Professional Documents

Culture Documents

Hazop Ip

Hazop Ip

Uploaded by

Harold fotsingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazop Ip

Hazop Ip

Uploaded by

Harold fotsingCopyright:

Available Formats

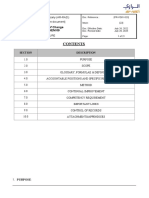

M/s. RL FineChem Pvt. Ltd.

RISK ASSESSMENT

7.1 INTRODUCTION

The pharmaceutical and bulk drug industries are generally associated with use of raw

materials and chemicals which are hazardous in nature. The process activities of these

industries are also associated with certain risks. Therefore Hazop analysis and risk

assessment are addressed in detail as additional studies.

Apart from the above studies air pollution dispersion modeling using US EPA approved

AERMOD software has been used to predict the profile of dispersion and associated

impacts within the project study area.

7.2 HAZOP ANALYSIS

Hazard and Operability Study (HAZOP) is a highly structured and detailed technique,

developed primarily for application to chemical process systems. A HAZOP can generate

a comprehensive understanding of the possible ‘deviations from design intent’ that may

occur. However, HAZOP is less suitable for identification of hazards not related to process

operations, such as mechanical integrity failures, procedural errors, or external events.

HAZOP also tends to identify hazards specific to the section being assessed, while hazards

related to the interactions between different sections may not be identified.

However, this technique helps to identify hazards in a process plant and the operability

problems. It is performed once the engineering line diagrams of the plant are made

available. It is carried out during or immediately after the design stage. The purpose of

the study is to identify all possible deviations from the way the design/operation is

expected to work and all the hazards associated with these deviations. A multidisciplinary

team was constituted with chemical, mechanical and instrumentationengineers, R&D

chemist and production manager. It is important to keep the team smallenough to be

efficient, while retaining a sufficient spread of skills and disciplines for all aspects of the

study to be covered comprehensively. The group discussion is facilitated by a Chairman

and the results of the discussion are recorded by a Secretary. Every investigation must be

led by Chairman who is familiar with the HAZOP study technique, which is primarily

concerned with applying, controlling the discussions and stimulating team thinking. The

preparative work for HAZOP studies consisted of four stages i.e., obtaining the data,

converting into usable form, planning the sequence of the study and arranging the

necessary meetings. The documents referred to for the study include process description,

process flow diagrams, P&I diagrams plant layout, operating manuals including startup &

shutdown, safety instructions etc., The parameters such as temperature, pressure, flow,

level were investigated for deviation and hazard situations are identified.

Risk Assessment Report- 1-

M/s. RL FineChem Pvt. Ltd.,

Some basic definitions of terms frequently used in HAZOP studies are deviation, causes,

consequences and guide words etc., Deviations are departures from the design intent

which are discovered by systematically applying the guide words. Causes are the reasons

why deviations might occur. Consequences are the reasons why deviations should they

occur. Guide words are simple words used to understand a particular plant section in

operating condition in order to guide and simulate the creative thinking process and so

discover deviations. NO, less, more, as well as, part of, reverse, other than are guide

words used.

Potential problems as represented by the consequences of the deviation should be

evaluated as they arise and a decision reached on whether they merit further

consideration or action. Except for major risk areas where a fully quantitative assessment

is required this decision is made semi-quantitatively on the consequence (usually scaled

as trivial, important or very probable).

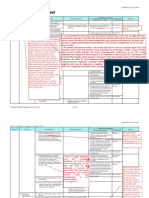

Detailed step-wise hazop analysis studies describing process, operation, possible hazard

failure and remedial actions for each of the product manufactured is given in the table

7.1 as under.

Table 7.1 HAZOP ANALYSIS

Sl.No PRODUCTS

1 Bromazepam

2 Cinnarizine

3 Clonazepam

4 Dothiepine Hydrochloride

5 Doxepin Hydrochloride

6 Flunarizine

7 Nitrazepam

Risk Assessment Report- 2-

M/s. RL FineChem Pvt. Ltd.,

7.2.1 Bromazepam

Hazop Analysis - Process – for Bromazepam product

1st Possible Hazards /

Process Operation Remedial Action

Stages failures

Dissolution of Operational control - checkpoint shall be included in the batch

Ammonia in solvent Preparation of Bottom valve sheet to indicate whether the bottom valve has been closed

Step -1

Methanol in SS ammonia solution opened prior to charging Methanol.

reactor

Methanol addition pipe is bent towards the wall of the reactor

so that the possibility of potential difference is avoided,

a) Charging of Fire hazard due to

vacuum sucking with negative pressure is done to avoid

Methanol static electricity

spillages.

Pipe lines are all SS and equipment motors are flame proof.

Ammonia is slowly passed with cooling and checking the

b) Purging of

Ammonia escape scrubber vent periodically for ammonia escape.

Ammonia

Ph paper test. Ensured No Ammonia should escape.

Reaction of bromo

Step-2 chloro compound in Reaction

SS Reactor

a) charging of SS scoop is used to prevent static electricity while charging the

Irritant to eyes &

bromo chloro solid.

skin

benzophenone Hand gloves & goggles should be used.

The temperature is raised by slow heating till

Required temperature is achieved; good condenser to prevent

solvent loss by circulating chilled water in condenser.

b) Heating the Escape of solvent

In case of overheating and pressure development rupture disc

reaction mass Ammonia escape

provided to the reactor will open up and the mass will come

out of the reactor and will be separately collected in the PP

vessel of 5000L which is kept outside the plant.

Risk Assessment Report- 3-

M/s. RL FineChem Pvt. Ltd.,

The centrifuge is earthed by

conducting wires.

The filtration is carried out through a

centrifuge, Centrifuges are high

speed machines and sources of

hazard in a chemical plant. Ample

precautions are taken to carry out the

centrifuging as hazard free as

possible. We are using a 36 inch dia

SS316 centrifuge, bottom driven and

top discharge. this is a four point

suspension machines which are put on

special vibra mount for smooth

Fire hazard due to static vibration free noiseless operation.

electricity, operator The speed is controlled by a variable

Centrifuging to remove the

c) To remove the by- hazard if any loading / frequency drive and the feeding of

Byproduct.

product amm. chloride unloading activity carried the centrifuge is done by

Separation of solid and liquid.

out in a running pneumatically controlled valves at

centrifuge lower RPM under nitrogen purging.

Even the bearing housing of the

centrifuge is provided with a nitrogen

purging facility. An interlocking

system is provided for ensuring that

the lids cannot be opened while the

centrifuge is running and thereby

preventing any human hazard. All the

limits switches and the safety

interlocking switches are flame proof

including the VFD controls. Collect

the mother liquor for isolating the

product. This is sucked back to the SS

reactor for recovery & isolation.

d) Distillation of Slow heating by passing steam in the

Methanol from the jacket &

Isolation of Bromazepam No specific hazard

filtrate of the Chilled water is circulated in the

reaction mass condenser.

Risk Assessment Report- 4-

M/s. RL FineChem Pvt. Ltd.,

Recover ~200L methanol ,cool to

<15*C.

The centrifuge is earthed by

conducting wires. The filtration is

carried out through a centrifuge;

Centrifuges are high speed machines

and sources of hazard in a chemical

plant. Ample precautions are taken

to carry out the centrifuging as

hazard free as possible. We are using

a 48 inch dia SS316 centrifuge,

bottom driven and top discharge. This

is a four point suspension machines

which are put on special vibra mount

Fire hazard due to static for smooth vibration free noiseless

electricity, operator operation. The speed is controlled by

Centrifuging to isolate the

To isolate the product hazard if any loading / a variable frequency drive and the

product.

Bromazepam unloading activity carried feeding of the centrifuge is done by

Separation of solid and liquid.

out in a running pneumatically controlled valves at

centrifuge lower RPM under nitrogen purging.

Even the bearing housing of the

centrifuge is provided with a nitrogen

purging facility. An interlocking

system is provided for ensuring that

the lids cannot be opened while the

centrifuge is running and thereby

preventing any human hazard. All the

limits switches and the safety

interlocking switches are flame proof

including the VFD controls

The MLR is taken for solvent

recovery.

All charging is done by vacuum

Solvent recovery (MLR)in SS Charging of MLR Haz.

Recovery No specific hazard sucking to avoid spillages and

reactor waste after distillation

through the SS pipe lines.

Risk Assessment Report- 5-

M/s. RL FineChem Pvt. Ltd.,

Distilled to recover Methanol. Un

distilled which is remaining at the

bottom of the reactor is Haz Waste.

