Professional Documents

Culture Documents

Capture D'écran . 2020-01-30 À 1.22.21 PM

Uploaded by

Haikel Ben SalahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Capture D'écran . 2020-01-30 À 1.22.21 PM

Uploaded by

Haikel Ben SalahCopyright:

Available Formats

1 2 3 4 5 6 7 8

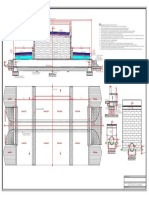

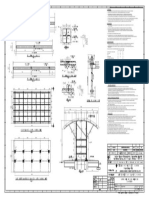

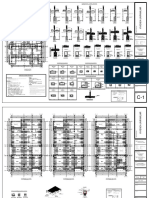

4650 GENERAL NOTES:-

1. ALL DIMENSIONS ARE IN MILLIMETERS. UNLESS OTHERWISE SPECIFIED.

2. TANK SHALL BE DESIGNED, FABRICATED, INSPECTED AND TESTED IN ACCORDANCE WITH ASME SEC

VIII,DIV.1

3. CUTTING OF PLATE CAN BE DONE BY SHEARING OR OXYGEN CUTTING.

A 4. ALL VERTICAL & HORIZONTAL SHELL JOINT SHALL BE BUTT JOINTS AND SHALL HAVE FULL PENETRATION

& FUSION THROUGH FULL THICKNESS OF PARENT PLATE.

5. BREAK ALL SHARP EDGES. REMOVE ALL BURRS AND WELD SPATTERS. CIRCUMFERENTIAL &

A

LONGITUDINAL WELD JOINTS IN SHELL SHALL BE GROUND SMOOTH FROM TANK INSIDE FOR SMOOTH

MOVEMENT.

6. ALL FLANGE BOLT HOLES SHALL STRADDLE, THE HORIZONTAL AXIS OF THE NOZZLE PIPE.

3232

7. FOR ALL SHELL NOZZLES PROJECTIONS SHALL BE MEASURED FROM CENTER OF TANK TO FLANGE FACE.

AND ALL ROOF NOZZLES PROJECTIONS SHALL BE MEASURED FROM TOP OF TOP SHELL COURSE TO

FLANGE FACE.

8. ALL NOZZLE REINFORCEMENT PADS SHALL HAVE ONE 1/4" NPT TELLTALE . THE LOCATION SHALL BE

Air Nozzle 4 Nors AT HORIZONTAL CENTER LINE OF NOZZLE. HOLE SHALL BE FILLED WITH GREASE.

A(0.012) 9. FLANGE BOLTING SHALL CONFORM TO ASTM SA-193 Grade B7 w/SA-194 Grade 2H. ALL BOLTS AND NUTS

SHALL BE THREADED IN ACCORDANCE WITH ISO THRD.

10. FLANGE FACE FINISH SHALL BE CONCENTRIC SERRATION Ra=125-250 MICROINCH.

11. NOZZLE FLANGES AS PER ASME B16.5 CLASS 150 SORF FOR FLANGES UPTO 24".

12. INTERNAL REMOVABLE PARTS SHALL PASS THROUGH MANWAY.

13. SHELL INTERNAL HORIZONTAL & VERTICAL WELDING SHALL BE SMOOTH FINISH (DO NOT FLUSH).

B Bucket

14. ALL PERMANENT ATTACHMENTS (PIPE SUPPORT, LADDER SUPPORT PADS ETC..) & TEMPORARY

ATTACHMENTS (ERECTION CLIPS ETC.) SHALL CLEAR HORIZONTAL SEAM BY 75mm AND VERTICAL SEAM BY

150mm. WHEN THE PERMANENT ATTACHMENTS ARE WELDED AND WHERE IT IS NOT POSSIBLE TO AVOID

B

OVERLAPPING SEAMS, THE OVERLAPPING SEAMS WELD WHICH ARE COVERED SHALL BE GROUND FLUSH,

22820 100% RT AND DP INSPECTED BEFORE THE ATTACHMENT IS FITTED.

15. PAD PLATES WITH TELL TALE HOLES/WEEP SHALL BE USED FOR ALL SUPPORTS WELDED TO SHELL &

BOTTOM PLATES, EDGES TO BE ROUNDED TO AVOID SHARP CORNERS.

