Battery Assembly Quality Control Chart

Uploaded by

karthikvelikannanBattery Assembly Quality Control Chart

Uploaded by

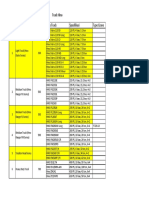

karthikvelikannanQUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 1

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

0005 BTM CELL BATTERY ASSY SENSORS VERIFY 1/WEE ENGG CHANGE ORIENTATION OF AS PER VISUAL 1/Shift 100% INFORM

HOLDER CONVYR-LINE 2 T277234 INTERLOCK & K THE INSERTS(BIGGER TMOS ENGG

INSERT ASSLY (5065248) 4 ALARM AGAINST SETTING AS SIDE IN) SUPERVISOR

AND LOADING PART T PER QCPC

BOTTOM CELL KE24 VERIFY 1/WEE ENGG CHANGE NO OF INSERTS ON 8.000 8.000 8.000 VISUAL 1/Shift 100% INFORM

HOLDER REVERSE 2080- K THE BOTTOM CELL ENGG

LOADING 05-01 SETTING AS HOLDER SUPERVISOR

PER QCPC

BOTOM COVER VERIFY 1/WEE ENGG CHANGE USE OF CORRECT VISUAL 100% INFORM TO

PROPER SEATING K THE INSERTS TEAMLEADER

SETTING AS

PER QCPC

RESTING BLOCK VERIFY 1/WEE ENGG CHANGE

CHA.OVER-MODEL K THE

TYPE SELECT SETTING AS

PER QCPC

RFID - OK STATUS VERIFY 1/4 PMD CHECK AND

IN HMI MONTH CORRECT

S THE

PARMETERS

ANTI-BACK VERIFY 1/4 PMD CHECK AND

PRESENCE MONTH CORRECT

S THE

PARMETERS

PNEUMATIC AIR bar 4.000 6.000 5.000 CHECK 1/DAY OPTR INFORM TO

PRESSURE TEAMLEADE

R

REPLACEMENT OF CHECK DURIN OPTR INFORM TO

MATERIAL DURING G TEAMLEADE

MODEL C/O CHANG R

E

OVER

0010 BTM CELL LASER NO OF each 29.000 29.000 29.000 CHECK 1/Month ENGG CHANGE QR CODE AS PER CHECK 1/day CHANGE THE

HOLDER - MARKING-5065232 T277234 CHARACTERS IN THE TSES 859 SETTING AS

LASER 2 QR 2D SETTING AS PER QCPC

MARKING PER QCPC

SIZE OF THE QR mm 8.000 8.000 8.000 VERNIER 1/Month ENGG CHANGE

(8*8mm) THE

SETTING AS

PER QCPC

SENSING OF CHECK 1/DAY OPTR INFORM TO

SERVO ZEROING TEAMLEADE

PIN (X & Z AXI R

OVER TRAVEL CHECK 1/4 PMD CHECK AND

SENSOR MONTH CORRECT

FUNCTIONING S THE

PARMETERS

QR CODE SCANNER CHECK 1/WEE ENGG CHANGE

FUNCTIONING K THE

SETTING AS

PER QCPC

HOME POSITION CHECK 1/DAY OPTR INFORM TO

PRECONDITIONS TEAMLEADE

R

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 2

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

POWER ON CHECK 1/DAY OPTR INFORM TO

PRECONDITIONS TEAMLEADE

R

SAFETY LIGHT KE24 CHECK 1/DAY OPTR INFORM TO

CURTAIN 2080- TEAMLEADE

FUNCTIONING 10-01 R

PART PRESENCE KE24 CHECK 1/DAY OPTR INFORM TO

SENSOR IN 2080- TEAMLEADE

GRIPPER 10-02 R

WORKING OF FUME CHECK 1/DAY OPTR INFORM TO

KILLER TEAMLEADE

R

FUME KILLER CHECK 1/4 PMD CHECK AND

FILTER CLEANING MONTH CORRECT

FREQUENCY S THE

PARMETERS

FUME KILLER CHECK AS PER PMD CHECK AND

FILTER PM CORRECT

REPLACEMENT SCHED THE

FREQUENCY ULE PARMETERS

FUNCTIONING OF CHECK 1/DAY OPTR INFORM TO

SAFETY DOOR TEAMLEADE

INTERLOCK R

MARKING POSITION mm 145.789 146.789 CHECK 1/WEE ENGG CHANGE

(Y-AXIS) 147.789 K THE

SETTING AS

PER QCPC

MARKING POSITION mm 25.587 27.587 26.587 CHECK 1/WEE ENGG CHANGE

(Z-AXIS) K THE

SETTING AS

PER QCPC

SCANNING mm 303.226 305.226 CHECK 1/WEE ENGG CHANGE

POSITION (Y-AXIS) 307.226 K THE

SETTING AS

PER QCPC

SCANNING mm 175.861 177.861 CHECK 1/WEE ENGG CHANGE

POSITION (Z-AXIS) 179.861 K THE

SETTING AS

PER QCPC

PICKING POSITION mm 153.462 155.462 CHECK 1/WEE ENGG CHANGE

(Y) LH STATION 157.462 K THE

SETTING AS

PER QCPC

PICKING POSITION mm 385.507 387.507 CHECK 1/WEE ENGG CHANGE

(Z) LH STATION 389.507 K THE

SETTING AS

PER QCPC

GRIPPING mm 53.243 57.243 55.243 CHECK 1/WEE ENGG CHANGE

POSITIION (Y -AXIS) K THE

SETTING AS

PER QCPC

GRIPPING mm 382.188 384.188 CHECK 1/WEE ENGG CHANGE

POSITION (Z-AXIS) 386.188 K THE

SETTING AS

PER QCPC

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 3

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

GRIPPER OPEN CHECK 1/WEE ENGG CHANGE

SENSOR K THE

SETTING AS

PER QCPC

GRIPPER CLOSE CHECK 1/WEE ENGG CHANGE

SENSOR K THE

SETTING AS

PER QCPC

PART PRESENCE CHECK 1/WEE ENGG CHANGE

SENSOR IN K THE

PALLET-14S7P SETTING AS

PER QCPC

SCANNER COVER CHECK 1/4 PMD CHECK AND

FORWARD MONTH CORRECT

PRESENCE S THE

PARMETERS

SCANNER COVER CHECK 1/4 PMD CHECK AND

REVERSE MONTH CORRECT

PRESENCE S THE

PARMETERS

IOT PARAMETERS CHECK 1/MON PMD CHECK AND

TRANSFER TO TH CORRECT

DATA LOGGER THE

PARMETERS

LASER HEAD mm 208.000 210.000 TAPE 1/YEAR PMD CHECK AND

DISTANCE TO 210.000 CORRECT

MARKING POSITION THE

PARMETERS

FUNCTION OF CHECK 1/MON PMD CHECK AND

ENTRY SIDE DOOR TH CORRECT

THE

PARMETERS

FUNCTION OF EXIT CHECK 1/MON PMD CHECK AND

SIDE DOOR TH CORRECT

THE

PARMETERS

0020 CELL SORTING CELL CELLS GRADING V 3.560 3.565 VOLT.MT 1/MON INSPT INFORM SCANNING OF QR PRESE PROGRA 1/DAY 100% IN INFORM

