Professional Documents

Culture Documents

(English (Auto-Generated) ) New Toyota Yaris - Ouality Throughout The Supply Chain (DownSub - Com)

(English (Auto-Generated) ) New Toyota Yaris - Ouality Throughout The Supply Chain (DownSub - Com)

Uploaded by

Hải my0 ratings0% found this document useful (0 votes)

3 views4 pagesOriginal Title

[English (auto-generated)] New Toyota Yaris - Ouality throughout the supply chain [DownSub.com]

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views4 pages(English (Auto-Generated) ) New Toyota Yaris - Ouality Throughout The Supply Chain (DownSub - Com)

(English (Auto-Generated) ) New Toyota Yaris - Ouality Throughout The Supply Chain (DownSub - Com)

Uploaded by

Hải myCopyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 4

before mass production of the new yis

began Toyota's European purchasing

division implemented numerous procedures

designed to ensure that every single

component can be manufactured to the

highest possible quality

standards the new Yaris has benefited

from Toyota's continuous quality

improvement activities in three key

areas first intensive simult anous

engineering and supplier Parts

preparation both activities exist to

check the quality and production

processes of newly developed parts for

our vehicles second the supplier

development program this is a special

quality improvement activity reserved

for a small number of strategic Supply

Partners finally team our supplier

Association in Europe and whilst the

concept exists elsewhere I am sure that

the depth of Engagement and passion from

European suppliers to participate in

team is unique in the industry within

the simultaneous Engineering Process

Toyota and its suppliers reviewed the

design of 700 Parts resulting in 900

specific quality

[Music]

improvements as a supplier we can best

support Toyota by using our

manufacturing experience to review and

inform every aspect of the parts design

and production process in detail through

simultaneous engineering activities more

than 30 designs proposals were discussed

by the Toyota and the ficosa teams from

the earliest stage of the new yis

contract only through simultanous

engineering and our involvement in Parts

design from Project Inception can we

guarantee to consistently meet Toyota

requirements for components of the

highest standards a good example is the

washer capup for which much studies

happen and we could finally convince

Toyota to implement a standard fosa

component with approving

manufacturability and high level of

quality Toyota has also developed a

unique Supply development program this

is a key long-term process designed to

maximize the quality performance of the

company's principal Supply

Partners allore plant has recognized the

need to improve current practices and

challenge

every facet of established production

methods in order to set new industry

standards for component manufacturing

and the introduction of its unique

supplier development process has given

Mast an unprecedented opportunity to

learn adapt and develop fully embracing

this opportunity we created the concept

of usin Ideal model Factory at liur it

was 18 months ago working so closely

together with Toyota on site has been a

very beneficial process leading to a

fundamental cultural change within the

Liber cor plant and we are already

witnessing the mutual long-term

corporate benefits of Toyota's

development investment that is a real

success story the Toyota Europe

Association of Manufacturers team is

committed to achieving the highest

quality levels in the parts production

and Supply process team association was

set up in 1997 and today consists of 70

different suppliers of which 35 are

supplying Parts who assemble the new yis

the team association sets yearly

Improvement activity plans and targets

through the supplier executive committee

in partnership with the Tyra Executives

over the last four years an improvement

rate of over 91% in Supply quality was

achieved going down from 190 to just 17

part defects per million this will have

obvious benefits for the new smash

production quality the sharing of ideas

and constructive networking with open

dialogue must be unique in any industry

not just Automotive last year the theme

of the majority of suppliers application

of to to business practice was based on

projects relating to quality improvement

TI to acts really as a best practice

partner and we believe we have the

world's best methods for problem solving

quality control and production system

with the new Yaris we clearly show our

commitment to local supplier sources

this is the clear result of a supplier

selection strategy that seeks to

optimize quality technology and

Logistics from all 142 companies

supplying parts for the new Yaris I'm

convinced that Toyota and suppliers have

worked hard together to deliver the best

possible quality in this great car the

new Yaris

[Music]

You might also like

- Value Chain Analysis of ToyotaDocument9 pagesValue Chain Analysis of Toyotafazlin100% (1)

- FIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesFrom EverandFIRST 6.0: Flexographic Image Reproduction Specifications and TolerancesNo ratings yet

- Case Study InnovationDocument4 pagesCase Study InnovationAmira Messaoud100% (1)

- A CASE STUDY ToyotaDocument10 pagesA CASE STUDY ToyotaMd Alamgir Mollah0% (1)

- OM Presentation: Honda Vs ToyotaDocument40 pagesOM Presentation: Honda Vs ToyotaParandeep Chawla100% (3)

- Coefficient of Friction - PLASTIC On STEELDocument1 pageCoefficient of Friction - PLASTIC On STEELScooby DooNo ratings yet

- A Case Study of Toyota Marketing EssayDocument8 pagesA Case Study of Toyota Marketing EssayHND Assignment HelpNo ratings yet