16. ALL TEMPORARY ATTACHMENTS (LIKE : MEASURING PIECE) SHALL BE REMOVED & THE WELDS ON THE

Sliding gate REMOVED PORTION GROUND SMOOTH AND SHALL BE EXAMINED VISUALLY AND BY LIQUID PENETRANT

METHOD.

17. DIMENSIONAL TOLERANCES AS PER ANSI/ASME STANDARD Y14.5M.

18. TANK INTERNAL & EXTERNAL PAINTING SYSTEM WILL BE AS PER CUSTOMER REQUIREMENT.

17332

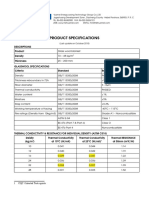

C Material specification & standard C

Description Specification STD

Shell/ Foof /Cone 6 mm Thk A36

Silo Base Plate 20 mm Thk A36

HEM 200

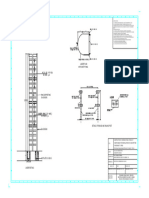

Ladder Ladder/Cage A36

Mnnway 24" A36

Lifting Lugs 20 mm THK SA-36/SA 106 Gr.B

Nozzle Neck Pipe SH40 SA-106 Gr.B

Nozzle Flange CL #150 ANSI SA-105

Cone Bottom Flange 250 A36

Fittings Air Nozzle SA-234 WPB

D 3450

17332

Stud Assly Fastener SA-193 Gr B7 & SA-194 Gr 2H

Spiral wound graphite filled

Gasket Nozzle

innerSS 316 & Outer CS ring

Platform Structure Structure S275JR HEM 200

6816

ASTM A1011(Shall be hot dip

galvanized in

Grating Structure Grating accordance with ASTM A123

and

4350 ASTM A385.)

Grounding Lug - -

A Name plate/Bracket Tank & Structure SS 316/A36

Electrical Conduit pipe -

IPE 200

4319

100x100x4.00

E

filling pipe (Option)

0

600

4650 856 4050 4050

580

Project Description:

Job Title: Ref Drawing No:

STORAGE SILO 103 m3 Each

REV: DESCRIPTION: CHECKED BY DATE

REVISION STATUS Unless Otherwise Specified All Main Drawing No: Sheet n /n : Scale: Date:

Dimensions Are In Millimeter

F Size: Material A36 Weight kg Tolerances Are:

/ 1/1 NTS 22-Jul-19 F

DESG/FM01-2/V1/6/18

ANSI/ASME Standard Y14.5M-1994 www.sabk.com.sa

Client: P.O No: W.O No: This drawing and the information

P.O Box 27335,

Design by : Checked by: Approved by:

Linear Dimensions contained herein are the sole property of

ASTRA SABK Industrial Equipment Co Ltd. The Riyadh 11417

Saudi Arabia JP YS YS

X = 0.5 ANG = 0.5 contents thereof must not be imported

by a third party nor be used for any Head Office

Project & Location: PROJECT NO: File No: X.X = 0.2

unauthorized purpose without the T:+966 1 244 8738 Part Number: Rev: Size:

X.XX = 0.01 F:+966 1 244 8293

KSA written permission of SABK Industrial

Equipment Co Ltd. infosabk.com.sa 010 A3

1 2 3 6 7 8

You might also like

- Isometric View: Dymac GlobalDocument2 pagesIsometric View: Dymac GlobalMaarij AnjumNo ratings yet

- STR - 1Document1 pageSTR - 1shankar9841469226No ratings yet

- 1 Footing Plan PDFDocument1 page1 Footing Plan PDF114 Gopal jagtapNo ratings yet

- Treehouse, Waiheke Island: Structural Steelwork NotesDocument12 pagesTreehouse, Waiheke Island: Structural Steelwork NotesKesavan DhuraiNo ratings yet

- General Notes and Specification: 3-LegendDocument1 pageGeneral Notes and Specification: 3-LegendReadian FedelinNo ratings yet

- D-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021Document1 pageD-EUGP1-TPT-G-000-GEN-FWG-001-R00 With Comments 18 10 2021debapriyoNo ratings yet