& CELL SORTING-5065231 T277235 <5mV G1 R TH ENGG CODE NCE OF M T&T ENGG

SCANNING 7 SUPERVISO COMPL SUPERVISOR

R ETE

MARKIN

G

CELLS GRADING V 3.565 3.570 VOLT.MT 1/MON INSPT INFORM CELL OCV RANGE mV 0 5.000 3/SHIFT INFORM

<5mV G2 R TH ENGG WITHIN MODULE ENGG

SUPERVISO SUPERVISOR

R

CELLS GRADING V 3.570 3.575 VOLT.MT 1/MON INSPT INFORM CELL IR RANGE M. 13.100 17.000 3/SHIFT INFORM

<5mV G3 R TH ENGG WITHNIN MODULE Ohm ENGG

SUPERVISO SUPERVISOR

R

CELLS GRADING V 3.575 3.580 VOLT.MT 1/MON INSPT INFORM CELL 2D DATA 3/SHIFT 1/SHIFT INFORM

<5mV G4 R TH ENGG VALIDATION ENGG

SUPERVISO SUPERVISOR

R

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 4

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

CELLS GRADING V 3.580 3.585 VOLT.MT 1/MON INSPT INFORM NO DAMAGE ON 3/SHIFT INFORM

<5mV G5 R TH ENGG CELLS ENGG

SUPERVISO SUPERVISOR

R

CELLS GRADING V 3.585 3.590 VOLT.MT 1/MON INSPT INFORM NO CELL 3/SHIFT INFORM

<5mV G6 R TH ENGG SHORTCIRCUIT ENGG

SUPERVISO SUPERVISOR

R

CELLS GRADING V 3.590 3.595 VOLT.MT 1/MON INSPT INFORM

<5mV G7 R TH ENGG

SUPERVISO

R

CELLS GRADING V 3.595 3.600 VOLT.MT 1/MON INSPT INFORM

<5mV G8 R TH ENGG

SUPERVISO

R

CELLS GRADING V 3.600 3.605 VOLT.MT 1/MON INSPT INFORM

<5mV G9 R TH ENGG

SUPERVISO

R

CELLS GRADING V 3.605 3.610 VOLT.MT 1/MON INSPT INFORM

<5mV G10 R TH ENGG

SUPERVISO

R

CELLS GRADING V 3.610 3.615 VOLT.MT 1/MON INSPT INFORM

<5mV G11 R TH ENGG

SUPERVISO

R

CELLS GRADING V 3.615 3.620 KE24 VOLT.MT 1/MON INSPT INFORM

<5mV G12 2080- R TH ENGG

20-01 SUPERVISO

R

CELL IR SETTING MOh 13.000 16.000 15.000 KE24 DISPLAY 1/MON QINSP INFORM

m 2080- TH ENGG

20-02 SUPERVISO

R

BOX PRESNECE KE24 1/4 PMD CHECK AND

SENSOR AT 2080- MONTH CORRECT

LOADING POSITION 20-03 S THE

PARMETERS

BOX TRAVEL 1/4 PMD CHECK AND

SENSOR OK/NOK MONTH CORRECT

ALARM S THE

PARMETERS

BOX STOPPER UP 1/4 PMD CHECK AND

DURING TRAVEL MONTH CORRECT

S THE

PARMETERS

BOX STOPPER 1/4 PMD CHECK AND

DOWN DURING MONTH CORRECT

PREVIOUS BOX AUT S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 5

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

AREA CLEAR KE24 1/4 PMD CHECK AND

SENSOR OK/NOK - 2080- MONTH CORRECT

INFEED ZONE 20-04 S THE

PARMETERS

AREA CLEAR 1/4 PMD CHECK AND

SENSOR OK/NOK - MONTH CORRECT

OP30A ZONE S THE

PARMETERS

AREA CLEAR 1/4 PMD CHECK AND

SENSOR OK/NOK - MONTH CORRECT

OP30B ZONE S THE

PARMETERS

BOX PRESENCE 1/4 PMD CHECK AND

SENSOR AT THE MONTH CORRECT

PICKING POSIT S THE

PARMETERS

WORKING OF 1/4 PMD CHECK AND

CAMERA BAR LIGHT MONTH CORRECT

DURING CYCLE S THE

PARMETERS

CONVEYOR 1/4 PMD CHECK AND

DIRECTION DURING MONTH CORRECT

EMPTY BOX DISP S THE

PARMETERS

UNLOADING 1/4 PMD CHECK AND

CONVEYOR MONTH CORRECT

ALIGNMENT S THE

SENSOR STAT PARMETERS

REMOVAL OF 100% OPTR INFORM TO

PERFORATED TEAMLEADE

SHEET FROM THE R

BOX

EMPTY BOX 100% OPTR INFORM TO

PRESENCE FOR TEAMLEADE

UNLOADING R

UNLOADING OF 100% OPTR INFORM TO

EMPTY BOX TEAMLEADE

R

ENSURE NO CELLS 100% OPTR INFORM TO

PRESENT DURING TEAMLEADE

DISPOSAL R

LOADING OF 100% OPTR INFORM TO

TEMPLATE ON TEAMLEADE

INPUT CELL BOX R

CLAMPING OF 100% OPTR INFORM TO

COTTON BOX TEAMLEADE

R

LH INFEED Hz 35.000 1/4 PMD CHECK AND

CONVEYOR SPEED MONTH CORRECT

S THE

PARMETERS

RH INFEED Hz 35.000 1/4 PMD CHECK AND

CONVEYOR SPEED MONTH CORRECT

S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 6

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

LH LIFTER Hz 35.000 1/4 PMD CHECK AND

CONVEYOR SPEED MONTH CORRECT

S THE

PARMETERS

RH LIFTER Hz 35.000 1/4 PMD CHECK AND

CONVEYOR SPEED MONTH CORRECT

S THE

PARMETERS

LH RETURN Hz 35.000 1/4 PMD CHECK AND

CONVEYOR SPEED MONTH CORRECT

S THE

PARMETERS

RH RETURN Hz 35.000 1/4 PMD CHECK AND

CONVEYOR SPEED MONTH CORRECT

S THE

PARMETERS

WORKING OF LH 1/4 PMD CHECK AND

CONVEYOR MONTH CORRECT

STOPPER S THE

CYLINDER PARMETERS

WORKING OF LH 1/4 PMD CHECK AND

CONVEYOR MONTH CORRECT

SINGLING CYLINDE S THE

PARMETERS

WORKING OF LH 1/4 PMD CHECK AND

CONVEYOR CLAMP MONTH CORRECT

CYLINDER 1& S THE

PARMETERS

WORKING OF LH 1/4 PMD CHECK AND

TILT CONVEYOR MONTH CORRECT

TILTER CYLIN S THE

PARMETERS

WORKING OF RH 1/4 PMD CHECK AND

CONVEYOR MONTH CORRECT

STOPPER S THE

CYLINDER PARMETERS

WORKING OF RH 1/4 PMD CHECK AND

CONVEYOR MONTH CORRECT

SINGLING CYLINDE S THE

PARMETERS

WORKING OF RH 1/4 PMD CHECK AND

CONVEYOR CLAMP MONTH CORRECT

CYLINDER 1& S THE

PARMETERS

WORKING OF RH 1/4 PMD CHECK AND

TILT CONVEYOR MONTH CORRECT

TILTER CYLIN S THE

PARMETERS

CELL PRESENT AT mm 0.950 1.100 1/4 PMD CHECK AND

ROBOT GRIPPER MONTH CORRECT

S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 7

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

CELL NOT mm 0.300 1.500 1/4 PMD CHECK AND

PRESENT AT MONTH CORRECT

ROBOT GRIPPER S THE

PARMETERS

CAMERA LIGHT 1/4 PMD CHECK AND

INTENSITY MONTH CORRECT

S THE

PARMETERS

CAMERA 1/4 PMD CHECK AND

CALIBRATION MONTH CORRECT

FREQUENCY S THE

PARMETERS

ZEROING OF 1/4 PMD CHECK AND

INSPECTION MONTH CORRECT

CONVEYOR S THE

PARMETERS

WORKING OF 1/4 PMD CHECK AND

MAGNETIC MONTH CORRECT

CYLINDER S THE

PARMETERS

WORKING OF 1/4 PMD CHECK AND

TILTER CYCLINDER MONTH CORRECT

(90 DEG) S THE

PARMETERS

WORKING OF 1/4 PMD CHECK AND

BUFFER STATION MONTH CORRECT

CYLINDER S THE

PARMETERS

WORKING OF 2D 1/4 PMD CHECK AND

STATION LIFTER MONTH CORRECT

S THE

PARMETERS

WORKING OF 2D 1/4 PMD CHECK AND

STATION LH MONTH CORRECT

