Professional Documents

Culture Documents

Sspc-Sp1: Saudi Aramco: Company General Use

Uploaded by

obaid anwar0 ratings0% found this document useful (0 votes)

4 views1 pageThis document provides guidelines for coating selection and application for industrial plants and equipment. It describes various coating systems for new and maintenance applications for different material types, including galvanized steel and stainless steel. Requirements and remarks are provided for each coating system. The document aims to help select appropriate coatings to protect equipment from corrosion in various environments.

Original Description:

Original Title

9 - Copy (2)

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides guidelines for coating selection and application for industrial plants and equipment. It describes various coating systems for new and maintenance applications for different material types, including galvanized steel and stainless steel. Requirements and remarks are provided for each coating system. The document aims to help select appropriate coatings to protect equipment from corrosion in various environments.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

4 views1 pageSspc-Sp1: Saudi Aramco: Company General Use

Uploaded by

obaid anwarThis document provides guidelines for coating selection and application for industrial plants and equipment. It describes various coating systems for new and maintenance applications for different material types, including galvanized steel and stainless steel. Requirements and remarks are provided for each coating system. The document aims to help select appropriate coatings to protect equipment from corrosion in various environments.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

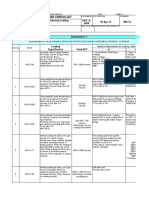

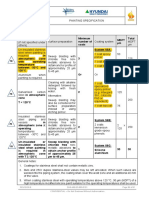

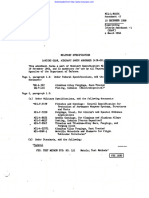

Document Responsibility: Paints and Coatings Standards Committee SAES-H-001

Issue Date: 21 February 2018 Coating Selection and Application

Next Planned Update: 5 April 2019 Requirements for Industrial Plants and Equipment

Coating System

Description New Maintenance Remarks

107.

2. Galvanizing is acceptable for onshore

equipment and areas that will not be

subjected to water.

H. Galvanized APCS-1B APCS-1B 1. Materials to be galvanized are

Steel APCS-1E APCS-1C specified in 12-SAMSS-007.

APCS-12 APCS-1E 2. Coating of galvanized steel is not

APCS-22A APCS-12 required for mild environment.

APCS-22B APCS-22A

3. Coating is recommended at corrosive

APCS-26 APCS-22B

and humid areas to increase chemical

APCS-26T APCS-26

and corrosion resistance.

APCS-26T

4. Prior to the application of coating on

galvanized surface, remove any

hydrocarbon contamination with

solvent as per SSPC-SP1. In addition,

the surface shall be roughened with

sweep blasting. Painting should begin

as soon as possible after cleaning

and profiling.

5. Use APCS-26 on galvanized steel

operating up to 120°C and located

indoors or outdoors.

6. Use APCS-26T on galvanized steel

operating up to 80°C; located

outdoors.

7. Use APCS-22A or APCS-22B on

galvanized steel operating up to

120°C that is located outdoors and

that will be coated in the field when

surfaces will be damp during

application.

6. Use APCS-1C primer only to touch-

up and repair galvanizing that will not

be coated with another system.

7. Refer to paragraph 7.1.E for

galvanized steel requiring fireproofing

materials.

8. Use APCS-12 only for galvanized

steel floors and decks that require

non-slip properties. APCS-12 is not

acceptable, however, for galvanized

steel grating-type floors or decks.

1. Normally, coating is not required. If

I. Stainless APCS-1B APCS-1B coating is needed in industrial areas

Steel APCS-11C APCS-11C with high humidity and aggressive

Saudi Aramco: Company General Use

Page 23 of 120

You might also like

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- AMS-2404-G - Electroless Nickel CoatingDocument9 pagesAMS-2404-G - Electroless Nickel CoatingaadmaadmNo ratings yet

- Inspection HandbookDocument127 pagesInspection HandbookWalter Rueda100% (2)

- Inspection HandbookDocument126 pagesInspection Handbooksteffy18295% (21)

- Exhaust System TechnologyDocument18 pagesExhaust System TechnologyDastagir ShaikhNo ratings yet

- Siemens Dishwasher ManualDocument28 pagesSiemens Dishwasher ManualChrister NilssonNo ratings yet

- Aramcoinspectionhandbook 150311084705 Conversion Gate01 PDFDocument126 pagesAramcoinspectionhandbook 150311084705 Conversion Gate01 PDFMuhammed SulfeekNo ratings yet

- Standards MaterialDocument19 pagesStandards MaterialnaveenkumarNo ratings yet

- Chapter 8 - Electric Current & ResistivityDocument5 pagesChapter 8 - Electric Current & ResistivityFritz NatividadNo ratings yet

- Inspection HandbookDocument126 pagesInspection HandbookMiguel Angel Mora PazNo ratings yet

