Professional Documents

Culture Documents

Gallery Shifting Method Statement

Uploaded by

shahhussain1031Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Gallery Shifting Method Statement

Uploaded by

shahhussain1031Copyright:

Available Formats

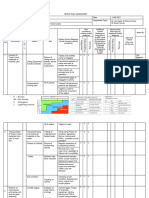

LAFARGE JOJOBERA GU EXPANSION PROJECT

METHOD STATEMENT

Method Statement for (Description & location):

442BC28 Gallery Erection

1 Document details and control:

Approved

Rev Date Prepared by Designation Signature Signature

by

0 16/12/2011 SHEKHAR ENGINEER

1

2 Individual/s in charge & responsible for supervising the Activity

and the Safety of the activity(Whether line manager /safety

personnel)(Contractor / LIPL)

Occupation /

SN Name Surname Signature Company

Designation

1 SHEKHAR MUKHERJEE ENGINEER L&T

2

Drafted by ManieTaljaard Page 1

3. Detailed step-by-step sequence of activities and tasks involved in

performing the task:(Work procedure)

Step 1

Preparation of gallery end connection:

1. Fabricated stool and stiffener will place at TT4 and TT5 at the level of

203.924m and 208.925m platform/ beam by using cherry picker.

2. Welding will complete by using cherry picker.

Step:2

Preparation of ground:

1. Earth will shift, dump, level and compact by vibro max.

2. Care should be taken; the distance from out rigger to earthen edge

should not be less than 1.5 times of depth.

Step:3

Position of Crane:

1. 350T crane will place in 20m radius from assembled gallery and centre

line of permanent position of gallery.

2. Steel plate and wooden sleeper will place on compacted earth or

concrete road, where out rigger will place.

Step:4

Gallery shifting

1. Gallery will shift in designated location by 200T crane.

2. Before shifting the gallery welding protocol should be approved by LIPL.

Step:5

Lifting of Gallery:

1. 4 nos 32 dia Sling , 10T’ D’ shackle and 3T/5T chain pulley will fix for lifting.

2. Sling eye will fix on crane hook with proper packing.

3. PPE rope of good quality and free of damage will fix both end of gallery to

control the heavy swings

4. Lift the gallery gradually by 350T crane.

5. Position the gallery on stool.

6. Welding will complete with stool and bottom cord extension beam.

7. Release the sling from crane hook.

Step:6

General precautions:

1. Provide barrication before erection and ensure nobody will enter the

barrication while erection.

2. Ensure proper lifeline on top cord before erection.

3. Workmen will use retractable fall arrestor by using web sling for

Drafted by ManieTaljaard Page 2

anchorage point.

4. Ensure proper welding and painting before shifting the gallery.

5. Gallery will lift as per approved load chart.

6. In erection time presence of rigging person must required.

7. Ensure proper supervision while erection.

8. Place the fire extinguisher near the working place.

9. Workmen will reach the TT5 working place by using permanent stair of

existing MFH,DOKA tower and 442BC 32 walkway or TT5 platform and

TT4 working place by using TT4 stair.

10. Lifting tools should be checked and colour coated before erection.

11. Work men should not enter in barrication area and below the

suspended load.

12. Work men should anchor on life line while release the sling eye

from crane hook.

13. Approve load chart will be attached

14. WAH approved workmen will be allowed to work at top level.

Step:7

Equipments for gallery erection.

1. 350T crane-1 no

2. 200T crane-1 no

3. Sling-32 dia-4 no

4. D-sheckle-10T-4 no

5. Chain block-1T/2T/3T/5T

6. PPE rope

7. Enclinometer-1no

8. Cherry picker

9. Packing materials.

Step :8

Crane details:

1. Radius -20mtr

2. Swl -33MT

3. Boom length-52mtr

4. Crane main boom degree- as per site condition

5. Gallery weight-22 MT

Step: 9

WAH:

Drafted by ManieTaljaard Page 3

1. Sup. Must inform the responsible in charge of the area before to

start any Job.