- TOYOTA Indus Motor Co FinalDocument8 pagesTOYOTA Indus Motor Co FinalImran Memon0% (1)

- Strategic Management: International Strategy Case Study "Toyota"Document10 pagesStrategic Management: International Strategy Case Study "Toyota"Jagadeesh YathirajulaNo ratings yet

- Viscosity and Hardness ComparisonDocument2 pagesViscosity and Hardness ComparisonAshish GuptaNo ratings yet

- DOREEN Val Verde Unified School District-Approved+ContractorsDocument31 pagesDOREEN Val Verde Unified School District-Approved+ContractorsJP StorkNo ratings yet

- TOYOTA-V5 15217 Body Paint Sales GuideDocument48 pagesTOYOTA-V5 15217 Body Paint Sales GuidesedfrayNo ratings yet

- Toyota and Component SuppliersDocument17 pagesToyota and Component SuppliersWilliam WuNo ratings yet

- Am Assignment ToyotaDocument8 pagesAm Assignment ToyotaTahnee TsenNo ratings yet

- SUMMARIZEExpurma Supply ProcurementDocument6 pagesSUMMARIZEExpurma Supply ProcurementYuji KojimaNo ratings yet

- Toyota Business Practices and Academe - Industry Linkage - GasparDocument7 pagesToyota Business Practices and Academe - Industry Linkage - GasparEldori1988No ratings yet

- Assignment Toyota Case Study MsbeDocument2 pagesAssignment Toyota Case Study MsbeAmodh SehgalNo ratings yet

- Presentation: Appraising Quality Assurance Practices Observed by Toyota PakistanDocument25 pagesPresentation: Appraising Quality Assurance Practices Observed by Toyota PakistanwajidsattarchNo ratings yet

- TQM Toyota IndividualDocument14 pagesTQM Toyota IndividualWisam_Ali_3121100% (2)

- Tayota Company ProfileDocument8 pagesTayota Company ProfileRamana GNo ratings yet

- TQM in ToyotaDocument7 pagesTQM in ToyotaJaspreet SinghNo ratings yet

- SCM ToyotaDocument37 pagesSCM ToyotaDiksha Badoga0% (1)

- Toyota Essay CuegisDocument2 pagesToyota Essay CuegisKristen NallanNo ratings yet

- Toyota SCMDocument23 pagesToyota SCMSoujanya Nagaraja100% (1)

- How Toyota Creates Supplier RelationshipsDocument14 pagesHow Toyota Creates Supplier Relationshipsshshafei8367100% (2)

- Toyota ChallengesDocument19 pagesToyota ChallengesmizomizomezoNo ratings yet

- Worldwide Operations of ToyotaDocument42 pagesWorldwide Operations of Toyotaniom0250% (2)

- Group Members: Waseem RidhiDocument58 pagesGroup Members: Waseem RidhiFaiz AlbahrainNo ratings yet

- Presentation Pom Final EditedDocument27 pagesPresentation Pom Final EditedALI SHER HaidriNo ratings yet

- ENGGMGMT CASE (Group 10) - UNDERSTANDING MANAGEMENT'S CONTEXTDocument1 pageENGGMGMT CASE (Group 10) - UNDERSTANDING MANAGEMENT'S CONTEXTshop printNo ratings yet

- M1 BulauitanDocument4 pagesM1 BulauitanJoriz BulauitanNo ratings yet

- Supply Chain Management of Honda ToyotaDocument52 pagesSupply Chain Management of Honda ToyotaAayush SharmaNo ratings yet

- Toyota CRM FinalDocument40 pagesToyota CRM FinalShreyaNo ratings yet

- ToyotaDocument5 pagesToyotaSahil ChaudharyNo ratings yet

- BCG Toyota Supplier Relationships PDFDocument14 pagesBCG Toyota Supplier Relationships PDFsaket raj100% (1)

- Toyota Supply ChainDocument21 pagesToyota Supply ChainArmo LuangNo ratings yet

- Toyota CRM FinalDocument40 pagesToyota CRM FinalShreyaNo ratings yet

- TOYOTA (Guru)Document49 pagesTOYOTA (Guru)Gurudatt BakaleNo ratings yet

- Chapter 1. Introduction: 1.1. BackgroundDocument92 pagesChapter 1. Introduction: 1.1. BackgroundSanjay KmrNo ratings yet

- Change Factors and Drives Analysis:: Discussion Task: 1Document17 pagesChange Factors and Drives Analysis:: Discussion Task: 1Arsalan ChaudhryNo ratings yet

- Assigment TQM Version 4 ParapharasedDocument10 pagesAssigment TQM Version 4 ParapharasedSHINDE ANIKET MARUTI / UPMNo ratings yet

