Professional Documents

Culture Documents

Hazardous Spray Exercise

Uploaded by

Mohamed OmarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hazardous Spray Exercise

Uploaded by

Mohamed OmarCopyright:

Available Formats

Hazardous Spray Exercise

Initial Conditions: Thursday, January 3, 10:35 control room and talked to the Shift Both rinsed the fluid off their skin.

AM. Normal plant operations. Removal and Supervisor. He gave them permission to

The Unit Operator notified the Shift

replacement of Line “A” pressure detector install the new A2 detector and told them to

Supervisor of the problem who had the two

number 2 on Tank G1036 was in progress. inform the Unit Operator about the

pipefitters report to the site first-aid station.

replacement.

Description of Incident: Two pressure The pipefitters were referred to the county

detectors (to provide a redundant capacity) are They then went to the unit, found the Unit hospital where they were observed overnight

available on each of three feed inlet lines. Operator (making hourly reading checks) and released the next morning.

Pressure detector number 2 on Line “A” failed and informed him that they were there to

Both pipefitters were wearing safety glasses

low at 10:15 PM on Wednesday, January 2. replace detector A2. The Unit Operator said

but not full face shields nor protective gloves

Maintenance and Operations management that he told them the off-going shift had

as required by SDS. One received first

decided to replace the detector with a pre- drained the system and that it was ready for

degree burns to his face and hands. The

calibrated spare during the day shift on work. The Unit Operator did not go to the

other received a first degree burn to one

Thursday. work site and review the work with the

hand. Both returned to work the next day on

pipefitters (required by plant policy).

The midnight-shift Unit Operator prepared the a restricted work basis.

work request and tagout for detector A2 and had The pipefitters then went to the detector

Further investigation showed that the

it authorized by the midnight-shift Shift platform (an elevated platform that provides

detectors were not within sight of the locked-

Supervisor. The midnight-shift Unit Operator easy access to the detectors which are

out isolation valves (isolation valves were at

says that on Thursday, she isolated detector A2, approximately 10 feet above floor level) and

floor level underneath the platform), there

drained the hazardous fluid into an approved began to loosen the detector's connecting

were no equipment identification labels on

container, and placed appropriate isolation tags flange bolts. They did not hang their own

the detectors, and the senior pipefitter, who

and locks on the A2 isolation valves. She then locks or tags on the isolation valves or trace

was familiar with this type of unit, said he

called the Shift Supervisor and informed him the lines (required by plant policy). When

thought he was disconnecting detector A2

that detector A2 was ready for removal and the third bolt was about three turns loose

because he believed the detector

replacement. (they had already removed two of four bolts),

arrangement was the same as the "identical

hazardous material began spraying from the

At 8:00 AM shift turnover occurred. The day-shift units" he was used to working on. However,

flange onto the pipefitters. They re-

Unit Operator and Shift Supervisor were told he disconnected detector A1 instead of A2

tightened the third bolt, but the spray

detector A2 was ready for removal and because the arrangement is backward to the

continued until one of the previously

replacement. The day-shift Shift Supervisor other "identical units". The company’s line

removed bolts was inserted and tightened.

contacted the Maintenance Foreman to get the break policy requires pipefitters to loosen all

Overall, the spray lasted about one to two

work started. The Maintenance Foreman bolts and break the line away from them

minutes.

assigned two pipefitters to the job. before they remove any bolts.

The Unit Operator, who had just come by,

At 10:00 AM, the two pipefitters arrived at the

took them to a nearby eyewash and wash

down station.

You might also like

- JSA For Cutting, Grinding and WeldingDocument4 pagesJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JOB SAFETY ANALYSIS - Hydro Testing of Domestic Piping System.Document2 pagesJOB SAFETY ANALYSIS - Hydro Testing of Domestic Piping System.salauddin0mohammedNo ratings yet

- Maintenance Work Instruction: Instrument To Be Tagged With Dated Test LabelDocument2 pagesMaintenance Work Instruction: Instrument To Be Tagged With Dated Test Labelhobam3297No ratings yet

- Yokoten Accident - Nov'23Document12 pagesYokoten Accident - Nov'23MTS EHSNo ratings yet

- International General Certificate Candidate 'S Observation (2013 Specification) Sheet Igc3 - The Health and Safety Practical ApplicationDocument10 pagesInternational General Certificate Candidate 'S Observation (2013 Specification) Sheet Igc3 - The Health and Safety Practical ApplicationRakesh ShambharkarNo ratings yet

