Professional Documents

Culture Documents

SG5 - PA of Rahzi Dilemma - S Case

Uploaded by

Fadhila HanifOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SG5 - PA of Rahzi Dilemma - S Case

Uploaded by

Fadhila HanifCopyright:

Available Formats

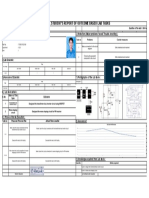

Problem Analysis of

Rahzi Dilemma’s Case

Decision Making and Negotiation

1. SG5 SLEMBA BPOM 1:

2. 1. Ely Rahmawati (NIM 29320072)

3. 2. Imam Luqman Hakim (NIM 29320073)

4. 3. Jazari Alfaridi (NIM 29320067)

5. 4. Kurniawan Norat (NIM 29320042)

6. 5. Rizka Ayu Kusuma Widjanarko (NIM 29320139)

7. 6. Shanty Sarah (NIM 29320212)

June 2021

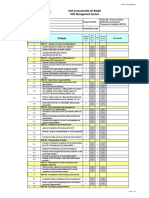

SITUATION APPRAISAL

Score*

Concerns Timing Trend Impact Process

(Priority)

1. The urge from SPC and Braxton’s leaders to use the H H H DA 9 (1)

‘frozen’ Epogex commercially instead of discard them

due to the claim of QA data study provided

2. Timeline for conducting clinical study of Epogex in H H H DA 9 (1)

Indonesia may not be fulfilled if the Epogex are not

ordered immediately

3. Temperature deviation during epogex storage (frozen M M H PA 7 (2)

epogex)

4. The QA study data of a “freeze-thaw” Epogex that M L H PA 6 (3)

Braxton had conducted in 2012 may be out of date &

irrelevant because it was not tested on the human

(patient), related to patient safety issue

5. As a new player in biosimilar market in Indonesia, any L L H PPA 5 (4)

issues regarding products safety and efficacy could

be jeopardize the reputation of SPC

6. The shelf life of Epogex only 18 months (limited), H M M DA 7 (2)

urgently required decision to be made

7. Potential financial loss if the frozen Epogex are L L M PPA 4 (5)

*score for each prioritiy: Low (L) = 1; Medium (M) = 2; High (H) = 3

discarded

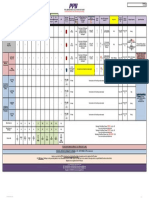

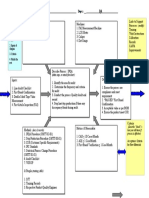

PROBLEM ANALYSIS

(Fishbone/Ishikawa Diagrams)

Machinery Manpower

Temperature 3PL does not 3PL does not carry

regulator was Not yet using understand the

technology for out the procedures

broken procedures

monitoring e.g., RFID There has been no

The temperature gauge

Equipment training for the

was not calibrated Lack of logistics

maintenance personnel involved

The logistics personnel/over workload

Cold storage was is not routine

not calibrated Refrigerant

officer misread Lack of experience of Supply Temperature

the procedures Chain Div. in logistics arrangement

leak

of cold supply chain

deviation

during epogex

storage

Temperature

Length of

shipment sensitive product Method has

Method does

not updated

(frozen

Uninformative

Sea wave

label packaging

been not epogex)

Transit validated Method is hard

time Do not have cold chain to understand

Method has not

monitoring equipment

been socialized No performance

on packaging

No adequate method in evaluation

handling temperature scoreboard

sensitive products

Environment Materials Methods

*methods including procedures, SOPs

CONCLUSION

Problem Analysis based on fishbone/ishikawa diagrams showed

possible causes from the aspect of methods, manpower,

materials, machinery and environment

It is necessary to verify each possible causes as the basis for

Decision Analysis to examine the available options and the risks

of each alternative

For the next process, Potential Problem Analysis can be done to

avoid possible negative consequences and turn situations to the

advantage

THANK YOU

You might also like

- Guidelines For Site Specific Assessments of Jack-UpsDocument28 pagesGuidelines For Site Specific Assessments of Jack-UpsBooraj DuraisamyNo ratings yet

- Work Place Audit ChecklistDocument4 pagesWork Place Audit Checklistbonney kumar100% (1)

- SG 4 - Moms - Com Negotiation Result Form-Hasil DiskusiDocument23 pagesSG 4 - Moms - Com Negotiation Result Form-Hasil DiskusiFadhila Hanif100% (1)

- SG 4 - Answer Form For Assignments of Film Tragedy of Commons and Beautiful MindDocument3 pagesSG 4 - Answer Form For Assignments of Film Tragedy of Commons and Beautiful MindFadhila HanifNo ratings yet

