Professional Documents

Culture Documents

Temperature Measuring Device

Temperature Measuring Device

Uploaded by

NicoleAmparoGarcia0 ratings0% found this document useful (0 votes)

3 views8 pagesOriginal Title

TEMPERATURE MEASURING DEVICE

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views8 pagesTemperature Measuring Device

Temperature Measuring Device

Uploaded by

NicoleAmparoGarciaCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

TEMPERATURE MEASURING DEVICE

INSTRUMENT PICTURE OR HOW IT WORKS APPLICATIONS TYPES RANGE

DIAGRAM

Thermometers typically Thermometers are There are different Liquid-in-Glass

THERMOMETER consist of a tiny glass tube used in a wide range of types of • -38.9 oC

that is hollow. The tube has field because they can thermometers to 356.7

a bulb at the bottom, accurately measure available, each o

C

containing a liquid like temperature. Some designed for Mercury

alcohol or mercury. As the typical uses are: specific uses. Let's • 32 oC to

temperature rises, the • Medical Use take a look at some 357 oC

liquid in the bulb expands, • Food Industry commonly used Digital

rising up the tube. On the • Laboratory thermometers: • -40 oC to

other hand, a drop in • Mercury 50 oC

temperature causes the • Liquid-in-

liquid to contract, moving Glass

back down the tube. • Digital

Filled bulb In industrial Filled Bulb

FILLED BULB Bulb-filled systems utilize thermometers are applications, there Systems

fluid expansion to commonly found in are essentially four • -125 0 F to

SYTEM determine temperature. different industries different types of 1200 oF

When a fluid is trapped in a like meteorology, filled bulb

closed system and heated, healthcare, food temperature Class I

the molecules within the processing, and sensors being • -125 F to

fluid will apply more scientific research. But utilized. 600 F

pressure on the container they might not work • Liquid filled Class II

walls. By gauging this well in very high or low system • -40 F to

pressure, or by enabling temperatures, or in • Vapor filled 32 F or 32

the fluid to expand at a places where the system F to 600 F

constant pressure, we can temperature changes • Gas filled Class III

deduce the temperature of quickly. system • -450 F to

the fluid. • Mercury 1400 F

filled system Class IV

• -40 F to

1200 F

BIMETALLIC The bimetallic strip is Bimetal thermometers

known for being a reliable are used in many There are two types A range of

and long-lasting different industrial of bimetallic 100to 1000°F

thermometer. It's basically applications: thermometers: (−73 to537°C)

two metal strips joined • machine

together and anchored at • building • helix strip

one end. As they heat up, • heating bimetallic

the strips expand at technology thermometer

different speeds, causing • air conditioning • spiral strip

them to bend and provide a • refrigeration bimetallic

temperature reading. technology thermometer

• fire alarms

Phase-change or bi-state Phase-change or bi- There are the types A wide range of

PHASE CHANGE thermometers operate by state thermometers of Bi- state: temperatures

OR BI-STATE utilizing the concept of a are widely used. They • Phase- from 100 to

substance shifting have a range of Change 3000 oF (38 to

between two separate practical applications. Material 1650 oF)

phases in response to Here are a few • Wax-Filled

alterations in temperature. examples: • Vapor-

These thermometers are • Home pressure

commonly known as Thermometer • Liquid Crystal

phase-change or bi-state • Food Safety

thermometers since they • Educational

employ the transition Tools

between liquid and solid • Industrial

phases of a substance to Monitoring

indicate temperature

variations. Liquid crystal

thermometers and phase-

change materials

thermometers are the

most prevalent examples

of phase-change

thermometers.