- Quotation ASl HARMONY ELECTRICDocument4 pagesQuotation ASl HARMONY ELECTRICalim mukhtarNo ratings yet

- HIRA No 22 Installation Use of Temp Electrical Supplies SBDDocument2 pagesHIRA No 22 Installation Use of Temp Electrical Supplies SBDMobin Thomas AbrahamNo ratings yet

- Method of Statement MetsDocument5 pagesMethod of Statement MetsEmmanuel ToretaNo ratings yet

- Fire Alarm System Installation Inspection Checkllist PDFDocument4 pagesFire Alarm System Installation Inspection Checkllist PDFAhmed KhamisNo ratings yet

- E 24 25 GP 001 Isolation, Lockout and Permit To Work On Any Hazardous SystemDocument13 pagesE 24 25 GP 001 Isolation, Lockout and Permit To Work On Any Hazardous SystemJohn KalvinNo ratings yet

- WMS - MV PANEL Maintenance - BIN MAHMOUD PLAZADocument7 pagesWMS - MV PANEL Maintenance - BIN MAHMOUD PLAZAvipinkmlNo ratings yet

- JOB SAFETY ANALYSIS No - 3 - Pressure Testinmg For GRE Pipess For Infrastructure Services (Chilled Water)Document2 pagesJOB SAFETY ANALYSIS No - 3 - Pressure Testinmg For GRE Pipess For Infrastructure Services (Chilled Water)salauddin0mohammedNo ratings yet

- Collision Between TDS and Pipe Racker - Ver 6Document12 pagesCollision Between TDS and Pipe Racker - Ver 6vikrant911No ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- Jsa PVC, CPVC, Teflon, PVDFDocument7 pagesJsa PVC, CPVC, Teflon, PVDFM. MagnoNo ratings yet

- Installation of GlassDocument6 pagesInstallation of GlassVilky VargheseNo ratings yet

- RT Svx21f en (3 10 Ton Iom)Document56 pagesRT Svx21f en (3 10 Ton Iom)jfisher54100% (1)

- VAR TEC FDR Series User ManualDocument2 pagesVAR TEC FDR Series User ManualmicrajacutNo ratings yet

- Hd912 ManualDocument2 pagesHd912 ManualrhomadonaNo ratings yet

- 5151 - Manual - I56-5151 DHCDocument2 pages5151 - Manual - I56-5151 DHCmeribout adelNo ratings yet

- Hydro Test PipesDocument3 pagesHydro Test PipesVikram Kumar MvsNo ratings yet

- Thermographic Inspections Detect Electrical FaultsDocument2 pagesThermographic Inspections Detect Electrical Faultsdragoon wmdNo ratings yet

- A Safety Alert Maintenance 1 IADCDocument2 pagesA Safety Alert Maintenance 1 IADCvsrslmNo ratings yet

- A Safety-Alert-Maintenance 1-IADC PDFDocument2 pagesA Safety-Alert-Maintenance 1-IADC PDFVeeramuthu SundararajuNo ratings yet

- Remote-Controlled Hot Tapping SubseaDocument4 pagesRemote-Controlled Hot Tapping SubsearamyzottyNo ratings yet

- 8300-0027 SK-300 Trifasica ItDocument24 pages8300-0027 SK-300 Trifasica Itankarthik11No ratings yet

- 621-CC#09 Idler and Frame ChangingDocument4 pages621-CC#09 Idler and Frame ChangingBuddy Hart100% (1)

- MS FSK PSK Fiber Optic 031120Document3 pagesMS FSK PSK Fiber Optic 031120DilxazNo ratings yet

- JSA For MV SWGR. ReplacementDocument5 pagesJSA For MV SWGR. ReplacementSharjeel AhmedNo ratings yet

- PermitDocument7 pagesPermitdeepak bhagatNo ratings yet

- Monthly Scope of Inspection and ContentDocument21 pagesMonthly Scope of Inspection and ContentkokoNo ratings yet

- Dedsp Experiment 1 (Oct 2016) 1 Modified by TehghDocument7 pagesDedsp Experiment 1 (Oct 2016) 1 Modified by TehghClarence ClarNo ratings yet

- Site Coordination Meeting: Elimination: Nil Substitution:Scissors Lift PPE:Dust Mask, SafetyDocument2 pagesSite Coordination Meeting: Elimination: Nil Substitution:Scissors Lift PPE:Dust Mask, SafetyRama RajanNo ratings yet

