Professional Documents

Culture Documents

1structrul Erection Method Statement

Uploaded by

shahhussain1031Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1structrul Erection Method Statement

Uploaded by

shahhussain1031Copyright:

Available Formats

LAFARGE JOJOBERA GU EXPANSION PROJECT

METHOD STATEMENT

Method Statement for (Description & location):

TT5 STRUCTURAL ERECTION

1 Document details and control:

Approved

Rev Date Prepared by Designation Signature Signature

by

0 15/12/2011 SHEKHAR ENGINEER

1

2 Individual/s in charge & responsible for supervising the Activity

and the Safety of the activity(Whether line manager /safety

personnel)(Contractor / LIPL)

Occupation /

SN Name Surname Signature Company

Designation

1 SHEKHAR MUKHERJEE ENGINEER L&T

2

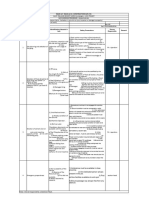

3A. Detailed step-by-step sequence of activities and tasks involved in

performing the task:(Work procedure for crane lifting)

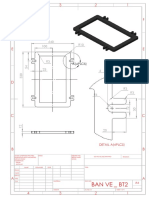

1) Assembly member or individual member will shift from yard to erection

location by hydra or crane.

2) Ensure proper welding before shifting the assembly member.

3) 200T crane will place as per lifting plan.

4) Member/assembly member will lift as per approved load chart.

5) In erection time presence of Rigging person must required.

6) Ensure proper lifeline before erection.

7) Workmen will use rectractable fall arrestor by using web sling for anchorage

point.

8) Member/assembly member will place and make proper alignment and do

the necessary welding.

9) Guy rope will fix if required.Do not realise the guy rope before tie beam

fixing.

10) Provide barrication before erection and ensure nobody will enter the

barrication while erection.

11) Ensure proper supervision.

12) Place the fire extinguisher near the working place.

13) Workmen will reach the working place by using permanent stair of existing

MFH,DOCA tower and 442BC 32 walkway or TT5 column step ladder.

Drafted by ManieTaljaard Page 1

3B. Detailed step-by-step sequence of activities and tasks involved in

performing the task:(Work procedure for Manually lifting)

14) Assembly member or individual member will shift from yard to erection

location by hydra or crane.

15) Ensure proper welding before shifting the assembly member.

16) Chain Pulley (3T,2Tand 1T) will place for lifting.

17) Rope pulley with 25mm dia PPE will place for small member lifting (ie below

200kg).

18) Ensure proper anchorage for lifting tools.

19) Member/assembly member will lift by lifting tools.

20) In erection time presence of Rigging person must required.

21) Ensure proper lifeline before erection.

22) Workmen will use rectractable fall arrestor by using web sling for anchorage

point.

23) Member/assembly member will place and make proper alignment and do

the necessary welding.

24) Provide barrication before erection and ensure nobody will enter the

barrication while erection.

25) Ensure proper supervision.

26) Place the fire extinguisher near the working place.

27) Workmen will reach the working place by using permanent stair of existing

MFH,DOCA tower and 442BC 32 walkway or TT5 column step ladder.

WAH:

1. Sup. Must inform the responsible in charge of the area before to

start any

Job.

2. Sup. Must have been training to analyse all any risk and must be

sure

that

Any job could be done as safely as possible in a location before to

start it.

(Ex: to avoid to work above each other).

3. Sup. Must inform the team about any risks in the location where they

have To work.

Drafted by ManieTaljaard Page 2

4. Sup. Must check that all workers use WAH PPE according the

standards

LAFARGE rules.

5. Sup. Must check any WAH PPE equipments before to use it and fill

out aSafety harnesses registers.

6. Sup.must install the PPE safely for the workers.Retractable fall

arresters must be installed above each work platform. -1 Retractable fall

arresters =1 man

7. Man basket and cherry picker must be use at first measure when it

is Impossible to install any WAH PPE safely.

8. All the workers must have completed and succeed in the

WAHcourse Training.

9. All the workers must follow the Lafarge safety rules at site.

4. Potential hazards and risks associated with the work activities and

control measures – to be detailed in the Risk Assessment form:

5. In the event of a sudden change in original scope of work/activity –

re-submit a new method statement and Risk Assessment for the

activity:

5- Relevant Legislation; i.e. Construction Regulations, etc:

FACTORY ACT 1948.