- DSS - Layout.Without - TX AP-2023.07.06Document1 pageDSS - Layout.Without - TX AP-2023.07.06sundareee96No ratings yet

- J1273-S001-General NotesDocument1 pageJ1273-S001-General Notesroy jackNo ratings yet

- Construction Notes-AaDocument2 pagesConstruction Notes-AaRieo VillaNo ratings yet

- Jurucita ConsultantDocument1 pageJurucita ConsultantHong Jin YaoNo ratings yet

- General Notes: General Notes: NOTES FOR STORM WATER: (Continuation) Notes For Sewer LinesDocument1 pageGeneral Notes: General Notes: NOTES FOR STORM WATER: (Continuation) Notes For Sewer LinestogireeshNo ratings yet

- J1078-S001-General NotesDocument1 pageJ1078-S001-General Notesroy jackNo ratings yet

- Distribution - SS Rev.7A AP-2023.07.06Document12 pagesDistribution - SS Rev.7A AP-2023.07.06sundareee96No ratings yet

- Drawing Sheet 4Document1 pageDrawing Sheet 4Kunal SharmaNo ratings yet

- 20171003-Beam & Slab Schedule-01Document1 page20171003-Beam & Slab Schedule-01Atul ShrivastavaNo ratings yet

- J0535-S001 - General Notes PDFDocument1 pageJ0535-S001 - General Notes PDFSaiful IslamNo ratings yet

- E. Reinforcement A. General B. Foundation: NotesDocument12 pagesE. Reinforcement A. General B. Foundation: NotesIsrael AdegboyegaNo ratings yet

- For Construction: General Notes For Structural SteelDocument1 pageFor Construction: General Notes For Structural SteelTOM YEENo ratings yet

- J0673-S001 - General NotesDocument1 pageJ0673-S001 - General NotesEmon RayNo ratings yet

- J-S001-General NotesDocument1 pageJ-S001-General Notesroy jackNo ratings yet

- I - General NotesDocument1 pageI - General NotesReadian FedelinNo ratings yet

- SM Consultants: Tunnel Support in Rock Class-IDocument1 pageSM Consultants: Tunnel Support in Rock Class-IShivendra KumarNo ratings yet

- Plumbing1 ModelDocument1 pagePlumbing1 ModelMarvin VinaraoNo ratings yet

- Plumbing1 ModelDocument1 pagePlumbing1 ModelMarvin VinaraoNo ratings yet

- Structural Notes 1Document1 pageStructural Notes 1missiklein3No ratings yet

- 4 Dygal ST, Mona Vale - Stormwater DrawingDocument8 pages4 Dygal ST, Mona Vale - Stormwater DrawingRohan Dutt SharmaNo ratings yet

- 3.5xRC 21.5'X46.5' - Structural Drawing - R00Document31 pages3.5xRC 21.5'X46.5' - Structural Drawing - R00Moe Oo HtunNo ratings yet

- 200 Item Answer SheetDocument4 pages200 Item Answer SheetFroilan EspinosaNo ratings yet

- Pipeworks DrawingsDocument4 pagesPipeworks DrawingsMOHD AFIQ CAIREL AHMADNo ratings yet

- Construction Notes:: General MasonryDocument1 pageConstruction Notes:: General MasonryJohn And ThenaNo ratings yet

- (S01-S12) CDocument12 pages(S01-S12) CMa'arif Nuzul AddibNo ratings yet

- For Construction Drawing - FCD: General Structural Notes & SpecificationsDocument1 pageFor Construction Drawing - FCD: General Structural Notes & SpecificationsJossell De AlaNo ratings yet

- HPC VupDocument1 pageHPC VupShivam SharmaNo ratings yet

- J0647-S001 - General NotesDocument1 pageJ0647-S001 - General NotesEmon Ray100% (1)

- Column LayoutDocument1 pageColumn Layoutlagnajit dasNo ratings yet

- Column LayoutDocument1 pageColumn Layoutlagnajit dasNo ratings yet

- Preliminary ContractsDocument16 pagesPreliminary ContractsLaura Rivas LópezNo ratings yet

- SD10102-002 - Pile Cap Bar Bending Schedule and Details PDFDocument1 pageSD10102-002 - Pile Cap Bar Bending Schedule and Details PDFMohammed AdilNo ratings yet

