Professional Documents

Culture Documents

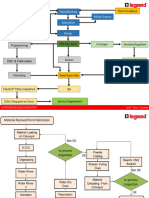

Causes of Dehydration Package Failure: Process Machine

Uploaded by

Ibn MasrOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Causes of Dehydration Package Failure: Process Machine

Uploaded by

Ibn MasrCopyright:

Available Formats

Causes Of Dehydration Package Failure

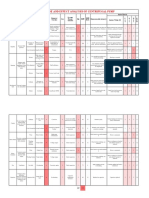

Insufficient

planning No spare in

W/H Process Machine

Preceding

coalescing filter regeneration

Delay of reorder inefficient Over Lack of

temperature manpower PCV not

Filter exceeded Insufficient calibrated

operation time Knowledge from Lack of during last

limit worker

glycol training PM

contaminants on Postponed

individual

mole sieve Wrong Temp. due to

operational Inadequate

Control valve overtasks PCV

actions from

suppliers setting output

Lack of

Thermal PCV

Coordination

stresses on Malfunction

gas Flow rate mole sieve

Failure of

Gas over

fluctuating during

pressurized dehydration

normal operation package

(molecular

Crush strength value Operators Start Bad handling sieve)

out of specs. the unit in of Mol. sieve

Lack of training harmful manner during filling

to sieve

Over Self

Confidence Lack of

Didn’t anticipate supervision Service

lack of company not

Labor aging following best

knowledge No commitment

to plant written practice

Unable to perform procedure

standard acceptance

inspection

People Method

Material

You might also like

- 4 Modern Developments 2Document1 page4 Modern Developments 2ocallagrNo ratings yet

- Maintenance Patterns and Fmea AnalysisDocument11 pagesMaintenance Patterns and Fmea AnalysisAdaaNo ratings yet

- Pss Cidade SaoDocument25 pagesPss Cidade SaoElla AgbettorNo ratings yet

- Product Quality: Inefficient Quality Control SystemDocument3 pagesProduct Quality: Inefficient Quality Control SystemRafael ObusanNo ratings yet

- 2013 SSB F23DP-A Conductor Repair Lesson Learnt (Final)Document10 pages2013 SSB F23DP-A Conductor Repair Lesson Learnt (Final)Azim SamiinNo ratings yet

- Six Sigma and Preventive Maintenance Reduce Fabric DefectsDocument10 pagesSix Sigma and Preventive Maintenance Reduce Fabric DefectsAnisa FauziahNo ratings yet

- Natural gas dehydration problem preventionDocument3 pagesNatural gas dehydration problem preventionIbn MasrNo ratings yet

- Tripod Sample HSEFAMDocument2 pagesTripod Sample HSEFAMAbdou BencheikhNo ratings yet

- Production Process OverviewDocument14 pagesProduction Process Overviewniraj4141gNo ratings yet

- Fishbone Diagram: Other Factors Environment PeopleDocument1 pageFishbone Diagram: Other Factors Environment Peoplebhargav121No ratings yet

- Safety MomentDocument5 pagesSafety Momenttarek_bouzayaniNo ratings yet

- How To Do Focuses ImprovementDocument39 pagesHow To Do Focuses Improvementashutoshpal21No ratings yet

- FMEA MAIN 1Document9 pagesFMEA MAIN 1krishnan selvanNo ratings yet

- Incident Tree For LSA ViolationDocument1 pageIncident Tree For LSA ViolationLewis EkiyorNo ratings yet

- Failure Mode and Effect Analysis of Centrifugal PumpDocument2 pagesFailure Mode and Effect Analysis of Centrifugal PumpHAFIZMUHAMMAD SAJID100% (4)

- Group Alpha (Widy, Yoga, Fadly) - FMEA - ManRisk - MK3L 2019Document3 pagesGroup Alpha (Widy, Yoga, Fadly) - FMEA - ManRisk - MK3L 2019Widy Abe Wibisono100% (1)

- MMP Module 2 - Assignment No. 3 - Muhammad QasimDocument6 pagesMMP Module 2 - Assignment No. 3 - Muhammad QasimMuhammad Qasim MalikNo ratings yet

- Process FMEA analysisDocument4 pagesProcess FMEA analysisMadan PrakashNo ratings yet

- Emergency Action Plan DibbaDocument6 pagesEmergency Action Plan Dibbaabisankar333No ratings yet

