Professional Documents

Culture Documents

Coal Conversion Facts Calculations

Coal Conversion Facts Calculations

Uploaded by

sumitrochakrabortiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Coal Conversion Facts Calculations

Coal Conversion Facts Calculations

Uploaded by

sumitrochakrabortiCopyright:

Available Formats

Alain DELOYE - Technical Services Manager DST- BP 4114 76020 Rouen Cedex - F

Coal Conversion Facts & Calculations

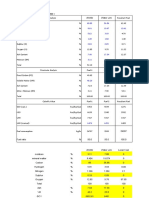

1. 1.1 Analysis basis Definitions includes Total moisture (Tm) includes Inherent moisture (Im) only excludes all Moisture excludes all Moisture & Ash

As Received (AR): Air Dried (AD): Dry Basis (DB): Dry Ash Free (DAF):

The Proximate Analysis of any coal ie the % contents of Moisture, Ash (A), Volatile Matter (VM), Fixed Carbon (FC) - also Sulphur (S) and Calorific Value (CV) - can be expressed on any of the above bases. 1.2 Conversions

To obtain: multiply AR by: AD by: DB by:

Air Dry

Dry Basis

As Received

(100 - Im%) 100 (100 - Tm%) (100 - Tm%) (100 - Im%) 100 100 (100 - Im%) -

(100 - Tm%) (100 - Im%) (100 - Tm%) 100

Where Im: inherent moisture Where Tm: total moisture [For DAF, multiply DB by 100/(100-A)]

Alain DELOYE - Technical Services Manager DST- BP 4114 76020 Rouen Cedex - F

Example: AR Tm Im Ash (A) VM FC Sulfur (S) 11.0 2.0 12.0 30.0 47.0 1.0 AD 2.0 13.2 33.0 51.8 1.1 DB 13.5 33.7 52.8 1.12 DAF 39.0 61.0 -

2. 2.1

MASS Units: 1,000 kilograms (= 2,204.6 lb) 1,016.05 kilograms (= 2,240 lb) 907.19 kilograms (= 2,000 lb)

Metric ton (t) = tonne = Imperial or Long ton (lt) = Short (US) ton (st) = 2.2 Conversions:

From long ton to metric ton From metric ton to long ton From short ton to metric ton

multiply by 1.016 multiply by 0.984206 multiply by 0.9072

Mt - million tonnes Mtce - million tonnes of coal equivalent (= 0.697 Mtoe) Mtoe - million tonnes of oil equivalent 3. CALORIFIC VALUES (CV) 3.1 Units: kcal/kg - Kilocalories per kilogram MJ/kg* - Megajoules per kilogram Btu/lb - British Thermal Units per pound * 1 MJ/kg = 1 Gigajoule/tonne (GJ/t)

Alain DELOYE - Technical Services Manager DST- BP 4114 76020 Rouen Cedex - F

3.2 Gross & Net Calorific Values:

Gross CV or 'upper heating value' is the CV under laboratory conditions. Net CV or 'Net Effective Calories' (NEC) is the useful calorific value in boiler plant. The difference is essentially the latent heat of the water vapor produced. 3.3 Conversions Units: From kcal/kg to MJ/kg From kcal/kg to Btu/lb kcal/kg = From MJ/kg to kcal/kg MJ/kg = From MJ/kg to Btu/lb MJ/kg = From Btu/lb to kcal/kg From Btu/lb to MJ/kg multiply by 0.004187 multiply by 1.800 Btu/lb / 1.800 multiply MJ/kg by 238.846 kcal/kg / 238.846 multiply MJ/kg by 429.923 Btu/lb / 429.923 multiply Btu/lb by 0.5556 multiply Btu/lb by 0.002326

3.4 Formulas and conversions - Gross/Net : Ref: Net Calorific Value (ASTM D5865-03) The heat produced by combustion of a substance at a constant pressure of 0.1 Mpa (1 Atm), with any water formed remaining as vapor. ISO 1928-2009 at constant volume Qv, net,m, J/g = ( Q gr,v,d - 206.0 [ wHd ] ) x (1-0.01 x Tm) - (23.05 x Tm) Qv, net,m, kcal/kg = ( Q gr,v,d - 49.20 [ wHd ] ) x (1-0.01 x Tm) - (5.51 x Tm) ISO 1928-2009 at constant pressure Qp, net,m, J/g = { Q gr,v,d 212.0 [ wHd ] - 0.8 x [wOd + wNd] } x (1- 0.01Tm) - 24.43 x Tm Qp, net,m, kcal/kg = { Q gr,v,d - 50.64 [ wHd ] - 0.191 x [wOd + wNd] } x (1- 0.01Tm) - 5.84 x Tm

