Professional Documents

Culture Documents

Test Plan 3340f370g

Test Plan 3340f370g

Uploaded by

MilanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Test Plan 3340f370g

Test Plan 3340f370g

Uploaded by

MilanCopyright:

Available Formats

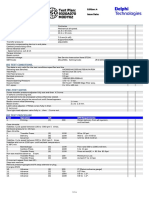

Test Plan: 3340370

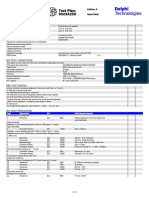

Applic: Perkins Vista A 86HP 2200 R Shut-off - (C) 400 De-energise solenoid, wait 5 seconds.

Issue No: 2 Solenoid Max. 3.0 mm3/st.

Date: 00/00/00 Stop test machine.

Pumps covered: 3340F370G 3340F371G 14. Delivery (C) 100 Minimum 55.0 mm3/st.

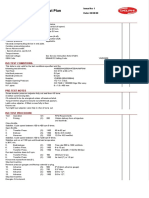

15. Timing S/C Outlet 'U ', Pressure 55 bar

Indexing tool at 114.0°, Scribe line.

PUMP SPECIFICATION. Depressurise. Rotate drive 168.0° to

Rotation: Clockwise. pos'n 282.0°. Slide washer and torque

Gov. Link Length: 53.5 ± 0.2 mm. shaft locking screw to 17.0 Nm.

Governor spring position : 5. PRE-OVERCHECK NOTES

Plunger Diameter: 8.5 mm (2 off). .

Drive Type: Uprated with supported shaft. The Overcheck section of this plan has been developed in

Advance Type: Fixed Phase. conjunction with the Original Equipment Manufacturer.

Adjusting plate max. fuel delivery control. Providing all values are achieved, the pump settings will

Solenoid voltage: See Service Instruction Note DT294 maintain the original homologated engine performance. Failure to

OEM Code: 2644H046 Setting Code: EU/5/2360 attain any one of the values will indicate a pump setting or

function failure and require further investigation.

.

ISO TEST CONDITIONS. No adjustments to be made unless otherwise stated.

This data is only valid for the test conditions specified and the .

following test benches: HA3000/HA2500/HA700/AVM/PGM ISO OVERCHECK PROCEDURE

Test Fluid: ISO 4113 at 40 ± 2°C. 16. Timing S/C For validation:

Inlet feed pressure: 0.3 bar Indexing tool set to 282 ± 0.5°

Nozzles: BDL0S6844 (YDB286) 17. Priming (C) 200 Obtain delivery from all injectors

Nozzle Opening Pressure: 172 + 3 - 0 bar. and backleak.

Nozzle Holder: ISO 7440 + YDB288 Edge filter assy. 18. Shut-off - (C) 400 De-energise solenoid, wait 5 seconds.

H.P. pipes: 6 x 1.8 x 450 mm Solenoid Max. 3.0 mm3/st.

Stop test machine.

19. Delivery (C) 100 Minimum 50.0 mm3/st.

PRE-TEST NOTES 20. Stabilisation (C) 1100 Run pump for 3 minutes to stabilise.

Lock throttle lever in the fully open position. 21. Delivery (C) 1100 72.7 to 76.7 mm3/st.

22. Delivery (C) 1255 Maximum 4.0 mm3/st.

ISO TEST PROCEDURE

1. Priming (C) 200 Obtain delivery from all injectors

and backleak.

2. Stabilisation (C) 1100 Run pump for 3 minutes to stabilise.

3. Transfer Press. (C) 100 Minimum 0.7 bar, ( 10psi).

4. Transfer Press. (S) 1100 5.52 to 5.79 bar( 80 to 84 psi)

5. Cambox Press. (C) 1100 0.06 to 0.27 bar( 1 to 4psi)

6. Delivery (S) 1100 74.7 ± 0.5 mm3/st.

Stop test machine.

Remove pressure gauges and fit stop solenoid or plug.

7. Delivery (C) 1100 As test ( 6) ± 0.5 mm3/st.

8. Governor (S) 1180 12.0 to 16.0 mm3/st.

9. Gov. cut-off (C) 1255 Maximum 2.0 mm3/st.

10. Delivery (C) 1100 As test ( 7) ± 0.5 mm3/st.

Move throttle lever to closed position.