- Toyota Internship ReportDocument10 pagesToyota Internship Reportm usman100% (1)

- The History of ToyotaDocument46 pagesThe History of ToyotaFathima AmeerNo ratings yet

- Task 19.1.a Operations ManagementDocument7 pagesTask 19.1.a Operations ManagementManuAbrahamNo ratings yet

- TQM in ToyotaDocument6 pagesTQM in ToyotabhatiaharryjassiNo ratings yet

- Space MatrixDocument9 pagesSpace MatrixClaude PlaysNo ratings yet

- Toyota'S Case StudyDocument19 pagesToyota'S Case Studysuchi_mohan08No ratings yet

- Knowledge Management in Toyota MalaysiaDocument7 pagesKnowledge Management in Toyota MalaysiaAbdul Muhaimin100% (1)

- Lean Manufacturing in Toyota Motor CorporationDocument8 pagesLean Manufacturing in Toyota Motor CorporationArousha SultanNo ratings yet

- Production and OperationDocument14 pagesProduction and Operationarshitwork19No ratings yet

- TQM Implementation in ToyotaDocument15 pagesTQM Implementation in ToyotaSaikat GhoshNo ratings yet

- Toyota Organisational Dynamics CaseDocument16 pagesToyota Organisational Dynamics Casejacobmathew1706No ratings yet

- Honda Supply TeamDocument7 pagesHonda Supply TeamGermán MariacaNo ratings yet

- Case Study Denso-ToyotaDocument3 pagesCase Study Denso-ToyotaDiyanah Akop0% (1)

- Or Project On ToyotaDocument62 pagesOr Project On ToyotaHimanshu GuptaNo ratings yet

- Process Improvement Project: ToyotaDocument15 pagesProcess Improvement Project: ToyotaMuhammad Sajid Saeed100% (5)

- Toyota Process Flow Analysis: ToyotaprocessflowanalysisDocument5 pagesToyota Process Flow Analysis: ToyotaprocessflowanalysisRoel DavidNo ratings yet

- Value Chain Analysis of Toyota Co.Document6 pagesValue Chain Analysis of Toyota Co.ehsan7686% (14)

- Operation Management ToyotaDocument16 pagesOperation Management Toyotahusain albaqali100% (1)

- Presentation On Automobile Industry: by Shailesh PatelDocument28 pagesPresentation On Automobile Industry: by Shailesh PatelParthiban DhakshnamurthyNo ratings yet

- Efficient Music Production: How To Make Better Music, FasterFrom EverandEfficient Music Production: How To Make Better Music, FasterRating: 5 out of 5 stars5/5 (1)

- Application of Lean in Non-manufacturing Environments - Series Books 18 to 19: Toyota Production System ConceptsFrom EverandApplication of Lean in Non-manufacturing Environments - Series Books 18 to 19: Toyota Production System ConceptsNo ratings yet

- SuzukiDocument1 pageSuzukiHải myNo ratings yet

- Calculus For Economics2021Document227 pagesCalculus For Economics2021Hải myNo ratings yet

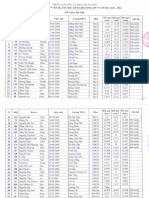

- Ket Qua Doi Tuyen TinhDocument9 pagesKet Qua Doi Tuyen TinhHải myNo ratings yet

- Chap003 National Environment+5-11 SocioCulture+Eco+Natural+pl+legalDocument111 pagesChap003 National Environment+5-11 SocioCulture+Eco+Natural+pl+legalHải myNo ratings yet

- NGHIÊN CỨU VĂN HÓA-SV- CÂU HỎI ÔN TẬP-ĐỢT 2-2023-SVDocument20 pagesNGHIÊN CỨU VĂN HÓA-SV- CÂU HỎI ÔN TẬP-ĐỢT 2-2023-SVHải myNo ratings yet

- Chap002 Inter environment+Trade+FDI+institutionDocument107 pagesChap002 Inter environment+Trade+FDI+institutionHải myNo ratings yet

- Personal Finance Course. Mock Exam 2021.2022.without AnswerDocument16 pagesPersonal Finance Course. Mock Exam 2021.2022.without AnswerHải myNo ratings yet

- Project Intern Cover Letter - Nguyen An QuynhDocument2 pagesProject Intern Cover Letter - Nguyen An QuynhHải myNo ratings yet

- ReviewDocument17 pagesReviewHải myNo ratings yet

- Chap006 Inter Management+15-20+ Mark+ SCM+HRM+FInManDocument62 pagesChap006 Inter Management+15-20+ Mark+ SCM+HRM+FInManHải myNo ratings yet

- Overview of US Insurance 3-30-23Document26 pagesOverview of US Insurance 3-30-23Hải myNo ratings yet

- Chap005 Analysis+Access 14+15Document26 pagesChap005 Analysis+Access 14+15Hải myNo ratings yet