- 2.0 Pre - Commissioning 2.1 Pre - Commissioning ActivitiesDocument6 pages2.0 Pre - Commissioning 2.1 Pre - Commissioning Activitiessamtom100% (1)

- Ok-Hydraulic Oil Flushing at Terminal AreaDocument4 pagesOk-Hydraulic Oil Flushing at Terminal AreaEric TingNo ratings yet

- Testing & Commissioning of Fire Suppression SystemDocument5 pagesTesting & Commissioning of Fire Suppression Systemmyanmarfire100% (2)

- Solar Hot Water System - Repair and ServiceDocument4 pagesSolar Hot Water System - Repair and Servicehari karanNo ratings yet

- Observations Control Measures TimescaleDocument13 pagesObservations Control Measures TimescaleDENISNo ratings yet

- HWC - O&M ManualDocument16 pagesHWC - O&M ManualAONLANo ratings yet

- Maintenance Work Instruction: Page. 1 of 2Document2 pagesMaintenance Work Instruction: Page. 1 of 2hobam3297No ratings yet

- Trace Insulation FaultsDocument2 pagesTrace Insulation FaultsRamakantNo ratings yet

- DVD PLAYER SERVICE MANUALDocument79 pagesDVD PLAYER SERVICE MANUALRomer AlfonsoNo ratings yet

- G1533-90327 Installation Guide ECDDocument30 pagesG1533-90327 Installation Guide ECDFelipe AndrinoNo ratings yet

- Dcs Translation - pdf1Document7 pagesDcs Translation - pdf1gnrcwd924bNo ratings yet

- Electrical Equipment 2010Document3 pagesElectrical Equipment 2010victorNo ratings yet

- Spiral Plate Heat Exchanger ApparatusDocument6 pagesSpiral Plate Heat Exchanger ApparatusmjunaidNo ratings yet

- Procedure For Well TestingDocument4 pagesProcedure For Well TestingTg TarroNo ratings yet

- PTW Test Questions & Answers For Mech. TechnicanDocument9 pagesPTW Test Questions & Answers For Mech. TechnicanNoohu FasilullaNo ratings yet

- Simplified LOTO ProcedureDocument8 pagesSimplified LOTO ProcedureLuqman OsmanNo ratings yet

- Job Safety Analysis for Overhauling OH Cranes in Ammonia, Urea and Nitric Acid PlantsDocument2 pagesJob Safety Analysis for Overhauling OH Cranes in Ammonia, Urea and Nitric Acid PlantsSharjeel AhmedNo ratings yet

- FF Water Sprinkler Test ProcedureDocument2 pagesFF Water Sprinkler Test ProcedureSalim Bakhsh100% (1)

- Work Permit - Ionizing Radiation: Work Should Not Commence Until Stages 1 To 5 Are CompletedDocument2 pagesWork Permit - Ionizing Radiation: Work Should Not Commence Until Stages 1 To 5 Are CompletedIonian TribeNo ratings yet

- MS Old CCR Fiber Optic PSK CPF & Meeting Room 220221Document3 pagesMS Old CCR Fiber Optic PSK CPF & Meeting Room 220221DilxazNo ratings yet

- Installation Guide For Heater Interface For MSD-SDocument12 pagesInstallation Guide For Heater Interface For MSD-SMatthieu BuecheNo ratings yet

- Electrical Inspection ProceduresDocument21 pagesElectrical Inspection ProceduresbernardNo ratings yet

- T&C of Fire Supression SystemDocument5 pagesT&C of Fire Supression Systemamg007100% (1)

- JSA - Mechanical Excavation PDFDocument4 pagesJSA - Mechanical Excavation PDFMohammed MinhajNo ratings yet

- Unit IG2: Risk AssessmentDocument14 pagesUnit IG2: Risk AssessmentSardar100% (2)

- Ongoing / Upcoming Activities at Manifa CHF Project: HSE HSEDocument12 pagesOngoing / Upcoming Activities at Manifa CHF Project: HSE HSERahil TasawarNo ratings yet

- HIMA Planar4 Alternative for CERN Interlocking SystemsDocument15 pagesHIMA Planar4 Alternative for CERN Interlocking SystemsMohamed OmarNo ratings yet

- Hipps Brochure PDFDocument16 pagesHipps Brochure PDFDiarista Thoma SaputraNo ratings yet

- Safety Barrier Management: Risk-Based Approach For The Oil and Gas SectorDocument21 pagesSafety Barrier Management: Risk-Based Approach For The Oil and Gas Sectorfzida8942No ratings yet