A thermocouple is made of Principle of Type T

two metal wires connected Thermocouple are Operation -300 to 700 F

THERMOCOUPLE used in many different

at one end (hot end) and • Peltier Effect Type J

the voltage is measured at industrial applications: • Thompson 32 to 1400 F

the other end (cold • Industrial Effect Type E

junction). The voltage, Process Control • Seeback 32 to 1600 F

known as Seebeck voltage, • HVAC Systems effect Type K

is affected by temperature • Power Three 32 to 2300 F

difference and metal Generation Thermocouple Type S

coefficients. • Automotive junction 32 to 2700 F

Industry • Grounded Type B

• Medical Devices Junction 32 to 3380 F

• Food Industry • Ungrounded

Junction

• Exposed

Junction

RTD are used in many The most common Temperature

RTD RTDs work on a basic different industrial RTD types are: Range (-250 C

correlation applications: • platinum to 1000 C)

between metals and • Aerospace and • nickel

temperature. As the Aviation • copper

temperature of a metal • Energy

increases, the metal's Generation

resistance to the flow of • Environmental

electricity increases. Monitoring

• Food Industry

Thermistor are used in Thermistors are Temperature Range

The thermistor is a resistor many different available in two types: (-55 C to 150 C)

THERMISTOR that changes resistance industrial • Negative

predictably with Temperature

applications: Coefficients

temperature. It has a large • Overcurrent (NTC

resistance change per Protection Thermistors)

degree, making it great for • Temperature • Positive

precise measurements in a Condensation Temperature

limited range. Its high Coefficients

• Environmental (PTC

resistance minimizes errors Monitoring Thermistors).

from lead wires. • Liquid Level

Sensing

THERMOPILE Temperature

Thermopile sensors are Various types of Types of range (25 C to

thermal sensors that use application of Thermopiles: 100 C)

the Seebeck effect to Thermopiles: • Thin-Film

produce a thermal • Temperature • MEMS

electromotive force based measurement • Pyroelectric

on the amount of infrared • human body • Single point

light they receive. Unlike sensing

other detectors, • gas analysis

thermopile sensors are not

affected by different

wavelengths of light.

They are non-contact Pyrometer are used Pyrometers are used to

temperature sensors that in: mainly measure

PYROMETER measure temperature • Steel And Metal divided to two temperature

from the Industry types: above 1500

amount of thermal • Automative a.) Radiation degree Celsius,

electromagnetic radiation Manufacturing Pyrometers contact

received from a • Glass and b.) Optical devices may

spot on the object of ceramics Pyrometers melt at this

measurement. Production temperature.

• Power

Generation

You might also like

- Lec 9+10Document76 pagesLec 9+10Ahsan HameedNo ratings yet

- Temperature Measurement Presentation FinDocument49 pagesTemperature Measurement Presentation Fintarikayehu amanuelNo ratings yet

- Temperature Measurement: Group 1Document101 pagesTemperature Measurement: Group 1Anonymous udJfQxX1rNo ratings yet

- Temperature Measurement: Prepared By: DbaDocument63 pagesTemperature Measurement: Prepared By: DbaJohn Russell GarciaNo ratings yet

- IPC CH 4A Temperature MeasurementDocument57 pagesIPC CH 4A Temperature Measurementyashy4032No ratings yet

- Thermocouples: Using Thermocouples in Temperature MeasurementDocument4 pagesThermocouples: Using Thermocouples in Temperature MeasurementAnkit KumarNo ratings yet

- 1 5 PDFDocument359 pages1 5 PDFZenobia Joy VillarbaNo ratings yet

- Basic Sensor Principles (Temperature)Document30 pagesBasic Sensor Principles (Temperature)Hui QingNo ratings yet

- 2.2 Filled System or Pressure Spring ThermometersDocument20 pages2.2 Filled System or Pressure Spring ThermometersxxyzNo ratings yet

- Temperature Measurement PDFDocument136 pagesTemperature Measurement PDFGaming User100% (2)

- 2 car sensors v1-temperature (翻譯)Document35 pages2 car sensors v1-temperature (翻譯)WNo ratings yet

- Lecture 4Document55 pagesLecture 4Alhaj MassoudNo ratings yet

- Temperature MeasurementDocument35 pagesTemperature MeasurementNikunj YagnikNo ratings yet

- Temperature and HeatDocument20 pagesTemperature and HeatMer ryNo ratings yet

- What Is A Thermocouple Sensor?: Room-Temperature Insulation Resistance Ungrounded ThermocoupleDocument3 pagesWhat Is A Thermocouple Sensor?: Room-Temperature Insulation Resistance Ungrounded ThermocoupletbmariNo ratings yet