11. Delivery (C) 400 Maximum 3.0 mm3/st.

12. Idle delivery (S) 400 12.0 to 16.0 mm3/st. Throttle closed.

Open throttle.

13.

You might also like

- NVH Ford PDFDocument188 pagesNVH Ford PDFReshma Mohamed71% (7)

- w202 - Wiring Diagram - ME-SFI Fuel Injection and Ignition SystemDocument5 pagesw202 - Wiring Diagram - ME-SFI Fuel Injection and Ignition Systemحجت زارع100% (2)

- Soil C and Phi ValuesDocument3 pagesSoil C and Phi ValuesthamiradNo ratings yet

- 3239F592TDocument2 pages3239F592TAnderson London67% (3)

- Test Plan Delphi TechnologiesDocument2 pagesTest Plan Delphi TechnologiesFRANCISCONo ratings yet

- Zoomlion Mobile Crane RT75 Operation ManualDocument178 pagesZoomlion Mobile Crane RT75 Operation Manualmonsieur_sonNo ratings yet

- 8520A060A TestplanDocument2 pages8520A060A TestplanBaytolga can100% (1)

- Test Plan: 9320A210: Pump Specification Iso Test ProcedureDocument3 pagesTest Plan: 9320A210: Pump Specification Iso Test ProcedureBaytolga100% (1)

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- 9521A030H DATA CatalogDocument3 pages9521A030H DATA CatalogLIONN SOFTWARES100% (1)

- Test Plan: 9320A070 MODY02: Pump SpecificationDocument7 pagesTest Plan: 9320A070 MODY02: Pump SpecificationUserfabian215No ratings yet

- 9320a217 TabelaDocument4 pages9320a217 TabelaLIONN SOFTWARESNo ratings yet

- 9320a217 TabelaDocument4 pages9320a217 TabelaLIONN SOFTWARESNo ratings yet

- 3042f843 Plano de TesteDocument1 page3042f843 Plano de TesteJose Alexandre Sunhega100% (1)

- 9320a075g Test DataDocument4 pages9320a075g Test DataPedro AbellanNo ratings yet

- Boiler MaintenanceDocument144 pagesBoiler Maintenanceaziz100% (2)

- Test Plan: Pump SpecificationDocument4 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Injection Pump Specification ©Document4 pagesInjection Pump Specification ©LIONN SOFTWARESNo ratings yet

- 013 NDT-UT TSE API 1104 - Rev 00-2-21Document21 pages013 NDT-UT TSE API 1104 - Rev 00-2-21zainalNo ratings yet

- 9323A271G CatalogDocument8 pages9323A271G CatalogLIONN SOFTWARESNo ratings yet

- Test Plan: Pump SpecificationDocument3 pagesTest Plan: Pump SpecificationBaytolgaNo ratings yet

- Test Plan: 8923A050: Pump SpecificationDocument2 pagesTest Plan: 8923A050: Pump Specificationveshat100% (1)

- 3340F401G Plano de Teste DelphiDocument2 pages3340F401G Plano de Teste DelphiJunior Iung100% (1)

- Bomba Dpa 3340f371g - TesteDocument2 pagesBomba Dpa 3340f371g - TesteOseasJuniorNo ratings yet

- Bha Coil Tubing Tools PDFDocument35 pagesBha Coil Tubing Tools PDFJose Leonardo Materano Perozo100% (2)

- Handbook of Comparative World Steel StandardsDocument1 pageHandbook of Comparative World Steel StandardsAhmed GomaaNo ratings yet

- Test Plan: 3443890: Pump SpecificationDocument2 pagesTest Plan: 3443890: Pump SpecificationLTurboNo ratings yet

- Honeywell S8600HDocument29 pagesHoneywell S8600HmariopilarNo ratings yet

- 3349F330Document2 pages3349F330marco rod100% (1)

- 9323a251g PTDocument3 pages9323a251g PTClarice Alves de FreitasNo ratings yet

- Test Plan: 9521A030: Pump SpecificationDocument3 pagesTest Plan: 9521A030: Pump Specificationjohnny sabinNo ratings yet

- 9320a225g Plano LHDocument3 pages9320a225g Plano LHForteLubNo ratings yet

- Ariel Application ManualDocument126 pagesAriel Application ManualnizarcecgmailNo ratings yet