- Standard Operating Procedures For Data ManagementDocument104 pagesStandard Operating Procedures For Data Managementcalu_2005100% (3)

- Hse ProcedureDocument47 pagesHse Proceduremarius_brkt6284No ratings yet

- Principles and Applications of Thermal AnalysisFrom EverandPrinciples and Applications of Thermal AnalysisPaul GabbottRating: 4 out of 5 stars4/5 (1)

- Decision Tree Analysis: Merck & Co. Case StudyDocument8 pagesDecision Tree Analysis: Merck & Co. Case StudyFadhila Hanif100% (1)

- Temperature Mapping ProtocolDocument20 pagesTemperature Mapping ProtocolBudi Susanto100% (2)

- SG 5 - Situation Appraisal Rahzi - S Dilemma (Final Edit)Document7 pagesSG 5 - Situation Appraisal Rahzi - S Dilemma (Final Edit)Fadhila HanifNo ratings yet

- Negotiation Result Form of Energetic Meets GenerexDocument3 pagesNegotiation Result Form of Energetic Meets GenerexFadhila HanifNo ratings yet

- DryDock CompleteDocument24 pagesDryDock Completeashry_tarek100% (2)

- SG 4 - Answer Form For Case Mannx - OTCDocument2 pagesSG 4 - Answer Form For Case Mannx - OTCFadhila Hanif100% (1)

- EGA2 Lessons Learned QualityDocument4 pagesEGA2 Lessons Learned QualityfaizanAkhtar100% (3)

- Intertanko Dry Dock ChecklistDocument14 pagesIntertanko Dry Dock Checklistsandeepkumar2311No ratings yet

- HSE Evaluation CriteriaDocument2 pagesHSE Evaluation CriteriaChan RizkyNo ratings yet

- Business Models Lesson 1 (3-5) PDFDocument22 pagesBusiness Models Lesson 1 (3-5) PDFLaíze LemosNo ratings yet

- PROJECT STUDY (Road Construction)Document11 pagesPROJECT STUDY (Road Construction)mmabee100% (3)

- Cascading KRAsDocument8 pagesCascading KRAsS.Ramani, A.G.M - HR & Admin100% (1)

- Formal Design ProcessDocument6 pagesFormal Design ProcesskapsarcNo ratings yet

- Project Management Process GroupsDocument10 pagesProject Management Process GroupsQueen Valle100% (1)

- A Practical Approach To Steam Autoclave Cycle Development: Byvictor Tsui, P.E. and Ward Wiederhold, B.S.M.EDocument10 pagesA Practical Approach To Steam Autoclave Cycle Development: Byvictor Tsui, P.E. and Ward Wiederhold, B.S.M.EJawad HussainNo ratings yet

- 13 - External LogisticxDocument17 pages13 - External LogisticxAdriana HubleaNo ratings yet

- Basic Reservoir Engineering: About This ProgramDocument6 pagesBasic Reservoir Engineering: About This ProgramGeñito VoltioNo ratings yet

- GET Karan RanaDocument12 pagesGET Karan RanaKaRan RanaNo ratings yet

- Welcome TO Jharkhand Telecom CircleDocument20 pagesWelcome TO Jharkhand Telecom CircleSanjay KumarNo ratings yet

- Operating Systems in Practice: Process SchedulingDocument15 pagesOperating Systems in Practice: Process SchedulingBigu Marius AlinNo ratings yet

- Integrated Quality Control, The Graz SystemDocument56 pagesIntegrated Quality Control, The Graz SystemYaser MNo ratings yet

- Checklist For Port State Control: - ISPS CheckDocument5 pagesChecklist For Port State Control: - ISPS CheckTan DatNo ratings yet

- Atp Itla ComunicacionesDocument19 pagesAtp Itla ComunicacionesJeffry Rafael PérezNo ratings yet

- Week 1Document21 pagesWeek 1gaditya17No ratings yet

- Integration Test Between MSC and SCPDocument19 pagesIntegration Test Between MSC and SCPQuyen Le ThanhNo ratings yet

- Areva FatigueDocument26 pagesAreva Fatigueevo2005_2006No ratings yet

- Inspection and Audit Preparation ChecklistDocument64 pagesInspection and Audit Preparation Checklistdavid.greeleyNo ratings yet

- v02 Epoc Accordion Brochure en USDocument2 pagesv02 Epoc Accordion Brochure en USglenniesamuelNo ratings yet

- Preservation of Product ProcedureDocument3 pagesPreservation of Product ProcedureNinew KusumaNo ratings yet