BOCW 1996.

LIPL G2.

5- Names && Qualifications of personnel who may inspect and

approve work area, conditions, methods, protective measures

and equipments to be used: (who is authorised to approve

other than scaffold and rigging operation).

Occupation /

SN Name Surname Qualification

Designation

1 SHEKHAR MUKHERJEE Engineer BE

8. Training requirements for personnel involved in this activity,

including specialised training for specific tasks to be added:

Required

SN Type of Training

YES NO

1 JOB CLEARENCE

2 Work at Height

3 Hot work (cutting & welding)

4 MATARIAL HANDLING

Drafted by ManieTaljaard Page 3

9. List of workmen who will be performing activity and are trained

or to be trained for the task:

Trained

SN Name Surname Occupation Signature

YES NO

1

2

3

4

5

6

10. Details of permits required for the task; i.e. WAH, etc:

1. JOB CLEARENCE PERMIT.

2. HOT WORK PERMIT

3. HEIGHT WORK PERMIT

4. LIFTING WORK PERMIT.

5. FHRA

11. Identify all resources required to perform the task and

inspections required:

Required Inspection Frequency

SN Equipment type

YES NO Daily Weekly Monthly Quarterly

1 SLING

2 D- SHACKLE

3 CUTTING TORCH

4 WELDING MACHINE

5. Chain Pulley

6 Rope Pulley and PPE Rope

12. Identify all Personal Protective Equipment required to perform

the task:

Drafted by ManieTaljaard Page 4

Required

SN Equipment type

YES NO

1 Safety Helmet

2 Gloves

3 Safety goggles

4 Reflective jacket

5 Welding shield

6 Cutting torch goggles

7 Confined Space testing

8 DUST NOSE MASK

13. Document sign off and approval by Contractor Management and

Lafarge:

Approved

Name & Surname Designation Date Signature

YES NO

Contractor Safety

S. K. PATRA Contractor Site manager

LIPL First Line Engineer

LIPL Safety

H.K. SAHA LIPL Manager

WAH Expert

C.N.K.PRASAD HOD MECHANICAL

Drafted by ManieTaljaard Page 5

You might also like

- Job Safety Analysis: Abqaiq Plants OperationDocument5 pagesJob Safety Analysis: Abqaiq Plants OperationZia ur RehmanNo ratings yet

- Plant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerDocument6 pagesPlant: Work Location: Date:: Saudi Aramco PMT Saudi Aramco Project EngineerJoypee MacasamponNo ratings yet

- Hydro TestDocument8 pagesHydro Testmozzammil saqibNo ratings yet

- JSA - For Trays ErectionDocument1 pageJSA - For Trays ErectionAvinash RaiNo ratings yet

- Job Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety PersonnelDocument2 pagesJob Safety Analysis Pre-Task Briefing: Reviewed / Approved By: Safety Personnelmahammed saleemNo ratings yet

- Installation of Pannel JSADocument6 pagesInstallation of Pannel JSAOFFSHORE OFFSITENo ratings yet

- Welding and Gas CuttingDocument2 pagesWelding and Gas CuttingKrishna Patil100% (2)

- Work at HeightDocument36 pagesWork at HeightSantosh KolhatkarNo ratings yet

- Lock-Out / Tag-Out (L.O.T.O.) Permit To Work: Form No: P224-7 Rev0 Page 1 of 2Document2 pagesLock-Out / Tag-Out (L.O.T.O.) Permit To Work: Form No: P224-7 Rev0 Page 1 of 2Ionian TribeNo ratings yet

- 5.JSA of Batching Plant InstallationDocument4 pages5.JSA of Batching Plant InstallationNitesh kumar yadavNo ratings yet

- Concrete Floor Breaking MSDocument6 pagesConcrete Floor Breaking MSBilalNo ratings yet

- Beam Splice Connection With End Plate CalculationDocument76 pagesBeam Splice Connection With End Plate CalculationFajar Alam HudiNo ratings yet

- JSA Pipe Installation 2012Document2 pagesJSA Pipe Installation 2012Deshbandhu Aman Pandey100% (2)

- Manual: Original InstructionsDocument118 pagesManual: Original InstructionsMelanie GerdesNo ratings yet