- Hắc Hường - Written Summary (AutoRecovered)Document10 pagesHắc Hường - Written Summary (AutoRecovered)Hải myNo ratings yet

- Online RiskyDocument1 pageOnline RiskyHải myNo ratings yet

- Law ôn tậpDocument67 pagesLaw ôn tậpHải myNo ratings yet

- Generate Longterm Cash FlowDocument1 pageGenerate Longterm Cash FlowHải myNo ratings yet

- Chap004 InterStrategy+struc 12+13Document31 pagesChap004 InterStrategy+struc 12+13Hải myNo ratings yet

- Giao tiếp kinh doanhDocument1 pageGiao tiếp kinh doanhHải myNo ratings yet

- The Relationship Between Social Media Use and Fear of Missing Out - A Meta-AnalysisDocument16 pagesThe Relationship Between Social Media Use and Fear of Missing Out - A Meta-AnalysisHải myNo ratings yet

- AccountingDocument2 pagesAccountingHải myNo ratings yet

- Collection of Publications From The NaturalHy ProjectDocument84 pagesCollection of Publications From The NaturalHy Projectleih09240No ratings yet

- Fabricf37 PDFDocument8 pagesFabricf37 PDFGerardo HernándezNo ratings yet

- Propulsion and Power Formula SheetDocument4 pagesPropulsion and Power Formula SheetArun VinthanNo ratings yet

- Manual Proheat II Indoor Eng Jun18-95023Document41 pagesManual Proheat II Indoor Eng Jun18-95023Moch SolichinNo ratings yet

- Steam Ejector TroubleshootingDocument6 pagesSteam Ejector Troubleshootingponnusj100% (2)

- Piping FBE Spool MethodologyDocument28 pagesPiping FBE Spool MethodologyHariharan MNo ratings yet

- 1296 MHZ TransverterDocument8 pages1296 MHZ TransverterNestor Alberto EscalaNo ratings yet

- Woodworking - Basics-Shopjigs PDFDocument4 pagesWoodworking - Basics-Shopjigs PDFv00d00blues100% (1)

- Pre Fabricated House ModelsDocument72 pagesPre Fabricated House ModelsjayakumargarudaNo ratings yet

- Optimizing Costs in Zero Liquid Discharge' Textile Unit - A Case Study by FICCIDocument9 pagesOptimizing Costs in Zero Liquid Discharge' Textile Unit - A Case Study by FICCIDiksha SinghNo ratings yet

- Small Waste Water Treatment Plant ReportDocument57 pagesSmall Waste Water Treatment Plant Reportraviswm180100% (2)

- 081 Areca Plate Making Machine Barath 1582957225367 PDFDocument2 pages081 Areca Plate Making Machine Barath 1582957225367 PDFBharath Naik ANo ratings yet

- En 42Document2 pagesEn 42Meghan GhoneNo ratings yet

- Chapter II.Document18 pagesChapter II.Paulo GalleraNo ratings yet

- Viking Oil PumpsDocument9 pagesViking Oil Pumpssteve@air-innovations.co.zaNo ratings yet

- Experiment 5 Aim::-Diagnosis of Ignition System Faults Apparatus RequiredDocument5 pagesExperiment 5 Aim::-Diagnosis of Ignition System Faults Apparatus Requiredbansalmohit01No ratings yet

- Westinghouse Ds 416 PDFDocument28 pagesWestinghouse Ds 416 PDFLuiz_F_A_ViannaNo ratings yet

- Non-Newtonian Fluid PDFDocument6 pagesNon-Newtonian Fluid PDFJaime BallesterosNo ratings yet

- Highway Failure & Their Maintenance: Government Polytechnic, KoraputDocument12 pagesHighway Failure & Their Maintenance: Government Polytechnic, KoraputAniket zNo ratings yet

- C101 Electrolytic Tough Pitch CopperDocument2 pagesC101 Electrolytic Tough Pitch CopperMADDI MADHAV.No ratings yet

- Ripples, v9.0: SMT PartsDocument6 pagesRipples, v9.0: SMT PartsrubixkubeNo ratings yet

- English Instructions 1Document2 pagesEnglish Instructions 1api-397845913No ratings yet

- 58 F 1 Dec 0965 BDocument2 pages58 F 1 Dec 0965 BrizalbasoNo ratings yet

- Water Cooled Cable For Electric FurnaceDocument4 pagesWater Cooled Cable For Electric FurnaceWAWANNo ratings yet

- Taufik Paraphrasing TaskDocument4 pagesTaufik Paraphrasing TaskIr Fik TNo ratings yet

- Upvc Window & Door SystemDocument20 pagesUpvc Window & Door SystemJohn AssadNo ratings yet

- MIR Log - ElectricalDocument5 pagesMIR Log - ElectricalAnonymous yniiLtiNo ratings yet