Professional Documents

Culture Documents

Hira Fabrication

Uploaded by

shahhussain1031Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hira Fabrication

Uploaded by

shahhussain1031Copyright:

Available Formats

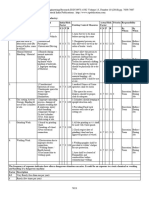

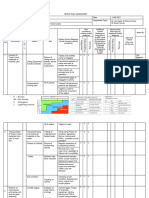

HAZARD IDENTIFICATION AND RISK ASSESSMENT – DEVELOPMENT OF RISK CONTROL

MEASURES

S. ACTIVITY HAZARD CONSEQUENCE PROBABILITY SEVIRITY RISKLEVEL RISK CONTROL MEASURES

No. FACTOR FACTOR RATING

ACTIVITY - 65: FABRICATION YARD OPERATIONS

1 Fabrication of

plate Rolling

work.

1 Grinding and 1. Absence of tool rest on 1. Eye / face injury 3 4 MODERATE 3 1. Use proper PPE. ( Face shield )

grinding wheel bench grinder.

replacing. 2. Hand injury 2. Mount the tool rest on both sides.

2. More gap between the wheel

and tool rest of bench grinder. 3. Gap more than 3mm is unsafe.

3. Improper/wrong size grinding 4. Use grinding wheel of correct size.

wheel.

5. Training & instruction.

4. Excess pressure on wheel.

6. Provide fire extinguisher.

5. Breakage of wheel.

7. Proper tightening of wheel.

2 Working with 1. Damaged cable . 1. Electric shock. 3 4 MODERATE 3 1. Daily check up before start.

portable electric

tools 2. Defective tool. 2. Spark/shock. 2. Replace defective tools.

3. Loose components (wheel, 3. Physical injury. 3. Proper maintenance.

switch)

4. Training on proper use & care.

4. Excess pressure on tool.

5. Inspection and corrective action to follow correct

5. Improper handling. handling procedures.

3 Gas welding / 1. Backfiring. 1. Fatality / burn injury, fire / 2 5 HIGH 4 1. Work only after wearing PPE.

cutting / heating. explosion.

2. Splashing splinters. 2. Fit flash back arrestor and NRV on both cylinder

2. Gas leakage due to fall of cylinder outlets.

3. Gas leakage. and damage of valves.

3. Use face shield and fire proof gloves.

4. Wrong positioning of

cylinders. 4. Daily check up before start of work.

5. Presence of flammable 5. Keep cylinders in trolleys or chain to some firm

gases. structure to prevent fall.

6. Gas testing before start of work.

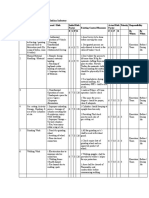

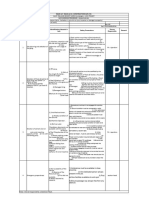

HAZARD IDENTIFICATION AND RISK ASSESSMENT – DEVELOPMENT OF RISK CONTROL

MEASURES

S. ACTIVITY HAZARD CONSEQUENCE PROBABILITY SEVIRITY RISK LEVEL RISK CONTROL MEASURES

No. FACTOR FACTOR RATING

4 Arc welding 1. Radiation harmful to naked 1. Welder's cataract. 2 5 HIGH 4 1.Use welding shield / goggles.

eyes.

2. Burn injury. 2. Fireproof apron / gloves / screen.

2. Splinters / slag.

3.Toxic flames. 3. Lung ailments 3. Ventilation (local or exhaust if possible)

4. Loose connections / Loss of 4. Electric shock. 4. Full-sleeved coverall and gloves.

insulation.

5. Fire / explosion. 5. Proper clamping system / material handling

5. Flammable gases. techniques.

6. Asphyxiation.

6. Poor ventilation 6. Use shock proof boots and hand gloves.

7. Provide earthing to the plant.

5 Material handling 1. Lack of co-ordination in 1. Back pain,sprain,etc. 3 4 MODERATE 3 1. Training & instructions.

(manual) group effort.

2. Body Injury 2. Use hand gloves/ packing materials.

2. Wrong body posture.

3. Remove protruding nails before handling.

3. Lifting error.

4. Use proper lifting devices for good grip.

4. Sharp

5. Fasten the item properly or use suitable packing /

edges/corners/projecting container.

parts/protruding nails.