- Method Statement: QC InspectorDocument7 pagesMethod Statement: QC InspectorCobbinah MarkNo ratings yet

- Construction Project Schedule Template G1 Residential BuildingDocument85 pagesConstruction Project Schedule Template G1 Residential BuildingMansi PatilNo ratings yet

- Swms Pile Test RKDocument13 pagesSwms Pile Test RKrakeshkhanna78No ratings yet

- Work Permit Format - Jul 2014Document2 pagesWork Permit Format - Jul 2014NilamSanjeev Kumar SinghNo ratings yet

- Belt Conveyor Bearing InspectionDocument3 pagesBelt Conveyor Bearing InspectionKarthikeyan MNo ratings yet

- Loto Procedure: Construction of Coal Berth, Civil Works & Stock Yard Development at ParadipDocument12 pagesLoto Procedure: Construction of Coal Berth, Civil Works & Stock Yard Development at ParadipTarun KakkarNo ratings yet

- Falih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NODocument9 pagesFalih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NOSreejith SureshNo ratings yet

- Small Unit Leaders Operational Planning GuideFrom EverandSmall Unit Leaders Operational Planning GuideRating: 5 out of 5 stars5/5 (1)

- Method Statement For Scaffolding ActivitiesDocument8 pagesMethod Statement For Scaffolding ActivitiesMohsen KeramatiNo ratings yet

- Ntw-U Spring Latch Core BarrelDocument1 pageNtw-U Spring Latch Core BarrelRossin Hernan Zamora GarciaNo ratings yet

- John Deere 924 Flex Cutterbar Platform With Pickup Reel Parts CatalogDocument20 pagesJohn Deere 924 Flex Cutterbar Platform With Pickup Reel Parts Catalogjohnny100% (29)

- Operation Manual For The RX 29 ShakerDocument19 pagesOperation Manual For The RX 29 ShakerCarlos Esaú López GómezNo ratings yet

- PC400LC-8 Shop ManualDocument995 pagesPC400LC-8 Shop ManualNike ColeNo ratings yet

- MOS For Hot Tapping Work PDFDocument20 pagesMOS For Hot Tapping Work PDFAho Chi- ShuenNo ratings yet

- Gallery Shifting Method StatementDocument7 pagesGallery Shifting Method Statementshahhussain1031No ratings yet

- Name &signature: Shakil: Nature PF WPRK - Destimatiom Ascavabteof Issued Agency B2Um Lnaia PuDocument3 pagesName &signature: Shakil: Nature PF WPRK - Destimatiom Ascavabteof Issued Agency B2Um Lnaia PuArnab PatraNo ratings yet

- MOS of Shear Stud InstallationDocument3 pagesMOS of Shear Stud InstallationViisshnu SilvarajooNo ratings yet

- SOP-12-Installation and Disconnection of Live Head of Drilliing LineDocument6 pagesSOP-12-Installation and Disconnection of Live Head of Drilliing LineDQE040 HSSENo ratings yet

- WHR AQC-2 DS (7-10) Column Lift PlanDocument5 pagesWHR AQC-2 DS (7-10) Column Lift Planshahhussain1031No ratings yet

- JSA-Fabrication, AssemblyDocument19 pagesJSA-Fabrication, AssemblyAshfaq Husain AnsariNo ratings yet

- 1 JSA Pemasangan DuctingDocument4 pages1 JSA Pemasangan Ductingfitri widya100% (1)

- AB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main DeckDocument2 pagesAB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main Deckvikrant911No ratings yet

- PL in DNODocument3 pagesPL in DNOAbdullah DhiaNo ratings yet

- DQE SOP-183-Upper Substructure DisassemblyDocument8 pagesDQE SOP-183-Upper Substructure DisassemblyDQE040 HSSENo ratings yet

- Welding, Grinding, Oxy-Cutting JSA-007 PDFDocument6 pagesWelding, Grinding, Oxy-Cutting JSA-007 PDFNazmi DhiyauddinNo ratings yet

- MS For Fixing Loose and Detached PipeDocument5 pagesMS For Fixing Loose and Detached PipeSujan AugustinNo ratings yet

- SOP-16-Load and Offload SledgeDocument6 pagesSOP-16-Load and Offload SledgeDQE040 HSSENo ratings yet