2. Sup. Must have been training to analyse all any risk and must be

sure that ny job could be done as safely as possible in a location before

to start it.(Ex: to avoid to work above each other).

3. Sup. Must inform the team about any risks in the location where they

have to work.

4. Sup. Must check that all workers use WAH PPE according the

standards

LAFARGE rules.

5. Sup. Must check any WAH PPE equipments before to use it and fill

out a Safety harnesses registers.

6. Sup. must install the PPE safely for the workers. Retractable fall

arresters must be installed above each work platform. -1 Retractable fall

arresters =1 man

7. Man basket and cherry picker must be use at first measure when it

is Impossible to install any WAH PPE safely.

8. All the workers must have completed and succeed in the WAH

course Training.

9. All the workers must follow the Lafarge safety rules at site.

4. Potential hazards and risks associated with the work activities and

control measures – to be detailed in the Risk Assessment form:

5. In the event of a sudden change in original scope of work/activity –

re-submit a new method statement and Risk Assessment for the

activity:

5- Relevant Legislation; i.e. Construction Regulations, etc:

FACTORY ACT 1948.

BOCW 1996.

LIPL G2.

5- Names & Qualifications of personnel who may inspect and

approve work area, conditions, methods, protective measures

and equipments to be used: (who is authorised to approve

other than scaffold and rigging operation).

Drafted by ManieTaljaard Page 4

Occupation /

SN Name Surname Qualification

Designation

1 SHEKHAR MUKHERJEE Engineer BE

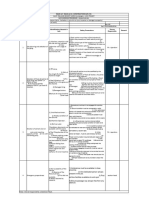

8. Training requirements for personnel involved in this activity,

including specialised training for specific tasks to be added:

Required

SN Type of Training

YES NO

1 JOB CLEARENCE

2 Work at Height

3 Hot work (cutting & welding)

4 MATARIAL HANDLING

9. List of workmen who will be performing activity and are trained

or to be trained for the task:Attached the pep talk

Trained

SN Name Surname Occupation Signature

YES NO

1

2

3

4

5

6

10. Details of permits required for the task; i.e. WAH, etc:

1. JOB CLEARENCE PERMIT.

2. HOT WORK PERMIT

3. HEIGHT WORK PERMIT

4. LIFTING WORK PERMIT.

5. FHRA

11. Identify all resources required to perform the task and

inspections required:

Drafted by ManieTaljaard Page 5

Required Inspection Frequency

SN Equipment type

YES NO Daily Weekly Monthly Quarterly

1 SLING

2 D- SHACKLE

3 CUTTING TORCH

4 WELDING MACHINE

5. Chain Pulley

6 Rope Pulley and PPE Rope

12. Identify all Personal Protective Equipment required to perform

the task:

Required

SN Equipment type

YES NO

1 Safety Helmet

2 Gloves

3 Safety goggles

4 Reflective jacket

5 Welding shield

6 Cutting torch goggles

7 Confined Space testing

8 DUST NOSE MASK

13. Document sign off and approval by Contractor Management and

Lafarge:

Approved

Name & Surname Designation Date Signature

YES NO

Contractor Safety

S. K. PATRA Contractor Site manager

LIPL First Line Engineer

LIPL Safety

H.K. SAHA LIPL Manager

WAH Expert

C.N.K.PRASAD HOD MECHANICAL

Drafted by ManieTaljaard Page 6

Drafted by ManieTaljaard Page 7

You might also like

- 1structrul Erection Method StatementDocument5 pages1structrul Erection Method Statementshahhussain1031No ratings yet

- Name &signature: Shakil: Nature PF WPRK - Destimatiom Ascavabteof Issued Agency B2Um Lnaia PuDocument3 pagesName &signature: Shakil: Nature PF WPRK - Destimatiom Ascavabteof Issued Agency B2Um Lnaia PuArnab PatraNo ratings yet

