Professional Documents

Culture Documents

1.28.16 Coca Cola Femsa Commercial Proposal

1.28.16 Coca Cola Femsa Commercial Proposal

Uploaded by

Hausland Const. Corp.0 ratings0% found this document useful (0 votes)

8 views4 pagesOriginal Title

1.28.16 COCA COLA FEMSA COMMERCIAL PROPOSAL

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

8 views4 pages1.28.16 Coca Cola Femsa Commercial Proposal

1.28.16 Coca Cola Femsa Commercial Proposal

Uploaded by

Hausland Const. Corp.Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

Document Code:

BIPL-SMD-OF-012.00

Etfetivty Date:

BAUER [Apri 01, 2015

Client: (Coca Cola FEMSA Philippines, Inc. as

saa Proposed Upgrading of WWTP (180 CMH); existing 130 CMH, |SMDGFO12-SMD0102

eoiect Tie: additional 50 CMH

: Misamis Oriental Pant, Brgy. Katipunan, Vilanueva, Misamis

oo [Oriental Prepared Dato:

Jattention: Mr. Julius Velasco [January 25, 2016

Designation: Procurement Category Coordinator (CAPEX) Revision No: 00

‘QUANTITY DESCRIPTION AMOUNT

tlot —_|I. General Requirements Php —2,500,000.00

Bonds and Insurances

Permits and Clearances

IMobitzation/ Demobiization

Health and Safety

Temporary Facility

Shipping, Transportation and Accomodation

I. Mechanical Works and Supply Php 10,700,000.00

Pre-treatment

‘unit | Lift station Transfer Pump (additional)

tunit | Static Screen

2units | Influent Flowmeter

2units | Motorized Valve

pH Adjustment

‘unit | Sulfuric Acid Dosing Pump

‘unit | Sulfuric Acid Stock Solution Tank

‘unit | Sulfuric Acid Solution Tank Air Mixing

‘unit | Caustic Dosing Pump

tunit | Caustic Stock Solution Tank

tunit | Caustic Solution Tank Air Mixing

‘tunit | pH Adjustment reaction Loop

‘unit | pH Controller

Bauer Dynamic SBR Section

2units | SBR Air Motorized Valve

SBR Air Biowers

2 unit

‘Document Code:

BIPI-SMD-OF-012-00

COMMERCIAL PROPOSAL

BAUER Jono 2018

(Client: [Coca Gola FEMSA Philippines, Inc. eee

Project Title: a — ‘of WWTP (180 CMH); existing 130 CMH, |SMDQFO12-SMD0102

ILocation: Sear ‘Oriental Plant, Brgy. Katipunan, Villanueva, Misamis ae

Attention: Mr. Julius Velasco are

Designation: Procurement Category Coordinator (CAPEX) [Revision No: 00

QUANTITY DESCRIPTION AMOUNT

2 ike ‘SBR Waste Sludge Pump

340 units | SBR Diffusers

aunts | Featng Decanter

2 units: Decanter Motorized Valve

2 units Air Solenoid Valve for Decanter

Disinfection Section

4 unit Chlorine Dosing Pump

1 unit Chlorine Solution Tank

41 unit Chlorine Solution Diffuser

1 unit Effiuent Flowmeter

Aerobic Sludge Digester Section

1 unit ASD Blower

30 units ASD Diffuser

2 units ‘Sludge Transfer Pump

|Sludge Dewatering System

1 unit ‘Sludge reaction Loop

1 unit ‘Screw press

1 unit Polymer Dosing Pump

1 unit Polymer Stock Solution Tank for Dewatering

1 unit Polymer Solution Tank Ar Mixing

|Access platforms

Ladders, catwalk

4 hot 111. Electrical, Instrumentation, Control and Php 4,750,000.00

Programming Works

PLC and SCADA

Electrical Panel, magnetic starter, breakers, relays, other

programming and integration of sensors.

‘Document Code:

BIPI-SMD-QF-012-00

Bacterial seed/ inoculum’ nutrient

Laboratory analysis for effluent wastewater

Training! Seminar

Documentation

‘Six- month commissioning

Interim Operation plan

**NOTHING FOLLOWS**

Eftoctivity Date:

BAUER |April 01, 2015

(Client: [Coca Cola FEMSA Philippines, Inc. eee

5 [Proposed Upgrading of WWTP (180 CMH); existing 130 CMH, |SMOQF012-SMD0102

project Tie: additional 50 CMH

eae [Misamis Oriental Plant, Brgy. Katipunan, Vilanueva, Misamis

nea Oriental Prepared Date:

Attention: Mr. Julius Velasco peaaury 25, 206:

Designation: Procurement Category Coordinator (CAPEX) Revision No: 00

QUANTITY DESCRIPTION ‘AMOUNT

Others

1lot__|IV. Pipes, Valves and Fittings Php 4,800,000.00

Installation of all wastewater, chemical, air, treated water

valves and fittings.