CYLINDER S THE

PARMETERS

WORKING OF 2D 1/4 PMD CHECK AND

STATION RH MONTH CORRECT

CYLINDER S THE

PARMETERS

WORKING OF HIOKI 1/4 PMD CHECK AND

STATION CELL MONTH CORRECT

LEVEL CYLI S THE

PARMETERS

WORKING OF HIOKI 1/4 PMD CHECK AND

STATION LH SLIDE MONTH CORRECT

S THE

PARMETERS

WORKING OF HIOKI 1/4 PMD CHECK AND

STATION RH SLIDE MONTH CORRECT

S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 8

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

WORKING OF CELL 1/4 PMD CHECK AND

ROTATION AT 2D MONTH CORRECT

READ STAT S THE

PARMETERS

RFID SENSOR mm 0 1/4 PMD CHECK AND

POSITION AT MONTH CORRECT

LOADING STATION S THE

PARMETERS

RFID SENSOR mm 0 1/4 PMD CHECK AND

POSITION AT MONTH CORRECT

BUFFER STATION S THE

PARMETERS

RFID SENSOR mm 0 1/4 PMD CHECK AND

POSITION AT 2D MONTH CORRECT

SCAN STATION S THE

PARMETERS

RFID SENSOR mm 0 1/4 PMD CHECK AND

POSITION AT HIOKI MONTH CORRECT

TEST STATI S THE

PARMETERS

RFID SENSOR mm 0 1/4 PMD CHECK AND

POSITION AT MONTH CORRECT

UNLOADING STATI S THE

PARMETERS

WORKING OF 2D 1/4 PMD CHECK AND

SCANNER MONTH CORRECT

S THE

PARMETERS

SCANNER LIGHT LX 0 1/4 PMD CHECK AND

INTENSITY MONTH CORRECT

S THE

PARMETERS

FUNCTIONING OF each 4.000 4.000 4.000 1/WEE ENGG INFORM

LIGHTS IN 2D K ENGG

STATION SUPERVISO

R

NO DAMAGES IN 1/DAY OPTR INFORM TO

THE PROBE TEAMLEADE

R

HIOKI CALIBRATION PMD CHANGE

1/6MON THE

THS SETTING AS

PER QCPC

HIOKI PROBE LIFE 1/MON ENGG CHANGE

TH THE

SETTING AS

PER QCPC

NO DAMAGES IN 1/DAY OPTR INFORM TO

THE CLAMPING PU TEAMLEADE

PADS R

PAD LIFE 1/MON ENGG CHANGE

TH THE

SETTING AS

PER QCPC

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 9

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

HIOKI IR OFFSET 1/MON ENGG CHANGE

CORRECTION TH THE

SETTING AS

PER QCPC

HIOKI UNIT CHECK PMD CHECK AND

CALIBRATION 1/YEAR CORRECT

THE

PARMETERS

HIOKI ZERO 1/MON ENGG CHANGE

ADJUSTMENT TH THE

FREQUENCY SETTING AS

PER QCPC

CELL PRESENT AT mm 1.300 1.400 1/4 PMD CHECK AND

GANTRY GRIPPER MONTH CORRECT

S THE

PARMETERS

CELL NOT mm 0.100 2.000 1/4 PMD CHECK AND

PRESENT AT MONTH CORRECT

GANTRY GRIPPER S THE

PARMETERS

GANTRY SPEED % 100.000 1/4 PMD CHECK AND

MONTH CORRECT

S THE

PARMETERS

UNLOADING each 100000.0 100000. 100000.0 1/MON ENGG INFORM

GANTRY FINGER 00 000 00 TH ENGG

LIFE SUPERVISO

R

FINGER PU COAT 1/MON ENGG INFORM

CHECK TH ENGG

SUPERVISO

R

FUNCTIONING OF 1/4 PMD CHECK AND

AREA SCANNER MONTH CORRECT

S THE

PARMETERS

GRADING % 100.000 1/4 PMD CHECK AND

CONVEYOR SPEED MONTH CORRECT

S THE

PARMETERS

2D SCAN STEPPER % 40.000 1/4 PMD CHECK AND

MOTOR SPEED MONTH CORRECT

S THE

PARMETERS

SPACING IN each 60.000 1/4 PMD CHECK AND

GRADING MONTH CORRECT

CONVEYOR S THE

PARMETERS

INSPECTION CONV mm 1/4 PMD CHECK AND

UNLOAD POSITION 1740.249 MONTH CORRECT

X AIXS S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 10

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

INSPECTION CONV mm 144.552 1/4 PMD CHECK AND

UNLOAD POSITION MONTH CORRECT

Z AIXS S THE

PARMETERS

A GRADE CONV1 mm 1/4 PMD CHECK AND

LOAD POSITION IN 2038.980 MONTH CORRECT

X AXIS S THE

PARMETERS

A GRADE CONV2 mm 1/4 PMD CHECK AND

LOAD POSITION IN 2139.911 MONTH CORRECT

X AXIS S THE

PARMETERS

A GRADE CONV3 mm 1/4 PMD CHECK AND

LOAD POSITION IN 1134.449 MONTH CORRECT

X AXIS S THE

PARMETERS

A GRADE CONV4 mm 1/4 PMD CHECK AND

LOAD POSITION IN 1033.392 MONTH CORRECT

X AXIS S THE

PARMETERS

B GRADE CONV1 mm 1/4 PMD CHECK AND

LOAD POSITION IN 2359.134 MONTH CORRECT

X AXIS S THE

PARMETERS

B GRADE CONV2 mm 1/4 PMD CHECK AND

LOAD POSITION IN 2460.247 MONTH CORRECT

X AXIS S THE

PARMETERS

B GRADE CONV3 mm 815.717 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

X AXIS S THE

PARMETERS

B GRADE CONV4 mm 715.036 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

X AXIS S THE

PARMETERS

C GRADE CONV1 mm 1/4 PMD CHECK AND

LOAD POSITION IN 2676.808 MONTH CORRECT

X AXIS S THE

PARMETERS

C GRADE CONV2 mm 1/4 PMD CHECK AND

LOAD POSITION IN 2778.399 MONTH CORRECT

X AXIS S THE

PARMETERS

C GRADE CONV3 mm 496.990 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

X AXIS S THE

PARMETERS

C GRADE CONV4 mm 395.667 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

X AXIS S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 11

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

TEMP REJECTION mm 1/4 PMD CHECK AND

CONV LOAD 386.021- MONTH CORRECT

POSITION X AXIS S THE

PARMETERS

PERM REJECTION mm 1/4 PMD CHECK AND

CONV LOAD 236.945- MONTH CORRECT

POSITION X AXIS S THE

PARMETERS

A GRADE CONV1 mm 145.395 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

A GRADE CONV2 mm 143.039 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

A GRADE CONV3 mm 153.722 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

A GRADE CONV4 mm 154.444 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

B GRADE CONV1 mm 143.667 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

B GRADE CONV2 mm 144.686 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

B GRADE CONV3 mm 154.171 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

B GRADE CONV4 mm 154.274 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

C GRADE CONV1 mm 143.082 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

C GRADE CONV2 mm 142.472 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

C GRADE CONV3 mm 154.938 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 12