- Quality & Industrial Performance: External LogisticsDocument55 pagesQuality & Industrial Performance: External LogisticsMojtaba MousaviNo ratings yet

- Web Extra We RCDocument9 pagesWeb Extra We RCJasan MuhamendNo ratings yet

- Review of The Operation Scenarios and Required Manning of The ActivitiesDocument24 pagesReview of The Operation Scenarios and Required Manning of The ActivitieshasanNo ratings yet

- MoP - Restart Access Point All Regional Batch 1Document7 pagesMoP - Restart Access Point All Regional Batch 1nandipuraNo ratings yet

- Strategy 1 Process Efficiencies Strategy 2: Strengthen Organization Strategy 3: People DevelopmentDocument17 pagesStrategy 1 Process Efficiencies Strategy 2: Strengthen Organization Strategy 3: People DevelopmentjohnmarcNo ratings yet

- WBS - MC - Task 1Document6 pagesWBS - MC - Task 1Siddhant sharmaNo ratings yet

- DLL 12 Aqua W1 Q2Document3 pagesDLL 12 Aqua W1 Q2Joewellyn LimNo ratings yet

- Dynamic NMRDocument1 pageDynamic NMRSocrates M.No ratings yet

- Minerals 08 00232 PDFDocument45 pagesMinerals 08 00232 PDFDanyel Hidalgo BrunaNo ratings yet

- TCI IntroDocument6 pagesTCI IntroMuhammad Berry YudhatamaNo ratings yet

- Learners' Achievement Monitoring Report: Using Hand Tools 5 HrsDocument9 pagesLearners' Achievement Monitoring Report: Using Hand Tools 5 HrsFERDINAND BANAGANo ratings yet

- DQSP-00033 Storage and ShipmentDocument13 pagesDQSP-00033 Storage and Shipmentalexvo.1612No ratings yet

- Inventory QRG - Material Deletion Post Impact AnalysisDocument46 pagesInventory QRG - Material Deletion Post Impact AnalysisTunkuFarahNo ratings yet

- Cp-Pro-Covlp-021 Phaseiii MDCG Synh0016 CFC v4.0 01jun2021Document1 pageCp-Pro-Covlp-021 Phaseiii MDCG Synh0016 CFC v4.0 01jun2021blackantroNo ratings yet

- Modul Praktikum ISR 2019-2WST - 3TDCDocument52 pagesModul Praktikum ISR 2019-2WST - 3TDCAhmad Farhan FarabiNo ratings yet

- STEP09 - CustomCode March 11th 2021Document27 pagesSTEP09 - CustomCode March 11th 2021fazrul fuadNo ratings yet

- IPQA - QA: Turtle Diagram - Process: Dept.Document1 pageIPQA - QA: Turtle Diagram - Process: Dept.SMTT WORK OFFICIALNo ratings yet

- 8EC5-12 - Digital Image and Video Processing - Gloria JosephDocument700 pages8EC5-12 - Digital Image and Video Processing - Gloria JosephOm VermaNo ratings yet

- STEP08 - PostActivities - March 10th 2021Document46 pagesSTEP08 - PostActivities - March 10th 2021fazrul fuadNo ratings yet

- MF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceDocument2 pagesMF Group of Industries: RISK MANAGEMENT-CORE PROCESS - Quality AssuranceRohit VishwakarmaNo ratings yet

- DC Internal Audit Done at 14Document3 pagesDC Internal Audit Done at 14oketchodoleNo ratings yet

- MOP For Manual LTE ENodeB Integration - SiteDocument16 pagesMOP For Manual LTE ENodeB Integration - SiteNguyễn Đình TrườngNo ratings yet

- HACCP Plan For The Production of Squid BallDocument1 pageHACCP Plan For The Production of Squid BallCallisto Regulus100% (1)

- d3 1000 228 AhmedDocument18 pagesd3 1000 228 Ahmedsvaja_1No ratings yet

- Composite Score (Lower Is Better) Final RankDocument2 pagesComposite Score (Lower Is Better) Final RankAnushkaSinhaNo ratings yet

- Jesd51 6Document20 pagesJesd51 6Daniel BeattieNo ratings yet

- A Real-Time Ensemble Hydrological Forecasting System Over Germany at Sub-Seasonal To Seasonal Time RangeDocument12 pagesA Real-Time Ensemble Hydrological Forecasting System Over Germany at Sub-Seasonal To Seasonal Time RangeMonica Ionita-ScholzNo ratings yet

- Ryan Brylle ZZ Met 0-1 LA 2.1Document3 pagesRyan Brylle ZZ Met 0-1 LA 2.1Ryan Brylle LuzonNo ratings yet