- TemperaturesDocument23 pagesTemperaturesanwar9602020No ratings yet

- Heat and TemperatureDocument25 pagesHeat and Temperaturekoromamoses235No ratings yet

- Thermo Scientific HAAKE RheoStress 6000 Accessories BrochureDocument30 pagesThermo Scientific HAAKE RheoStress 6000 Accessories BrochureQuế NghiNo ratings yet

- Chapter4 9 TemperatureMeasurementDocument25 pagesChapter4 9 TemperatureMeasurementMitul ShahNo ratings yet

- Temperature MeasurementDocument50 pagesTemperature MeasurementAkpevweoghene Kelvin IdogunNo ratings yet

- Week 3 Reporting - ABRINA, ADONA, BERNABE PDFDocument47 pagesWeek 3 Reporting - ABRINA, ADONA, BERNABE PDFVenrick CamposNo ratings yet

- SSC Unit - I Lecture 2Document29 pagesSSC Unit - I Lecture 2Girish Shankar MishraNo ratings yet

- Heat Exchangers 2016-2017Document52 pagesHeat Exchangers 2016-2017Alif Rizki BastoniNo ratings yet

- Heat PipesDocument25 pagesHeat PipessssNo ratings yet

- TemperatureDocument51 pagesTemperaturekartheek viswanathNo ratings yet

- CH 11 - Temperature ControlDocument84 pagesCH 11 - Temperature ControlOSAMA BIN NAVEDNo ratings yet

- For Haake Rheostress 6000Document29 pagesFor Haake Rheostress 6000Biotec Biolog BiologNo ratings yet

- Physics: Senior Secondary School: SecondDocument53 pagesPhysics: Senior Secondary School: SecondHASSAN OLUMIDENo ratings yet

- Heat Treatment of Pressure VesselsDocument31 pagesHeat Treatment of Pressure VesselsAkeel Aijaz Malik100% (1)

- Thermometry PDFDocument49 pagesThermometry PDFYe YeoNo ratings yet

- Mini Project ReportDocument14 pagesMini Project ReportfatinNo ratings yet

- Temperature SensorsDocument10 pagesTemperature Sensorsdevashish.jo11No ratings yet

- Temperature MeasurementDocument26 pagesTemperature MeasurementaqhammamNo ratings yet

- Process Instrumentation of TemperatureDocument58 pagesProcess Instrumentation of TemperatureVIGNESHWARAN.SNo ratings yet

- Lecture24 - Temp MeasurmentDocument29 pagesLecture24 - Temp MeasurmentYatharth YatharthNo ratings yet

- Electric HeatingDocument13 pagesElectric HeatingSarala NandanNo ratings yet

- Utilization of Electric Power: Module 02: Electric Heating Lec 02: Resistance Heating, Resistance FurnaceDocument11 pagesUtilization of Electric Power: Module 02: Electric Heating Lec 02: Resistance Heating, Resistance FurnaceAbhishek SharmaNo ratings yet

- Electric Heating and WeldingDocument84 pagesElectric Heating and WeldingReddy Sekhar75% (16)

- Thermocouples: Prepared By: K Krishna Kishore 4 Year ECE 15F41A0440 Presented To: Mr. S. Nanda Kishore (PH.D.)Document17 pagesThermocouples: Prepared By: K Krishna Kishore 4 Year ECE 15F41A0440 Presented To: Mr. S. Nanda Kishore (PH.D.)k kNo ratings yet

- Temperature MeasurementPpt2Document30 pagesTemperature MeasurementPpt2harishcsharmaNo ratings yet

- Catalogo Caldera Aceite Termico FT-C FultonDocument16 pagesCatalogo Caldera Aceite Termico FT-C FultonELTIPAZONo ratings yet

- Experiment: - 1: AIM: To Calibrate and Measure Temperature Using Thermocouple. 1. ThermocoupleDocument59 pagesExperiment: - 1: AIM: To Calibrate and Measure Temperature Using Thermocouple. 1. Thermocouplejasmin rachhadiyaNo ratings yet

