CADANGAN TAMBAHAN DAN

UBAHSUAI BAGI SEBUAH PUSAT

JAGAAN AMBULATORI SWASTA

SETINGGI 4 TINGKAT DI ATAS

LOT 3140, BANDAR TAIPING

DAERAH LARUT DAN MATANG,

PERAK DARUL RIDZUAN

Document No:

Method Statement for GLSS-JP-MS-CS13

Installation of Suspended Rev : 00

Ceilings Date: 24/07/2019

Page 1 of 11

METHOD STATEMENT FOR

INSTALLATION OF SUSPENDED CEILINGS

Issue No.: 0

Revision No. 0

� CADANGAN TAMBAHAN DAN

UBAHSUAI BAGI SEBUAH PUSAT

JAGAAN AMBULATORI SWASTA

SETINGGI 4 TINGKAT DI ATAS

LOT 3140, BANDAR TAIPING

DAERAH LARUT DAN MATANG,

PERAK DARUL RIDZUAN

Document No:

Method Statement for GLSS-JP-MS-CS13

Installation of Suspended Rev : 00

Ceilings Date: 24/07/2019

Page 2 of 11

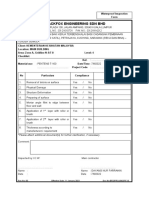

Revision Record

1. This cover page is a record of all revisions of the document identified above by number and title. All

previous cover pages are hereby superseded and are to be destroyed.

2. The contractor has the full right to modify, amend or change Method Statement and supporting

documents as required or as deemed necessary. All such documents will be submitted to the

“CONSULTANT” for approval.

Prepared Reviewed Approval for Description & page Number of

Rev Date

By by Issuance by Revision

00 24/07/19 Afiq Faisal GLS Setia

CONTENTS

1.0 PURPOSE

2.0 SCOPE

Issue No.: 0

Revision No. 0

� CADANGAN TAMBAHAN DAN

UBAHSUAI BAGI SEBUAH PUSAT

JAGAAN AMBULATORI SWASTA

SETINGGI 4 TINGKAT DI ATAS

LOT 3140, BANDAR TAIPING

DAERAH LARUT DAN MATANG,

PERAK DARUL RIDZUAN

Document No:

Method Statement for GLSS-JP-MS-CS13

Installation of Suspended Rev : 00

Ceilings Date: 24/07/2019

Page 3 of 11

3.0 REFERENCES

4.0 DEFINITIONS AND ABBREVIATIONS

5.0 RESPONSIBILITIES

6.0 MATERIALS

7.0 EQUIPMENT & TOOLS

8.0 SAFETY & HEALTH

9.0 PROCEDURE

10.0 ATTACHMENTS

1.0 PURPOSE

The purpose of producing this method statement is to describe the procedure for installation of suspended ceiling systems as specified in the specification and

as indicated on approved relevant shop drawings.

2.0 SCOPE

This method statement applies to supply and installation of suspended ceiling systems as indicated on approved relevant shop drawings with all necessary

accessories to complete the installation to the satisfaction of CONSULTANT as specified in the specification section # 09510.

3.0 REFERENCES

Project Specifications – Suspended Ceilings

Project Specifications – Gypsum and Cement Boards

Project Specifications – Metal Fabrication

Project Specifications

Issue No.: 0

Revision No. 0

� CADANGAN TAMBAHAN DAN

UBAHSUAI BAGI SEBUAH PUSAT

JAGAAN AMBULATORI SWASTA

SETINGGI 4 TINGKAT DI ATAS

LOT 3140, BANDAR TAIPING

DAERAH LARUT DAN MATANG,

PERAK DARUL RIDZUAN

Document No:

Method Statement for GLSS-JP-MS-CS13

Installation of Suspended Rev : 00

Ceilings Date: 24/07/2019

Page 4 of 11

Project Specifications

Contract Drawings

Approved shop drawings

Approved Material Submittal

Approved supplier details

Bill of Quantity

Project Quality Plan

Project HSE Plan

4.0 DEFINITIONS & ABBREVIATIONS

PM: Project Manager

CM: Construction Manager

PE: Project Engineer

QCE: Quality Control Engineer

QA QC: Quality Assurance and quality Control

PPE: Personal Protective Equipment

HSE: Health, Safety and Environment

5.0 RESPONSIBILITIES

Project Manager is responsible for overall project execution, quality and safety. Adopt a leading role with respect to Contractor’s quality and safety

procedures. The PM is responsible for the overall implementation of this method statement. The Project Manager shall ensure that the key personnel

are well aware of the specifications and method statement.