6 Material handling 1. Lack of knowledge / skills. 1. Body injury. 2 4 MODERATE 3 1. Only trained and approved operator shall be

with forklift / crane deployed for equipment operations.

etc. 2. Defective equipment. 2. Material losses.

2. Equipment to be tested and certified by competent

3. Defective lifting jacks. 3. Tilting of jacks / boom. person before deployment.

4. Overloading. 3. No overloading allowed.

4. Follow procedures.

HAZARD IDENTIFICATION AND RISK ASSESSMENT – DEVELOPMENT OF RISK CONTROL

MEASURES

S. ACTIVITY HAZARD CONSEQUENCE PROBABILITY SEVIRITY RISK LEVEL RISK CONTROL MEASURES

No. FACTOR FACTOR RATING

7 Transporting gas 1. Falling of cylinders 2. Gas leakage due to valve damage. 2 5 HIGH 4 1. Keep charged cylinder only.

cylinders:

2. Explosion 3. Human injury by fall of cylinder. 2. Keep vertically and tie with chain to a fixed

* Oxygen structure.

4. Fire / body injury due to explosion

* Acetylene. 3. Keep in specially fabricated cage to prevent fall.

* Argon. 4. Keep valve cap in position during transportation.

* Nitrogen. 5. Different types of gas cylinders not to be loaded in

the same vehicle at a time.

* LPG.

6. Only authorized vehicle and specially trained driver

shall be engaged in gas cylinder transportation.

7. Do not use leaking cylinder.

8. Keep cylinder tied up/chained & locked

independently on truck to prevent falling of one

cylinder while loading/unloading the other.

8 Laying out 1. Unstable Cable drum. 1. Body injury due to fall of cable 3 4 MODERATE 3 1. Cable shall be handled by experienced persons.

electrical cables drum or jack.

(Cable drum 2. Wrong position of jack. 2. Adopt proper procedure.

handling) 2. Injury by hitting / caught in.

3. Inadequate jack / spindle. 3. Use only tested and certified jack and spindle.

3. Finger injury due to trapping

4. Rotating parts. between drum / rollers. 4. Keep fingers away from nip points.

5. Drum rollers. 5. Use hand gloves.

6. Pulling in wrong posture. 6. Use cable roller.

7. Open trench. 7. Keep cable-laid trenches backfilled before leaving

site.

You might also like

- 2.preheater Building HiraDocument2 pages2.preheater Building HirasgcworkjpflNo ratings yet

- Construction Work JsaDocument21 pagesConstruction Work Jsaitsumar632No ratings yet

- JSA Rebar Cutting & BendingDocument2 pagesJSA Rebar Cutting & BendingGunjan Sinha AdityaNo ratings yet

- JSA Torque WrenchDocument2 pagesJSA Torque Wrenchanon_281257101100% (1)

- Job Safety Analysis: Description of Job: Torque Wrench OperationDocument2 pagesJob Safety Analysis: Description of Job: Torque Wrench OperationPrakash PalaiNo ratings yet

- JHA For Shuttring and DeshuttringDocument2 pagesJHA For Shuttring and DeshuttringTigor GurningNo ratings yet

- JSA - Erection Boiler Install (SFILEDocument35 pagesJSA - Erection Boiler Install (SFILEHilman NugrahaNo ratings yet

- Hira SMSDocument51 pagesHira SMSAbrar ArijitNo ratings yet

- 4 JSA For Structural Fabrication and Erection WorkDocument4 pages4 JSA For Structural Fabrication and Erection WorkHappy Prajapat67% (3)

- Ijaerv13n10 56-15Document1 pageIjaerv13n10 56-15nazasraf2012No ratings yet

- Boiler JSADocument42 pagesBoiler JSApankajbhatt376No ratings yet

- Arch WeldingDocument16 pagesArch WeldingDarren OscarNo ratings yet

- cONSTRUCTION WORK JSADocument21 pagescONSTRUCTION WORK JSAMohammed AlshehhiNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- JSA For New Wear House Excavation Barrication Activitys GKR ConstructionDocument3 pagesJSA For New Wear House Excavation Barrication Activitys GKR ConstructionKoneti JanardhanaraoNo ratings yet