FBD is fitted with flame proof

motors.SS scoops are employed

Separation of solvents from Drying of the product No specific hazard

Drying operation while charging and unloading.

the product in FBD Irritant to eyes & skin

Hand gloves & goggles should be

used.

Risk Assessment Report- 6-

M/s. RL FineChem Pvt. Ltd.,

SAFETY DATA

Name of the product 1) Bromo chloro 2) Methanol (RM)

acetylaminoBenzophenone.

Chemical name 5-bromo 2-chloroacetylamino phenyl Methyl alcohol

pyridine ketone

CAS NO: 67-56-1

MW: 353.0 32.0

Physical appearance Yellowish coloured solid Colorless liquid

Odour Pungent, hygroscopic acidic like Characteristic

Melting point 135-140* C --

Boiling point --- 65*C

Health hazards Irreversible effects if swallowed. Irreversible effects if swallowed.

Danger of very serious effect on eye& Danger of very serious effect on

harmful if absorbed through the skin. eye& harmful if absorbed through

Slow absorption. the skin. Slow absorption.

Very serious effect on inhalation. Very serious effect on inhalation.

First aid measure Eyes: rinse out plenty of water. Get Eyes: rinse out plenty of water.

medical help immediately. Do not allow Get medical help immediately. Do

the victim to rub the eyes. Keep eyes not allow the victim to rub the

closed. eyes. Keep eyes closed.

Induce vomiting & make him drink Induce vomiting & make him drink

ethanol. ethanol .

Skin: Flush skin with plenty of water. Get Skin: Flush skin with plenty of

medical aid. water. Get medical aid.

Ingestion: Get medical aid. Ingestion: Get medical aid.

Inhalation: Remove fromexposure and Inhalation: Remove from

move to fresh air immediately mouth to exposure and move to fresh

mouth respiration if required. air immediately mouth to mouth

respiration if required.

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. breathing apparatus.

Do not use water spray directly on the fire. Do not use water spray directly on the

Use dry chemical, Carbon dioxide or fire. Use dry chemical, Carbon

Chemical foam. dioxide or Chemical foam.

Storage Store in large tanks as per flammable liquid Store in large tanks as per flammable

store, as per Rules ,away from naked fame liquid store, as per Rules ,away from

& hot elements and ignition sources. naked fame & hot elements and

ignition sources.

Hazards Highly flammable, flashpoint Highly flammable, flashpoint

11*C.Electrostatic charge possible. 11*Celectrostatic charge possible.

Incompatibility Avoid contact with water, ammonia, alkali Avoid contact with water, ammonia,

metals, strong oxidizing agents et. alkali metals, strong oxidizing agents

etc.

Hazardous decomposition Hazardous decomposition products in the Hazardous decomposition products in

product event of fire. the event of fire.

Carcinogenetic Not reported in OSHA Disposal Not reported in OSHA Disposal

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 7-

M/s. RL FineChem Pvt. Ltd.,

Name of the product 3) Ammmonia 4) Bromazepam( FG)

Chemical name Gas liquefied under pressure. 1,3-Dihydro-7-bromo-5-(pyridine2-yl)

2h-1,4-Benzodiazepin-2-One

CAS NO: 7664-41-7 1812-30-2

MW: 17.0 316.

Physical appearance Liquid, colorless Yellow, crystalline powder

Odour Pungent Odourless

Melting point -77.7*C : about – 2370 C.

Boiling point -33.5* C ---

Health hazards Will cause eye burns. Risk of blindness. Harmful if swallowed.

Harmful if swallowed. May be harmful if May cause eye irritation.

absorbed through the skin; cause skin May be harmful if absorbed through

irritations. the skin

May cedemass in the respiratory tract. May cause respiratory tract

irritation. Effects central nervous

system.

First aid measure Eyes: rinse with plenty of water for at Eyes: Flush eyes with plenty of

least 10 min& get medical help water. Get medical help

immediately. Do not allow the victim to Skin: Flush skin with plenty of

rub the eyes. Keep eyes closed. water. Get medical aid.

If swallowed drink lot of water & induce Ingestion: Get medical aid.

vomiting. Call doctor. Inhalation: remove from

Skin: Flush skin with plenty of water. Dab exposure &move to fresh air

with PEG 400 remove contaminated immediately

clothing.

Inhalation: Remove fromexposure and

move to fresh air immediately.

Calldoctor

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. Not combustible. breathing apparatus.

Do not use water. Use dry chemical, Carbon Use water spray, dry chemical,

dioxide or Chemical foam. Carbon dioxide or Chemical foam.

Storage Store in a dry cool place, protected from Store in a dry cool place, protected

light in tightly closed containers. from light in tightly closed containers.

Hazards Not reported. Stable

Incompatibility Incompatible with various metals. Avoid strong oxidizing agents etc.

Hazardous decomposition Nitrogen oxides generate. In event of fire . Carbon monoxide, carbon dioxide,

product Nitrogen oxide

Carcinogenetic Not reported . Not reported

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 8-

M/s. RL FineChem Pvt. Ltd.,

7.2.2 Cinnarizine

Hazop Analysis - Process – for CINNARIZINE product

Possible Hazards /

1st Stages Process Operation Remedial Action

failures

Operational control - checkpoint shall be included in

Reaction of Benzhydryl Charging of

the batch sheet to indicate whether the bottom

piperizine& Cinnamyl alcohol Benzhydrylpiperizine

Step -1 Bottom valve opened valve has been closed prior to charging Toluene.

acid in solvent Toluene in SS Cinnamyl alcohol&

reactor Toluene

Toluene addition pipe is bent towards the wall of

the reactor so that the possibility of potential

a) Charging of Fire hazard due to static difference is avoided .vacuum sucking is done to

Toluene electricity avoid spillages.

Pipe lines are all SS and equipment motors are flame

proof .

b) Charging of SS scoops are used to avoid static electricity.

Irritation to skin.

Benzhydrylpiperizine Using hand gloves & goggles.

Charging of Vacuum sucking into the DOSING TANK The tank is

Cinnamyl alcohol Irritation to skin. earthed by conducting wires

Using hand gloves & goggles

The temperature is raised by slow heating till

Reflux; good condenser to prevent solvent loss by

circulating chilled water in condenser.

The water is co distills along with Toluene which is

separated during the reaction. After complete

d) Refluxing the

Escape of solvent removal of water, the reaction is complete.

reaction mass

In case of overheating and pressure development

rupture disc provided to the reactor will open up and

the mass will come out of the reactor and will be

separately collected in the PP vessel of 5000L which

is kept outside the plant.

Risk Assessment Report- 9-

M/s. RL FineChem Pvt. Ltd.,

e) cooling the reaction Chilled water is circulated in the Jacket.

No specific hazard

mass

The centrifuge is earthed by conducting wires.

The filtration is carried out through a

centrifuge, Centrifuges are high speed

machines and sources of hazard in a chemical

plant. Ample precautions are taken to carry out

the centrifuging as hazard free as possible. We

are using a 48 inch dia SS316 centrifuge, bottom

driven and top discharge. this is a four point

suspension machines which are put on special

Fire hazard due to static vibra mount for smooth vibration free noiseless

To isolate the product electricity, operator operation. The speed is controlled by a variable

Centrifuging to isolate the

2) Isolation of Cinnarizine hazard if any loading / frequency drive and the feeding of the

product.

product. unloading activity centrifuge is done by pneumatically controlled

Separation of solid and liquid.

carried out in a running valves at lower RPM under nitrogen purging.

centrifuge Even the bearing housing of the centrifuge is

provided with a nitrogen purging facility. An

interlocking system is provided for ensuring

that the lids cannot be opened while the

centrifuge is running and thereby preventing

any human hazard. All the limits switches and

the safety interlocking switches are flame proof

including the VFD controls

The MLR is taken for solvent recovery.

The wet product is sent for drying.

All charging is done by vacuum sucking to avoid

Charging of MLR Haz.

spillages and through the SS pipe lines.

Solvent recovery (MLR)in SS waste after

Recovery No specific hazard Distilled to recover Toluene. Un distilled which

reactor distillation

is remaining at the bottom of the reactor is Haz

Waste.

FBD is fitted with flame proof motors. SS scoops

Drying Separation of solvents from Drying of the product

No specific hazard are employed while charging and unloading.

operation the product in FBD

Hand gloves & goggles should be used.