- MS For Fixing Loose and Detached PipeDocument5 pagesMS For Fixing Loose and Detached PipeSujan AugustinNo ratings yet

- PL in DNODocument3 pagesPL in DNOAbdullah DhiaNo ratings yet

- MOS of Shear Stud InstallationDocument3 pagesMOS of Shear Stud InstallationViisshnu SilvarajooNo ratings yet

- DQE SOP-183-Upper Substructure DisassemblyDocument8 pagesDQE SOP-183-Upper Substructure DisassemblyDQE040 HSSENo ratings yet

- SOP-12-Installation and Disconnection of Live Head of Drilliing LineDocument6 pagesSOP-12-Installation and Disconnection of Live Head of Drilliing LineDQE040 HSSENo ratings yet

- METHODOLOGY EE-Hanger Support InstallationDocument4 pagesMETHODOLOGY EE-Hanger Support Installationjerrick raulNo ratings yet

- Welding, Grinding, Oxy-Cutting JSA-007 PDFDocument6 pagesWelding, Grinding, Oxy-Cutting JSA-007 PDFNazmi DhiyauddinNo ratings yet

- PGAT2-MOS-CSA-001 - MOS of Moisture Board Installation at AHU RoomDocument3 pagesPGAT2-MOS-CSA-001 - MOS of Moisture Board Installation at AHU RoomViisshnu SilvarajooNo ratings yet

- MOS For Hot Tapping Work PDFDocument20 pagesMOS For Hot Tapping Work PDFAho Chi- ShuenNo ratings yet

- RKIPL-WMS 01 Fire Rated Partition WorkDocument13 pagesRKIPL-WMS 01 Fire Rated Partition Workvivekwagh09No ratings yet

- Lifting Permit: Form No: P224-6 Rev0 Page 1 of 2Document2 pagesLifting Permit: Form No: P224-6 Rev0 Page 1 of 2Ionian TribeNo ratings yet

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEEDNo ratings yet

- 14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneDocument1 page14 - JSA For Replacement of Tube Bundles of (100-EA4-C3, C8) & 284-E52 & 810E7 With New OneSHAH NAWAZ SAEED100% (1)

- Cable Laying MsDocument6 pagesCable Laying MsSawLaiBoyanNo ratings yet

- Cgk063-Rfa-Mos-M-Xxx - Unloading DahuDocument23 pagesCgk063-Rfa-Mos-M-Xxx - Unloading Dahudiki anggriawanNo ratings yet

- SOP-16-Load and Offload SledgeDocument6 pagesSOP-16-Load and Offload SledgeDQE040 HSSENo ratings yet

- Excavation Permit and ChecklistDocument3 pagesExcavation Permit and Checklistjeffry EscletoNo ratings yet

- SPI-HSE-GL-02-Work at Height-EHS GuidelinesDocument6 pagesSPI-HSE-GL-02-Work at Height-EHS GuidelinesPraveen NairNo ratings yet

- Pipeline Maintenance Section: IndexDocument55 pagesPipeline Maintenance Section: Indextenneti CHALAPATHY RAONo ratings yet

- AB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main DeckDocument2 pagesAB8-ELE 74 - JPO - Shaker Motors Dismantling and Shifting To Main Deckvikrant911No ratings yet

- Mooring Pin Instl MsDocument14 pagesMooring Pin Instl MsAtty AttyNo ratings yet

- RKIPL-WMS 02 - Polyurethane Painting WorkDocument10 pagesRKIPL-WMS 02 - Polyurethane Painting Workvivekwagh09No ratings yet

- MS For Scaffold and Cladding WorkDocument16 pagesMS For Scaffold and Cladding WorkSujan AugustinNo ratings yet

- Mercure Hotel Barsha Heights - MOS - v1.0Document5 pagesMercure Hotel Barsha Heights - MOS - v1.04jan1980No ratings yet