- Instructions Hydraulic Table PressDocument26 pagesInstructions Hydraulic Table PressHanna HorváthNo ratings yet

- Risk Assessment in Maintenance Work at Diesel Locomotive WorkshopDocument5 pagesRisk Assessment in Maintenance Work at Diesel Locomotive WorkshopanasNo ratings yet

- Guillotine Blade Change: Take Exceptional Care When Handling The Blade. If You Are Unsure Stop & AskDocument2 pagesGuillotine Blade Change: Take Exceptional Care When Handling The Blade. If You Are Unsure Stop & AskRiddhi SarvaiyaNo ratings yet

- Novibra SpindlesDocument12 pagesNovibra SpindlesAbirami SpinnersNo ratings yet

- Tuaman Engineering Limited: Job Safety Analysis (Jsa)Document6 pagesTuaman Engineering Limited: Job Safety Analysis (Jsa)abhijit janaNo ratings yet

- Risk Assessment Sheet - in An Indian IndustryDocument2 pagesRisk Assessment Sheet - in An Indian IndustryAswini AcharyaNo ratings yet

- HIRA Single FormatDocument6 pagesHIRA Single FormatGuptaNo ratings yet

- Tire Changer OSDocument1 pageTire Changer OSZombieNo ratings yet

- Job Hazard Analysis: Amichand Technological Pvt. LTDDocument6 pagesJob Hazard Analysis: Amichand Technological Pvt. LTDSandeep KumarNo ratings yet

- HIRA of Gas Cutting Work.Document1 pageHIRA of Gas Cutting Work.Gyanendra SrivastavaNo ratings yet

- 52 Job Safety Analysis FormDocument2 pages52 Job Safety Analysis FormkananiNo ratings yet

- CE05 Working in A SubstationDocument4 pagesCE05 Working in A SubstationTafireyi TeveraNo ratings yet

- Gas Cutting Work: Hazard Identification and Risk AssessmentDocument3 pagesGas Cutting Work: Hazard Identification and Risk AssessmentAchalere Shekhar Kashinath100% (2)

- AHA - Retrofitting WorkDocument1 pageAHA - Retrofitting WorkarjunkoiralaNo ratings yet

- M/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisDocument3 pagesM/S Gubbi Civil Engineer: Hazard Identification & Risk AnalysisHARSHADNo ratings yet

- CE20 Installation of Crosby ClampsDocument3 pagesCE20 Installation of Crosby ClampsTafireyi TeveraNo ratings yet

- HHR6 Pipe FittingDocument4 pagesHHR6 Pipe FittingEjike Francis ChizobaNo ratings yet

- JSA USE of Table SawDocument1 pageJSA USE of Table Sawsajjadliaqat3No ratings yet

- JSA USE of Table SawDocument1 pageJSA USE of Table Sawsajjadliaqat3No ratings yet

- 38 Chipping Work at Height - Co GenDocument3 pages38 Chipping Work at Height - Co GenKoneti JanardhanaraoNo ratings yet

- Injury & Illness Prevention Program: Job Safety Analysis FormDocument2 pagesInjury & Illness Prevention Program: Job Safety Analysis FormArif RachmanNo ratings yet

- JSA GrinderAngleDocument2 pagesJSA GrinderAngleslamet_rNo ratings yet

- Sporting Rifle M07As Match/M07Af MatchDocument24 pagesSporting Rifle M07As Match/M07Af MatchGer Adinolfi-FebreNo ratings yet

- Octopus Jsa For Fusion WeldingDocument2 pagesOctopus Jsa For Fusion WeldingOgunwa EmmanuelNo ratings yet

- Job Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteDocument5 pagesJob Safety Analysis: Organization: JSA Number: Work Type: Work Activity: Specific SiteM M PRADHANNo ratings yet

- Safety N/A Ergonomics N/A Environment 1. Dust Prone Zone. Positive Isolation & Work Permit Special Climatic ConditionsDocument8 pagesSafety N/A Ergonomics N/A Environment 1. Dust Prone Zone. Positive Isolation & Work Permit Special Climatic ConditionsAnjanav RoyNo ratings yet

- Scrap Material Cutting, Handling & Loading Jha - 2Document3 pagesScrap Material Cutting, Handling & Loading Jha - 2Dwitikrushna Rout100% (5)