Risk Assessment Report- 10-

M/s. RL FineChem Pvt. Ltd.,

SAFETY DATA

Name of the product 1) Benzhydryl piperizine 2) Toluene

Chemical name 1 diphenyl-piperizine Toluene

CAS NO: 108-88-3

MW: 252 92.0

Physical appearance Pale yellow coloured solid Colorless liquid

Odour Amine like Aromatic pungent smell.

Melting point 72-76*C*C -

Boiling point -- 111*C

Health hazards Harmful if swallowed. Effects central Harmful if swallowed.

nervous system Vapors cause eye irritation.

May cause eye irritation. May cause May be harmful if absorbed through

corneal damage. the skin

May be harmful if absorbed through the May cause respiratory irritation&

skin arrest on inhalation.

May cause respiratory tract irritation. On

inhalation.

First aid measure Eyes: Flush eyes with plenty of water. Eyes: Flush eyes with plenty of

Get medical help water. Get medical help

Skin: Flush skin with plenty of water. Get Skin: Flush skin with plenty of

medical aid. water. Remove contaminated

Ingestion: Get medical aid. cloth. Get medical aid.

Inhalation: remove from exposure &move Ingestion: Get medical aid.

to fresh air immediately. Inhalation: remove from exposure

&move to fresh air immediately.

Fire fighting As in any fire, use a self-contained breathing As in any fir, use a self-contained

apparatus. breathing apparatus.

Use water spray, dry chemical, Carbon Use dry chemical, Carbon dioxide or

dioxide or Chemical foam. Chemical foam. DONOT USE WATER.

Storage Store in a dry cool place, protected from Store in large tanks as per flammable

light in tightly closed containers. liquid store. as per Rules, away from

naked fame & hot elements and

ignition sources.

Hazards Stable. Flammable , flash point 4* C

Incompatibility Avoid strong oxidizing agents. Avoid strong oxidizing agents.

Hazardous decomposition Hazardous decomposition products. Carbon Hazardous combustion gases &vapors

product monoxide, carbon dioxide, oxides of in the event of fire.

nitrogen.

Carcinogeneticity Not classified as a human carcinogen.. Not reported in OSHA

Disposal Dispose in a manner according to state & Dispose in a manner according to

federal laws. state & federal laws.

Risk Assessment Report- 11-

M/s. RL FineChem Pvt. Ltd.,

Name of the product 3) Cinnamylalcohol 4) Cinnarizine

Chemical name 3-phenyl 2-propene-1-ol 1-diphenyl 4-cinamyl pyperizine

CAS NO: 104-54-1 298-57-7

MW: 134.0 368.0

Physical appearance Colorless liquid. White powder

Odour Mint fragrant. Odorless

Melting point 30-33*C 1180 C To 1200 C

Boiling point 250*C --

Health hazards Harmful if swallowed. Harmful if swallowed.

Vapors irritate eyes Serious to eye.

Dryness of skin May be harmful if absorbed through

Causes irritation to respiratory tract, the skin

causes headache & dizziness May cause respiratory irritation on

inhalation

First aid measure Eyes: rinse with plenty of water. Get Eyes: Flush eyes with plenty of

medical help immediately. Do not allow water. Get medical help

the victim to rub the eyes. Keep eyes Skin: Flush skin with plenty of

closed. water. Remove contaminated

Drink lot of water.No milk risk of cloth. Get medical aid.

aspiration on swallowing.Get medical Ingestion: wash out mouth with lot

aid. of water. .Get medical aid.

Skin: Flush skin with plenty of water. Inhalation: remove from exposure

Remove contaminated cloth &move to fresh air immediately.

Inhalation: Remove from exposure and Give artificial respiration

move to fresh air immediately. Give

mouth to mouth respiration if required.

Fire fighting As in any fire, use a self-contained breathing Use dry chemical, Carbon dioxide or

apparatus. Chemical foam.

Do not use water spray directly on the fire. As in any fire, use a self-contained

Use dry chemical, Carbon dioxide or breathing apparatus

Chemical foam.

Storage Store in large tanks as per flammable liquid, Store in a dry cool place, protected

store as per Rules,away from naked flame & from light in tightly closed containers

hot elements and ignition sources.

Hazards Highly flammable, flashpoint low, Not reported

electrostatic charge possible.

Incompatibility Avoid contact with water, ammonia, alkali Avoid contact with water, ammonia,

metals, strong oxidizing agents etc. alkali metals, strong oxidizing agents

etc.

Hazardous decomposition Hazardous decomposition products in the Hazardous decomposition products in

product event of fire. the event of fire.

Carcinogeneticity Not reported in OSHA disposal Not reported in OSHA disposal

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 12-

M/s. RL FineChem Pvt. Ltd.,

7.2.3 Clonazepam

Hazop Analysis - Process – for Clonazepam product

1st Stages Process Operation Possible Hazards / failures Remedial Action

Operational control - checkpoint shall be included

Dissolution of Ammonia in Preparation of ammonia

Step -1 Bottom valve opened in the batch sheet to indicate whether the bottom

solvent Methanol in SS reactor solution

valve has been closed prior to charging Methanol

Methanol addition pipe is bent towards the wall of

the reactor so that the possibility of potential

a) Charging of Fire hazard due to static difference is avoided .vacuum sucking is done to

Methanol electricity avoid spillages.

Pipe lines are all SS and equipment motors are

flame proof.

Ammonia is slowly passed with cooling and

b) Purging of Ammonia checking the scrubber vent periodically for

Ammonia escape

ammonia escape.

Ph paper test. No Ammonia should escape.

Reaction of nitro dichloro

Step-2 Reaction

compound in SS Reactor

SS scoop is used to prevent static electricity while

a) charging of nitro dichloro

Irritant to eyes & skin charging the solid.

benzophenone

Hand gloves & goggles should be used.

The temperature is raised by slow heating till

Required temperature is achieved; good

condenser to prevent solvent loss by circulating

chilled water in condenser.

Escape of solvent

b) Heating the reaction mass In case of overheating and pressure development

Ammonia escape

rupture disc provided to the reactor will open up

and the mass will come out of the reactor and will

be separately collected in the PP vessel of 5000L

which is kept outside the plant.

Risk Assessment Report- 13-

M/s. RL FineChem Pvt. Ltd.,

The centrifuge is earthed by conducting wires.

The filtration is carried out through a centrifuge,

Centrifuges are high speed machines and sources

of hazard in a chemical plant. Ample precautions

are taken to carry out the centrifuging as hazard

free as possible. We are using a 36 inch dia SS316

centrifuge, bottom driven and top discharge. this

is a four point suspension machines which are put

on special vibra mount for smooth vibration free

Fire hazard due to static

noiseless operation. The speed is controlled by a

electricity, operator

Centrifuging to remove the variable frequency drive and the feeding of the

c) To remove the by hazard if any loading /

Byproduct. centrifuge is done by pneumatically controlled

product amm. chloride unloading activity carried

Separation of solid and liquid. valves at lower RPM under nitrogen purging. Even

out in a running

the bearing housing of the centrifuge is provided

centrifuge

with a nitrogen purging facility. An interlocking

system is provided for ensuring that the lids

cannot be opened while the centrifuge is running

and thereby preventing any human hazard. All the

limits switches and the safety interlocking

switches are flame proof including the VFD

controls. Collect the mother liquor for isolating

the product. This is sucked back to the SS reactor

for recovery & isolation.

d) Distillation of Slow heating by passing steam in the jacket &

Methanol from the Chilled water is circulated in the condenser.

Isolation of clonazepam No specific hazard

filtrate of the Recover ~200L methanol ,cool to <15*C.

reaction mass

Risk Assessment Report- 14-

M/s. RL FineChem Pvt. Ltd.,

The centrifuge is earthed by conducting wires.

The filtration is carried out through a centrifuge;

Centrifuges are high speed machines and sources

of hazard in a chemical plant. Ample precautions

are taken to carry out the centrifuging as hazard

free as possible. We are using a 48 inch dia SS316

centrifuge, bottom driven and top discharge. this

is a four point suspension machines which are put

Fire hazard due to static on special vibra mount for smooth vibration free

To isolate the product electricity, operator noiseless operation. The speed is controlled by a

Centrifuging to isolate the

Clonazepam. hazard if any loading / variable frequency drive and the feeding of the

product.

unloading activity carried centrifuge is done by pneumatically controlled

Separation of solid and liquid.

out in a running valves at lower RPM under nitrogen purging. Even

centrifuge the bearing housing of the centrifuge is provided

with a nitrogen purging facility. An interlocking

system is provided for ensuring that the lids

cannot be opened while the centrifuge is running

and thereby preventing any human hazard. All the

limits switches and the safety interlocking

switches are flame proof including the VFD

controls

The MLR is taken for solvent recovery.