CM / Project Engineer shall arrange all materials, equipment, safety related items & manpower & direct the Site Engineers & Foremen to resort

appropriate action for the smooth execution of the works.

Safety Engineer shall be responsible for safe working environment & conditions. Coordinate with Site Engineer to identify potential hazards before

works and advise methods of safe working from new developments.

Surveyor shall be responsible for setting out for levels, layout, and lines & establish top levels. Ensuring setting out books are properly maintained and

filed when completed. To coordinate with the CONSULTANT surveyor in determining coordinates, levels, and limits.

QA/QC Engineer shall be responsible for ensuring that execution of works are complying with approved method statement; specifications, approved

shop drawings and ensure ITR are submitted based on ITP requirements.

Site Engineer shall ensure that all works are carried out according to approved shop drawings. He shall direct the surveyor for the setting out lines &

levels in concurrence from the Construction Manager/Senior Civil Engineer.

Coordinator / Engineer shall be responsible for proper execution of MEP works involved before, during and after the works.

6.0 MATERIALS

As per approved material submittal

7.0 EQUIPMENTS & TOOLS

Leveling Instruments

Line dory

Cutting Tool

Measuring tape

Issue No.: 0

Revision No. 0

� CADANGAN TAMBAHAN DAN

UBAHSUAI BAGI SEBUAH PUSAT

JAGAAN AMBULATORI SWASTA

SETINGGI 4 TINGKAT DI ATAS

LOT 3140, BANDAR TAIPING

DAERAH LARUT DAN MATANG,

PERAK DARUL RIDZUAN

Document No:

Method Statement for GLSS-JP-MS-CS13

Installation of Suspended Rev : 00

Ceilings Date: 24/07/2019

Page 5 of 11

Spirit level

Screw driver

Drilling Machine

Hammer

Wire Cutter

Nail Gun with cartridge

Mobile scaffolds

ladders

The capacity / size of the above tools and equipment shall be judged in accordance with site

conditions, requirements, and availability at the time of execution

8.0 SAFETY & HEALTH

All employees shall be provided with complete personal Protection equipment PPE.

All employees shall attend Safety Induction and training Course to identify all Hazards associated with this work.

All workers shall be provided with proper tools and equipment to execute the work safely.

MSDS (material safety data sheet) shall be displayed at work location as appropriate

9.0 PROCEDURE

9.1 Preparatory Works

Ensure that materials, samples, shop drawing and method statement submitted and approved by the Engineer.

Aluminum tiles plain and perforated and gypsum plaster tiles of specified type and thickness shall be used.

Mock up of suspended ceiling systems shall be arranged at location designated by the CONSULTANT for the final approval.

Approved Mock Up and sample shall be available at site and the materials delivered to site shall be checked with respect to the approved sample.

Ensure materials delivered in original packaging, bearing name of manufacturer and product.

Ensure that materials are stored in an enclosed area and protected from damages.

Ensure that Plaster works and painting work shall be done up to the required height.

Verify Layout of false ceiling tiles showing the position of cut tiles, pattern, etc are approved by the Engineer.

Ensure that setting out of fixing of MEP services and ceiling suspension system shall be similarly coordinated.

Ensure that MEP services have been installed and clearance obtained from the concerned department.

Proper working platform shall be provided for the safe access of works.

9.2 Installation

Ceiling height in each area shall be marked in relation to the elevation of bench marks & transferred by water level

Powder coated angles as per approved materials and section details of false ceilings will be fixed on level markings with screws and plugs

The grids shall be laid out as per reflected ceiling layout.

All setting out shall be carried out according to the working / shop drawing.

The hangers will be installed according to spacing and level required.