- P 651 14 HPC 3 08 DSD DSDX SeriesDocument7 pagesP 651 14 HPC 3 08 DSD DSDX Serieseka prasetia0% (1)

- Working Procedure For Coating Repair C4Document7 pagesWorking Procedure For Coating Repair C4tuyen nguyenNo ratings yet

- Abu Ali project-APCS 1D Using Hempel Paint REV.01 PDFDocument10 pagesAbu Ali project-APCS 1D Using Hempel Paint REV.01 PDFravi ajith100% (1)

- Sci8 q3 Mod4 v4Document25 pagesSci8 q3 Mod4 v4Amber SumalpongNo ratings yet

- Astm A780Document4 pagesAstm A780Raúl Venegas Munita100% (5)

- Inspection Handbook PDFDocument20 pagesInspection Handbook PDFSamuel JohnNo ratings yet

- Asean Process Validation GuidelineDocument6 pagesAsean Process Validation GuidelineWilliam Chandra100% (1)

- APCS DeatailsDocument3 pagesAPCS DeatailsnasirNo ratings yet

- Pages From SAES-H-001-19Document1 pagePages From SAES-H-001-19mohammed s fawabNo ratings yet

- Larsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingDocument10 pagesLarsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingPrince Jose100% (1)

- @coating Book - Aramco Inspection HandbookDocument126 pages@coating Book - Aramco Inspection HandbookUmair AhmadNo ratings yet

- Astm A 780 - A 780M-09Document4 pagesAstm A 780 - A 780M-09Ramsi AnkziNo ratings yet

- ASTM A780 - Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsDocument4 pagesASTM A780 - Repair of Damaged and Uncoated Areas of Hot-Dip Galvanized CoatingsvajidqcNo ratings yet

- Safety For LNG PlantsDocument13 pagesSafety For LNG Plantsravikb27100% (1)

- Pharmaceutical Water System Design OperationDocument11 pagesPharmaceutical Water System Design OperationManivannan KathirvelNo ratings yet

- API-653 Tank Inspection Sample ReportDocument19 pagesAPI-653 Tank Inspection Sample Reportツ ツ93% (15)

- Pipe Coat & LiningDocument22 pagesPipe Coat & Liningjadav parixeet100% (3)

- Saic H 2082Document8 pagesSaic H 2082jerin100% (1)

- Technology Guide No. 19: SSPC: The Society For Protective CoatingsDocument3 pagesTechnology Guide No. 19: SSPC: The Society For Protective CoatingsMia AndinoNo ratings yet

- Larsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingDocument10 pagesLarsen & Toubro Atco Saudi LLC: Procedure For Repair Touch-Up Paint of Equipment, Structural and PipingEstebanCastellanosBorreroNo ratings yet

- Vitreous China Plumbing Fixtures 75SMSS2Document25 pagesVitreous China Plumbing Fixtures 75SMSS2Pageduesca RouelNo ratings yet

- Api 652Document2 pagesApi 652muhammadazhanudinNo ratings yet

- Pages From SAES-H-001-18Document1 pagePages From SAES-H-001-18mohammed s fawabNo ratings yet

- InternalDocument2 pagesInternalSUNIL RAJPUTNo ratings yet

- Saic P 3311Document7 pagesSaic P 3311Arshad ImamNo ratings yet

- Al 6XNDocument59 pagesAl 6XNJose'toño BernalNo ratings yet

- Abstract of ASTM B695 2000Document8 pagesAbstract of ASTM B695 2000Jesse ChenNo ratings yet

- Schedule G - Attachment I-VII 3000953944Document18 pagesSchedule G - Attachment I-VII 3000953944xue jun xiangNo ratings yet

- Saic M 1034Document2 pagesSaic M 1034noor mohamedazeezNo ratings yet

- AC-REPAIR-10: Ready To Use Castable Grout & RepairDocument2 pagesAC-REPAIR-10: Ready To Use Castable Grout & RepairBhagwat PatilNo ratings yet

- LAPRIL-C004 Rev.02Document6 pagesLAPRIL-C004 Rev.02alpha NEPALNo ratings yet

- Moti SS 216Document14 pagesMoti SS 216jennifergiannouNo ratings yet

- Saic M 1033Document7 pagesSaic M 1033noor mohamedazeezNo ratings yet

- Inspection 2Document1 pageInspection 2Iftikhar AhmedNo ratings yet

- IS218.02B - Suggested Specification For Concrete Parking AreasDocument2 pagesIS218.02B - Suggested Specification For Concrete Parking AreasfarhanNo ratings yet

- HHI Coat SystemDocument1 pageHHI Coat SystemAiman AhmadNo ratings yet

- Mil L 8552C - Amendment 2Document7 pagesMil L 8552C - Amendment 2moonstarNo ratings yet