- Working at Stabbing Board During CasingDocument2 pagesWorking at Stabbing Board During CasingkhurramNo ratings yet

- SOP-15-Installation and Disassembly of BOP Hydraulic Control LineDocument6 pagesSOP-15-Installation and Disassembly of BOP Hydraulic Control LineDQE040 HSSENo ratings yet

- General Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedDocument2 pagesGeneral Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedIonian TribeNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- RKIPL-WMS 01 Fire Rated Partition WorkDocument13 pagesRKIPL-WMS 01 Fire Rated Partition Workvivekwagh09No ratings yet

- Excavation Permit and ChecklistDocument3 pagesExcavation Permit and Checklistjeffry EscletoNo ratings yet

- Cgk063-Rfa-Mos-M-Xxx - Unloading DahuDocument23 pagesCgk063-Rfa-Mos-M-Xxx - Unloading Dahudiki anggriawanNo ratings yet

- Lifting Permit: Form No: P224-6 Rev0 Page 1 of 2Document2 pagesLifting Permit: Form No: P224-6 Rev0 Page 1 of 2Ionian TribeNo ratings yet

- PGAT2-MOS-CSA-001 - MOS of Moisture Board Installation at AHU RoomDocument3 pagesPGAT2-MOS-CSA-001 - MOS of Moisture Board Installation at AHU RoomViisshnu SilvarajooNo ratings yet

- Method of Work - Pressure Test - Rev. 01Document10 pagesMethod of Work - Pressure Test - Rev. 01Rizki FadillahNo ratings yet

- MS FSK Demolition 071119Document2 pagesMS FSK Demolition 071119DilxazNo ratings yet

- Mercure Hotel Barsha Heights - MOS - v1.0Document5 pagesMercure Hotel Barsha Heights - MOS - v1.04jan1980No ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- New Sop DemolitionDocument8 pagesNew Sop Demolitionabhishek narayan singhNo ratings yet

- Welder SMAW MAG MIG SAWDocument88 pagesWelder SMAW MAG MIG SAWjayson acunaNo ratings yet

- SWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Document8 pagesSWMS FOR INSTALLATION OF 5x500 KVA GENERATORS AND TOTALIZING PANEL 25.01.23Md Shahbaz AlamNo ratings yet

- China Harbour Engineering Company LFTZ Enterprise. Excavation PermitDocument2 pagesChina Harbour Engineering Company LFTZ Enterprise. Excavation PermitWealth EwomazinoNo ratings yet

- SOP For Maintenance & Testing of 6.6KV BET-CETDocument2 pagesSOP For Maintenance & Testing of 6.6KV BET-CETArbind NathNo ratings yet

- Job Safety Analysis Worksheet: Tie - in For Power Cable 33 KVDocument3 pagesJob Safety Analysis Worksheet: Tie - in For Power Cable 33 KVmohammed a hseNo ratings yet

- Permit-to-Work - Night WorkDocument1 pagePermit-to-Work - Night Worksrinu degalaNo ratings yet

- Working Overside Permit Prepare Pilot LadderDocument1 pageWorking Overside Permit Prepare Pilot LadderPratap Singh Rathore KinsariyaNo ratings yet

- JMS-STS-PIP - JMS Latest FormatDocument2 pagesJMS-STS-PIP - JMS Latest Formatmohd as shahiddin jafriNo ratings yet

- F 2.14 A 4 Ergonomic Study For OHTL Work at HeightsDocument2 pagesF 2.14 A 4 Ergonomic Study For OHTL Work at HeightsSn AhsanNo ratings yet

- SOP-13-Loading and Offloading Casings With CraneDocument7 pagesSOP-13-Loading and Offloading Casings With CraneDQE040 HSSENo ratings yet

- R 02 Fitouts General Work PermitDocument1 pageR 02 Fitouts General Work PermitPRIYESH . K. PRIYANNo ratings yet

- PGAT2 MOS CSA 001 - MOS of Plastering WorkDocument4 pagesPGAT2 MOS CSA 001 - MOS of Plastering WorkViisshnu SilvarajooNo ratings yet

- Work Method Statment For Lifting With Winch MachineDocument9 pagesWork Method Statment For Lifting With Winch Machineshahhussain1031No ratings yet