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

C GRADE CONV4 mm 154.026 1/4 PMD CHECK AND

LOAD POSITION IN MONTH CORRECT

Z AXIS S THE

PARMETERS

TEMP REJECTION mm 139.408 1/4 PMD CHECK AND

CONV LOAD MONTH CORRECT

POSITION X AXIS S THE

PARMETERS

PERM REJECTION mm 139.736 1/4 PMD CHECK AND

CONV LOAD MONTH CORRECT

POSITION X AXIS S THE

PARMETERS

PU COATING ON 1/WEE INFORM

THE CELL PICKING K ENGG

FINGER SUPERVISO

R

0030 CELL LOADING CELL ROBOT IN SAFE 1/4 PMD CHECK AND POLARITY OF FIRST NEGATI VISUAL 1/DAY 3/SHIFT INFORM

IN BOTTOM SORTING-5065231 T277235 ZONE MONTH CORRECT ROW CELLS (-VE VE ENGG

CELL HOLDER 7 S THE SYMBOL) SUPERVISOR

PARMETERS

ROBOT SPEED % 100.000 1/4 PMD CHECK AND PRESENCE OF ALL each 98.000 98.000 98.000 VISUAL 1/DAY 3/SHIFT INFORM

MONTH CORRECT CELLS ENGG

S THE SUPERVISOR

PARMETERS

POLARITY 1/DAY OPTR INFORM TO

SEQUENCE TEAMLEADE

CHANGING R

POLARITY SERVO % 100.000 1/4 PMD CHECK AND

SPEED MONTH CORRECT

S THE

PARMETERS

FINGER WITH PU 1/MON PMD CHECK AND

COAT TH CORRECT

THE

PARMETERS

ALL SERVO ZERO 1/4 PMD CHECK AND

PIN IN POSITION MONTH CORRECT

S THE

PARMETERS

30A: HOME mm 559.814 1/4 PMD CHECK AND

POSITION IN X-AXIS MONTH CORRECT

S THE

PARMETERS

30A: A GRADE mm 146.830 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN X S THE

PARMETERS

30A: A GRADE mm 250.664 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN X S THE

PARMETERS

30A:B GRADE mm 465.909 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN X A S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 13

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

30A: B GRADE mm 569.897 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN X S THE

PARMETERS

30A:C GRADE mm 784.829 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN X A S THE

PARMETERS

30A: C GRADE mm 887.354 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN X S THE

PARMETERS

30A: GANTRY mm 469.762 1/4 PMD CHECK AND

LOADING POSITION MONTH CORRECT

1 IN X AXIS S THE

PARMETERS

30A: GANTRY mm 559.816 1/4 PMD CHECK AND

LOADING POSITION MONTH CORRECT

2 IN X AXIS S THE

PARMETERS

30A: HOME mm 50.003 1/4 PMD CHECK AND

POSITION IN Z-AXIS MONTH CORRECT

S THE

PARMETERS

30A: A GRADE mm 152.515 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN ZA S THE

PARMETERS

30A: A GRADE mm 153.034 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN Z S THE

PARMETERS

30A:B GRADE mm 151.919 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN Z A S THE

PARMETERS

30A: B GRADE mm 151.908 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN Z S THE

PARMETERS

30A:C GRADE mm 150.447 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN Z A S THE

PARMETERS

30A: C GRADE mm 150.556 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN Z S THE

PARMETERS

30A: TILTING AXIS mm 88.277 1/4 PMD CHECK AND

HOME POSITION MONTH CORRECT

S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 14

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

30A: TILTING AXIS mm 178.962 1/4 PMD CHECK AND

PLUS 90 DEG MONTH CORRECT

POSITION S THE

PARMETERS

30A: TILTING AXIS mm 8.180- 1/4 PMD CHECK AND

MINUS 90 DEG MONTH CORRECT

POSITION S THE

PARMETERS

30B: HOME mm 607.015 1/4 PMD CHECK AND

POSITION IN X-AXIS MONTH CORRECT

S THE

PARMETERS

30B: A GRADE mm 909.997 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN X S THE

PARMETERS

30B: A GRADE mm 816.610 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN X S THE

PARMETERS

30B:B GRADE mm 591.405 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN X A S THE

PARMETERS

30B: B GRADE mm 497.185 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN X S THE

PARMETERS

30B:C GRADE mm 271.806 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN X A S THE

PARMETERS

30B: C GRADE mm 177.510 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN X S THE

PARMETERS

30B: GANTRY mm 605.343 1/4 PMD CHECK AND

LOADING POSITION MONTH CORRECT

1 IN X AXIS S THE

PARMETERS

30B: GANTRY mm 521.094 1/4 PMD CHECK AND

LOADING POSITION MONTH CORRECT

2 IN X AXIS S THE

PARMETERS

30B: HOME mm 50.008 1/4 PMD CHECK AND

POSITION IN Z-AXIS MONTH CORRECT

S THE

PARMETERS

30B: A GRADE mm 158.565 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN ZA S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 15

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

30B: A GRADE mm 160.195 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN Z S THE

PARMETERS

30B: B GRADE mm 161.051 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN Z S THE

PARMETERS

30B: B GRADE mm 160.014 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN Z S THE