Alain DELOYE - Technical Services Manager DST- BP 4114 76020 Rouen Cedex - F

[ wHd ] = w(H)d = Tm=

H content of the sample less hydrogen present in the moisture w(H) x 100/100-Tm Total moisture

ASTM 5865/3180 at constant pressure Qp(net)ar,J/g = Qp(net)ar,Btu/lb = Qp(net)ar,kcal/kg = Qvar(gross) - (215.5 x Har) Qvar(gross) - (92.67 x Har) Qvar(gross) - (51.47 x Har)

Har = total hydrogen where hydrogen includes hydrogen in sample moisture Har = [(Had-0.1119xMad) x (100-Mar)/(100-Mad)] + 0.1119 x Mar 4. 4.1 VARIOUS PARAMETERS CALCULATIONS: Seylers Formula:

Various parameters of coal can be estimated from the Ultimate Analysis and Calorific Value determinations, using Seyler's formula, and other similar calculations (e.g. Dulong's or Channivalas formulas). Reference: VM daf = H daf = C daf = 10.61H daf - 1.24C daf + 84.15 0.069 (Q daf/100+VM daf) - 2.86 [0.59 (Q daf/100 - 0.367VM daf) + 43.4]

Estimate of the hydrogen content, calculated using Seyler's Formula: wH = w(H) = w(V) = w(A) = qv,gr,m = Note 1 * 0.07 x w(V) + 0.000165 x qv,gr,m - 0.0285 x [ 100 - Tm - w(A)] is the H content of sample less H contained in moisture, as % mass is the VM content of sample with moisture content Tm, as % mass is the ash content of sample with moisture content Tm, as % mass is the gross CV of sample with moisture content Tm, in j/g Only valid when the calculated H db is greater than 3% *ISO 1928-2009 E.3.3 Only valid when the O daf content is less than 15% ** COAL -Typology -Physics -Chemistry -Constitution D.W. Van Krevelen (third edition 1993) Page 47 Can give erroneous results if coal shipments are a blend of low and high rank coals.

Note 2 **

Note 3

Alain DELOYE - Technical Services Manager DST- BP 4114 76020 Rouen Cedex - F

4.1

Dulong's Formula:

GCV(db) = 333xC(db) + 1442(H(db) - O(db) / 8) + 93xS(db) GCV is in (kJ/kg dry basis) - C, H, O, S as percent on a dry basis.

Other calculations formulas related to CV: kcal/kg: MJ/kg: Btu/lb: Net CV = Gross CV - 50.6H - 5.85M - 0.191O Net CV = Gross CV - 0.212H - 0.0245M - 0.0008O Net CV = Gross CV - 91.2H - 10.5M - 0.34O

- where M is % Moisture, H is % Hydrogen, O is % Oxygen (from ultimate analysis, also As Received). For typical bituminous coal with 10% M and 25% Volatile Matter, the differences between gross and net calorific values are approximately as follows: 260 kcal/kg 1.09 MJ/kg 470 Btu/lb

5.

CO2 EMISSION FACTOR:

t/CO2/TJ = C % As Received x 3.667 x [NCV/10000)] in kJ/kg = C % As Received x 3.667 x [NCV/2388.46/NCV] in kcal/kg Note 1 6. Coefficient is 3,664 for France. POWER GENERATION:

1 MWh = 3,600 MJ 1 MW = 1 MJ/s 1 MW (thermal power) [MWth] = approx 1,000 kg steam/hour 1 MW (electrical power) [MWe] = approx MWth / 3 A 600 MWe coal-fired power station operating at 38% efficiency and 75% overall availability will consume approximately: Bituminous coal (CV 6,000 kcal/kg NAR): Brown coal (CV 2,250 kcal/kg NAR): 1.5 Mt/year 4.0 Mt/year

Alain DELOYE - Technical Services Manager DST- BP 4114 76020 Rouen Cedex - F

7.

MOISTURE:

Two Stage Total Moisture Formula (Refer to ASTM / ISO) Two stage total moisture determination is used when the coal sample is too wet to divide or crush without the potential of loosing significant amounts of moisture. Tm ar, % = Tm = 8. [Rm ad, % x (100 Fm ad, %) / 100] + Fm ad % Fm = Free moisture; Rm = Residual moisture.

Total moisture; FUEL RATIO:

= Fixed Carbon / Volatile Matter 9. HYDROGEN & OXYGEN (Refer to ASTM 3180 / ISO 1170)

In Coal:

Inasmuch as hydrogen and oxygen values may be reported on the basis of containing or not containing the hydrogen and oxygen in water (moisture) associated with the sample, alternative conversion procedures are defined below:

Hydrogen and Oxygen Factors based on the atomic weight of H20: Hydrogen = Moisture X 0.1119 Oxygen = Moisture X 0.8881 Sources: GWC Coal Handbook, ASTM & ISO Standards & others.

