloDocument19 pages2001 Caf Turbine Blade Flokanbur.191No ratings yet

- Blade Shape Optimization of An Axial Turbine Using The Adjoint MethodDocument89 pagesBlade Shape Optimization of An Axial Turbine Using The Adjoint Methodkanbur.191No ratings yet

- Baum Koschichow Froehlich GT2016-57399 ASME TurboExpo 2016 FinalDocument14 pagesBaum Koschichow Froehlich GT2016-57399 ASME TurboExpo 2016 Finalkanbur.191No ratings yet

- Numerical Simulations On Flow and Heat Transfer inDocument10 pagesNumerical Simulations On Flow and Heat Transfer inkanbur.191No ratings yet

- A Parametric Method of Turbine BladeDocument10 pagesA Parametric Method of Turbine Bladekanbur.191No ratings yet

- A Method For Parametrically Representing The Aerodynamic Profiles of Axial Turbine Machinery BladesDocument8 pagesA Method For Parametrically Representing The Aerodynamic Profiles of Axial Turbine Machinery Bladeskanbur.191No ratings yet

- Numerical Analysis of Vertical Axis Gas Turbine Blade of Different MaterialsDocument7 pagesNumerical Analysis of Vertical Axis Gas Turbine Blade of Different Materialskanbur.191No ratings yet

- EUROGEN99 MD Constrained Hybrid GADocument27 pagesEUROGEN99 MD Constrained Hybrid GAkanbur.191No ratings yet

- GT2008 50103finalDocument10 pagesGT2008 50103finalkanbur.191No ratings yet

- ADA801197Document22 pagesADA801197kanbur.191No ratings yet

- Design Optimization Workflow and Performance AnalyDocument15 pagesDesign Optimization Workflow and Performance Analykanbur.191No ratings yet

- Cobem2007 0070Document9 pagesCobem2007 0070kanbur.191No ratings yet

- US8841584Document10 pagesUS8841584kanbur.191No ratings yet

- BFGDeice30 60 01Document38 pagesBFGDeice30 60 01kanbur.191No ratings yet

- art3A10.10072Fs11814 014 0022 6Document15 pagesart3A10.10072Fs11814 014 0022 6kanbur.191No ratings yet

- Pcs Ice Protection Systems v2Document2 pagesPcs Ice Protection Systems v2kanbur.191No ratings yet

- Analisa Pengaruh Temperatur Gas Buang Terhadap Material Propeller UavDocument6 pagesAnalisa Pengaruh Temperatur Gas Buang Terhadap Material Propeller Uavkanbur.191No ratings yet

- CFD Study of Propeller Blade Temperature For Pusher Configured Turbo Prop EngineDocument4 pagesCFD Study of Propeller Blade Temperature For Pusher Configured Turbo Prop Enginekanbur.191No ratings yet

- 2021 Equipment Price ListDocument5 pages2021 Equipment Price Listkanbur.191No ratings yet

- Cost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle SystemsDocument19 pagesCost Engineering Techniques and Their Applicability For Cost Estimation of Organic Rankine Cycle Systemskanbur.191No ratings yet

- Production of Hydroprocessed Esters and Fatty AcidDocument14 pagesProduction of Hydroprocessed Esters and Fatty Acidkanbur.191No ratings yet

- Boliers and Pressure VesselsDocument33 pagesBoliers and Pressure VesselsMarcelo Chaves RestrepoNo ratings yet

- Axial CompressorDocument64 pagesAxial CompressorElmer100% (1)

- Experiment No - 6 Impact of Jet On Vanes Aim: The Aim of This Experiment Is To Demonstrate The Impulse Momentum Theorem As It Applies ToDocument4 pagesExperiment No - 6 Impact of Jet On Vanes Aim: The Aim of This Experiment Is To Demonstrate The Impulse Momentum Theorem As It Applies ToMohammed MehthabNo ratings yet

- A Instalasi Pipa Steam No Discription Size QTY SAT Harga A Pipe Line Steam Dari Boiler Ke HeaderDocument1 pageA Instalasi Pipa Steam No Discription Size QTY SAT Harga A Pipe Line Steam Dari Boiler Ke HeadersetyaNo ratings yet