- 9320A093GDocument4 pages9320A093GKevin TtitoNo ratings yet

- Test Plan: 9320A530: Pump SpecificationDocument4 pagesTest Plan: 9320A530: Pump SpecificationVyacheslav ShatalovNo ratings yet

- Test Plan: 3349330: Pump SpecificationDocument2 pagesTest Plan: 3349330: Pump SpecificationLIONN SOFTWARESNo ratings yet

- Testplan 3239590Document2 pagesTestplan 3239590Fx_2050% (1)

- 3230f582T PTDocument2 pages3230f582T PTHeitor Gael Alves de FreitasNo ratings yet

- 8961A020WDocument2 pages8961A020WLTurboNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- 3340F322 Lionn Auto SoftwaresDocument2 pages3340F322 Lionn Auto SoftwaresLIONN ONESOLUTIONNo ratings yet

- Test Plan 8523a320Document2 pagesTest Plan 8523a320taniaNo ratings yet

- Test Plan: Pump SpecificationDocument2 pagesTest Plan: Pump SpecificationClarice Alves de FreitasNo ratings yet

- Testplan 3238360Document1 pageTestplan 3238360Fx_205No ratings yet

- 8921A091WDocument2 pages8921A091WLTurboNo ratings yet

- 3662F871 TablaDocument1 page3662F871 TablaLIONN SOFTWARESNo ratings yet

- 823A593T DATA CatalogDocument2 pages823A593T DATA CatalogMilanNo ratings yet

- 3249F532 TabelaDocument1 page3249F532 TabelaLIONN SOFTWARESNo ratings yet

- 9320A380 TestDocument4 pages9320A380 TestVyacheslav ShatalovNo ratings yet

- 3230F250 DATA CatalogDocument1 page3230F250 DATA CatalogLIONN TESTE2021No ratings yet

- 9323A271G Catalog DATADocument4 pages9323A271G Catalog DATALIONN SOFTWARESNo ratings yet

- 9320A185H TestplanDocument4 pages9320A185H TestplanBaytolga canNo ratings yet

- TP 9320a210gDocument4 pagesTP 9320a210gVyacheslav ShatalovNo ratings yet

- 8520A020A TestplanDocument2 pages8520A020A TestplanBaytolga canNo ratings yet

- Testplan 9521A330TDocument3 pagesTestplan 9521A330TMilanNo ratings yet

- 3042F331 DATA CatalogDocument2 pages3042F331 DATA CatalogMilanNo ratings yet

- Testplan 3242920Document1 pageTestplan 3242920Fx_205No ratings yet

- 9520a950 Lionn Auto SoftwaresDocument4 pages9520a950 Lionn Auto SoftwaresLIONN SOFTWARESNo ratings yet

- Test PlanDocument1 pageTest PlanOFFICE DANACNo ratings yet

- Test Plan: 8522A130: Pump SpecificationDocument2 pagesTest Plan: 8522A130: Pump SpecificationJose Alexandre SunhegaNo ratings yet

- 3233F390 TabelaDocument1 page3233F390 TabelaOFFICE DANACNo ratings yet

- Test Plan 8923a177gDocument2 pagesTest Plan 8923a177gMilanNo ratings yet

- Testplan 3343010Document1 pageTestplan 3343010Fx_205No ratings yet

- Test Plan 8925A150Document2 pagesTest Plan 8925A150MilanNo ratings yet

- 821A661X DATA CatalogDocument2 pages821A661X DATA CatalogMilanNo ratings yet

- Pump SpecificationDocument2 pagesPump Specificationedgar ricoNo ratings yet

- 8550A223ADocument2 pages8550A223ALTurboNo ratings yet

- TestplanDocument3 pagesTestplanGiorgio Di CesareNo ratings yet

- Richard VargasDocument1 pageRichard VargasRicardo NarvaezNo ratings yet

- Group 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddyDocument16 pagesGroup 3 Tests and Adjustments: 1. Hydraulic Oil Clean Up Procedure Using Portable Filter CaddySergeyNo ratings yet

- DPC 8443b184bDocument2 pagesDPC 8443b184bBaytolgaNo ratings yet

- Smart 2: User and M Maintenance Manual Warranty InformationDocument20 pagesSmart 2: User and M Maintenance Manual Warranty InformationRogério PereiraNo ratings yet