- ThermometersDocument7 pagesThermometersChinthaka WeerasingheNo ratings yet

- Accessories For HAAKE MARS v1 3Document35 pagesAccessories For HAAKE MARS v1 3Sư PhápNo ratings yet

- PHYSICSDocument53 pagesPHYSICSAliyu Lawal KofaNo ratings yet

- Post Weld Heat TreatmentDocument71 pagesPost Weld Heat TreatmentaamirapiNo ratings yet

- TC DatasheetDocument6 pagesTC DatasheetEnrique AntonioNo ratings yet

- 9 Temperature OrigDocument49 pages9 Temperature Origrodel.verzosaNo ratings yet

- Temperature MeasurementDocument28 pagesTemperature Measurementritikshariya47No ratings yet

- TFS Assets LED Brochures LED FurnacesBrochure BRFURNACE0316 enDocument19 pagesTFS Assets LED Brochures LED FurnacesBrochure BRFURNACE0316 enBIANCA SALGADONo ratings yet

- SS2 First Term Lesson NoteDocument58 pagesSS2 First Term Lesson Noteojo ayodeji johnsonNo ratings yet

- Temperature-Measurements-01 IIT RoorkeeDocument47 pagesTemperature-Measurements-01 IIT RoorkeeBHAVESH JAINNo ratings yet

- Heat Treatment of Pressure VesselsDocument14 pagesHeat Treatment of Pressure VesselsAkeel Aijaz Malik100% (1)

- Report On Thermometers-CalambaDocument6 pagesReport On Thermometers-CalambaJessa Sumaylo CalambaNo ratings yet

- Two Units Notes.Document58 pagesTwo Units Notes.Priyan VpNo ratings yet

- Thermographic Testing PresentationDocument40 pagesThermographic Testing PresentationChandraSathwickNo ratings yet

- Physics Lesson Notes On Heat and TemperatureDocument6 pagesPhysics Lesson Notes On Heat and TemperatureRoland TchanaNo ratings yet

- Mechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesFrom EverandMechanics of the Household: A Course of Study Devoted to Domestic Machinery and Household Mechanical AppliancesNo ratings yet

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsFrom EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsRating: 5 out of 5 stars5/5 (1)

- Liquid Helium Technology: Proceedings of the International Institute of Refrigeration Commission 1, Boulder (U.S.A.) 1966From EverandLiquid Helium Technology: Proceedings of the International Institute of Refrigeration Commission 1, Boulder (U.S.A.) 1966No ratings yet

- Final Control ElementDocument36 pagesFinal Control ElementNicoleAmparoGarciaNo ratings yet

- Fundamentals of InstrumenatationDocument12 pagesFundamentals of InstrumenatationNicoleAmparoGarciaNo ratings yet

- Activity Sheet - ResumeDocument1 pageActivity Sheet - ResumeNicoleAmparoGarciaNo ratings yet

- Pressure MeasurementsDocument42 pagesPressure MeasurementsNicoleAmparoGarciaNo ratings yet

- Cover PageDocument1 pageCover PageNicoleAmparoGarciaNo ratings yet

- Z TableDocument1 pageZ TableNicoleAmparoGarciaNo ratings yet

- FundaDocument10 pagesFundaNicoleAmparoGarciaNo ratings yet

- Belga Cem 2012Document6 pagesBelga Cem 2012بلال بن عميرهNo ratings yet

- Electromagnetism 2 Study Exit Exam - 2023Document10 pagesElectromagnetism 2 Study Exit Exam - 2023Esubalew Molla100% (1)

- Experiment 3: Study of Powder Compaction BehaviourDocument17 pagesExperiment 3: Study of Powder Compaction BehaviourBhavika TambiNo ratings yet

- A New Approach To Arc Resistance CalculationDocument7 pagesA New Approach To Arc Resistance Calculationautomation vguardNo ratings yet

- Underground Cable Fault Distance Locator: © MAY 2021 - IRE Journals - Volume 4 Issue 11 - ISSN: 2456-8880Document5 pagesUnderground Cable Fault Distance Locator: © MAY 2021 - IRE Journals - Volume 4 Issue 11 - ISSN: 2456-8880Cristian GalvezNo ratings yet