- WHR AQC-2 DS (7-10) Column Lift PlanDocument5 pagesWHR AQC-2 DS (7-10) Column Lift Planshahhussain1031No ratings yet

- PGAT2 MOS CSA 001 - MOS of Plastering WorkDocument4 pagesPGAT2 MOS CSA 001 - MOS of Plastering WorkViisshnu SilvarajooNo ratings yet

- SOP-15-Installation and Disassembly of BOP Hydraulic Control LineDocument6 pagesSOP-15-Installation and Disassembly of BOP Hydraulic Control LineDQE040 HSSENo ratings yet

- Loto Procedure: Construction of Coal Berth, Civil Works & Stock Yard Development at ParadipDocument12 pagesLoto Procedure: Construction of Coal Berth, Civil Works & Stock Yard Development at ParadipTarun KakkarNo ratings yet

- Hot Work Pre-Inspection ChecklistDocument2 pagesHot Work Pre-Inspection Checklistஹரிஹரசுதன்No ratings yet

- Log Book c16Document11 pagesLog Book c16NikhilNo ratings yet

- Method Statment For Cut and Weld WorksDocument4 pagesMethod Statment For Cut and Weld WorksravikumarNo ratings yet

- Wms Infineon Project Tower (Manhole Installation)Document5 pagesWms Infineon Project Tower (Manhole Installation)tanaNo ratings yet

- Method Statment Cable Tray & TrunkingDocument4 pagesMethod Statment Cable Tray & Trunkingmahroof mkuttyNo ratings yet

- Work Permit Format - Jul 2014Document2 pagesWork Permit Format - Jul 2014NilamSanjeev Kumar SinghNo ratings yet

- Method Statement For Scaffolding ActivitiesDocument8 pagesMethod Statement For Scaffolding ActivitiesMohsen KeramatiNo ratings yet

- SOP TowingDocument6 pagesSOP TowingbasdNo ratings yet

- PGAT2-MOS-CSA-001 - MOS of Light Weight Block Installation ReiseDocument3 pagesPGAT2-MOS-CSA-001 - MOS of Light Weight Block Installation ReiseViisshnu SilvarajooNo ratings yet

- Lock-Out / Tag-Out (L.O.T.O.) Permit To Work: Form No: P224-7 Rev0 Page 1 of 2Document2 pagesLock-Out / Tag-Out (L.O.T.O.) Permit To Work: Form No: P224-7 Rev0 Page 1 of 2Ionian TribeNo ratings yet

- General Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedDocument2 pagesGeneral Work Permit: Work Should Not Commence Until Stages 1 To 5 Are CompletedIonian TribeNo ratings yet

- Section - I: Cover Page Section - II:: IndexDocument21 pagesSection - I: Cover Page Section - II:: Indexamit rajputNo ratings yet

- UntitledDocument5 pagesUntitledPranayNo ratings yet

- Welder SMAW MAG MIG SAWDocument88 pagesWelder SMAW MAG MIG SAWjayson acunaNo ratings yet

- JSA-Fabrication, AssemblyDocument19 pagesJSA-Fabrication, AssemblyAshfaq Husain AnsariNo ratings yet

- Mos-Replacement Gasket For PP Piping - 2024Document6 pagesMos-Replacement Gasket For PP Piping - 2024habibullah.centroironNo ratings yet

- Method of Work - Pressure Test - Rev. 01Document10 pagesMethod of Work - Pressure Test - Rev. 01Rizki FadillahNo ratings yet

- 002 Under Ground CableDocument8 pages002 Under Ground CableMohamed KasemNo ratings yet

- Method Statement: QC InspectorDocument7 pagesMethod Statement: QC InspectorCobbinah MarkNo ratings yet

- Water Injection AreaDocument5 pagesWater Injection Areasudeesh kumarNo ratings yet