- Time Stamped Anti-Entropy ProtocolDocument23 pagesTime Stamped Anti-Entropy ProtocolkemosadeNo ratings yet

- Handbook of Hydroinformatics Volume Ii Advanced Machine Learning Techniques Saeid Eslamian Full ChapterDocument51 pagesHandbook of Hydroinformatics Volume Ii Advanced Machine Learning Techniques Saeid Eslamian Full Chapteralfred.kassin632100% (3)

- Operating System Kcs-401. Question Bank À Unit-Iii: Cpu Scheduling and DeadlocksDocument4 pagesOperating System Kcs-401. Question Bank À Unit-Iii: Cpu Scheduling and DeadlocksNishant MishraNo ratings yet

- PTA-JSA-006-Erection of PipesSpools at HeightsDocument3 pagesPTA-JSA-006-Erection of PipesSpools at HeightsSaiyad RiyazaliNo ratings yet

- ASM360S GA4 n1Document1 pageASM360S GA4 n1wobster 02No ratings yet

- A3 Report Template - Lab TasksDocument1 pageA3 Report Template - Lab TasksGOWTHAM SNo ratings yet

- New Template IJBADocument2 pagesNew Template IJBAFadhila HanifNo ratings yet

- Midterm SG1 - EL - SLEMBA - Summary CompleteDocument19 pagesMidterm SG1 - EL - SLEMBA - Summary CompleteFadhila HanifNo ratings yet

- 27BUSADM Doctorate of Business AdminDocument10 pages27BUSADM Doctorate of Business AdminFadhila HanifNo ratings yet

- 1 s2.0 S1877042814059710 MainDocument9 pages1 s2.0 S1877042814059710 MainFadhila HanifNo ratings yet

- Full Paper - Scenario Planning For Supervision of The Procurement Process in The Covid-19 EraDocument15 pagesFull Paper - Scenario Planning For Supervision of The Procurement Process in The Covid-19 EraFadhila HanifNo ratings yet

- Variabel Illegal DrugsDocument4 pagesVariabel Illegal DrugsFadhila HanifNo ratings yet

- Midterm SG1 - EL - SLEMBA - Complete ExplanationDocument46 pagesMidterm SG1 - EL - SLEMBA - Complete ExplanationFadhila HanifNo ratings yet

- Midterm SG1 - EL - SLEMBApoleslagiDocument38 pagesMidterm SG1 - EL - SLEMBApoleslagiFadhila HanifNo ratings yet

- Cost Benefit Analysis On Food Safety ComplianceDocument14 pagesCost Benefit Analysis On Food Safety ComplianceFadhila HanifNo ratings yet

- Midterm SG1 - EL - SLEMBA (No. 3)Document18 pagesMidterm SG1 - EL - SLEMBA (No. 3)Fadhila HanifNo ratings yet

- Draft Jawaban #4Document11 pagesDraft Jawaban #4Fadhila HanifNo ratings yet

- CB Insights Global Unicorn Club 2021Document72 pagesCB Insights Global Unicorn Club 2021Fadhila HanifNo ratings yet

- Midterm SG1 - EL - SLEMBA - Summary+#4Document20 pagesMidterm SG1 - EL - SLEMBA - Summary+#4Fadhila HanifNo ratings yet

- Final Exam Bsem Emba 61 Yuni Fitria 29119194 PT Indofood CBPDocument12 pagesFinal Exam Bsem Emba 61 Yuni Fitria 29119194 PT Indofood CBPFadhila HanifNo ratings yet

- Rich Pictures: Sustainable Development, and Stakeholders - The Benefits of Content AnalysisDocument22 pagesRich Pictures: Sustainable Development, and Stakeholders - The Benefits of Content AnalysisFadhila HanifNo ratings yet

- Midterm SG1 - EL - SLEMBA - Summary LengkapDocument18 pagesMidterm SG1 - EL - SLEMBA - Summary LengkapFadhila HanifNo ratings yet

- EditDocument33 pagesEditFadhila HanifNo ratings yet

- Competitor Analysis: Kimia Farma (Dhila) Kalbe (Monik) Soho (Imam) Dexa Medica (Akur)Document1 pageCompetitor Analysis: Kimia Farma (Dhila) Kalbe (Monik) Soho (Imam) Dexa Medica (Akur)Fadhila HanifNo ratings yet

- Competitor Analysis SOHO + TempoDocument1 pageCompetitor Analysis SOHO + TempoFadhila HanifNo ratings yet