Main –T-sections as per approved materials will then be tied to hangers at sufficient intervals

Cross T-BAR will then be fixed in between all the Main-T-sections to its lock position perpendicular to it at sufficient intervals

Leveling shall be carried out to prevent any subsequent download movement.

During these installation process MEP items installed were to be taken care, ensuring no damages.

Issue No.: 0

Revision No. 0

� CADANGAN TAMBAHAN DAN

UBAHSUAI BAGI SEBUAH PUSAT

JAGAAN AMBULATORI SWASTA

SETINGGI 4 TINGKAT DI ATAS

LOT 3140, BANDAR TAIPING

DAERAH LARUT DAN MATANG,

PERAK DARUL RIDZUAN

Document No:

Method Statement for GLSS-JP-MS-CS13

Installation of Suspended Rev : 00

Ceilings Date: 24/07/2019

Page 6 of 11

Where hangers cannot be fixed at the recommended spacing due to the presence of services, equipment or other obstructions, a sub-grid of appropriate

span & performance shall be used with prior permission from the Customer.

It shall be securely supported to prevent lateral movement.

Access panels and MEP opening location to be determined and set according to approved shop drawings details.

MEP clearance shall be obtained prior to commencing ceiling tile /gypsum board works.

Upon completion of framing work including final adjustment to ensure entire suspension is level, the ceiling boards were then be fixed up at proper

intervals.

Air terminal devices like grills or similar equipment shall be incorporated in the ceiling as specified.

After ensuring the ceiling boards/tiles were installed accordingly and acceptable flatness, sealing up of joints will proceed.

Final inspection will be made by the Engineer and contractor and to be rectified to any comments given by them.

Leveling & Fixing of Wall Angles (10% of ceiling scope of work):

All pre-coating, damp proof coats works and MEP Related activities above False Ceiling Level to be completed Prior to start of Ceiling Works.

Finished floor level marks must be available in all areas by Main Contractor by level instrument.

Powder coated wall channels will be fixed on the marked lines to the wall by using steel galvanized steel concrete nails of 25mm length and will be

fixed to the wall at a spacing of 300mm c/c starting at 100mm from both ends of wall channels.

Installation of Suspension Grid:

After obtaining clearances from MEP– Coordinator, galvanized steel Ceiling Nails l shaped 20 x 20 mm will be fixed to the soffit structure by using

drill machine at a spacing of 1200mm c/c distributed according to match ceiling tiles lay out as per approved shop drawings.

Hooked galvanized steel rods of diameter 4mm as per submittal will be inserted to the ceiling nails from one end. The other end of the rods will be

inserted in a steel adjustment clip. The length of the rods will be equal to the height of structural ceiling to the false ceiling less 200mm.

Another set of 4mm diameter galvanized steel rods as per submittal will be inserted to the other end of each adjacent clip. The length of these rods is

200mm in which they have hooked shape at the other end.

For Strip Ceiling the Main Runners will be fixed at 1200mm c/c spacing. The Runners are galvanized steel special U-Section and have locks and

holes and will be fixed directly to the adjustment clips by clipping into the holes of the carriers. The strip panels will be slided into place by clipping

them into the locks of the Main Runners as per catalogue.

For Lay In Ceiling Tiles the 6mm threaded rod will be inserted into the holes of ‘L’ clips vertical flange of the Main Runners galvanized steel T-grid

suspension. Length of Main Runners is 3600mm. In long span rooms, T.L will place the Main Runners consecutively and connect them to each other

at their ends by riveting 100mm steel thin plates to the vertical flanges of the

consecutive Main Runners. Finally, the Cross Galvanized T-Grid Runners of length 1200mm will be fixed to Main Runners by inserting Cross

Runners both ends in the opening holes of Main Runners every 600mm. Then, the Cross Galvanized T-Grid Runners of length 600mm will be inserted

between the Cross Galvanized T-Grid runners 1200mm to from a module size of 600 x 600mm as per catalogue.

Fixing of Ceiling Tiles:

After fixing external glass and perform service testing above ceiling by others, ceiling tiles will be fixed by laying them on the suspension grid system

according to the ceiling layout in the approved shop drawing.

Holes in tiles will be cut for services according to the approved opening sizes requirements (such as Diffusers, sprinklers, Grills etc.) as per electrical

and electro mechanical requirements.