You might also like

- Landfill Operations Manual FN ENGDocument110 pagesLandfill Operations Manual FN ENGaudilioNo ratings yet

- Heat of Formation of GypsumDocument2 pagesHeat of Formation of GypsumMohammed Shafi AhmedNo ratings yet

- Your Energy Account: 31st March 2021 - 12th June 2021Document4 pagesYour Energy Account: 31st March 2021 - 12th June 2021Eduardo JunioNo ratings yet

- Coal Testing and Analysis MethodsDocument12 pagesCoal Testing and Analysis MethodsIzzan Ferdi AndrianNo ratings yet

- Combustion in Coal StockpilesDocument12 pagesCombustion in Coal StockpilesMuksin SalehNo ratings yet

- Astm CoalDocument10 pagesAstm CoalKaret PdpNo ratings yet

- Internship Report Fauji Cement FinalDocument53 pagesInternship Report Fauji Cement FinalSHAHEER HASHMINo ratings yet

- ASTM Coal ClassificationsDocument14 pagesASTM Coal ClassificationsRat100% (1)

- The Standard Coal Analysis: M M M WDocument6 pagesThe Standard Coal Analysis: M M M WHazem Diab100% (1)

- Design Coal Worst Coal Coal Consumption Capacity CalculationDocument6 pagesDesign Coal Worst Coal Coal Consumption Capacity CalculationPrasanna kumar subudhiNo ratings yet

- Impact of Alkali, Sulphur and Chlorine in The KilnDocument3 pagesImpact of Alkali, Sulphur and Chlorine in The KilnJa Phe Ti100% (1)

- ME Lab 1 Exp 7 Bomb CalorimeterDocument18 pagesME Lab 1 Exp 7 Bomb CalorimeterJAMAL HALIBAYNo ratings yet

- Clinker Vs Kiln Feed FactorDocument3 pagesClinker Vs Kiln Feed FactorSSAC PVT.LTD.100% (2)

- Coal & Ash Calculations-350&135 MW Units - 290307Document3 pagesCoal & Ash Calculations-350&135 MW Units - 290307srigirisetty208No ratings yet

- Coal CalculationDocument11 pagesCoal CalculationUrej BandiolaNo ratings yet

- Coal ConversionDocument3 pagesCoal ConversionchcrrNo ratings yet

- Measuring Coal Quality: Moisture: VolatilesDocument5 pagesMeasuring Coal Quality: Moisture: VolatilesZegera MgendiNo ratings yet

- Ultimate AnalysisDocument3 pagesUltimate AnalysisComputer Maintainance Hardware and softwareNo ratings yet

- Analysis of Coal-TutorialDocument14 pagesAnalysis of Coal-TutorialratNo ratings yet

- CoalDocument227 pagesCoalchenukapNo ratings yet

- Quality - Ash Fusion TempDocument30 pagesQuality - Ash Fusion TempNoviandryNo ratings yet

- Analysis of Pulverizers: Multi Task Machines To Meet The Rate of Rapid Coal CombustionDocument23 pagesAnalysis of Pulverizers: Multi Task Machines To Meet The Rate of Rapid Coal CombustionHemant PatilNo ratings yet

- Coal Analysis ParameterDocument21 pagesCoal Analysis ParameterYuliyanti YuliyantiNo ratings yet

- Coal Sampling ProcedureDocument56 pagesCoal Sampling ProcedurePrudhvi RajNo ratings yet

- Coal and Its AnalysisDocument8 pagesCoal and Its AnalysisPratik AgajNo ratings yet

- Heat Balance DataDocument6 pagesHeat Balance DataOuaddani amineNo ratings yet

- Cost of Klinker Against C3SDocument2 pagesCost of Klinker Against C3SIrfan AhmedNo ratings yet

- Alternative Fuel Requirements SolutionsDocument3 pagesAlternative Fuel Requirements SolutionsIrfan AhmedNo ratings yet

- AF Ash IncorporationDocument7 pagesAF Ash Incorporationirfan100% (1)

- Unit Iii Fuels and CombustionDocument30 pagesUnit Iii Fuels and CombustionarchitNo ratings yet

- Design of A Rotary Kiln For The ReductionDocument16 pagesDesign of A Rotary Kiln For The ReductionMadhav Krishna M100% (2)

- Coking CoalDocument13 pagesCoking CoalAhmad Faozan0% (1)

- Calciner Op Ex CalculationDocument9 pagesCalciner Op Ex CalculationNair YadukrishnanNo ratings yet