All charging is done by vacuum sucking to avoid

spillages and through the SS pipe lines.

Solvent recovery (MLR)in SS Charging of MLR Haz.

Recovery No specific hazard Distilled to recover Methanol. Un distilled which is

reactor waste after distillation

remaining at the bottom of the reactor is Haz.

Waste.

FBD is fitted with flame proof motors. SS scoops

Separation of solvents from Drying of the product No specific hazard

Drying operation are employed while charging and unloading.

the product in FBD Irritant to eyes & skin

Hand gloves & goggles should be used

Risk Assessment Report- 15-

M/s. RL FineChem Pvt. Ltd.,

SAFTY DATA

Name of the product 1) 2’Chloro,5-Nitro 2-chloro 2) Methanol (RM)

acetylaminoBenzophenone.(nitro dicloro

benzophenone)

Chemical name 2’chloro, 5-nitro 2chloroacetylamino Methyl alcohol

benzophenone.

CAS NO: 67-56-1

MW: 353.0 32.0

Physical appearance Yellow coloured solid Colorless liquid

Odour Pungent hygroscopic acidic Characteristic

Melting point 176-186*C --

Boiling point --- 65*C

Health hazards Irreversible effects if swallowed. Irreversible effects if swallowed.

Danger of very serious effect on eye & Danger of very serious effect on

harmful if absorbed through the skin. eye.& harmful if absorbed through

Slow absorption. the skin. slow absorption.

Very serious effect on inhalation. very serious effect on inhalation.

First aid measure Eyes: rinse out plenty of water. Get Eyes: rinse out with plenty of

medical help immediately. Do not allow water. Get medical help

the victim to rub the eyes. Keep eyes immediately. Do not allow the

closed. victim to rub the eyes. Keep eyes

Induce vomiting & make him drink closed.

ethanol. Induce vomiting & make him drink

Skin: Flush skin with plenty of water. Get ethanol.

medical aid. Skin: Flush skin with plenty of

Ingestion: Get medical aid. water. Get medical aid.

Inhalation: Remove from exposure and Ingestion: Get medical aid.

move to fresh air immediately, give Inhalation: Remove fromexposure

mouth to mouth respiration if required. and move to fresh air immediately;

give mouth to mouth respiration if

required.

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. breathing apparatus.

Do not use water spray directly on the fire. Do not use water spray directly on the

Use dry chemical, Carbon dioxide or fire. Use dry chemical, Carbon

Chemical foam. dioxide or Chemical foam.

Storage Store in large tanks as per flammable liquid Store in large tanks as per flammable

store as per Rules,away from naked fame & liquid store as per Rules,away from

hot elements and ignition sources. naked fame & hot elements and

ignition sources.

Hazards Highly flammable, flashpoint Highly flammable, flashpoint

11*C.Electrostatic charge possible. 11*C.Electrostatic charge possible.

Incompatibility Avoid contact with water, ammonia, alkali Avoid contact with water, ammonia,

metals, strong oxidizing agents etc. alkali metals, strong oxidizing agents

etc.

Hazardous decomposition Hazardous decomposition products in the Hazardous decomposition products in

product event of fire. the event of fire.

Carcinogenetic Not reported in OSHAdisposal Not reported in OSHA disposal

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 16-

M/s. RL FineChem Pvt. Ltd.,

Name of the product 3) Ammmonia 4) Clonazepam(FG)

Chemical name Gas liquefied under pressure. 1,3-Dihydro-7-nitro-5-(o-

chlorophenyl)-2h-1,4-Benzodiazepin-

2-One

CAS NO: 7664-41-7 1622-61-3

MW: 17.0 : 315.72.

Physical appearance Liquid, colorless Yellow, crystalline powder. Odorless

Odour Pungent Odourless

Melting point -77.7*C : about – 2400 C.

Boiling point -33.5* C ---

Health hazards Will cause eye burns. Risk of blindness. Harmful if swallowed.

Harmful if swallowed. May be harmful if May cause eye irritation.

absorbed through the skin, cause skin May be harmful if absorbed through

irritations. the skin

May cedemass in the respiratory tract. May cause respiratory tract

irritation. Effects central nervous

system.

First aid measure Eyes: rinse with plenty of water for at Eyes: Flush eyes with plenty of

least 10 min& get medical help water. Get medical help

immediately. Do not allow the victim to Skin: Flush skin with plenty of

rub the eyes. Keep eyes closed. water. Get medical aid.

If swallowed drink lot of water & induce Ingestion: Get medical aid.

vomiting. Call doctor. Inhalation: remove from exposure

Skin: Flush skin with plenty of water. Dab &move to fresh air immediately

with PEG 400 remove contaminated

clothing.

Inhalation: Remove fromexposure and

move to fresh air immediately. Call

doctor

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. Not combustible. breathing apparatus.

Do not use water. Use dry chemical, Carbon Use water spray, dry chemical,

dioxide or Chemical foam. Carbon dioxide or Chemical foam.

Storage Store in a dry cool place, protected from Store in a dry cool place, protected

light in tightly closed containers. from light in tightly closed containers

Hazards Not reported. Stable

Incompatibility Incompatible with various metals. Avoid strong oxidizing agents etc.

Hazardous decomposition Nitrogen oxides generate. In event of fire. Carbon monoxide, carbon dioxide,

product Nitrogen oxide

Carcinogenetic Not reported. Not reported

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 17-

M/s. RL FineChem Pvt. Ltd.,

7.2.4 Dothiepine hydrochloride

Hazop Analysis - Process – for Dothiepine hydrochloride product

st

1 Possible Hazards /

Process Operation Remedial Action

Stages failures

Operational control - checkpoint shall be included in the

Dissolution of HCL as in

Step -1 Charging of Acetone Bottom valve opened batch sheet to indicate whether the bottom valve has been

solvent acetone in GL reactor

closed prior to charging Acetone.

Acetone addition pipe is bent towards the wall of the reactor

a) Charging of Fire hazard due to static so that the possibility of potential difference is avoided

Acetone electricity .vacuum sucking is done to avoid spillages.

Pipe lines are all SS and equipment motors are flame proof .

The gas is passed through the gas trap containing sulphuric

acid and empty trap to prevent back suck.

The dry gas coming out from the trap is connected to the dip

pipe of the GL Reactor which is dipped in the solvent.

b) Purging of HCL gas.

Irritant to eyes & skin The gas is passed till required sp. gravity and assay is

achieved.

The outlet of the reactor is connected to the scrubber where

alkali is circulated.

Using hand gloves & goggles.

Operational control - checkpoint shall be included in the

Reaction of dothepine base

a) Charging of batch sheet to indicate whether the required pH has been

Step-2 with acetone- HCL in GL Irritant to eyes & skin

dissolved base achieved.

Reactor

Using hand gloves & goggles

The temperature is raised by slow heating till

Required temperature is achieved; good condenser to

prevent solvent loss by circulating chilled water in condenser.

c) Heating the The acidic fumes are scrubbed in alkali scrubber.

Escape of solvent & Hcl

reaction mass In case of overheating and pressure development rupture disc

provided to the reactor will open up and the mass will come

out of the reactor and will be separately collected in the PP

vessel of 5000L which is kept outside the plant.

Risk Assessment Report- 18-

M/s. RL FineChem Pvt. Ltd.,

d) cooling the Chilled water is circulated in the Jacket.

No specific hazard

reaction mass

The centrifuge is earthed by conducting wires.

The filtration is carried out through a centrifuge,

Centrifuges are high speed machines and sources

of hazard in a chemical plant. Ample precautions

are taken to carry out the centrifuging as hazard

free as possible. We are using a 48 inch dia SS316

centrifuge, bottom driven and top discharge. this

is a four point suspension machines which are put

Fire hazard due to static

To isolate the product on special vibra mount for smooth vibration free

electricity, operator

Centrifuging to isolate the Dothepine noiseless operation. The speed is controlled by a

hazard if any loading /

product. hydrochloride. variable frequency drive and the feeding of the

unloading activity carried

Separation of solid and liquid. centrifuge is done by valves at lower RPM under

out in a running

nitrogen purging. Even the bearing housing of the

centrifuge

centrifuge is provided with a nitrogen purging

facility. An interlocking system is provided for

ensuring that the lids cannot be opened while the

centrifuge is running and thereby preventing any

human hazard. All the limits switches and the

safety interlocking switches are flame proof

including the VFD controls

The MLR is taken for solvent recovery.