Closing Ceiling Tiles pieces will be cut by Jack saw cutter for Aluminium Ceiling Tiles and by knife blade for Mineral Fibre ceiling tiles. Edges will

be chamfered.

Gypsum Board False Ceiling:

Leveling & Fixing of Wall Angles:

Finished floor level marks shall be made available in all areas by Main Contractor’s surveyor.

Reference points will be marked by measuring the required ceiling level from the existing marks by using measuring tapes from permanent

benchmarks given by surveyor. The maximum spacing between points should be five meters. Then, using chalk line will mark a continuous line.

Issue No.: 0

Revision No. 0

� CADANGAN TAMBAHAN DAN

UBAHSUAI BAGI SEBUAH PUSAT

JAGAAN AMBULATORI SWASTA

SETINGGI 4 TINGKAT DI ATAS

LOT 3140, BANDAR TAIPING

DAERAH LARUT DAN MATANG,

PERAK DARUL RIDZUAN

Document No:

Method Statement for GLSS-JP-MS-CS13

Installation of Suspended Rev : 00

Ceilings Date: 24/07/2019

Page 7 of 11

Galvanized wall channels will be fixed on the marked lines to the wall by using galvanized concrete nails of 25mm length and will fixed to wall at a

spacing of 300mmc/c starting at 100mm both ends of the wall angles

Fixing of Suspension Grid:

After receiving clearances from MEP – Coordinator. Galvanized steel Ceiling Nails will be fixed to the soffit by using shooting gun machines at a

spacing of 1200mm C/C distributed as per submittal, according to the ceiling lay out on the approved shop drawings.

Hooked galvanized steel rods of diameter 4mm as per submittal will be inserted to the ceiling nails from one end. The other end of the rods will be

inserted in a steel adjustment clip. The length of the rods will equal to the height of structural soffit to the False Ceiling less 200mm.

Another set of 4mm diameter galvanized steel rods as per submittal will be inserted to the other end of each adjacent clip. The length of these rods is

200mm in which they have hooked shape at the other end.

The Main Runners will be fixed at 1200mm C/C spacing as per submittal. The Runners are galvanized steel of 38mm wide U Channel Sections. The

channel bracket clips will be fixed into the hooked end of the lower rod. The channel brackets will hold the Main Runners. Finally, galvanized Spring

Tee will be fixed to the Main Runner at 600mm spacing using wire clips.

Fixing of Gypsum Board:

The12.5mm Gypsum Board will be fixed on the Furring Channel by Dry Wall screws at 200mmat the tapered edges and 250mm C/C at the center of

the board.

50 mm Fiber Tape will be fixed on the tapered edges of Gypsum Board Joints.

Special joint compound (Total cote-Boral) will be applied for covering Gypsum Board Joints and spotting fasteners.

MEP marked holes will be cut in Gypsum Board for services according to approved opening sizes requirements (such as lights, Sprinklers, etc) as per

electrical and mechanical requirements

Wall Lining & Vertical Bulkheads:

Ceiling soffit should be smooth and free of any concrete debris.

Ceiling tracks will be fixed using Partition Hilti Nails.

Vertical studs will be fixed inside the tracks every 600 mm center to center Wherever is possible using Rivet Pins.

In a similar way, the lower tracks will be fixed to the vertical studs by rivet pins.

If required, extra metal supports from the back face of Metal Framing will be fixed at 45º Angle to the lower track form one side by rivet pins

and to the ceiling soffit structure from the other side using Partition Hilti Nails @ 1600mm spacing.

12.5mm Gypsum Board will be fixed to the facing of Metal Framing by Drywall screws spacing at max 200 mm c/c.

Fiber Tape will be applied to cover Gypsum Board joints (Gypsum Board at same plane) and spotting fasteners.

Steel Corner Tape 50mm with joint compound will be applied to cover the exposed corners of Gypsum Board.

Free ends of Gypsum Board will be encased with Galvanized Steel J-Profile30 mmx13x15mm & Putty.

10.0 ATTACHMENTS

ITP

Checklist

Risk Assessment

Issue No.: 0

Revision No. 0