- Method-Statement-For-Tank-Jack-Lifting Rev01Document8 pagesMethod-Statement-For-Tank-Jack-Lifting Rev01tundeNo ratings yet

- ACMV Hirac - Mcintyre Prep Room 2Document13 pagesACMV Hirac - Mcintyre Prep Room 2NethiyaaRajendranNo ratings yet

- Falih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NODocument9 pagesFalih Falih SDN SDN BHD BHD JOB Job Safety Safety Analysis Analysis Jsa/Piling Jsa/Piling 1 1 of OF5 5 Doc. Doc. No. NO. Page No. NOSreejith SureshNo ratings yet

- Lifting Plan For Erection of 2nd To 6th r.1Document10 pagesLifting Plan For Erection of 2nd To 6th r.1Rhannie GarciaNo ratings yet

- 14) SWP-14 Concrete Core Drilling MachineDocument4 pages14) SWP-14 Concrete Core Drilling MachineFIKdtec duplicateNo ratings yet

- 2.1 Method of Statement - Installation of Aircon Diffuser and Sensors - Comments 4 Sep 2023Document1 page2.1 Method of Statement - Installation of Aircon Diffuser and Sensors - Comments 4 Sep 2023Suresh NaiduNo ratings yet

- SOP-17-Installation and Disassembly of CatwalkDocument7 pagesSOP-17-Installation and Disassembly of CatwalkDQE040 HSSENo ratings yet

- MS FSK Demolition 071119Document2 pagesMS FSK Demolition 071119DilxazNo ratings yet

- Subsea Rigid Pipelines – Methods of InstallationFrom EverandSubsea Rigid Pipelines – Methods of InstallationRating: 5 out of 5 stars5/5 (1)

- Work Method Statment For Lifting With Winch MachineDocument9 pagesWork Method Statment For Lifting With Winch Machineshahhussain1031No ratings yet

- Hira For CyclonDocument6 pagesHira For Cyclonshahhussain1031No ratings yet

- WHR AQC-2 DS (7-10) Column Lift PlanDocument5 pagesWHR AQC-2 DS (7-10) Column Lift Planshahhussain1031No ratings yet

- Hira For Appron Fidder ErectionDocument5 pagesHira For Appron Fidder Erectionshahhussain1031No ratings yet

- Errection HIRA For RelianceDocument2 pagesErrection HIRA For Relianceshahhussain1031No ratings yet

- Man Basket JsaDocument2 pagesMan Basket Jsashahhussain1031No ratings yet

- Hira For Cement MillDocument6 pagesHira For Cement Millshahhussain1031No ratings yet

- HIRA of Tower CraneDocument3 pagesHIRA of Tower Craneshahhussain1031No ratings yet

- Hydra - Dos & Dont'sDocument5 pagesHydra - Dos & Dont'sshahhussain1031No ratings yet

- Hira For Esp Outlet PannalDocument5 pagesHira For Esp Outlet Pannalshahhussain1031No ratings yet

- Liftting Plan - With Winch MachineDocument3 pagesLiftting Plan - With Winch Machineshahhussain1031No ratings yet

- Bag House ChimmenyDocument2 pagesBag House Chimmenyshahhussain1031No ratings yet

- Hira FabricationDocument5 pagesHira Fabricationshahhussain1031No ratings yet

- MS Erection of Blending Silo Roof GirderDocument6 pagesMS Erection of Blending Silo Roof Girdershahhussain1031No ratings yet

- Chapter 1Document26 pagesChapter 1aamir iqbalNo ratings yet

- Green Unikleen 1223 MSDSDocument2 pagesGreen Unikleen 1223 MSDSMurtaza SherwaniNo ratings yet

- MSDS AstDocument6 pagesMSDS AstKRRNo ratings yet

- Employee Welfare Scheme BirlaDocument63 pagesEmployee Welfare Scheme BirlaAbhay JainNo ratings yet