All charging is done by vacuum sucking to avoid

Charging of MLR Haz. spillages and through the SS pipe lines.

Solvent recovery (MLR)in SS

Recovery waste after distillation No specific hazard Distilled to recover Acetone. Un distilled which is

reactor

remaining at the bottom of the reactor is Haz

Waste.

Separation of solvents from Drying of the product No specific hazard, FBD is fitted with flame proof motors.

Drying operation Hand gloves & goggles should be used

the product in FBD irritant to eyes & skin

Risk Assessment Report- 19-

M/s. RL FineChem Pvt. Ltd.,

SAFETY DATA

Name of the product 1) Dothiepine base 2) Acetone

Chemical name 3-Dibenzo [b,e]thiepin-11(6H)-ylidene-N,N- Dimethyl ketone

dimethyl-1-propanamine

CAS NO: 67-64-1

MW: 295.0 58.0

Physical appearance Pale yellow colored viscous liquid Colorless liquid.

Odour Amine like Mint fragrant.

Melting point -- --

Boiling point ~200*C at 0.5mm 57*C

Health hazards Harmful if swallowed. Harmful if swallowed.

May cause eye irritation. May cause Vapors irritate eyes

corneal damage. Dryness of skin

May be harmful if absorbed through the Causes irritation to respiratory

skin. tract, causes headache & dizziness

May cause respiratory tract irritation.

First aid measure Eyes: Flush eyes with plenty of water. Eyes: rinse out plenty of water.

Get medical help Get medical help immediately. Do

Skin: Flush skin with plenty of water. Get not allow the victim to rub the

medical aid. eyes. Keep eyes closed.

Ingestion: Get medical aid. Drink lot of water .No milk risk of

Inhalation: remove from exposure &move aspiration on swallowing.Get

to fresh air immediately. medical aid.

Skin: Flush skin with plenty of

water. Remove contaminated

cloth

Inhalation: Remove from exposure

and move to fresh air

immediately, give mouth to mouth

respiration if required.

Fire fighting As in any fire, use a self-containedbreathing As in any fire, use a self-contained

apparatus. breathing apparatus.

Use water spray, dry chemical, Carbon Do not use water spray directly on the

dioxide or Chemical foam. fire. Use dry chemical, Carbon

dioxide or Chemical foam.

Storage Store in a dry cool place, protected from Store in large tanks as per flammable

light in tightly closed containers. liquid store as per Rules,away from

naked flame & hot elements and

ignition sources.

Hazards Stable flash point notavailable. Highly flammable, flashpoint

low.Electrostatic charge possible.

Incompatibility Avoid acids bases & strong oxidizing agents. Avoid contact with water, ammonia,

alkali metals, strong oxidizing agents

etc.

Hazardous decomposition Hazardous decomposition products. Carbon Hazardous decomposition products in

product monoxide, carbon dioxide, oxides of the event of fire.

nitrogen.

Carcinogenetic Not classified as a human carcinogen. Not reported in OSHA disposal

Disposal Dispose in a manner according to state & Dispose in a manner according to

federal laws. State and Federal laws

Risk Assessment Report- 20-

M/s. RL FineChem Pvt. Ltd.,

Name of the product 3)HCl GAS 4)Dothiepine HCL(FG)

Chemical name Hydrogen chloride 3-Dibenzo [b,e]thiepin-11(6H)-

ylidene-N,N-dimethyl-1-propanamine

hydrocloride

CAS NO: 7647-01-0 897-15-4

MW: 36.5 331.91

Physical appearance Colorless liquid,fuming with acid White crystalline solid.

Odour Characteristic Pungent , acidic

Melting point -- : 218-221°

Boiling point ----

Health hazards Irreversible effects if swallowed. Harmful if swallowed.

Danger of very serious effect on eye& May cause eye irritation.

harmful if absorbed through the skin. May be harmful if absorbed

Slow absorption. through the skin

Very serious effect on inhalation. May cause respiratory tract

irritation

Effects CNS.

First aid measure Eyes: rinse out plenty of water. Get Eyes: Flush eyes with plenty of

medical help immediately. Do not allow water. Get medical help

the victim to rub the eyes. Keep eyes Skin: Flush skin with plenty of

closed. water. Get medical aid.

Induce vomiting & make him drink Ingestion: Get medical aid.

ethanol. Inhalation: remove from exposure

Skin: Flush skin with plenty of water. Get &move to fresh air immediately

medical aid.

Ingestion: Get medical aid.

Inhalation: Remove from exposure and

move to fresh air immediately mouth to

mouth respiration if required.

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. breathing apparatus.

Do not use water spray directly on the fire. Use water spray, dry chemical,

Use dry chemical, Carbon dioxide or Carbon dioxide or Chemical foam.

Chemical foam.

Storage Store in large tanks as per flammable liquid Store in a dry cool place, protected

store as per Rules,away from naked fame & from light in tightly closed containers.

hot elements and ignition sources.

Hazards Highly flammable, flashpoint Stable.

11*C.Electrostatic charge possible.

Incompatibility Avoid contact with water, ammonia, alkali Avoid strong bases & oxidizing agents

metals, strong oxidizing agents etc. etc.

Hazardous decomposition Hazardous decomposition products in the Carbon monoxide, carbon dioxide,

product event of fire. oxides of nitrogen.

Carcinogeneticity Not reported in OSHA. Disposal Not reported

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 21-

M/s. RL FineChem Pvt. Ltd.,

7.2.5 Doxepin hydrochloride

Hazop Analysis - Process – for Doxepin hydrochloride product

Possible Hazards /

1st Stages Process Operation Remedial Action

failures

Operational control - checkpoint shall be included in the

Dissolution of HCL as in

Step -1 Charging of Acetone Bottom valve opened batch sheet to indicate whether the bottom valve has been

solvent acetone in GL reactor

closed prior to charging Acetone

Acetone addition pipe is bent towards the wall of the reactor

a) Charging of Fire hazard due to static so that the possibility of potential difference is avoided

Acetone electricity .vacuum sucking is done to avoid spillages.

Pipe lines are all SS and equipment motors are flame proof .

The gas is passed through the gas trap containing sulphuric

acid and empty trap to prevent back suck.

The dry gas coming out from the trap is connected to the dip

pipe of the GL Reactor which is dipped in the solvent.

b) Purging of HCL gas.

Irritant to eyes & skin The gas is passed till required sp. gravity and assay is

achieved.

The outlet of the reactor is connected to the scrubber where

alkali is circulated.

Using hand gloves & goggles.

Operational control - checkpoint shall be included in the

Reaction of Doxepin base with a) Charging of batch sheet to indicate whether the required pH has been

Step-2 Irritant to eyes & skin

acetone- HCL in GL Reactor dissolved base achieved.

Using hand gloves & goggles

The temperature is raised by slow heating till

Required temperature is achieved; good condenser to prevent

solvent loss by circulating chilled water in condenser. The

c) Heating the acidic fumes are scrubbed in alkali scrubber.

Escape of solvent & HCl

reaction mass In case of overheating and pressure development rupture disc

provided to the reactor will open up and the mass will come

out of the reactor and will be separately collected in the PP

vessel of 5000L which is kept outside the plant.

Risk Assessment Report- 22-

M/s. RL FineChem Pvt. Ltd.,

d) cooling the reaction Chilled water is circulated in the Jacket.

No specific hazard

mass

The centrifuge is earthed by conducting wires.

The filtration is carried out through a centrifuge;

Centrifuges are high speed machines and sources

of hazard in a chemical plant. Ample precautions

are taken to carry out the centrifuging as hazard

free as possible. We are using a 48 inch dia SS316

centrifuge, bottom driven and top discharge. this

is a four point suspension machines which are put

Fire hazard due to static

To isolate the on special vibra mount for smooth vibration free

electricity, operator

Centrifuging to isolate the product Doxepin noiseless operation. The speed is controlled by a

hazard if any loading /

product. hydrochloride. variable frequency drive and the feeding of the

unloading activity carried

Separation of solid and liquid. centrifuge is done by valves at lower RPM under

out in a running

nitrogen purging. Even the bearing housing of the

centrifuge

centrifuge is provided with a nitrogen purging

facility. An interlocking system is provided for

ensuring that the lids cannot be opened while the

centrifuge is running and thereby preventing any

human hazard. All the limits switches and the

safety interlocking switches are flame proof

including the VFD controls

The MLR is taken for solvent recovery.