- Jsa For Welding, Grinding, Gas CuttingDocument2 pagesJsa For Welding, Grinding, Gas Cuttingwahyu nugroho50% (2)

- Installation and Operating InstructionsDocument18 pagesInstallation and Operating InstructionsMarco LatosaNo ratings yet

- Jsa For Cutting, Grinding and Welding For GulfconDocument3 pagesJsa For Cutting, Grinding and Welding For GulfconOgunwa Emmanuel100% (1)

- CE04 Replacing Light BulbsDocument3 pagesCE04 Replacing Light BulbsTafireyi TeveraNo ratings yet

- HIRADocument120 pagesHIRAMohammed Amine MelouahNo ratings yet

- JSA Mengelas Di Dalam Tanki Boiler (Rev1)Document3 pagesJSA Mengelas Di Dalam Tanki Boiler (Rev1)DanangNo ratings yet

- JSA Mengelas Di Dalam Tanki BoilerDocument3 pagesJSA Mengelas Di Dalam Tanki BoilerDanangNo ratings yet

- Tanner Saw - MJ2325BDocument27 pagesTanner Saw - MJ2325BZL2ABVNo ratings yet

- PPQ M-Series Pistols: Safety & Instruction ManualDocument36 pagesPPQ M-Series Pistols: Safety & Instruction Manualcarlos pinedaNo ratings yet

- Work Instruction NPF STRETCH FILM (Stretch Film Operation)Document5 pagesWork Instruction NPF STRETCH FILM (Stretch Film Operation)Jed BrionesNo ratings yet

- IFU PFM Rotary 3004 M - EN - Rev.2016-12 - LowresDocument20 pagesIFU PFM Rotary 3004 M - EN - Rev.2016-12 - LowresDương HưngNo ratings yet

- Falih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NODocument9 pagesFalih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NOSreejith SureshNo ratings yet

- HIRA Format (2) Structural WorkDocument9 pagesHIRA Format (2) Structural WorkR. Ayyanuperumal AyyanuperumalNo ratings yet

- Carpentry Works 20.09.2020Document11 pagesCarpentry Works 20.09.2020Amit BhattNo ratings yet

- Risk Assessment - HorizonDocument5 pagesRisk Assessment - HorizonFebilaNo ratings yet

- HM0810TDocument32 pagesHM0810TIVOR COSTANo ratings yet

- Job Activity Hazard Effect Control Measures: Project in ChargeDocument3 pagesJob Activity Hazard Effect Control Measures: Project in Chargeperquino oasanNo ratings yet

- A Practical Approach to Hazard Identification for Operations and Maintenance WorkersFrom EverandA Practical Approach to Hazard Identification for Operations and Maintenance WorkersNo ratings yet

- Work Method Statment For Lifting With Winch MachineDocument9 pagesWork Method Statment For Lifting With Winch Machineshahhussain1031No ratings yet

- WHR AQC-2 DS (7-10) Column Lift PlanDocument5 pagesWHR AQC-2 DS (7-10) Column Lift Planshahhussain1031No ratings yet

- Hira For Appron Fidder ErectionDocument5 pagesHira For Appron Fidder Erectionshahhussain1031No ratings yet

- Errection HIRA For RelianceDocument2 pagesErrection HIRA For Relianceshahhussain1031No ratings yet

- Hira For CyclonDocument6 pagesHira For Cyclonshahhussain1031No ratings yet

- Man Basket JsaDocument2 pagesMan Basket Jsashahhussain1031No ratings yet

- Hydra - Dos & Dont'sDocument5 pagesHydra - Dos & Dont'sshahhussain1031No ratings yet

- Hira For Cement MillDocument6 pagesHira For Cement Millshahhussain1031No ratings yet

- HIRA of Tower CraneDocument3 pagesHIRA of Tower Craneshahhussain1031No ratings yet

- Hira For Esp Outlet PannalDocument5 pagesHira For Esp Outlet Pannalshahhussain1031No ratings yet

- Bag House ChimmenyDocument2 pagesBag House Chimmenyshahhussain1031No ratings yet

- MS Erection of Blending Silo Roof GirderDocument6 pagesMS Erection of Blending Silo Roof Girdershahhussain1031No ratings yet

- Liftting Plan - With Winch MachineDocument3 pagesLiftting Plan - With Winch Machineshahhussain1031No ratings yet