‘(lot IV. Civil Works Php 15,000,000.00

Excavation

Formworks/ Rebar

Gravel bedding and compaction

Others

1lot__|VI. Start- up, Testing and Commissioning Php 1,000,000.00

‘TOTAL AMOUNT VAT INCLUSIVE

Php 38,750,000.00

Less VAT|

Php 4,151,785.71

GRAND TOTAL VAT EXCLUSIVE|

Php 34,598,214.29

‘Document Code:

BIPL-SMD-QF-012.00

Effectvity Date:

BAUER JApril 01, 2015,

|Client: |Coca Cola FEMSA Philippines, Inc. Roteronce No:

[Proposed Upgrading of WWTP (180 CMH); existing 130 CMH, |SMDQF012-SMD0102

|additional 50 CMH

(Misamis Oriental Plant, Bray. Katipunan, Villanueva, Misamis

Oriental |Prepared Date:

IMr. Julius Velasco Bee

[Procurement Category Coordinator (CAPEX) [Revision No: 00

DESCRIPTION AMOUNT

JOPTIONAL ITEM: — |Two (2) Units On-line DO Meter for Two Basins Php 400,000.00

JEXCLUSIONS —: | Feeder Line and Power Supply

Incoming and outgoing piping outside the treatment area

|All chemicals, power and water during construction and commissioning

COMPLETION; [Fourteen (14) weeks upon receipt of P.O., downpayment and approved construction

TERMS : |Im accordance with Coca Cola FEMSA Philippines Inc. terms and conditions

lEquipment: We guarantee all equipment supplied by us for a period of one (1) year

Irom the date of acceptance, however if the defects are due to wrong operation,

loperation abuse or neglected maintenance,our company shall not be liable for any

WARRANTY —:_|replacement.

|System: We also guarantee that BAUER INTERNATIONALPHILIPPINES INC. shall

lassume full responsibility for the issuance of “Permit to Operate" with an influent

lwater quality stipulated in our proposal

Thank you very much for giving us the opportunity to quote on your requirement and we hope to merit

xyour kind approval. Should you need further queries, please let us know.

Very truly yours,

Shairaharmaine Montero

Sales Engineer

Noted by

Ms. Liza M.

‘and Marketing Manager

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Pamana Expenses NewDocument48 pagesPamana Expenses NewHausland Const. Corp.No ratings yet

- Canva 5 Design Milestone BadgeDocument3 pagesCanva 5 Design Milestone BadgeHausland Const. Corp.No ratings yet

- TFOE Membership Application Form - FINAL2024Document3 pagesTFOE Membership Application Form - FINAL2024Hausland Const. Corp.No ratings yet

- The Diverse WorkforceDocument22 pagesThe Diverse WorkforceHausland Const. Corp.No ratings yet

- CH10 Foundations of Control (Group4 14-MMPA)Document16 pagesCH10 Foundations of Control (Group4 14-MMPA)Hausland Const. Corp.No ratings yet

- Group 3 (MMPA) Chapter 8 CommunicationDocument66 pagesGroup 3 (MMPA) Chapter 8 CommunicationHausland Const. Corp.No ratings yet

- Complete Colution CalcualtionDocument80 pagesComplete Colution CalcualtionHausland Const. Corp.No ratings yet

- 02.01.16 Process Flow DiagramDocument1 page02.01.16 Process Flow DiagramHausland Const. Corp.No ratings yet

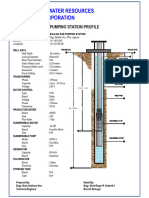

- Water Resources Inc - Pumping Station Profile - Well DesignDocument2 pagesWater Resources Inc - Pumping Station Profile - Well DesignHausland Const. Corp.No ratings yet

- 01.25.16 BOQ2 Civil EstimateDocument25 pages01.25.16 BOQ2 Civil EstimateHausland Const. Corp.No ratings yet

- Le JaDocument198 pagesLe JaHausland Const. Corp.No ratings yet

- Report RCC DesignDocument21 pagesReport RCC DesignHausland Const. Corp.No ratings yet

- MP OrgDocument2 pagesMP OrgHausland Const. Corp.No ratings yet

- Le Ja COMPLTE ANALYSISDocument630 pagesLe Ja COMPLTE ANALYSISHausland Const. Corp.No ratings yet

- ExcavationDocument5 pagesExcavationHausland Const. Corp.No ratings yet

- Refined Process Flow-Concrete ProductsDocument2 pagesRefined Process Flow-Concrete ProductsHausland Const. Corp.No ratings yet

- Layout & StakingDocument5 pagesLayout & StakingHausland Const. Corp.No ratings yet

- Org Chart 1Document2 pagesOrg Chart 1Hausland Const. Corp.No ratings yet

- 11.90 Design ReprotDocument10 pages11.90 Design ReprotHausland Const. Corp.No ratings yet

- 8.75 DesignDocument26 pages8.75 DesignHausland Const. Corp.No ratings yet

- Scheduling PlanDocument1 pageScheduling PlanHausland Const. Corp.No ratings yet

- Engaging Theme - ReportDocument2 pagesEngaging Theme - ReportHausland Const. Corp.No ratings yet

- Project Schedule HCDocument8 pagesProject Schedule HCHausland Const. Corp.No ratings yet

- Executive SummaryDocument3 pagesExecutive SummaryHausland Const. Corp.No ratings yet

- Kpi OpsDocument2 pagesKpi OpsHausland Const. Corp.No ratings yet

- Alfonso Project Sched For ExecomDocument1 pageAlfonso Project Sched For ExecomHausland Const. Corp.No ratings yet

- For BILLING For Next BillingDocument28 pagesFor BILLING For Next BillingHausland Const. Corp.No ratings yet

- BF Productivity RateDocument80 pagesBF Productivity RateHausland Const. Corp.No ratings yet

- Assignment TableDocument3 pagesAssignment TableHausland Const. Corp.No ratings yet

- 081223-Alfonso-Franco Boq - Client - OpDocument4 pages081223-Alfonso-Franco Boq - Client - OpHausland Const. Corp.No ratings yet