Charging of MLR All charging is done by vacuum sucking to avoid

Solvent recovery (MLR)in SS Haz waste after spillages and through the SS pipe lines.

Recovery No specific hazard Distilled to recover Acetone. Un distilled which

reactor distillation

is remaining at the bottom of the reactor is Haz

Waste.

Separation of solvents from Drying of the product No specific hazard

Drying operation FBD is fitted with flame proof motors.

the product in FBD Irritant to eyes & skin

Hand gloves & goggles should be used

Risk Assessment Report- 23-

M/s. RL FineChem Pvt. Ltd.,

SAFETY DATA

Name of the product 1) Doxepin base 2) Acetone

Chemical name 1-propylamine-3-dibenz(be)oxepine- Dimethyl ketone

11(6H)ylidine-NN-dimethyl base

CAS NO: 67-64-1

MW: 279.0 58.0

Physical appearance Pale yellow colored viscous liquid Colorless liquid.

Odour Amine like Mint fragrant.

Melting point -- --

Boiling point 180-190*C at 0.5mm 57*C

Health hazards Harmful if swallowed. Harmful if swallowed.

May cause eye irritation. May cause Vapours irritate eyes

corneal damage. Dryness of skin

May be harmful if absorbed through the Causes irritation to respiratory

skin. tract, causes headache & dizziness

May cause respiratory tract irritation.

First aid measure Eyes: Flush eyes with plenty of water. Eyes: rinse out plenty of water.

Get medical help Get medical help immediately. Do

Skin: Flush skin with plenty of water. Get not allow the victim to rub the

medical aid. eyes. Keep eyes closed.

Ingestion: Get medical aid. Drink lot of water .No milk risk of

Inhalation: remove from exposure &move aspiration on swallowing.get

to fresh air immediately. medical aid.

Skin: Flush skin with plenty of

water. Remove contaminated

cloth

Inhalation: Remove from

exposure and and move to

fresh air immediately mouth to

mouth respiration if required.

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. breathing apparatus.

Use water spray, dry chemical, Carbon Do not use water spray directly on the

dioxide or Chemical foam. fire. Use dry chemical, Carbon

dioxide or Chemical foam.

Storage Store in a dry cool place, protected from Store in large tanks as per flammable

light in tightly closed containers. liquid store. as per Rules ,away from

naked flame & hot elements and

ignition sources.

Hazards Stable flash point notavailable. Highly flammable, flashpoint

low.electrostatic charge possible.

Incompatibility Avoid acids bases & strong oxidizing agents. Avoid contact with water, ammonia,

alkali metals, strong oxidizing agents

etc.

Hazardous decomposition Hazardous decomposition products. Carbon Hazardous decomposition products in

product monoxide, carbon dioxide, oxides of the event of fire.

nitrogen.

Risk Assessment Report- 24-

M/s. RL FineChem Pvt. Ltd.,

Carcinogenetic Not classified as a human carcinogen.. Not reported in OSHA. Disposal

Disposal Dispose in a manner according to state & Dispose in a manner according to

federal laws. State and Federal laws

Name of the product 3) HCL ( gas) Doxepin hydrochloride (FG)

Chemical name Hydrogen chloride 1-propylamine-3-dibenz(be)oxepine-11(6H)ylidine-NN-

dimethyl hydrocloride

CAS NO: 7647-01-0 [1229-29-4]

MW: 36.5 315.8

Physical appearance Colorless liquid,fuming with acid White crystalline Solid.

Odour Characteristic Pungent acidic

Melting point -- Above 185-191 0 C

Boiling point 65*C -----

Health hazards Irreversible effects if swallowed. Harmful if swallowed.

Danger of very serious effect on eye& May cause eye irritation.

harmful if absorbed through the skin. May be harmful if absorbed through the skin

Slow absorption. May cause respiratory tract irritation.

Very serious effect on inhalation. Effects CNS.

First aid measure Eyes: rinse out plenty of water. Get Eyes: Flush eyes with plenty of water. Get medical

medical help immediately. Do not help

allow the victim to rub the eyes. Keep Skin: Flush skin with plenty of water. Get medical

eyes closed. aid.

Induce vomiting & make him drink Ingestion: Get medical aid.

ethanol . Inhalation: remove from exposure &move to fresh

Skin: Flush skin with plenty of water. air immediately

Get medical aid.

Ingestion: Get medical aid.

Inhalation: Remove from

exposure and move to fresh air

immediately; give mouth to mouth

respiration if required.

Fire fighting As in any fire, use a self-contained As in any fire, use a self-contained breathing

breathing apparatus. apparatus.

Do not use water spray directly on the Use water spray, dry chemical, Carbon dioxide or

fire. Use dry chemical, Carbon dioxide or Chemical foam.

Chemical foam.

Storage Store in large tanks as per flammable Store in a dry cool place, protected from light in tightly

liquid store as per Rules, away from naked closed containers with good

fame & hot elements and ignition sources.

Hazards Highly flammable, flashpoint Stable

11*C.Electrostatic charge possible.

Incompatibility Avoid contact with water, ammonia, Avoid base,strong oxidizing agents etc.

alkali metals, strong oxidizing agents etc.

Hazardous decomposition Hazardous decomposition products in the Carbon monoxide, carbon dioxide, oxides of nitrogen.

product event of fire.

Carcinogeneticity Not reported in OSHA Disposal Not reported

Disposal Dispose in a manner according to State and Dispose in a manner according to State and Federal laws

Federal laws

Risk Assessment Report- 25-

M/s. RL FineChem Pvt. Ltd.,

7.2.6 Flunarizine

Hazop Analysis - Process – for Flunarizine hydrochloride product

Possible Hazards /

1st Stages Process Operation Remedial Action

failures

Operational control - checkpoint shall be included in the batch

Dissolution of HCL as in

Step -1 Charging of Acetone Bottom valve opened sheet to indicate whether the bottom valve has been closed

solvent acetone in GLreactor

prior to charging Acetone.

Toluene addition pipe is bent towards the wall of the reactor

Fire hazard due to static so that the possibility of potential difference is avoided

a) Charging of Acetone

electricity .vacuum sucking is done to avoid spillages.

Pipe lines are all SS and equipment motors are flame proof.

The gas is passed through the gas trap containing sulphuric

acid and empty trap to prevent back suck.

The dry gas coming out from the trap is connected to the dip

pipe of the GL Reactor which is dipped in the solvent.

b) Purging of HCL gas.

Irritant to eyes & skin The gas is passed till required sp. gravity and assay is

achieved.

The outlet of the reactor is connected to the scrubber where

alkali is circulated.

Using hand gloves & goggles.

Reaction of flunarizine base Operational control - checkpoint shall be included in the batch

a) Charging of

Step-2 with acetone- HCL in Irritant to eyes & skin sheet to indicate whether the required pH has been achieved.

dissolved base

GLReactor Using hand gloves & goggles

The temperature is raised by slow heating till required

temperature is achieved; good condenser to prevent solvent

loss by circulating chilled water in condenser. The acidic

c) Heating the fumes are scrubbed in alkali scrubber.

Escape of solvent & HCl

reaction mass In case of overheating and pressure development rupture disc

provided to the reactor will open up and the mass will come

out of the reactor and will be separately collected in the PP

vessel of 5000L which is kept outside the plant.

Risk Assessment Report- 26-

M/s. RL FineChem Pvt. Ltd.,

d) cooling the Chilled water is circulated in the Jacket.

No specific hazard

reaction mass

The centrifuge is earthed by conducting wires.

The filtration is carried out through a

centrifuge, Centrifuges are high speed machines

and sources of hazard in a chemical plant.

Ample precautions are taken to carry out the

centrifuging as hazard free as possible. We are

using a 48 inch dia SS316 centrifuge, bottom

driven and top discharge. this is a four point

suspension machines which are put on special

Fire hazard due to static

To isolate the vibra mount for smooth vibration free noiseless

electricity, operator

Centrifuging to isolate the product Flunarizine operation. The speed is controlled by a variable

hazard if any loading /

product. Dihydrochloride. frequency drive and the feeding of the

unloading activity carried

Separation of solid and liquid. centrifuge is done by valves at lower RPM under

out in a running

nitrogen purging. Even the bearing housing of

centrifuge

the centrifuge is provided with a nitrogen

purging facility. An interlocking system is

provided for ensuring that the lids cannot be

opened while the centrifuge is running and

thereby preventing any human hazard. All the

limits switches and the safety interlocking

switches are flame proof including the VFD

controls

The MLR is taken for solvent recovery.