- Customer Complinat - SadhuDocument2 pagesCustomer Complinat - SadhuPANKAJ JAISWALNo ratings yet

- Fishbone DiagramDocument1 pageFishbone DiagramAsri Marwa UmniatiNo ratings yet

- Failure Mode and Effect Analysis of Centrifugal PumpDocument2 pagesFailure Mode and Effect Analysis of Centrifugal PumpHAFIZMUHAMMAD SAJIDNo ratings yet

- Hazop Study PrintDocument11 pagesHazop Study PrintKetan PatelNo ratings yet

- Malati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDocument1 pageMalati Founders PVT Ltd. Risk Analysis For Rework Rev No Rev DateDhananjay PatilNo ratings yet

- Chesterton-Mechanical Seal Failure Analysis WorksheetDocument4 pagesChesterton-Mechanical Seal Failure Analysis WorksheetAnonymous Bdt0OGhNo ratings yet

- OIL FILLING QUALITY ISSUEDocument2 pagesOIL FILLING QUALITY ISSUErama subrahmanyamNo ratings yet

- Failure Mode and Effects Analysis (Process Fmea) : Wrong Grade of Material ReeivedDocument6 pagesFailure Mode and Effects Analysis (Process Fmea) : Wrong Grade of Material Reeiveddada kolekarNo ratings yet

- StrelionDocument1 pageStrelionRoihan AngsoriNo ratings yet

- Fatigue Management ICMMDocument18 pagesFatigue Management ICMMdwinovriantiputriNo ratings yet

- Atac 113 Pfmea R10 IatfDocument50 pagesAtac 113 Pfmea R10 IatfAzlan MustaphaNo ratings yet

- HAZOP Workbook-Distillation Column 101-102Document4 pagesHAZOP Workbook-Distillation Column 101-102Ibrahim Nick DibalNo ratings yet

- Corrective Action Report (CAR) : Fish Bone AnalysisDocument2 pagesCorrective Action Report (CAR) : Fish Bone AnalysisFarrukh Jamil100% (1)

- Fmea ExampleDocument6 pagesFmea ExampleSandeepNo ratings yet

- LP - Process MappingDocument47 pagesLP - Process MappingMugur AchiteiNo ratings yet

- Potential failures in manufacturing processDocument24 pagesPotential failures in manufacturing processrodeth marquezNo ratings yet

- Quality Tools Cause and Effect DiagramDocument3 pagesQuality Tools Cause and Effect DiagramRaj SekarNo ratings yet

- PID Reversal Sample ReportDocument19 pagesPID Reversal Sample ReportPranav MaheshwariNo ratings yet

- 3-01 KanbanDocument58 pages3-01 KanbanJuan PabloNo ratings yet

- HỌC ONLINE 2022.11.12 CAP-Corrective Action Plan - Hướng Dẫn QA QC Làm Bảng Hành Động Khắc Phục LỗiDocument7 pagesHỌC ONLINE 2022.11.12 CAP-Corrective Action Plan - Hướng Dẫn QA QC Làm Bảng Hành Động Khắc Phục Lỗivuhien393No ratings yet

- Process FMEA: Deformation of The Case Thermo-Couples FailDocument4 pagesProcess FMEA: Deformation of The Case Thermo-Couples Failyohanes sukmana kuncaraNo ratings yet

- CSM by AramcoDocument3 pagesCSM by AramcoSharifullahNo ratings yet

- Check Point For RebberizingDocument1 pageCheck Point For RebberizingDilnesa EjiguNo ratings yet

- Production Study Sheet: Effective Non Effective ActivitiesDocument3 pagesProduction Study Sheet: Effective Non Effective Activitieslodestar ieNo ratings yet

- Customer:: Potential Failure Mode and Effect Analysis (Process FMEA)Document8 pagesCustomer:: Potential Failure Mode and Effect Analysis (Process FMEA)Rajnish PotdarNo ratings yet

- Root Cause Analysis of Motor Driven Fire Pump FailuresDocument5 pagesRoot Cause Analysis of Motor Driven Fire Pump FailuresadrianNo ratings yet

- Offshore Oil & Gas Facilities Decommissioning Pipeline CleaningDocument1 pageOffshore Oil & Gas Facilities Decommissioning Pipeline CleaninganishsrNo ratings yet

- PFMEA&control Plan LinkageDocument7 pagesPFMEA&control Plan LinkageToni HimawanNo ratings yet