PARMETERS

30B: C GRADE mm 159.727 1/4 PMD CHECK AND

CONV1 UNLOAD MONTH CORRECT

POSITION IN Z S THE

PARMETERS

30B: C GRADE mm 158.527 1/4 PMD CHECK AND

CONV2 UNLOAD MONTH CORRECT

POSITION IN Z S THE

PARMETERS

30A: TILTING AXIS mm 89.762 1/4 PMD CHECK AND

HOME POSITION MONTH CORRECT

S THE

PARMETERS

30A: TILTING AXIS mm 180.798 1/4 PMD CHECK AND

PLUS 90 DEG MONTH CORRECT

POSITION S THE

PARMETERS

30A: TILTING AXIS mm 9.045 1/4 PMD CHECK AND

MINUS 90 DEG MONTH CORRECT

POSITION S THE

PARMETERS

AREA CLEAR AS PER CHECK 1/WEE PMD CHECK AND

SENSOR POS PM K CORRECT

ALIGNMENT&FUNC CHECK THE

TION SHEET PARMETERS

0040 THERMISTOR Thermistor pasting FUNCTIONING OF KE24 VERIFY 1/DAY OPTR INFORM TO PULL OF 0.800 PULL&C 1/DAY CHANGE THE

PASTING-1,2,3& stations-5065233 T277233 SAFETY LIGHT 2080- TEAMLEADE STRENGTH HK SETTING AS

INSERT ASSY 4 CURTAIN 40-01 R PER QCPC

T277234

4

FUNCTIONING OF VERIFY 1/WEE PMD CHECK AND THERMISTOR mm 15.000 65.000 38.000 SCALE 3/SHIFT CHANGE THE

LASER SENSOR AS K CORRECT POSITION ON SETTING AS

PER SEQUE THE CELLS PER QCPC

PARMETERS

STOPPER UP AND VERIFY 1/4 PMD CHECK AND ORIENTATION OF AS PER VISUAL 3/SHIFT 100% INFORM

DOWN SIGNAL MONTH CORRECT CABLE TMOS ENGG

S THE SUPERVISOR

PARMETERS

PNEUMATIC AIR bar 4.000 6.000 5.000 CHECK 1/DAY OPTR INFORM TO PASTING OF COMPL VISUAL 3/SHIFT 100% INFORM

PRESSURE TEAMLEADE THERMISTOR ETE ENGG

R STICKER -1 ON PASTIN SUPERVISOR

CELL G

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 16

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

OPERATOR SKILL CL2 CHECK 1/MON ENGG TRAIN THE PASTING OF COMPL VISUAL 3/SHIFT 100% INFORM

LEVEL TH OPERATOR THERMISTOR ETE ENGG

STICKER-2 ON PASTIN SUPERVISOR

CABLE G

PUSH PULL GAUGE VERIFY 1/6MON ENGG CHANGE THERMISTOR AS PER VISUAL 3/SHIFT 100% INFORM

CALIBRATION THS THE CABLE BLACK TMOS ENGG

SETTING AS LOCATION (X7,Y4) SUPERVISOR

PER QCPC

FIXTURE LOCK VISUAL 1/MON ENGG CHANGE THERMISTOR VISUAL 3/SHIFT 100% CHECK AND

CONDITION TH THE CABLE WHITE CORRECT

SETTING AS LOCATION (X14,Y4 THE

PER QCPC PARMETERS

RFID - OK STATUS CHECK 1/4 PMD CHECK AND THERMISTOR VISUAL 3/SHIFT 100% CHECK AND

IN HMI MONTH CORRECT CABLE RED CORRECT

S THE LOCATION(X8,Y1) THE

PARMETERS PARMETERS

ORIENTATION OF VISUAL 1/SHIFT 100% CHECK AND

INSERTS( BIGGER CORRECT

SIDE IN) THE

PARMETERS

NO OF INSERTS ON each 7.000 7.000 7.000 VISUAL 1/SHIFT 100% CHECK AND

TOP CELL HOLDER CORRECT

THE

PARMETERS

0050 THERMISTOR Thermistor pasting FUNCTIONING OF VERIFY 1/DAY OPTR INFORM TO PULL OF kf 0.800 PULL&C 1/DAY CHANGE THE

PASTING-4 & stations-5065233 T277233 SAFETY LIGHT TEAMLEADE STRENGTH HK SETTING AS

ROUTING 4 CURTAIN R PER QCPC

FUNCTIONING OF VERIFY 1/WEE PMD CHECK AND THERMISTOR mm 15.000 65.000 38.000 SCALE 3/SHIFT CHANGE THE

LASER SENSOR AS K CORRECT POSITION ON SETTING AS

PER SEQUE THE CELLS PER QCPC

PARMETERS

STOPPER UP AND VERIFY 1/4 PMD CHECK AND ORIENTATION OF AS PER VISUAL 3/SHIFT 100% INFORM

DOWN SIGNAL MONTH CORRECT CABLE TMOS ENGG

S THE SUPERVISOR

PARMETERS

PNEUMATIC AIR bar 4.000 6.000 5.000 CHECK 1/DAY OPTR INFORM TO PASTING OF COMPL VISUAL 3/SHIFT 100% INFORM

PRESSURE TEAMLEADE THERMISTOR ETE ENGG

R STICKER -1 ON PASTIN SUPERVISOR

CELL G

OPERATOR SKILL CL2 CHECK 1/MON ENGG TRAIN THE PASTING OF COMPL VISUAL 3/SHIFT 100% INFORM

LEVEL TH OPERATOR THERMISTOR ETE ENGG

STICKER-2 ON PASTIN SUPERVISOR

CABLE G

PUSH PULL GAUGE VERIFY 1/6MON ENGG CHANGE THERMISTOR NO VISUAL 3/SHIFT 100% INFORM

CALIBRATION THS THE CABLE BLUE MISSIN ENGG

SETTING AS LOCATION(X1,Y4) G SUPERVISOR

PER QCPC

FIXTURE LOCK VISUAL 1/MON ENGG CHANGE ROUTING OF AS PER VISUAL 3/SHIFT 100% INFORM

CONDITION TH THE THERMISTOR TMOS ENGG

SETTING AS CABLES SUPERVISOR

PER QCPC

RFID - OK STATUS CHECK 1/4 PMD CHECK AND

IN HMI MONTH CORRECT

S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 17

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

0060 TOP CELL BATTERY ASSY TOP COVER VERIFY 1/WEE ENGG CHANGE NO THERMISTOR 3/SHIFT 100% INFORM

HOLDER CONVYR-LINE 2 T277234 PROPER SEATING K THE BULGE ENGG

CLOSING (5065248) 4 SETTING AS SUPERVISOR

PER QCPC

RFID - OK STATUS VERIFY 1/4 PMD CHECK AND

IN HMI MONTH CORRECT

S THE

PARMETERS

FUNCTIONING OF KE24 VERIFY 1/WEE PMD CHECK AND

TOP COVER 2080- K CORRECT

PRESENCE 60-01 THE

SENSOR PARMETERS

ANTI-BACK VERIFY 1/4 PMD CHECK AND

PRESENCE MONTH CORRECT

S THE

PARMETERS

STOPPER UP AND VERIFY 1/4 PMD CHECK AND

DOWN SIGNAL MONTH CORRECT

S THE

PARMETERS

PNEUMATIC AIR bar 4.000 6.000 5.000 CHECK 1/DAY OPTR INFORM TO

PRESSURE TEAMLEADE

R

OPERATOR SKILL CL2 CHECK 1/MON ENGG TRAIN THE

LEVEL TH OPERATOR

0065 POLARITY AND Vision & Polarity SENSING OF CHECK 1/DAY OPTR INFORM TO POLARITY OF FIRST NEGATI VISUAL 3/SHIFT 100% IN CHANGE THE