- Safety Barrier Management: Risk-Based Approach For The Oil and Gas SectorDocument21 pagesSafety Barrier Management: Risk-Based Approach For The Oil and Gas Sectorfzida8942No ratings yet

- D5096S - SIL 3 5A NO Relay ModuleDocument5 pagesD5096S - SIL 3 5A NO Relay ModuleMohamed OmarNo ratings yet

- Compliance: With IEC EN 61508:2010Document7 pagesCompliance: With IEC EN 61508:2010Mohamed OmarNo ratings yet

- HIPPS Solutions: Safe and Profitable OperationsDocument14 pagesHIPPS Solutions: Safe and Profitable OperationsMohamed OmarNo ratings yet

- How Can You Achieve Safety and Profitability ?Document32 pagesHow Can You Achieve Safety and Profitability ?Mohamed OmarNo ratings yet

- 968 EL 822 02 19 en ElDocument1 page968 EL 822 02 19 en ElMohamed OmarNo ratings yet

- In ProcessDocument16 pagesIn ProcessMohamed OmarNo ratings yet

- 2-Fold Analogue Limit Monitor 62 100 Safety-Related: Connection Not RequiredDocument20 pages2-Fold Analogue Limit Monitor 62 100 Safety-Related: Connection Not RequiredMohamed OmarNo ratings yet

- Planar4 System ManualDocument194 pagesPlanar4 System ManualMohamed OmarNo ratings yet

- IEC 61508 Functional Safety Assessment: Automation SolutionsDocument21 pagesIEC 61508 Functional Safety Assessment: Automation SolutionsMohamed OmarNo ratings yet

- L&T Valves Limited: S I L (SIL) V F H I P P S (H)Document14 pagesL&T Valves Limited: S I L (SIL) V F H I P P S (H)Mohamed OmarNo ratings yet

- Functional Safety Certificate Assessment 3051s Pressure Transmitter en 77168Document22 pagesFunctional Safety Certificate Assessment 3051s Pressure Transmitter en 77168Mohamed OmarNo ratings yet

- CPU 410 en en-USDocument422 pagesCPU 410 en en-USHammad AshrafNo ratings yet

- en Vegaswing 63 Relay (DPDT)Document2 pagesen Vegaswing 63 Relay (DPDT)MaxiwendelNo ratings yet

- For Information Only: Type Approval CertificateDocument3 pagesFor Information Only: Type Approval CertificateMohamed OmarNo ratings yet

- s7300 Failsafe Signal Modules Hardware Manual en-US en-US PDFDocument372 pagess7300 Failsafe Signal Modules Hardware Manual en-US en-US PDFJimy MendozaNo ratings yet

- SIL3 24/220Vdc/Vac Transistor-Out Detector: Technical DataDocument2 pagesSIL3 24/220Vdc/Vac Transistor-Out Detector: Technical DataMohamed OmarNo ratings yet

- IEC 61508 Functional Safety Assessment: Automation SolutionsDocument21 pagesIEC 61508 Functional Safety Assessment: Automation SolutionsMohamed OmarNo ratings yet

- Contactless electronic level switch specification sheetDocument2 pagesContactless electronic level switch specification sheetMohamed OmarNo ratings yet

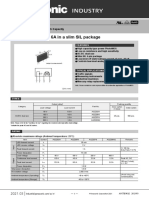

- Power: High Capacity Up To 6A in A Slim SIL PackageDocument14 pagesPower: High Capacity Up To 6A in A Slim SIL PackageMohamed OmarNo ratings yet

- Product Information: VibratingDocument28 pagesProduct Information: VibratingMohamed OmarNo ratings yet

- Prosafe Rs Im32q01s10 31eDocument27 pagesProsafe Rs Im32q01s10 31e최재호No ratings yet

- en VEGASWING 53 Contactless Electronic SwitchDocument32 pagesen VEGASWING 53 Contactless Electronic SwitchMohamed OmarNo ratings yet

- D5096S - SIL 3 5A NO Relay ModuleDocument5 pagesD5096S - SIL 3 5A NO Relay ModuleMohamed OmarNo ratings yet

- Point Level L Vibration L Liquids: Area of ApplicationDocument2 pagesPoint Level L Vibration L Liquids: Area of ApplicationMohamed OmarNo ratings yet

- Contactless electronic level switch specification sheetDocument2 pagesContactless electronic level switch specification sheetMohamed OmarNo ratings yet

- SMS Reliability HayesDocument42 pagesSMS Reliability HayesAldyan NurfaiziNo ratings yet