- 1structrul Erection Method StatementDocument5 pages1structrul Erection Method Statementshahhussain1031No ratings yet

- Ig2 Forms Electronic Submission v2Document8 pagesIg2 Forms Electronic Submission v2ammadNo ratings yet

- SIP Internship Report 1st Year (Batch 2019-21)Document45 pagesSIP Internship Report 1st Year (Batch 2019-21)Jatin Gupta100% (1)

- Strong Interest InventoryDocument14 pagesStrong Interest Inventoryapi-298977804No ratings yet

- Account Receible PDFDocument22 pagesAccount Receible PDFar ioNo ratings yet

- 2016 - Olsen Et Al - Lifecourse HT - Lancet ComissionDocument48 pages2016 - Olsen Et Al - Lifecourse HT - Lancet ComissionRafael Zambelli NobreNo ratings yet

- Daniel Valenzuela Arceo - Job SummaryDocument2 pagesDaniel Valenzuela Arceo - Job Summarydaniel.valarcNo ratings yet

- Transport Risk Assessment and Verification - From Theory To PracticeDocument2 pagesTransport Risk Assessment and Verification - From Theory To PracticePoppy TiaraNo ratings yet

- TCSDocument19 pagesTCSTanay SamantaNo ratings yet

- Unit 1Document77 pagesUnit 1Vanshika SharmaNo ratings yet

- Self-Assessment: ChecklistDocument28 pagesSelf-Assessment: Checklistgayathri gopalNo ratings yet

- Change Management Project PlanDocument14 pagesChange Management Project PlanAnkit BhattraiNo ratings yet

- Related LiteratureDocument10 pagesRelated LiteratureRoidenNo ratings yet

- Pert MasterDocument29 pagesPert MasterAlex Ciupitu100% (2)

- #14 PFRS 9 (Financial Instruments-Summary)Document5 pages#14 PFRS 9 (Financial Instruments-Summary)Zaaavnn Vannnnn100% (1)

- Fundamentals of Test ManagementDocument30 pagesFundamentals of Test ManagementsekararumughamNo ratings yet

- Cybersecurity .A State-Of-The-Art Review Phase 2. Final ReportDocument195 pagesCybersecurity .A State-Of-The-Art Review Phase 2. Final ReportSamir AlliouiNo ratings yet

- Mauboussin Form Follows Function Organizational Structure and Results PDFDocument12 pagesMauboussin Form Follows Function Organizational Structure and Results PDFTom TullyNo ratings yet

- Conducting A Business Impact Analysis GuideDocument7 pagesConducting A Business Impact Analysis GuideRajesh Iyer100% (1)

- 1.mandakini Garg PDFDocument4 pages1.mandakini Garg PDFDeeplakhan BhanguNo ratings yet

- Assignment Finance Review ChapterDocument22 pagesAssignment Finance Review ChapterSafuan HalimNo ratings yet

- ISO-9001-2015-quality Manual-Template-Sample PDFDocument11 pagesISO-9001-2015-quality Manual-Template-Sample PDFDayledaniel Sorveto100% (2)

- ProbabilityDocument7 pagesProbabilityJanaka PriyalalNo ratings yet

- Volunteer Management System Manual: City of HobartDocument126 pagesVolunteer Management System Manual: City of HobartIzhel Yuri RoqueNo ratings yet

- Wealth MaximisationDocument3 pagesWealth MaximisationAmandeep Singh MankuNo ratings yet

- Scientific ReportDocument19 pagesScientific ReportClifford Jay LachicaNo ratings yet

- Bancassurance A Swot AnalysisDocument6 pagesBancassurance A Swot AnalysisanuragNo ratings yet

- Strategic Report Shell Ar18 PDFDocument75 pagesStrategic Report Shell Ar18 PDFDương Minh KhánhNo ratings yet

- Manual MR Configurator 2Document13 pagesManual MR Configurator 2Juan Antonio Galvez RozasNo ratings yet

- 6152 10569211011025952 PDFDocument17 pages6152 10569211011025952 PDFAldii Cllalu CAyank QmNo ratings yet

- Safety Health and Environment (Norwegian Flag) WorkbookDocument48 pagesSafety Health and Environment (Norwegian Flag) WorkbookIlyaNo ratings yet