- SG5 - Da BKKDocument6 pagesSG5 - Da BKKFadhila HanifNo ratings yet

- Strategy and Tactics of Distributive Bargaining: Outline With A Main Point PresentationDocument18 pagesStrategy and Tactics of Distributive Bargaining: Outline With A Main Point PresentationFadhila HanifNo ratings yet

- Moms - Com Negotiation Result FormDocument2 pagesMoms - Com Negotiation Result FormFadhila HanifNo ratings yet

- Answer Form For Case Mannx - OTCDocument1 pageAnswer Form For Case Mannx - OTCFadhila HanifNo ratings yet

- Bulletlist - The Marketing ProcessDocument4 pagesBulletlist - The Marketing ProcessSs ArNo ratings yet

- 시행중 K-IFRS 제1021호 환율변동효과 (2010 개정 2018 타기준서 개정 수정목록 19-1 2020 구성양식 변경 반영)Document54 pages시행중 K-IFRS 제1021호 환율변동효과 (2010 개정 2018 타기준서 개정 수정목록 19-1 2020 구성양식 변경 반영)hanwook.yimNo ratings yet

- Resume Edited For JobfairDocument1 pageResume Edited For JobfairSurya Dwi Tama JeyNo ratings yet

- CHAPTER 5 Project Control and MonitoringDocument12 pagesCHAPTER 5 Project Control and MonitoringIqasya AhmadNo ratings yet

- GSO Citizen Charter 2021Document3 pagesGSO Citizen Charter 2021Sairel Daing MohammadNo ratings yet

- Romvolt: Hexagonal, Bracket Type ST-Y or STDocument1 pageRomvolt: Hexagonal, Bracket Type ST-Y or STcippy cipiNo ratings yet

- Hudson's Bay - EDI 810 Invoice PDFDocument19 pagesHudson's Bay - EDI 810 Invoice PDFkiran itharajuNo ratings yet

- The Professional Salesman's CreedDocument2 pagesThe Professional Salesman's CreedabmaboocnecieboycNo ratings yet

- China Railway Construction Corporation Attaining Globalization Via HighDocument18 pagesChina Railway Construction Corporation Attaining Globalization Via HighCyril Ang-numbaalaNo ratings yet

- 1 Production and Operations Management - Meaning and Important ConceptsDocument2 pages1 Production and Operations Management - Meaning and Important ConceptsSagarNo ratings yet

- Operations and Production Management: Toc Msc. Małgorzata Zalewska-TraczykDocument86 pagesOperations and Production Management: Toc Msc. Małgorzata Zalewska-TraczykAjay MsdNo ratings yet

- Ratio Analysis Performance ManagementDocument17 pagesRatio Analysis Performance ManagementPratik BasakNo ratings yet

- Handball Love ? ?Document1 pageHandball Love ? ?Ramona Ioana UngurNo ratings yet

- Financial Accounting - MGT101 Power Point Slides Lecture 39Document22 pagesFinancial Accounting - MGT101 Power Point Slides Lecture 39Mr. JalilNo ratings yet

- Managerial Level: May 2007 ExaminationsDocument35 pagesManagerial Level: May 2007 ExaminationsIsavic AlsinaNo ratings yet

- Reading 5Document3 pagesReading 5TRANG NGO THINo ratings yet

- PS Vs DM What Is The DifferenceDocument2 pagesPS Vs DM What Is The DifferenceHayu AriantiNo ratings yet

- Iso 22301 Business Continuity Management SystemDocument2 pagesIso 22301 Business Continuity Management SystemDexter Jay DomingoNo ratings yet

- GIL-PROJ-MGM-G-004-01 Template For IMS PlanDocument92 pagesGIL-PROJ-MGM-G-004-01 Template For IMS PlanRajarathinam1235463No ratings yet

- The Following Information Applies To The Questions Displayed Below.Document1 pageThe Following Information Applies To The Questions Displayed Below.Billy Tan Cheah MingNo ratings yet

- Golden Star Resource Limited Financial Statements AnalysisDocument9 pagesGolden Star Resource Limited Financial Statements AnalysisTetteh Mensah SolomonNo ratings yet

- Warehouse Decision R.P & Case StudyDocument15 pagesWarehouse Decision R.P & Case StudyAamir AyaanNo ratings yet

- Krispy Kreme Doughnuts, Inc. A Case Study: By: Wayne ParkerDocument10 pagesKrispy Kreme Doughnuts, Inc. A Case Study: By: Wayne ParkerAnonymous nj3pIshNo ratings yet

- Oa 113 - SG-1Document6 pagesOa 113 - SG-1Shelang TerradoNo ratings yet

- Uniform System of Accounts For The LodgingDocument6 pagesUniform System of Accounts For The LodgingRasika Sameera SampathNo ratings yet