- General Notes:: BOD Josephine P. Isturis Pablo G. Racines Romeo C. OcampoDocument1 pageGeneral Notes:: BOD Josephine P. Isturis Pablo G. Racines Romeo C. OcampoJay RickNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument1 pageGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- General Construction Notes: Schedule of Minimum Slab ReinforcementDocument2 pagesGeneral Construction Notes: Schedule of Minimum Slab ReinforcementDominic Robiso DatuinNo ratings yet

- General: 5. Construction Notes: WarehouseDocument1 pageGeneral: 5. Construction Notes: WarehouseJayson EscobarNo ratings yet

- PARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1Document1 pagePARKING SHED AT 220kV BHILDI GIS SUB-STATION - Layout1irshad khanNo ratings yet

- General Notes: D.P.W.HDocument1 pageGeneral Notes: D.P.W.HJemil Rose SamosNo ratings yet

- 1) General Notes:: Karthikeyan AssociatesDocument12 pages1) General Notes:: Karthikeyan AssociatesSLV GROUPNo ratings yet

- KPC Medical College & Hospital: 1F, Raja Subodh Chandra Mullick Road, Jadavpur, Kolkata, West Bengal 700 032Document1 pageKPC Medical College & Hospital: 1F, Raja Subodh Chandra Mullick Road, Jadavpur, Kolkata, West Bengal 700 032Kausik DewanNo ratings yet

- Fabrication: Structural and Miscellaneous Steel: (REF: TECH. SPEC. 143256-ES-C-1008, 1011 & 1012) Materials: PaintingDocument1 pageFabrication: Structural and Miscellaneous Steel: (REF: TECH. SPEC. 143256-ES-C-1008, 1011 & 1012) Materials: PaintingRoberto Andrés Fernández DomínguezNo ratings yet

- Dpw-1 Retaining Wall 1028' RFTDocument1 pageDpw-1 Retaining Wall 1028' RFTM JAVEDNo ratings yet

- Roxas PWD BuildingDocument32 pagesRoxas PWD BuildingDennis SariegoNo ratings yet

- Cemex Solid K4 - Raw Meal SiloDocument3 pagesCemex Solid K4 - Raw Meal Silojoselito navarroNo ratings yet

- FF To Roof: Storey MarkingDocument1 pageFF To Roof: Storey MarkingHong Jin YaoNo ratings yet

- Mace Ar 10 B1 02Document1 pageMace Ar 10 B1 02Syead OwaisNo ratings yet

- Symbology Legend: Ministry of Transport & CommunicationsDocument1 pageSymbology Legend: Ministry of Transport & CommunicationsAbid AyubNo ratings yet

- 2023-07-18 B159 STR 102 GFC R0Document1 page2023-07-18 B159 STR 102 GFC R0arjunNo ratings yet

- Ael ST DRW 0002 001Document1 pageAel ST DRW 0002 001slimNo ratings yet

- VKG Akhnoor Project DrawingDocument1 pageVKG Akhnoor Project DrawingNikhil Dwivedi Seismoflex Private LimitedNo ratings yet

- Detail - A Typical Plan For Module Mounting Structure: Section 1-1Document1 pageDetail - A Typical Plan For Module Mounting Structure: Section 1-1Spandan MurthyNo ratings yet

- 2.8 09 S002-General Notes - Sheet 2 - 02 PDFDocument1 page2.8 09 S002-General Notes - Sheet 2 - 02 PDFSaiful IslamNo ratings yet

- Pipe CulvertDocument12 pagesPipe CulvertSajjad Khan100% (1)

- Analysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionFrom EverandAnalysis and Design of Structural Sandwich Panels: The Commonwealth and International Library: Structures and Solid Body Mechanics DivisionRating: 5 out of 5 stars5/5 (1)

- Pile Analysis Summary:: Input DataDocument2 pagesPile Analysis Summary:: Input DataPatrick HenriNo ratings yet

- Mortar Analysis Part 3 - L SchnabelDocument4 pagesMortar Analysis Part 3 - L SchnabelSugarPOP666No ratings yet

- TS6 3.5 Tubing 15.8ppfDocument1 pageTS6 3.5 Tubing 15.8ppfKhairilsyam Abdul RashidNo ratings yet