INSERT VISION Check-5065234 SERVO ZEROING TEAMLEADE ROW CELLS (-VE VE T&T SETTING AS

INSPECTION PIN (X & Z AXI R SYMBOL) FIRST PER QCPC

ROW

OVER TRAVEL CHECK 1/4 PMD CHECK AND POLARITY OF EACH ALTER DISPLAY 3/SHIFT 100% IN CHANGE THE

SENSOR MONTH CORRECT ROW CELLS NATIVE T&T SETTING AS

FUNCTIONING S THE POLARI PER QCPC

PARMETERS TY

HOME POSITION CHECK 1/DAY OPTR INFORM TO PRESENCE OF 8 DISPLAY 3/SHIFT 100% IN CHANGE THE

PRECONDITIONS TEAMLEADE SIGNAL INSERT T&T SETTING AS

R @BTM HLDR PER QCPC

POWER ON CHECK 1/DAY OPTR INFORM TO PRESENCE OF 7 DISPLAY 3/SHIFT 100% IN CHANGE THE

PRECONDITIONS TEAMLEADE SIGNAL INSERT T&T SETTING AS

R @TOP HLDR PER QCPC

SAFETY LIGHT KE24 CHECK 1/DAY OPTR INFORM TO AUTO CYCLE CHECK 1/HOUR INFORM TO

CURTAIN 2080- TEAMLEADE START SIGNAL TEAMLEADER

FUNCTIONING 65-01 R FROM SERVER

RFID - OK STATUS CHECK 1/4 PMD CHECK AND NO TRACEABILITY DISPLAY 3/SHIFT INFORM TO

IN HMI MONTH CORRECT BYPASS IN HMI TEAMLEADER

S THE

PARMETERS

FUNCTIONING OF CHECK 1/DAY OPTR INFORM TO

SAFETY DOOR TEAMLEADE

INTERLOCK R

PART PRESENCE CHECK 1/WEE ENGG CHANGE

SENSOR IN PALLET K THE

SETTING AS

PER QCPC

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 18

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

IOT PARAMETERS CHECK 1/MON PMD CHECK AND

TRANSFER TO TH CORRECT

DATA LOGGER THE

PARMETERS

IOT PARAMETERS CHECK 1/MON PMD CHECK AND

USL & LSL LIMITS TH CORRECT

SETTING THE

PARMETERS

FUNCTIONING OF KE24 VERIFY 1/DAY OPTR INFORM TO

POLARITY CHECK 2080- TEAMLEADE

CAMERA 65-02 R

FUNCTIONING OF KE24 VERIFY 1/WEE PMD CHECK AND

INSERT CHECK 2080- K CORRECT

CAMERA 65-03 THE

PARMETERS

0070 MODULE Cell Holder top & BIT SLIP PROGRA 1/MON ENGG CHANGE PRESENCE OF 6 VISUAL 3/SHIFT CHANGE THE

TIGHTENING(A Bottom T215227 DETECTION - M TH THE SCREWS - M4x60 SETTING AS

UTO STATION) Tighte-5065235 4 DISABLE ON SETTING AS FLANGE HEAD PER QCPC

PER QCPC

THREAD DAMAGE PROGRA 1/MON ENGG CHANGE VERIFICATION NME 1.300 2.300 1.800 KE24 TRQ.WR 3/SHIFT 100% IN CHANGE THE

DETECTION M TH THE OFTIGHTENING 2080- EN T&T SETTING AS

-DISABLE ON SETTING AS TORQUE 6SCREWS 70-01 PER QCPC

PER QCPC

SCREWHEAD Deg 180.000 PROGRA 1/MON ENGG CHANGE TIGHTENING AS PER KE24 WORK- 3/SHIFT CHANGE THE

ENGMNT ANGLE M TH THE SEQUENCE TMOS 2080- INS SETTING AS

STEP1-CW SETTING AS 70-02 PER QCPC

PER QCPC

STEP 1 NME 1.000 1.500 1.300 PROGRA 1/MON ENGG CHANGE MODULE WIDTH mm 85.400 86.600 86.000 VERIFY 3/SHIFT CHANGE THE

TIGHTENING M TH THE AFTER TIGHTENING SETTING AS

TORQUE SETTING AS PER QCPC

PER QCPC

STEP 1 rpm 75.000 250.000 PROGRA 1/MON ENGG CHANGE AUTO CYCLE CHECK 1/HOUR INFORM TO

TIGHTENING SPEED 400.000 M TH THE START SIGNAL TEAMLEADER

SETTING AS FROM SERVER

PER QCPC

STEP 2 NME 1.500 2.000 1.800 PROGRA 1/MON ENGG CHANGE SCREW DISPENSE CHECK 1/HOUR INFORM TO

TIGHTENING M TH THE FROM BOWL TEAMLEADER

TORQUE SETTING AS FEEDER

PER QCPC

STEP 2 rpm 115.000 300.000 PROGRA 1/MON ENGG CHANGE TIGHTENING NME 1.300 2.300 1.800 KE24 DISPLAY 3/SHIFT 1/HOUR INFORM TO

TIGHTENING SPEED 442.000 M TH THE TORQUE IN 2080- TEAMLEADER

SETTING AS CONTROLLER 70-03

PER QCPC

FINAL TIGHTENING Deg 2500.000 1/MON ENGG CHANGE NO SCREW HEAD VISUAL 1/HOUR INFORM TO

TORQUE ANGLE 5000.00 TH THE DAMAGE TEAMLEADER

0 SETTING AS

PER QCPC

DC TOOL VERIFY ENGG CHANGE NO TRACEABILITY DISPLAY 3/SHIFT INFORM TO

CALIBRATION 1/YEAR THE BYPASS IN HMI TEAMLEADER

SETTING AS

PER QCPC

0080 INTERCONNEC Grippers & Fixtures OPERATOR SKILL CL2 CHECK 1/MON ENGG TRAIN THE PRESENCE OF 7 no VISUAL 3/SHIFT CHANGE THE