All charging is done by vacuum sucking to avoid

Charging of MLR

spillages and through the SS pipe lines.

Solvent recovery (MLR)in SS Haz waste after

Recovery No specific hazard Distilled to recover Acetone. Un distilled which

reactor distillation

is remaining at the bottom of the reactor is Haz

Waste.

Separation of solvents from Drying of the product No specific hazard FBD is fitted with flame proof motors.

Drying operation

the product in FBD Irritant to eyes & skin Hand gloves & goggles should be used

Risk Assessment Report- 27-

M/s. RL FineChem Pvt. Ltd.,

SAFETY DATA

Name of the product 1) Flunarizine base 2) Acetone

Chemical name 1-bis fluorophenyl methyl 4-cinamyl Dimethyl ketone

piperizine

CAS NO: 67-64-1

MW: 404 58.0

Physical appearance Pale yellow colored viscous liquid Colorless liquid.

Odour Amine like Mint fragrant.

Melting point -- --

Boiling point ~200*C at 0.5mm 57*C

Health hazards Harmful if swallowed. Harmful if swallowed.

May cause eye irritation. May cause Vapours irritate eyes

corneal damage. Dryness of skin

May be harmful if absorbed through the Causes irritation to respiratory

skin. tract, causes headache & dizziness

May cause respiratory tract irritation.

First aid measure Eyes: Flush eyes with plenty of water. Eyes: rinse out plenty of water.

Get medical help Get medical help immediately. Do

Skin: Flush skin with plenty of water. Get not allow the victim to rub the

medical aid. eyes. Keep eyes closed.

Ingestion: Get medical aid. Drink lot of water.No milk risk of

Inhalation: remove from exposure &move aspiration on swallowing.Get

to fresh air immediately. medical aid.

Skin: Flush skin with plenty of

water. Remove contaminated

cloth

Inhalation: Remove from exposure

and move to fresh air

immediately; give mouth to mouth

respiration if required.

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. breathing apparatus.

Use water spray, dry chemical, Carbon Do not use water spray directly on the

dioxide or Chemical foam. fire. Use dry chemical, Carbon

dioxide or Chemical foam.

Storage Store in a dry cool place, protected from Store in large tanks as per flammable

light in tightly closed containers. liquid store. as per Rules ,away from

naked flame & hot elements and

ignition sources.

Hazards Stable flash point notavailable. Highly flammable, flashpoint

low.Electrostatic charge possible.

Incompatibility Avoid acids bases & strong oxidizing agents. Avoid contact with water, ammonia,

alkali metals, strong oxidizing agents

etc.

Hazardous decomposition Hazardous decomposition products. Carbon Hazardous decomposition products in

product monoxide, carbon dioxide, oxides of the event of fire.

nitrogen.

Carcinogenetic Not classified as a human carcinogen. Not reported in OSHA disposal

Disposal Dispose in a manner according to state & Dispose in a manner according to

federal laws. State and Federal laws

Risk Assessment Report- 28-

M/s. RL FineChem Pvt. Ltd.,

Name of the product 3) HCL ( gas) 4)Flunarizine HCL(FG)

Chemical name Hydrogen chloride 1-bis fluorophenyl methyl 4-cinamyl

piperizine di hydochloride

CAS NO: 7647-01-0 30484-77-6

MW: 36.5 477.0

Physical appearance Colorless liquid,fuming with acid White colored solid

Odour Characteristic Pungent acidic, hygroscopic

Melting point -- ~208*C with decomposition

Boiling point 65*C -----

Health hazards Irreversible effects if swallowed. Harmful if swallowed.

Danger of very serious effect on eye& May cause eye irritation.

harmful if absorbed through the skin. May be harmful if absorbed

Slow absorption. through the skin

Very serious effect on inhalation. May cause respiratory tract

irritation

Effects CNS.

First aid measure Eyes: rinse out plenty of water. Get Eyes: Flush eyes with plenty of

medical help immediately. Do not allow water. Get medical help

the victim to rub the eyes. Keep eyes Skin: Flush skin with plenty of

closed. water. Get medical aid.

Induce vomiting & make him drink Ingestion: Get medical aid.

ethanol. Inhalation: remove from exposure

Skin: Flush skin with plenty of water. Get &move to fresh air immediately

medical aid.

Ingestion: Get medical aid.

Inhalation: Remove from exposure and

move to fresh air immediately; give

mouth to mouth respiration if required.

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. breathing apparatus.

Do not use water spray directly on the fire. Use water spray, dry chemical,

Use dry chemical, Carbon dioxide or Carbon dioxide or Chemical foam.

Chemical foam.

Storage Store in large tanks as per flammable liquid Store in a dry cool place, protected

store as per Rules,away from naked flame & from light in tightly closed containers

hot elements and ignition sources.

Hazards Highly flammable, flashpoint Stable.

11*C.Electrostatic charge possible.

Incompatibility Avoid contact with water, ammonia, alkali Avoid strong bases & oxidizing agents

metals, strong oxidizing agents etc. etc.

Hazardous decomposition Hazardous decomposition products in the Carbon monoxide, carbon dioxide,

product event of fire. oxides of nitrogen.

Carcinogeneticity Not reported in OSHA Disposal Not reported

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 29-

M/s. RL FineChem Pvt. Ltd.,

7.2.7 Nitrazepam

Hazop Analysis - Process – for Nitrazepam product

Possible Hazards /

1st Stages Process Operation Remedial Action

failures

Operational control - checkpoint shall be

Dissolution of Ammonia in Preparation of included in the batch sheet to indicate whether

Step -1 Bottom valve opened

solvent Methanol in SS reactor ammonia solution the bottom valve has been closed prior to

charging Methanol.

Methanol addition pipe is bent towards the wall

of the reactor so that the possibility of potential

a) Charging of Fire hazard due to static difference is avoided .vacuum sucking is done to

Methanol electricity avoid spillages.

Pipe lines are all SS and equipment motors are

flame proof.

Ammonia is slowly passed with cooling and

b) Purging of

checking the scrubber vent periodically for

Ammonia Ammonia escape

ammonia escape.

Ph paper test. No Ammonia should escape.

Reaction of nitro chloro

Step-2 Reaction

compound in SS Reactor

SS scoop is used to prevent static electricity while

a) charging of nitro

Irritant to eyes & skin charging the solid.

chloro benzophenone

Hand gloves & goggles should be used.

The temperature is raised by slow heating till

Required temperature is achieved; good

condenser to prevent solvent loss by circulating

chilled water in condenser.

b) Heating the Escape of solvent

In case of overheating and pressure development

reaction mass Ammonia escape

rupture disc provided to the reactor will open up

and the mass will come out of the reactor and will

be separately collected in the PP vessel of 5000L

which is kept outside the plant.

Risk Assessment Report- 30-

M/s. RL FineChem Pvt. Ltd.,

The centrifuge is earthed by conducting wires.

The filtration is carried out through a centrifuge,

Centrifuges are high speed machines and sources

of hazard in a chemical plant. Ample precautions

are taken to carry out the centrifuging as hazard

free as possible. We are using a 36 inch dia SS316

centrifuge, bottom driven and top discharge. this

is a four point suspension machines which are put

Fire hazard due to static on special vibra mount for smooth vibration free

electricity, operator noiseless operation. The speed is controlled by a

Centrifuging to remove the c) To remove the

hazard if any loading / variable frequency drive and the feeding of the

Byproduct. by product

unloading activity carried centrifuge is done by pneumatically controlled

Separation of solid and liquid. amm.chloride

out in a running valves at lower RPM under nitrogen purging. Even

centrifuge the bearing housing of the centrifuge is provided

with a nitrogen purging facility. An interlocking

system is provided for ensuring that the lids

cannot be opened while the centrifuge is running

and thereby preventing any human hazard. All

the limits switches and the safety interlocking

switches are flame proof including the VFD

controls. Collect the mother liquor for isolating

the product. This is sucked back to the SS reactor

for recovery & isolation.

Slow heating by passing steam in the jacket &

d) Distillation of Chilled water is circulated in the condenser.