- PAG1Document1 pagePAG1LIONN SOFTWARESNo ratings yet

- 0 400 075 995 Pag1Document1 page0 400 075 995 Pag1LIONN SOFTWARESNo ratings yet

- 0460494032Document1 page0460494032LIONN SOFTWARESNo ratings yet

- 0 400 075 995 Pag2Document1 page0 400 075 995 Pag2LIONN SOFTWARESNo ratings yet

- TABELADocument4 pagesTABELALIONN SOFTWARESNo ratings yet

- 7050Document7 pages7050LIONN SOFTWARESNo ratings yet

- 9521A300T Parts CatalogDocument7 pages9521A300T Parts CatalogLIONN SOFTWARESNo ratings yet

- Parts List 3717Document2 pagesParts List 3717LIONN SOFTWARESNo ratings yet

- 9323A271G Catalog DATADocument4 pages9323A271G Catalog DATALIONN SOFTWARESNo ratings yet

- 3239F600 DataDocument2 pages3239F600 DataLIONN SOFTWARESNo ratings yet

- Excavator Attachments BreakersDocument4 pagesExcavator Attachments BreakersBhagoo HatheyNo ratings yet

- Ambertech Price List As of June 2023Document14 pagesAmbertech Price List As of June 2023RM DulawanNo ratings yet

- CSEC Physics June 2015 Paper 2 LFXWZBDocument18 pagesCSEC Physics June 2015 Paper 2 LFXWZBinesh100No ratings yet

- Daikin BrouchreDocument1 pageDaikin Brouchresivaraj gNo ratings yet

- Broiler Preventive Maintenance ChecklistDocument5 pagesBroiler Preventive Maintenance ChecklistFaysbuk KotoNo ratings yet

- Oscillations TheoryDocument10 pagesOscillations TheoryJoanna PanayiNo ratings yet

- Californea Bearing Ratio Test (CBR) : Name: Zagros Othman AliDocument21 pagesCalifornea Bearing Ratio Test (CBR) : Name: Zagros Othman AlizagrosNo ratings yet

- Level (I)Document5 pagesLevel (I)SaiSastryKuppaNo ratings yet

- COMBILIFT C6000 14 - 26,000 Operator & Service Manual 07Document47 pagesCOMBILIFT C6000 14 - 26,000 Operator & Service Manual 07Holly DrinovzNo ratings yet

- BVI-Fin Stabi Type S 7 2013Document8 pagesBVI-Fin Stabi Type S 7 2013Shivananda PatraNo ratings yet

- B727 Amm - Pneumatic System Description and Operation: Fed AllDocument5 pagesB727 Amm - Pneumatic System Description and Operation: Fed AllSamuel RodriguezNo ratings yet

- Oil Field TerminologyDocument6 pagesOil Field Terminologyrcabrera90No ratings yet

- Activity Sheet SampleDocument5 pagesActivity Sheet SampleDhan GregorioNo ratings yet

- Rigid Body Tree Robot ModelDocument3 pagesRigid Body Tree Robot ModelSuhil IrshadNo ratings yet

- Pertanyaan TK PDBDocument4 pagesPertanyaan TK PDBHardenNo ratings yet

- 108A - W23 Homework 3Document3 pages108A - W23 Homework 3dawsontaylor26No ratings yet

- Chapter 1 Introduction To Engineering EconomyDocument8 pagesChapter 1 Introduction To Engineering EconomyJason AdiaNo ratings yet

- EXP 7 - Continuous Distillation-Bubble CapDocument19 pagesEXP 7 - Continuous Distillation-Bubble CapHamdan JasmiNo ratings yet

- Artikel Alifia-SriDocument5 pagesArtikel Alifia-SriYochanan meisandroNo ratings yet

- Axial Turbine Flowmeter For Liquids Type FVA915VTH: Swiviel Nut G3/4Document1 pageAxial Turbine Flowmeter For Liquids Type FVA915VTH: Swiviel Nut G3/4ALEKSANDARNo ratings yet

- What Should You Consider When Choosing A Wet-Mix Shotcrete Pump?Document3 pagesWhat Should You Consider When Choosing A Wet-Mix Shotcrete Pump?aeoiuNo ratings yet