TOR LOADING - for Plasma-5065238 T277236 LEVEL TH OPERATOR DUAL ROW SETTING AS

TOP 2 INTERCONNECTOR PER QCPC

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 19

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

RH SIDE VISUAL 100% OPTR INFORM TO LOADING OF DUAL each 14.000 14.000 14.000 VISUAL 100% INFORM TO

ORIENTATION -L TEAMLEADE ROW INTR.CNTRS TEAMLEADER

BEND TOWARDS R @ LH SIDE

OPTR

LHSIDE VISUAL 100% OPTR INFORM TO LOADING OF DUAL each 14.000 14.000 14.000 VISUAL 100% INFORM TO

ORIENTATION -L TEAMLEADE ROW INTR.CNTRS TEAMLEADER

BEND AWAYFROM R @ RH SIDE

OPTR

NO DAMAGE ON VISUAL 3/SHIFT 100% CHANGE THE

INTERCONNECTOR SETTING AS

S PER QCPC

0090 PLASMA Top Plasma AIR PRESSURE 1 bar 0.200 0.800 DISPLAY 1/MON PMD CHECK AND

CLEANING - Cleaning-5065236 T277236 TH CORRECT

TOP 2 THE

PARMETERS

AIR PRESSURE 2 bar 0.200 0.800 DISPLAY 1/MON PMD CHECK AND

TH CORRECT

THE

PARMETERS

CURRENT ZIP1 A 10.000 20.000 DISPLAY 1/MON PMD CHECK AND

TH CORRECT

THE

PARMETERS

CURRENT ZIP2 A 10.000 20.000 DISPLAY 1/MON PMD CHECK AND

TH CORRECT

THE

PARMETERS

VOLTAGE V 250.000 DISPLAY 1/MON PMD CHECK AND

350.000 TH CORRECT

THE

PARMETERS

ROTATION 1 rpm 2000.000 DISPLAY 1/MON PMD CHECK AND

3000.00 TH CORRECT

0 THE

PARMETERS

ROTATION 2 rpm 2000.000 DISPLAY 1/MON PMD CHECK AND

3000.00 TH CORRECT

0 THE

PARMETERS

FREQUENCY OF kHz 21.000 DISPLAY 1/MON PMD CHECK AND

ZIP1 TH CORRECT

THE

PARMETERS

FREQUENCY OF kHz 21.000 DISPLAY 1/MON PMD CHECK AND

ZIP2 TH CORRECT

THE

PARMETERS

PCT ZIP 1 % 100.000 DISPLAY 1/MON PMD CHECK AND

TH CORRECT

THE

PARMETERS

PCT ZIP 2 % 100.000 DISPLAY 1/MON PMD CHECK AND

TH CORRECT

THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 20

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

WORKING OF FUME CHECK 1/4 PMD CHECK AND

KILLER MONTH CORRECT

S THE

PARMETERS

PLASME KE24 CHECK 3/SHIFT ENGG CHECK AND

COVERAGE ON 2080- CORRECT

MODULE&INTCNTR 80&90 THE

-01 PARMETERS

FUNCTIONING OF KE24 1/MON PMD CHECK AND

AREA SCANNER 2080- TH CORRECT

80&90 THE

-02 PARMETERS

0100 GANTRY- TOP TOP HOME POSITION IN mm 798.272 DISPLAY 1/4 PMD CHECK AND NO DAMAGE ON VERIFY 3/SHIFT CHANGE THE

SIDE WELDING(GANTRY- X AXIS MONTH CORRECT MODULE SETTING AS

1)OP100A-5065239 S THE PER QCPC

PARMETERS

INFEED PICK mm 798.272 DISPLAY 1/4 PMD CHECK AND NO METAL VERIFY 3/SHIFT CHANGE THE

POSITION -Z1 RH IN MONTH CORRECT CONTACT B/W SETTING AS

X AXIS S THE GRIPPER AND PER QCPC

PARMETERS PART

MACHINE 1 DROP mm DISPLAY 1/4 PMD CHECK AND

POS IN X AXIS (Z1) 2402.124 MONTH CORRECT

S THE

PARMETERS

MACHINE 2 DROP mm DISPLAY 1/4 PMD CHECK AND

POS IN X AXIS (Z1) 1570.829 MONTH CORRECT

S THE

PARMETERS

MACHINE 3 DROP mm DISPLAY 1/4 PMD CHECK AND

POS IN X AXIS (Z1) 3486.288 MONTH CORRECT

S THE

PARMETERS

MACHINE 1 PICK mm DISPLAY 1/4 PMD CHECK AND

POS IN X AXIS (Z2) 1399.675 MONTH CORRECT

S THE

PARMETERS

MACHINE 2 PICK mm 568.354 DISPLAY 1/4 PMD CHECK AND

POS IN X AXIS (Z2) MONTH CORRECT

S THE

PARMETERS

MACHINE 3 PICK mm DISPLAY 1/4 PMD CHECK AND

POS IN X AXIS (Z2) 2483.542 MONTH CORRECT

S THE

PARMETERS

OUTFEED DROP mm DISPLAY 1/4 PMD CHECK AND

POS- Z2 RH IN X 3746.006 MONTH CORRECT

AXIS S THE

PARMETERS

INFEED PICK POS mm 786.950 DISPLAY 1/4 PMD CHECK AND

IN Z1 AXIS MONTH CORRECT

S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 21

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

MACHINE 1 DROP mm 842.637 DISPLAY 1/4 PMD CHECK AND

POS IN Z AXIS (Z1) MONTH CORRECT

S THE

PARMETERS

MACHINE 2 DROP mm 845.304 DISPLAY 1/4 PMD CHECK AND

POS IN Z AXIS (Z1) MONTH CORRECT

S THE

PARMETERS

MACHINE 3 DROP mm 845.290 DISPLAY 1/4 PMD CHECK AND

POS IN Z AXIS (Z1) MONTH CORRECT

S THE

PARMETERS

MACHINE 1 PICK mm 841.562 DISPLAY 1/4 PMD CHECK AND

POS IN Z AXIS (Z2) MONTH CORRECT

S THE

PARMETERS

MACHINE 2 PICK mm 841.562 DISPLAY 1/4 PMD CHECK AND

POS IN Z AXIS (Z2) MONTH CORRECT

S THE

PARMETERS

MACHINE 3 PICK mm 845.234 DISPLAY 1/4 PMD CHECK AND

POS IN Z AXIS (Z2) MONTH CORRECT

S THE

PARMETERS

OUTFEED DROP mm 843.910 DISPLAY 1/4 PMD CHECK AND

POS- Z2 RH IN Z MONTH CORRECT

AXIS S THE

PARMETERS

Z1 GRIPPER OPEN mm 786.740 DISPLAY 1/4 PMD CHECK AND

POSTION MONTH CORRECT

S THE

PARMETERS

Z1 GRIPPER CLOSE mm 13.000 DISPLAY 1/4 PMD CHECK AND

POSITION MONTH CORRECT

S THE

PARMETERS

Z2 GRIPPER OPEN mm 52.551 DISPLAY 1/4 PMD CHECK AND

POSTION MONTH CORRECT

S THE

PARMETERS

Z2 GRIPPER CLOSE mm 13.000 DISPLAY 1/4 PMD CHECK AND

POSITION MONTH CORRECT

S THE

PARMETERS

GANTRY SPEED X % 52.994 DISPLAY 1/4 PMD CHECK AND

AXIS MONTH CORRECT

S THE

PARMETERS

GANTRY SPEED Z1 % 50.000 DISPLAY 1/4 PMD CHECK AND

AXIS MONTH CORRECT

S THE

PARMETERS

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 22

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

GANTRY SPEED Z2 % 50.000 DISPLAY 1/4 PMD CHECK AND

AXIS MONTH CORRECT

S THE

PARMETERS

0101 TOP TOP Z1 AXIS:SQUEEZE ms 0 50.000 KE24 DISPLAY 1/MON ENGG CHANGE PULLOFF kf 6.000 KE24 PULL&C 1/DAY CHANGE THE

WELDING-A WELDING(GANTRY- T277234 TIME -MDB5000 2080- TH THE LOAD-(+ve&-ve LV 2080- HK SETTING AS

1)OP100A-5065239 5 101- SETTING AS cells)MIN 6 Kgf 101- PER QCPC

T277234 08 PER QCPC 01

6

T277234

7

Z1 AXIS :UP ms 0 0.500 DISPLAY 1/MON ENGG CHANGE WELD NUGGET mm 0.200 0.800 0.500 KE24 VERIFY 1/DAY CHANGE THE

TIME-MDB5000 TH THE DIAMETER 2080- SETTING AS

SETTING AS 101- PER QCPC

PER QCPC 02

Z1 AXIS:WELD ms 3.300 3.800 DISPLAY 1/MON ENGG CHANGE AUTO CYCLE KE24 CHECK 1/HOUR INFORM TO

TIME-MDB5000 TH THE START SIGNAL 2080- TEAMLEADER

SETTING AS FROM SERVER 101-

PER QCPC 03

Z1 AXIS: DOWN ms 0 0.500 DISPLAY 1/MON ENGG CHANGE NO TRACEABILITY KE24 DISPLAY 3/SHIFT INFORM TO