Methanol from the Recover ~250L methanol (50%),cool to <15*C.

Isolation of nitrazepam No specific hazard

filtrate of the

reaction mass

Risk Assessment Report- 31-

M/s. RL FineChem Pvt. Ltd.,

The centrifuge is earthed by conducting wires.

The filtration is carried out through a centrifuge;

Centrifuges are high speed machines and sources

of hazard in a chemical plant. Ample precautions

are taken to carry out the centrifuging as hazard

free as possible. We are using a 48 inch dia SS316

centrifuge, bottom driven and top discharge. this

is a four point suspension machines which are put

Fire hazard due to static on special vibra mount for smooth vibration free

To isolate the electricity, operator noiseless operation. The speed is controlled by a

Centrifuging to isolate the

product Nitrazepam. hazard if any loading / variable frequency drive and the feeding of the

product.

unloading activity carried centrifuge is done by pneumatically controlled

Separation of solid and liquid.

out in a running valves at lower RPM under nitrogen purging. Even

centrifuge the bearing housing of the centrifuge is provided

with a nitrogen purging facility. An interlocking

system is provided for ensuring that the lids

cannot be opened while the centrifuge is running

and thereby preventing any human hazard. All

the limits switches and the safety interlocking

switches are flame proof including the VFD

controls

The MLR is taken for solvent recovery.

All charging is done by vacuum sucking to avoid

spillages and through the SS pipe lines.

Solvent recovery (MLR)in SS Charging of MLR Haz.

Recovery No specific hazard Distilled to recover Methanol. Un distilled which

reactor waste after distillation

is remaining at the bottom of the reactor is Haz

Waste.

FBD is fitted with flame proof motors.SS scoops

Separation of solvents from Drying of the product No specific hazard

Drying operation are employed while charging and unloading.

the product in FBD Irritant to eyes & skin

Hand gloves & goggles should be used

Risk Assessment Report- 32-

M/s. RL FineChem Pvt. Ltd.,

SAFETY DATA

Name of the product 1) Nitro chloro acetylamino 2) Methanol (RM)

Benzophenone.

Chemical name 5-Nitro-2-chloroacetylamino benzophenone Methyl alcohol

CAS NO: 67-56-1

MW: 318.0 32.0

Physical appearance Yellow colored amorphous powder Colorless liquid

Odour Pungent hygroscopic, strong acidic. Characteristic

Melting point 170-172*C --

Boiling point ---- 65*C

Health hazards Irreversible effects if swallowed. Irreversible effects if swallowed.

Danger of very serious effect on eye & Danger of very serious effect on

harmful if absorbed through the skin. eye & harmful if absorbed through

Slow absorption. the skin. Slow absorption.

Very serious effect on inhalation. Very serious effect on inhalation.

First aid measure Eyes: rinse out plenty of water. Get Eyes: rinse out plenty of water.

medical help immediately. Do not allow Get medical help immediately. Do

the victim to rub the eyes. Keep eyes not allow the victim to rub the

closed. eyes. Keep eyes closed.

Induce vomiting & make him drink Induce vomiting & make him drink

ethanol. ethanol.

Skin: Flush skin with plenty of water. Get Skin: Flush skin with plenty of

medical aid. water. Get medical aid.

Ingestion: Get medical aid. Ingestion: Get medical aid.

Inhalation: Remove from exposure and Inhalation: Remove from exposure

move to fresh air immediately; give and move to Fresh air

mouth to mouth respiration if required. immediately; give mouth to mouth

respiration if required.

Fire fighting As in any fire, use a self-contained breathing As in any fire, use a self-contained

apparatus. breathing apparatus.

Do not use water spray directly on the fire. Do not use water spray directly on the

Use dry chemical, Carbon dioxide or fire. Use dry chemical, Carbon

Chemical foam. dioxide or Chemical foam.

Storage Store in large tanks as per flammable liquid Store in large tanks as per flammable

store as per Rules,away from naked flame & liquid store as per Rules ,away from

hot elements and ignition sources. naked fame & hot elements and

ignition sources.

Hazards Highly flammable, flashpoint Highly flammable, flashpoint

11*C.Electrostatic charge possible. 11*C.Electrostatic charge possible.

Incompatibility Avoid contact with water, ammonia, alkali Avoid contact with water, ammonia,

metals, strong oxidizing agents etc. alkali metals, strong oxidizing agents

etc.

Hazardous decomposition Hazardous decomposition products in the Hazardous decomposition products in

product event of fire. the event of fire.

Carcinogenetic Not reported in OSHA. Disposal Not reported in OSHA. Disposal

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 33-

M/s. RL FineChem Pvt. Ltd.,

Name of the product 3) AMMMONIA 4) Nitrazepam(FG)

Chemical name Gas liquefied under pressure. * 1,3-Dihydro-7-Nitro-5-Phenyl-2h-

1,4-Benzodiazepin-2-One

CAS NO: 7664-41-7 146-22-5

MW: 17.0 281.3

Physical appearance Liquid, colorless Yellow crystalline powder, odourless

Odour Pungent odourless

Melting point -77.7*C 2240 C – 2260 C.

Boiling point -33.5* C

Health hazards Will cause eye burns. Risk of blindness. Harmful if swallowed.

Harmful if swallowed. May be harmful if May cause eye irritation.

absorbed through the skin cause skin May be harmful if absorbed

irritations. through the skin

May cedemass in the respiratory tract. May cause respiratory tract

irritation. And effect Central

nervous system

First aid measure Eyes: rinse with plenty of water for at Eyes: Flush eyes with plenty of

least 10 mts & Get medical help water. Get medical help

immediately. Do not allow the victim to Skin: Flush skin with plenty of

rub the eyes. Keep eyes closed. water. Get medical aid.

If swallowed drink lot of water & induce Ingestion: Get medical aid.

vomiting. Call doctor. Inhalation: remove from exposure

Skin: Flush skin with plenty of water. Dab &move to fresh air immediately

with PEG 400 remove contaminated

clothing.

Inhalation: Remove from exposure

and move to fresh air immediately.

Calldoctor

Fire fighting As in any fire, use a self-contained breathing As in any fir, use a self-contained

apparatus. Not combustible. breathing apparatus.

Do not use water. Use dry chemical, Carbon Use water spray, dry chemical,

dioxide or Chemical foam. Carbon dioxide or Chemical foam.

Storage Store in a dry cool place, protected from Store in a dry cool place, protected

light in tightly closed containers. from light in tightly closed containers

with good

Hazards Not reported. Stable

Incompatibility Incompatible with various metals. Avoid strong oxidizing agents et.

Hazardous decomposition Nitrogen oxides generate. In event of fire. Carbon monoxide, carbon dioxide,

product Nitrogen oxide

Carcinogenetic Not reported. Not reported

Disposal Dispose in a manner according to State and Dispose in a manner according to

Federal laws State and Federal laws

Risk Assessment Report- 34-

M/s. RL FineChem Pvt. Ltd.,

7.3 SAFETY PRECAUTIONS FOR THE HANDLING OF HYDROGEN GAS AND CARBON

The following are the safety precautions adopted while handling hydrogen gas &carbon

1. It is ensured that all the equipments have earthing and bondings.

2. It is ensured that the mechanical seal pressure is +2.0 kg/cm2 with operating pressure.

3. Care is taken to see that there are no leackages in the mechanical seal.

4. Cleanliness of autoclave reactor and it is surroundings is maintained.

5. Before charging pressure test of autoclave is taken; only if it is ok proceed further otherwise leak

should be rectified.

6. Hydrogen lines and availability of required cylinders near header is ensured.

7. All the cylinders are tied with chain and it is ensured that there are no leackages in the manifold.

8. All the gauges are calibrated.

9. Presence of water in autoclave vent receiver is ensured.

10. Availability of suitable rupture disc & its connection to the dump vessel is ensured.

11. Use the necessary PPE’s before batch charging i.e., 3M cartridge mask, safety goggles, safety helmets,

safety shoes & safety gloves.

12. Availability of fire fighting equipments nearby is ensured.

13. ERT (Emergency Response Team) is available in case of emergency.

14. Hydrogen Gas detector is on.

15. 50% Pd/C making slurry with suitable solvent under nitrogen blanketing with proper earthing by

holding the vacuum into the receiver.

16. Vacuum is released with nitrogen pressure only through vent line.

17. Hydrogen gas 0.2 kg/cm2 is slowly applied and flushed out. The process is repeated once again.