- 5.1.1.2_Process Effectiveness and Efficiency_other ExampleDocument2 pages5.1.1.2_Process Effectiveness and Efficiency_other Examplerc2834338No ratings yet

- Risk Assessment-2021Document2 pagesRisk Assessment-2021Mayur KhalatkarNo ratings yet

- FMEA ExampleDocument8 pagesFMEA ExampleAhmed KsibiNo ratings yet

- Dr. Katsutoshi Toda 5 1Document23 pagesDr. Katsutoshi Toda 5 1Mihir RanaNo ratings yet

- CD6 Prototype PFMEADocument4 pagesCD6 Prototype PFMEAmpedraza-1No ratings yet

- Ix. Estblish Monitoring Systems For Each CCPDocument3 pagesIx. Estblish Monitoring Systems For Each CCPJema TanNo ratings yet

- Rawabi BUTEC - Amaala International Airport Project - Risk RegisterDocument26 pagesRawabi BUTEC - Amaala International Airport Project - Risk RegisterIdris AdeniranNo ratings yet

- Automotive FMEADocument5 pagesAutomotive FMEAAshish GuptaNo ratings yet

- Fishbone DiagramDocument2 pagesFishbone DiagramMai HươngNo ratings yet

- Assignment 6 MDocument2 pagesAssignment 6 MMuhammad Saad KamalNo ratings yet

- PSO-Ma- Nhóm lên ngọn lửa rực cháyDocument1 pagePSO-Ma- Nhóm lên ngọn lửa rực cháyduccutehandsomeNo ratings yet

- Studii de Caz IKRo - ToateDocument16 pagesStudii de Caz IKRo - ToateAlexandru VanceaNo ratings yet

- A Consistent Design of Offers From Medium Voltage To Ultra TerminalDocument53 pagesA Consistent Design of Offers From Medium Voltage To Ultra TerminalIbn MasrNo ratings yet

- VFD Inductor (Choke) TheoryDocument6 pagesVFD Inductor (Choke) TheoryAmit PandeyNo ratings yet

- Guidelines On The Calibration of Electromechanical and Mechanical ManometersDocument46 pagesGuidelines On The Calibration of Electromechanical and Mechanical ManometersdediprayogiNo ratings yet

- APPARATUS FOR POTENTIALLY EXPLOSIVE ATMOSPHERESDocument18 pagesAPPARATUS FOR POTENTIALLY EXPLOSIVE ATMOSPHERESOkan DumanNo ratings yet

- Gas Turbine Relibility StandardsDocument1 pageGas Turbine Relibility StandardsIbn MasrNo ratings yet

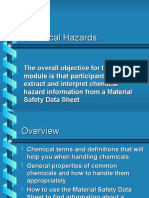

- Chemical HazardsDocument34 pagesChemical HazardsBorislav VulićNo ratings yet

- Chemical Hazard and Prevention: Firdaus Ali BSC (Health and Safety), Curtin University, Perth AustraliaDocument39 pagesChemical Hazard and Prevention: Firdaus Ali BSC (Health and Safety), Curtin University, Perth AustraliaIbn MasrNo ratings yet

- E&H LEVEL TechniqueDocument44 pagesE&H LEVEL TechniqueA.K. MAITINo ratings yet

- Example Test Procedures - DRAFTDocument8 pagesExample Test Procedures - DRAFTPurnawan RNo ratings yet

- Natural gas dehydration problem preventionDocument3 pagesNatural gas dehydration problem preventionIbn MasrNo ratings yet

- Natural gas dehydration problem preventionDocument3 pagesNatural gas dehydration problem preventionIbn MasrNo ratings yet

- Natural gas dehydration problem preventionDocument3 pagesNatural gas dehydration problem preventionIbn MasrNo ratings yet

- 7H RAM PredictionDocument11 pages7H RAM Predictionpartha6789No ratings yet

- Calibrating Microwave Lev. Trans.Document2 pagesCalibrating Microwave Lev. Trans.Ibn MasrNo ratings yet

- Calibrating Microwave Lev. Trans.Document2 pagesCalibrating Microwave Lev. Trans.Ibn MasrNo ratings yet

- Case Study Extension of The East London Line enDocument4 pagesCase Study Extension of The East London Line enPedro HenriquesNo ratings yet

- Credits: 112 Out of 133 CGPA: 6.21: Regd. NO: 18NH1A0316 Student Name: Nagidi Hijkiya RajuDocument1 pageCredits: 112 Out of 133 CGPA: 6.21: Regd. NO: 18NH1A0316 Student Name: Nagidi Hijkiya RajuKattula Anil kumarNo ratings yet