TIME-MDB5000 TH THE BYPASS IN HMI 2080- TEAMLEADER

SETTING AS 101-

PER QCPC 04

Z1 AXIS:HOLD ms 0 50.000 DISPLAY 1/MON ENGG CHANGE NO FLASHES NOT KE24 VISUAL 3/SHIFT 1/HOUR INFORM

TIME-MDB5000 150.000 TH THE ALLOW 2080- ENGG

SETTING AS ED 101- SUPERVISOR

PER QCPC 05

Z1 AXIS:WELD kA 3.300 3.800 DISPLAY 1/MON ENGG CHANGE NO PEEL OFF OF NOT KE24 VISUAL 3/SHIFT 1/HOUR INFORM

CURRENT-MDB5000 TH THE INTERCONNECTOR ALLOW 2080- ENGG

SETTING AS ED 101- SUPERVISOR

PER QCPC 06

Z1 AXIS:WELD V 3.400 3.800 DISPLAY 1/MON ENGG CHANGE NO CUT MARKS ON NOT KE24 VISUAL 3/SHIFT 1/HOUR INFORM

VOLTAGE-MDB5000 TH THE INTERCONNECTOR ALLOW 2080- ENGG

SETTING AS ED 101- SUPERVISOR

PER QCPC 07

Z1 DISPLAY 1/MON ENGG CHANGE NO.OF.SPOT PER each 3.000 4.000 4.000 CHECK 3/SHIFT CHECK AND

AXIS:PRECHECK- TH THE CELL PER SIDE CORRECT

MDB5000 SETTING AS THE

PER QCPC PARMETERS

Z1 AXIS:PRECHECK V 1.000 1.000 DISPLAY 1/MON ENGG CHANGE NO.OF.WELD SPOT each CHECK 3/SHIFT CHECK AND

VOLTAGE-MDB5000 TH THE PER MODULE 769.000 784.000 CORRECT

SETTING AS THE

PER QCPC PARMETERS

Z1 AXIS:PRECHECK ms 0.500 1.000 DISPLAY 1/MON ENGG CHANGE

TIME-MDB5000 TH THE

SETTING AS

PER QCPC

Z1 AXIS:PRECHECK kA 0.300 1.500 DISPLAY 1/MON ENGG CHANGE

PEAK -MDB5000 TH THE

SETTING AS

PER QCPC

Z1 AXIS:PRECHECK kA 0.300 1.200 DISPLAY 1/MON ENGG CHANGE

AVG-MDB5000 TH THE

SETTING AS

PER QCPC

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 23

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

Z1 AXIS:SQUEEZE ms 0.150 0.200 0.100 DISPLAY 1/MON ENGG CHANGE

TIME - MU100 TH THE

SETTING AS

PER QCPC

Z1 AXIS:WELD ms 0.150 0.250 0.250 DISPLAY 1/MON ENGG CHANGE

TIME- MU100 TH THE

SETTING AS

PER QCPC

Z1 AXIS:HOLD TIME- ms 50.000 0.100 DISPLAY 1/MON ENGG CHANGE

MU100 200.000 TH THE

SETTING AS

PER QCPC

Z1 AXIS:BEFORE N 40.000 65.000 DISPLAY 1/MON ENGG CHANGE

FORCE- MU100 TH THE

SETTING AS

PER QCPC

Z1 AXIS:AFTER N 40.000 65.000 DISPLAY 1/MON ENGG CHANGE

FORCE- MU100 TH THE

SETTING AS

PER QCPC

Z1 AXIS:BEFORE mm 1.000 3.000 DISPLAY 1/MON ENGG CHANGE

DISPLACEMENT- TH THE

MU100 SETTING AS

PER QCPC

Z1 AXIS:AFTER mm 1.000 3.000 DISPLAY 1/MON ENGG CHANGE

DISPLACEMENT- TH THE

MU100 SETTING AS

PER QCPC

Z1 mm 0.040 0.200 DISPLAY 1/MON ENGG CHANGE

AXIS:DISPLACEMEN TH THE

T- MU100 SETTING AS

PER QCPC

Z1 AXIS:SCHEDULE 1.000 DISPLAY 1/MON ENGG CHANGE

SELECTION +VE TH THE

TERMINAL SETTING AS

PER QCPC

Z1 AXIS:SCHEDULE 2.000 DISPLAY 1/MON ENGG CHANGE

SELECTION -VE TH THE

TERMINAL SETTING AS

PER QCPC

Z2 AXIS: SQUEEZE ms 0 50.000 DISPLAY 1/MON ENGG CHANGE

TIME -MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS: UP ms 0 0.500 DISPLAY 1/MON ENGG CHANGE

TIME-MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:WELD ms 3.400 3.800 DISPLAY 1/MON ENGG CHANGE

TIME-MDB5000 TH THE

SETTING AS

PER QCPC

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 24

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No

CONTROL ITEMS (CAUSES) CONTROLLING METHOD Reaction Cor CONTROL ITEMS CONTROLLING METHOD Reaction Cor

rect rect

Plan ive Plan ive

acti Acti

ons ons

Cell Leader/ Operator

Inspector

Process Parameter Spl UOM Lower Upper Target Poka Check Check Tool RESP Product Parameter Spl UOM Lower Upper Target Poka Check Check Tool Check Tool

Ch limit limit Value yoke Method FREQ of Ch limit limit Value yoke Method FREQ of FREQ. of

CTRL CTRL CTRL

Z2 AXIS: DOWN ms 0 0.500 DISPLAY 1/MON ENGG CHANGE

TIME-MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:HOLD ms 0 50.000 DISPLAY 1/MON ENGG CHANGE

TIME-MDB5000 150.000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:WELD kA 3.400 3.800 DISPLAY 1/MON ENGG CHANGE

CURRENT-MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:WELD V 3.400 3.800 DISPLAY 1/MON ENGG CHANGE

VOLTAGE-MDB5000 TH THE

SETTING AS

PER QCPC

Z2AXIS:PRECHECK- DISPLAY 1/MON ENGG CHANGE

MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:PRECHECK V 1.000 1.000 DISPLAY 1/MON ENGG CHANGE

VOLTAGE-MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:PRECHECK ms 0.500 1.000 DISPLAY 1/MON ENGG CHANGE

TIME-MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:PRECHECK kA 0.300 1.500 DISPLAY 1/MON ENGG CHANGE

PEAK -MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:PRECHECK kA 0.300 1.200 DISPLAY 1/MON ENGG CHANGE

AVG-MDB5000 TH THE

SETTING AS

PER QCPC

Z2 AXIS:SQUEEZE ms 0.050 0.150 0.100 DISPLAY 1/MON ENGG CHANGE

TIME - MU100 TH THE

SETTING AS

PER QCPC

Z2 AXIS:WELD ms 0.150 0.300 0.250 DISPLAY 1/MON ENGG CHANGE

TIME- MU100 TH THE

SETTING AS

PER QCPC

Z2 AXIS:HOLD TIME- ms 0.050 0.150 0.100 DISPLAY 1/MON ENGG CHANGE

MU100 TH THE

SETTING AS

PER QCPC

Z2 AXIS:BEFORE N 40.000 60.000 DISPLAY 1/MON ENGG CHANGE

FORCE- MU100 TH THE

SETTING AS

PER QCPC

TOOL OF CONTROL REVISION

TOOL CONDITION MONITORING OPERATOR DEPLOYMENT SPECIAL CHARACTERISTICS SYMBOLS REACTION PLAN ISSUE 00 PREPARED BCP

CALIBRATION CHECKSHEET BY

SHEET FOR CONTROL PM RECORD MAJOR FIT/ CRITICAL FIT/ C1- STOP, QUARANTINE, 100%, DATE 03.11.2023 CHECKED SA

OPERATORS CHART FUNCTION FUNCTION CHECK & ADJUST BY

SHEET FOR FIXTURE SAFETY/ APPEARANCE C2 - STOP, QUARANTINE, 100%, APPROVED MRS

VIEWERS/INSPECTORS CMM CALIBRATION REGULATIONS ITEMS CHECK & INFORM SUPERVISOR BY

QSF PED 02 03 009 Rev '2' Dated

QUALITY CONTROL PROCESS CHART

Model: PART No: PART Description: DRG Stage / Rev / LOCATION Valid For : Group No: Group

UP.467F KE242080 BATTERY PACK ASSY C2 1B 10.10.2023 50006777 02

DATE: 12.12.2023 PLANT: 3 UNIT: MODULE: CELL: PAGE No: 25

BA BATTERY ASSY LINE-2

OP OPN Machine Tool PROCESS PARAMETERS PRODUCT/PART PARAMETERS

No Description Description and No/

Number Fixture

No