- Hira For Appron Fidder ErectionDocument5 pagesHira For Appron Fidder Erectionshahhussain1031No ratings yet

- Errection HIRA For RelianceDocument2 pagesErrection HIRA For Relianceshahhussain1031No ratings yet

- Hira For CyclonDocument6 pagesHira For Cyclonshahhussain1031No ratings yet

- Man Basket JsaDocument2 pagesMan Basket Jsashahhussain1031No ratings yet

- Hira For Esp Outlet PannalDocument5 pagesHira For Esp Outlet Pannalshahhussain1031100% (1)

- Hira For Cement MillDocument6 pagesHira For Cement Millshahhussain1031No ratings yet

- HIRA of Tower CraneDocument3 pagesHIRA of Tower Craneshahhussain1031No ratings yet

- Hydra - Dos & Dont'sDocument5 pagesHydra - Dos & Dont'sshahhussain1031No ratings yet

- Bag House ChimmenyDocument2 pagesBag House Chimmenyshahhussain1031No ratings yet

- Hira FabricationDocument5 pagesHira Fabricationshahhussain1031No ratings yet

- Liftting Plan - With Winch MachineDocument3 pagesLiftting Plan - With Winch Machineshahhussain1031No ratings yet

- MS Erection of Blending Silo Roof GirderDocument6 pagesMS Erection of Blending Silo Roof Girdershahhussain1031No ratings yet

- Manual Abric PDFDocument32 pagesManual Abric PDFMihai ButuNo ratings yet

- Settingout Highwaycurve 1Document31 pagesSettingout Highwaycurve 1Ge NghisNo ratings yet

- Catalogue-Daemo Eng PDFDocument3 pagesCatalogue-Daemo Eng PDFMahendra Tyre Works RaigarhNo ratings yet

- Steeel Fourpoint Beding PDFDocument15 pagesSteeel Fourpoint Beding PDFVishnuNo ratings yet

- Chapter-3 PTD NewDocument34 pagesChapter-3 PTD NewGODNo ratings yet

- Technical Instructions 1: Supplies ToolsDocument8 pagesTechnical Instructions 1: Supplies ToolsservicerNo ratings yet

- Commissioning Checks of Gear ToothingDocument4 pagesCommissioning Checks of Gear Toothinghumayun121No ratings yet

- Bucket ElevatorDocument18 pagesBucket Elevatorlhmamda ismailNo ratings yet

- Other Buildings - Major Pending Work Orders To Be SubcontractedDocument10 pagesOther Buildings - Major Pending Work Orders To Be SubcontractedHmNo ratings yet

- (Note) : Parts GuideDocument16 pages(Note) : Parts GuideJeewana GooneratneNo ratings yet

- Radial Drilling Machine Definition Diagram Parts Working Advantages Disadvantages and Applications PDDocument5 pagesRadial Drilling Machine Definition Diagram Parts Working Advantages Disadvantages and Applications PDPrince JohnnyNo ratings yet

- 03 ShaperDocument5 pages03 ShaperHridoyNo ratings yet

- 180 07 018 04 Sdba-A1f-Er1-11Document15 pages180 07 018 04 Sdba-A1f-Er1-11TuấnNo ratings yet

- Pretest, RC Part 2 PDFDocument1 pagePretest, RC Part 2 PDFleanne DespaNo ratings yet

- Resume Zeeshan DalviDocument2 pagesResume Zeeshan DalviSyed AbuthahirNo ratings yet

- Bai Tap 2Document1 pageBai Tap 2Tuan ASNo ratings yet

- Prevent An - Insert Drum Cartridge - MessageDocument7 pagesPrevent An - Insert Drum Cartridge - Messageereslomaximo2014No ratings yet

- RSLF Mto Mechanical PDFDocument4 pagesRSLF Mto Mechanical PDFDusngi MoNo ratings yet

- LG - GC 151 ManualDocument13 pagesLG - GC 151 ManualadijayptNo ratings yet

- Timing Belt ReplacementDocument16 pagesTiming Belt ReplacementCarlos Medina CastilloNo ratings yet

- KBS Section 6 Brick WorkDocument22 pagesKBS Section 6 Brick WorkAmarendra KeerthiNo ratings yet

- Axial Load On Column CalculationDocument4 pagesAxial Load On Column CalculationMohdDanishNo ratings yet