- 160 88-CL2Document6 pages160 88-CL2vanthe140591No ratings yet

- HTML Facebook CokDocument3 pagesHTML Facebook CokAldi SoNNo ratings yet

- Regular Languages and Finite Automata: Lecture Notes OnDocument56 pagesRegular Languages and Finite Automata: Lecture Notes Onchandu903No ratings yet

- Ddrcs Unit 4Document22 pagesDdrcs Unit 4siva shanmukhaNo ratings yet

- IDBI Sample Test - 1Document5 pagesIDBI Sample Test - 1LalBabuNo ratings yet

- Hydac Ball ValvesDocument6 pagesHydac Ball ValvesSamad A BakarNo ratings yet

- Undergraduate Selected Applicants 2012-13 Part IDocument192 pagesUndergraduate Selected Applicants 2012-13 Part IchriszaidaNo ratings yet

- (WRC-SouthAfrica-2001-R. McKenzei) PRESMAC User GuideDocument80 pages(WRC-SouthAfrica-2001-R. McKenzei) PRESMAC User GuideStephenson Xavier Molina ArceNo ratings yet

- NTUST DCE Graduate Program ApplicationDocument1 pageNTUST DCE Graduate Program ApplicationDewi Hindra WijayaNo ratings yet

- Profile of NeoVChem, a Manufacturer and Exporter of Specialty Chemicals/TITLEDocument12 pagesProfile of NeoVChem, a Manufacturer and Exporter of Specialty Chemicals/TITLEShalimarNo ratings yet

- LPCBDocument3 pagesLPCBhomaNo ratings yet

- Philippine Presidents' Transportation Projects ComparisonDocument12 pagesPhilippine Presidents' Transportation Projects ComparisonEmmerson NavarroNo ratings yet

- General Description Features: 2A Step Down DC To DC ConverterDocument9 pagesGeneral Description Features: 2A Step Down DC To DC ConverterEmanuel CarageaNo ratings yet

- WIND LOADING ANALYSIS - Wall Components and Cladding: Input DataDocument15 pagesWIND LOADING ANALYSIS - Wall Components and Cladding: Input DataMartin VenichNo ratings yet

- Hilux Catalogue 2012 PDF-L0dxAt3980Document35 pagesHilux Catalogue 2012 PDF-L0dxAt3980Apal Vora100% (1)

- מפרט רכש טורבינות - - BoBo - UTEXDocument8 pagesמפרט רכש טורבינות - - BoBo - UTEXYoninNo ratings yet

- Exp 2 Friction LossesDocument15 pagesExp 2 Friction LossesDonna Mae Ramos Galaez0% (1)

- 2013 Beta 300 RR Carburetor Jetting Chart by Altitude and TemperatureDocument1 page2013 Beta 300 RR Carburetor Jetting Chart by Altitude and TemperaturemarceloNo ratings yet

- Simulate Variable Speed Motor Control - MATLAB & Simulink PDFDocument9 pagesSimulate Variable Speed Motor Control - MATLAB & Simulink PDFLanAnhThịNguyễnNo ratings yet

- It Is Best To Have A Quiet Moment ..Document5 pagesIt Is Best To Have A Quiet Moment ..Nuno AlvesNo ratings yet

- Kwa FORM RA2Document7 pagesKwa FORM RA2Anand Vamadevan0% (1)

- Company Profile Traya Lintas PersadaDocument24 pagesCompany Profile Traya Lintas PersadaAyu Catra KastaraNo ratings yet

- Entropy Problems AnswersDocument6 pagesEntropy Problems AnswersTots HolaresNo ratings yet

- SJ Asphalt 1Document8 pagesSJ Asphalt 1Estêvão MayrerNo ratings yet

- Tariff, Power Factor and Power Factor ImprovementDocument12 pagesTariff, Power Factor and Power Factor ImprovementnurliyanaNo ratings yet

- Continuous Beam AnalysisDocument42 pagesContinuous Beam AnalysisMuhd MuqhreyNo ratings yet

- MB09807UDocument27 pagesMB09807URavishka SilvaNo ratings yet

- Saudi Electricity Company Battery Charger Rating Standard TES-P-103.03-rev 0Document1 pageSaudi Electricity Company Battery Charger Rating Standard TES-P-103.03-rev 0Senthil RajanNo ratings yet