- 3 Kinds of de Facto Government:: CharacteristicsDocument10 pages3 Kinds of de Facto Government:: CharacteristicsAbigael SeverinoNo ratings yet

- NHBC Standards 2011 Bre SD 1 SRCDocument5 pagesNHBC Standards 2011 Bre SD 1 SRCSuresh RaoNo ratings yet

- j00m HD FLV SQL Injection - PyDocument4 pagesj00m HD FLV SQL Injection - PyZeljko PanovicNo ratings yet

- Tata Consulting Engineers Design Guide For Auxiliary Steam HeaderDocument10 pagesTata Consulting Engineers Design Guide For Auxiliary Steam HeadervijayanmksNo ratings yet

- 001-Numerical Solution of Non Linear EquationsDocument16 pages001-Numerical Solution of Non Linear EquationsAyman ElshahatNo ratings yet

- Elementos ElectrónicosDocument9 pagesElementos ElectrónicosKratt DeividNo ratings yet

- Parent DC Promo Ui LogDocument193 pagesParent DC Promo Ui LogRachell SmithNo ratings yet

- Workplace 2017Document8 pagesWorkplace 2017Vesign MediaNo ratings yet

- KEDIT User's GuideDocument294 pagesKEDIT User's GuidezamNo ratings yet

- AI Writing Tools For Social Media Marketing Creating Compelling PostsDocument5 pagesAI Writing Tools For Social Media Marketing Creating Compelling PostsJames DanielsNo ratings yet

- Bài tập Toán Cao Cấp - Tập 2 - Nguyễn Đình TríDocument272 pagesBài tập Toán Cao Cấp - Tập 2 - Nguyễn Đình TríMai Anh NguyễnNo ratings yet

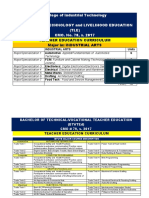

- College of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Document5 pagesCollege of Industrial Technology Bachelor of Technology and Livelihood Education (TLE) CMO. No. 78, S. 2017Industrial TechnologyNo ratings yet

- Nikita Rajput: Anchor/Host/Master of CeremoniesDocument21 pagesNikita Rajput: Anchor/Host/Master of CeremoniesnamanNo ratings yet

- Zodiac Working Boat MK6HDDocument4 pagesZodiac Working Boat MK6HDdan antonNo ratings yet

- 144-WARA AD 2.1 To AD 2.24 AIRAC AIP AMDT 125 26 JAN 23Document9 pages144-WARA AD 2.1 To AD 2.24 AIRAC AIP AMDT 125 26 JAN 23latsar kusumoNo ratings yet

- HQ 170aDocument82 pagesHQ 170aTony WellsNo ratings yet

- RTD Temperature Transmitter Calibration Report TemplateDocument1 pageRTD Temperature Transmitter Calibration Report TemplateSuswantoro ToroNo ratings yet

- Sample BudgetDocument109 pagesSample BudgetAnjannette SantosNo ratings yet

- Quiz ME 1Document4 pagesQuiz ME 1Radytia BimantaraNo ratings yet

- Consultants DirectoryDocument36 pagesConsultants DirectoryAnonymous yjLUF9gDTSNo ratings yet

- Appendix 2 Overview On HRM Defintions Contribution and Avenues For Future ResearchDocument6 pagesAppendix 2 Overview On HRM Defintions Contribution and Avenues For Future ResearchBarun Kumar SinghNo ratings yet

- Corbin Technical Bulletin Volume 4Document149 pagesCorbin Technical Bulletin Volume 4aikidomoysesNo ratings yet

- Global CityDocument3 pagesGlobal Citycr lamigoNo ratings yet

- Air ConditionDocument4 pagesAir ConditionTaller Energy EnergyNo ratings yet

- Control unit checks gas burner valve tightness according to EN 1643Document12 pagesControl unit checks gas burner valve tightness according to EN 1643alfredomamutNo ratings yet

- When a Free Patent is VoidDocument2 pagesWhen a Free Patent is VoidRyan AcostaNo ratings yet

- 04 Greeting Card Activity RubricDocument1 page04 Greeting Card Activity RubricJon Jon Marcos100% (2)

- Written Report Maneco FinalDocument31 pagesWritten Report Maneco FinalKymicah DesiertoNo ratings yet

- TUTO 4 PU Sol PDFDocument21 pagesTUTO 4 PU Sol PDFVievie Le BluewberrietrufflesNo ratings yet

- Lecture 08Document27 pagesLecture 08simraNo ratings yet