- 17.3: Applications of Second-Order Differential Equations: Simple Harmonic MotionDocument18 pages17.3: Applications of Second-Order Differential Equations: Simple Harmonic MotionNurNo ratings yet

- Physics Mid-Sem CompilationDocument220 pagesPhysics Mid-Sem Compilationdhruv goraiNo ratings yet

- 1586 - Part 3 - 2012 - ROCKWELLDocument16 pages1586 - Part 3 - 2012 - ROCKWELLSouvik MaityNo ratings yet

- Assignment-4 Umar IqbalDocument12 pagesAssignment-4 Umar IqbalAyush DubeyNo ratings yet

- LM一80认证PCT3030 TH LM-80 S-F3-10-THIDocument19 pagesLM一80认证PCT3030 TH LM-80 S-F3-10-THIsoufianeNo ratings yet

- Linear Momentum and CollisionsDocument7 pagesLinear Momentum and CollisionsFaris AlasmariNo ratings yet

- 2.1 Distance Protection Testing - WYUDocument25 pages2.1 Distance Protection Testing - WYU劉簡No ratings yet

- 2018 JC2 H2 Physics SA2 Temasek Junior CollegeDocument8 pages2018 JC2 H2 Physics SA2 Temasek Junior CollegeaarnaNo ratings yet

- Grade 9 Physics of MLC PHARODocument9 pagesGrade 9 Physics of MLC PHAROKeol AkumaNo ratings yet

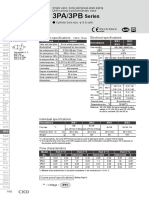

- 3PA - 3PB Series Specifications・How to Order・Dimensions (0.6MB)Document18 pages3PA - 3PB Series Specifications・How to Order・Dimensions (0.6MB)Fasta DriveNo ratings yet

- Echodis PB EN 09-12Document2 pagesEchodis PB EN 09-12Dwitha MeydinaNo ratings yet

- Genius by Pradeep Kshetrapal: Roblems Based On PressureDocument10 pagesGenius by Pradeep Kshetrapal: Roblems Based On PressureBanty SamantasingharNo ratings yet

- Module6 Fluid MechanicsDocument23 pagesModule6 Fluid MechanicsPaolo Martinez PHNo ratings yet

- E 617 Â " 97 - RTYXNY05NWDocument7 pagesE 617 Â " 97 - RTYXNY05NWhans ccNo ratings yet

- Instruction: ManualDocument20 pagesInstruction: ManualSiln BarNo ratings yet

- AMI UNIT III Presentation 2 01.09.2020Document18 pagesAMI UNIT III Presentation 2 01.09.2020Jayashree SathiyanarayananNo ratings yet

- M06 ElectricityDocument73 pagesM06 ElectricityAhmedNo ratings yet

- Design Report: HAWT Graduation ProjectDocument30 pagesDesign Report: HAWT Graduation ProjectMohamed MedhatNo ratings yet

- B&K Model 290 ManualDocument26 pagesB&K Model 290 ManualRadio TraderNo ratings yet

- Manipulator Dynamics: Amirkabir University of Technology Computer Engineering & Information Technology DepartmentDocument44 pagesManipulator Dynamics: Amirkabir University of Technology Computer Engineering & Information Technology DepartmentWajdi SadiqNo ratings yet

- ACTIVITY #1 SymbolsDocument5 pagesACTIVITY #1 Symbolskenneth jade orocayNo ratings yet

- HFRR BrochureDocument4 pagesHFRR BrochureScribd120307887No ratings yet

- University of Cebu Metc: Sto Competency 1 Assessment Questionnaire For Validation DeckDocument7 pagesUniversity of Cebu Metc: Sto Competency 1 Assessment Questionnaire For Validation DeckJuz Tobit EnanoriaNo ratings yet

- Fluid Dynamics (ADV) QPDocument11 pagesFluid Dynamics (ADV) QPAtharva Sheersh PandeyNo ratings yet

- Supercoductivity, Its Type and ApplicationsDocument8 pagesSupercoductivity, Its Type and ApplicationsRahul YadavNo ratings yet