- Effect of Cement Stabilization On Geotechnical Properties of Sandy Soils PDFDocument16 pagesEffect of Cement Stabilization On Geotechnical Properties of Sandy Soils PDFFahim KhanNo ratings yet

- Proy. C - Completo - 2018Document12 pagesProy. C - Completo - 2018Gosbony SKNo ratings yet

- Case Study On Ground Improvement by High Pressure Jet GroutingDocument6 pagesCase Study On Ground Improvement by High Pressure Jet Groutingnagy_andor_csongorNo ratings yet

- Bolt Calculation According To VDI 2230:2014: InputsDocument7 pagesBolt Calculation According To VDI 2230:2014: InputsSridhar TholasingamNo ratings yet

- Simplified Concrete Modeling With Mat - Concrete - Damage - Rel3: Leonard E SchwerDocument14 pagesSimplified Concrete Modeling With Mat - Concrete - Damage - Rel3: Leonard E Schwersvk_ntNo ratings yet

- Operating and Maintenance Manual: (Project Name)Document75 pagesOperating and Maintenance Manual: (Project Name)Bob MorrisNo ratings yet

- Guidance Note For ToleranceDocument5 pagesGuidance Note For ToleranceBui Chi TamNo ratings yet

- ENS 080312 en JZ Notes Chapter 1Document3 pagesENS 080312 en JZ Notes Chapter 1Kenny CasillaNo ratings yet

- Motor Multi v210Document20 pagesMotor Multi v210huayra85No ratings yet

- Aisc Asd Gusset Plate Aisc341 16Document12 pagesAisc Asd Gusset Plate Aisc341 16Zarna Modi100% (1)

- Guidance For The Approval and Type Approval of Materials and Equipment For Marine UseDocument321 pagesGuidance For The Approval and Type Approval of Materials and Equipment For Marine UseRafael Brito100% (1)

- QBC CRMB TDS Rev 0Document2 pagesQBC CRMB TDS Rev 0nainaNo ratings yet

- Design Constants For Working Stress MethodDocument4 pagesDesign Constants For Working Stress MethodArpit JaiswalNo ratings yet

- Analysis of Single and Group Micropile Behavior PDFDocument157 pagesAnalysis of Single and Group Micropile Behavior PDFLucas MartinsNo ratings yet

- Huamei Spec Sheets - 2018Document1 pageHuamei Spec Sheets - 2018Phan LongNo ratings yet

- ST Kevin's College, Victor McMahon Music Centre-ArjunPCDocument24 pagesST Kevin's College, Victor McMahon Music Centre-ArjunPCArjun MiddhaNo ratings yet

- Lec-2 Structural Steel PropertiesDocument10 pagesLec-2 Structural Steel PropertiesRifat HasanNo ratings yet

- 20550e00 PDFDocument120 pages20550e00 PDFhalim_kaNo ratings yet

- Procedures For Hot Insulation - 2Document8 pagesProcedures For Hot Insulation - 2Quy RomNo ratings yet

- Overview of Cross Laminated Timber CLT and Timber Structure Standards Across The WorldDocument13 pagesOverview of Cross Laminated Timber CLT and Timber Structure Standards Across The WorldMarkArchNo ratings yet

- Balancing Valve (DRV) (1 4218 4x) GMFDocument5 pagesBalancing Valve (DRV) (1 4218 4x) GMFSHINOS 3SNo ratings yet

- BIM and Sustainability in Terms of Philippine StandardsDocument6 pagesBIM and Sustainability in Terms of Philippine Standardsraifel100% (1)

- Chapter 4 GlassDocument51 pagesChapter 4 Glassaman sudiNo ratings yet

- 000 - Tie Coat - Arabian Vermiculite - FIREBOND - Data SheetDocument2 pages000 - Tie Coat - Arabian Vermiculite - FIREBOND - Data SheetNizarHamrouniNo ratings yet

- EC-EMX-instruction-inflatable Spider TentDocument2 pagesEC-EMX-instruction-inflatable Spider TentSerena WangNo ratings yet

- ELECTRICAL WIRING PLAN DemoDocument24 pagesELECTRICAL WIRING PLAN DemoTommy Dela CruzNo ratings yet