- Abstract of ASTM B766 1998Document11 pagesAbstract of ASTM B766 1998Jesse ChenNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 MechDocument4 pagesSaudi Aramco Inspection Checklist: Installation of Wellhead Guard Rails. SAIC-L-2088 30-Apr-17 Mechkarthi51289No ratings yet

- WSS M1P87 BXDocument6 pagesWSS M1P87 BXShu Fu100% (1)

- Specs 06620 GRP Louvered BladesDocument3 pagesSpecs 06620 GRP Louvered BladeswooderNo ratings yet

- G-8028-D02-002 (SHT.02 of 02)Document1 pageG-8028-D02-002 (SHT.02 of 02)Mohamed RafikNo ratings yet

- Corrosion Protection of Weldable AA2219 AlloyDocument5 pagesCorrosion Protection of Weldable AA2219 AlloySwarupendra BhattacharyyaNo ratings yet

- A.6 Coating System No. 6: Title: Coating and Painting Specification Rev.: Date: Doc. No.: 05-1 - EPC-SV-AEI-M-SA-00001Document1 pageA.6 Coating System No. 6: Title: Coating and Painting Specification Rev.: Date: Doc. No.: 05-1 - EPC-SV-AEI-M-SA-00001Tien Tran Kha TienNo ratings yet

- Submersible (Wastewater) PumpsDocument7 pagesSubmersible (Wastewater) PumpsCristi TanasescuNo ratings yet

- ASTM A780 v1Document1 pageASTM A780 v1Enzo GacitúaNo ratings yet

- 128 Data SheetDocument2 pages128 Data SheettrinhminhkhoaNo ratings yet

- Sabp P 012 PDFDocument8 pagesSabp P 012 PDFfaisalqrNo ratings yet

- Saic D 2016Document2 pagesSaic D 2016razzak.me.enggNo ratings yet

- Pages From SAES-H-001-3Document1 pagePages From SAES-H-001-3mohammed s fawabNo ratings yet

- Connecting Piping IBRDocument5 pagesConnecting Piping IBRgopaltryNo ratings yet

- AP Review CH 12Document6 pagesAP Review CH 12ygtefferaNo ratings yet

- Textbook Chapter 024 PDFDocument20 pagesTextbook Chapter 024 PDFEstudiante2346No ratings yet

- SpectrumPhysicsNovember2015 Ebook3000 PDFDocument84 pagesSpectrumPhysicsNovember2015 Ebook3000 PDFjagannivasNo ratings yet

- N Butanol As An Extractant For Lactic Acid Recovery PDFDocument4 pagesN Butanol As An Extractant For Lactic Acid Recovery PDFKanungnit ChawongNo ratings yet

- 65ah - 12V - 6FM65 VISIONDocument2 pages65ah - 12V - 6FM65 VISIONBashar Salah100% (1)

- As Revision Book PhysicsDocument72 pagesAs Revision Book PhysicsSrnt YyoNo ratings yet

- GCE O'Level 5070 Past Paper Questions (Salts)Document5 pagesGCE O'Level 5070 Past Paper Questions (Salts)Mohamed Saddam Hussain67% (3)

- MS 1972-2007Document5 pagesMS 1972-2007LAVOSNo ratings yet

- Teacher: Mervi Vera Buitron de Gratal Trabajo Grupal: 1) Giron Ugarte, Luis AurelioDocument3 pagesTeacher: Mervi Vera Buitron de Gratal Trabajo Grupal: 1) Giron Ugarte, Luis AurelioNaomi HerreraNo ratings yet

- Glossary: Essentials of Meteorology (7 Ed.)Document24 pagesGlossary: Essentials of Meteorology (7 Ed.)Shahed FacebookNo ratings yet

- Masteremaco S 488: Structural Repair MortarDocument3 pagesMasteremaco S 488: Structural Repair MortarKhan ShahzebNo ratings yet

- Sweco CatDocument21 pagesSweco CatArmandoZacariasAcostaNo ratings yet

- Chemical Basis of LifeDocument9 pagesChemical Basis of LifeRem AlbarnNo ratings yet

- KIMIA Kertas 2 4541/2Document2 pagesKIMIA Kertas 2 4541/2dranasridNo ratings yet

- Summer Training ReportDocument16 pagesSummer Training ReportmohitNo ratings yet

- Sandstone PropertiesDocument6 pagesSandstone Propertiesعصام السامرائيNo ratings yet

- Evaluation of A Bio CurtainsDocument7 pagesEvaluation of A Bio CurtainsrenicolaiNo ratings yet

- Bourdon Sensing Pressure GaugeDocument2 pagesBourdon Sensing Pressure GaugeJitendra BhosaleNo ratings yet

- MAT 435 Chapter 3: Functions of Two and Three Variables: 1 y X 3) Y, X (FDocument8 pagesMAT 435 Chapter 3: Functions of Two and Three Variables: 1 y X 3) Y, X (FlancaugilaNo ratings yet