- Vacuum Pumps - Calculating Flow Rate and Required Evacuation TimeDocument3 pagesVacuum Pumps - Calculating Flow Rate and Required Evacuation TimecordobaluisfNo ratings yet

- ESP Shroud Flow Path Final FORMATTEDDocument1 pageESP Shroud Flow Path Final FORMATTEDMohamed MostafaNo ratings yet

- AttachmentDocument19 pagesAttachmentIpank NoByNo ratings yet

- Field Instrument ListDocument15 pagesField Instrument Listmohamedsaib438No ratings yet

- KSB ZxsvaDocument12 pagesKSB Zxsvaconf useuseNo ratings yet

- HP Washing Pump ProcedureDocument1 pageHP Washing Pump ProcedureakinkanalangNo ratings yet

- Analysis of Surface Gathering SystemsDocument7 pagesAnalysis of Surface Gathering SystemsJatin RamboNo ratings yet

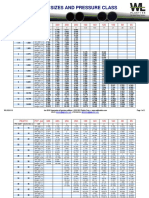

- WL102-0118 Ips Size Chart Pe4710Document2 pagesWL102-0118 Ips Size Chart Pe4710MarcoiNo ratings yet

- Fluid MachinesDocument14 pagesFluid MachinesNishankzattNo ratings yet

- Week 6-8Document3 pagesWeek 6-8Christian John Paul LijayanNo ratings yet

- TD S-10390 EngDocument45 pagesTD S-10390 EngHomer Edy Armas CalixtoNo ratings yet

- V V V V Vane Pump Ane Pump Ane Pump Ane Pump Ane Pump Series SD Series SD Series SD Series SD Series SDV V V V VDocument12 pagesV V V V Vane Pump Ane Pump Ane Pump Ane Pump Ane Pump Series SD Series SD Series SD Series SD Series SDV V V V VMario SouzaNo ratings yet

- ASME B31.9 Building Services Piping Code (2011) ComplianceDocument3 pagesASME B31.9 Building Services Piping Code (2011) ComplianceАнж БжлNo ratings yet

- Jet Engine IntegrationDocument8 pagesJet Engine IntegrationZeeshan100% (1)

- AAP S19 Check Valves & Strainers SDocument13 pagesAAP S19 Check Valves & Strainers SAppleuk SudarNo ratings yet

- Type 357 Control Valves: Bulletin 51.2:357Document10 pagesType 357 Control Valves: Bulletin 51.2:357Datt NguyenNo ratings yet

- Power PlanDocument22 pagesPower PlanBasem RajabNo ratings yet

- Ebook PDF Turbomachinery Basic Theory and Applications Second Edition PDFDocument41 pagesEbook PDF Turbomachinery Basic Theory and Applications Second Edition PDFalicia.mclaughlin973100% (32)

- Fig No.:WARREN-1155-8: Materials ListDocument2 pagesFig No.:WARREN-1155-8: Materials ListJavier FernandezNo ratings yet

- Stainless Steel Swing Check Valve: Threaded Connection - 200 WOGDocument1 pageStainless Steel Swing Check Valve: Threaded Connection - 200 WOGJuan Gutierrez CastilloNo ratings yet

- Transfer Pump Calculations - A TypeDocument20 pagesTransfer Pump Calculations - A TypeBala Krishna GallaNo ratings yet

- TF600-52 - Main Gear Fuel PumpDocument20 pagesTF600-52 - Main Gear Fuel PumpGiang NguyenNo ratings yet

- E PM 100Document29 pagesE PM 100masoudNo ratings yet

- 2097-1-G-G0-027 LDO and HFO System - Rev 00Document12 pages2097-1-G-G0-027 LDO and HFO System - Rev 00lightsonsNo ratings yet

- Model M05 Non-Metallic Design Level 2: Service & Operating ManualDocument33 pagesModel M05 Non-Metallic Design Level 2: Service & Operating ManualTrungGVNo ratings yet