- NEBOSH IGC 2 February 2022 Solved Paper NotesDocument10 pagesNEBOSH IGC 2 February 2022 Solved Paper Noteshealth saleh100% (1)

- MSDS Nitric Acid 68%Document8 pagesMSDS Nitric Acid 68%Noviyanti Violita HamisiNo ratings yet

- Page 1 of 7Document7 pagesPage 1 of 7Hazim OmarNo ratings yet

- Method Statement Trial TrenchDocument6 pagesMethod Statement Trial TrenchSasi KumarNo ratings yet

- Annual Medical ReportDocument7 pagesAnnual Medical ReportWitchy Mye0% (1)

- Global ShiftDocument10 pagesGlobal ShiftInglorious BusterNo ratings yet

- Occupational Health and Safety Management REVISION Guide OBFDocument15 pagesOccupational Health and Safety Management REVISION Guide OBFASHLEYNo ratings yet

- How To Prepare A Safety Data Sheet (SDS) For A Synthesized ChemicalDocument7 pagesHow To Prepare A Safety Data Sheet (SDS) For A Synthesized ChemicalDemna GvasaliaNo ratings yet

- Site Safety Audit Plan & Compliance For Tata Steel JodaDocument10 pagesSite Safety Audit Plan & Compliance For Tata Steel JodaShahid Raza100% (1)

- NEBOSH Diploma AstutisGuide (Distance)Document10 pagesNEBOSH Diploma AstutisGuide (Distance)Fuzail AyazNo ratings yet

- 2 - Introductory Concepts ME 70 Basic Occupational Safety and HealthDocument86 pages2 - Introductory Concepts ME 70 Basic Occupational Safety and Healths.salise.allendaveNo ratings yet

- HSE Requirements For Contracts 1Document31 pagesHSE Requirements For Contracts 1bibin0474No ratings yet

- Case Study 2Document9 pagesCase Study 2Duventhiren0% (1)

- AnsiDocument4 pagesAnsijeanyoperNo ratings yet

- 50 Oil SDS 111314Document8 pages50 Oil SDS 111314Muhammad Asim ShahzadNo ratings yet

- Ibs Catalogue For Precast Concrete Building System Revision 2017Document196 pagesIbs Catalogue For Precast Concrete Building System Revision 2017jeman100% (2)

- Action Plan in Disaster Risk Reduction Management: Division of Cebu ProvinceDocument2 pagesAction Plan in Disaster Risk Reduction Management: Division of Cebu ProvinceCharie P. GraciaNo ratings yet

- Chemical Safety 2019Document42 pagesChemical Safety 2019Maria OzaoNo ratings yet

- Handing Over and Confirming Completion of Maintenance ActivitiesDocument5 pagesHanding Over and Confirming Completion of Maintenance ActivitiesJordan Leah100% (7)

- Compresor Up6-50pe-125Document208 pagesCompresor Up6-50pe-125AngelNo ratings yet

- Kesehatan Dan Keselamatan Kerja (K3) Di Bagian FilingDocument5 pagesKesehatan Dan Keselamatan Kerja (K3) Di Bagian FilingTantri Dwi LestariNo ratings yet

- 11 SITXHRM001 Assessment Task 2 ProjectDocument21 pages11 SITXHRM001 Assessment Task 2 ProjectTajinder Singh100% (2)

- Guidance To The IRATA Membership Requirements GU-301ENGDocument29 pagesGuidance To The IRATA Membership Requirements GU-301ENGowusu-nyarko AaronNo ratings yet

- N 1009 Iso CD 19650-6Document38 pagesN 1009 Iso CD 19650-6Orsolya HeidenwolfNo ratings yet

- Vendor Application Form - LAFONDocument9 pagesVendor Application Form - LAFONmusewejamesoumaNo ratings yet

- CBC Security Services NC IIDocument64 pagesCBC Security Services NC IILee Sy LemNo ratings yet