- Effect of False Air On Heat Consumption: Note Change Values Only in Shaded CellsDocument7 pagesEffect of False Air On Heat Consumption: Note Change Values Only in Shaded Cellshmaza shakeelNo ratings yet

- WHR Calculation For Cement KilnDocument11 pagesWHR Calculation For Cement KilnHieu DuongNo ratings yet

- Raw Meal To Clinker RatioDocument3 pagesRaw Meal To Clinker RatiohamedNo ratings yet

- ASTM ClasificacionDocument8 pagesASTM ClasificacionJUAN CAMILO AYALA GOMEZNo ratings yet

- Coal Blending PaperDocument21 pagesCoal Blending PaperPradeep SrikanthNo ratings yet

- Ball Mill PulveriserDocument67 pagesBall Mill PulveriserMURALIGOCAM_29070605100% (1)

- Plant Location: Preheater Feed Preheater String - Calciner TypeDocument33 pagesPlant Location: Preheater Feed Preheater String - Calciner TypeDilnesa EjiguNo ratings yet

- Coal Blend Moisture-A Boon or Bane in Cokemaking?: Coke and Chemistry April 2013Document12 pagesCoal Blend Moisture-A Boon or Bane in Cokemaking?: Coke and Chemistry April 2013jayaNo ratings yet

- D388-05 - Standard Classification of Coals by Rank PDFDocument7 pagesD388-05 - Standard Classification of Coals by Rank PDFandi100% (1)

- Dry Feed: Feed Entered SP H2O Content in SP H2O Content in SPDocument20 pagesDry Feed: Feed Entered SP H2O Content in SP H2O Content in SPIrfan Ahmed100% (1)

- Detailed Study of Burining Problems Caused by Sulphur: Prepared by Suraj Bhaskaran Process EngineerDocument14 pagesDetailed Study of Burining Problems Caused by Sulphur: Prepared by Suraj Bhaskaran Process Engineerbsuraj100% (2)

- Fuel Cost ComaparaisionDocument8 pagesFuel Cost ComaparaisionIrfan AhmedNo ratings yet

- Coal NCV and GCVDocument5 pagesCoal NCV and GCVirfanNo ratings yet

- WHR Kcal Per HR Calculation SheetDocument4 pagesWHR Kcal Per HR Calculation SheetirfanNo ratings yet

- Abstract of Papaer On Coal Quality-Blending A Perspective at RINLDocument15 pagesAbstract of Papaer On Coal Quality-Blending A Perspective at RINLbhujakhia_748657110No ratings yet

- Grate CoolerDocument10 pagesGrate CoolerAamir HayatNo ratings yet

- 4 Coal As A Substance 113: 1. North America: Original Parr FormulaDocument2 pages4 Coal As A Substance 113: 1. North America: Original Parr FormulaFadhil Zuhdi100% (1)

- Low Sulfer Coal BlendingDocument18 pagesLow Sulfer Coal BlendingSuparjianto Qhaedir Al FaatihNo ratings yet

- Paper 2 Optimization of Coal Blend Proportions For Sustained Improvements in Generation & Efficiency PDFDocument23 pagesPaper 2 Optimization of Coal Blend Proportions For Sustained Improvements in Generation & Efficiency PDFRc TuppalNo ratings yet

- Daily Power Generation Report: Fuel ReceivedDocument10 pagesDaily Power Generation Report: Fuel ReceivedJacky KaruppaiahNo ratings yet

- Lecture 7 FuelsDocument50 pagesLecture 7 FuelsRed BilbitNo ratings yet

- Anthracite Firing at Central Power Stations For The - Foster WheelerDocument21 pagesAnthracite Firing at Central Power Stations For The - Foster WheelerThanh Luan NguyenNo ratings yet

- Heat Balance ComparisionDocument5 pagesHeat Balance Comparisiongvrr1954No ratings yet

- Coal CV 6000Document2 pagesCoal CV 6000AnGahBasHaNo ratings yet

- Target SHC Target Production Afghan Local S.AfricaDocument3 pagesTarget SHC Target Production Afghan Local S.AfricaIrfan AhmedNo ratings yet

- Guuuuuu MMMMM PDFDocument6 pagesGuuuuuu MMMMM PDFfitroNo ratings yet

- Coal Conversion StatisticsDocument2 pagesCoal Conversion StatisticsPaulo BarraNo ratings yet

- C:/Users/quisp/Downloads/episummary - Out - Doc: CH O O CHDocument4 pagesC:/Users/quisp/Downloads/episummary - Out - Doc: CH O O CHalexander condoNo ratings yet

- Material Stream: Gas Mainfold: ConditionsDocument4 pagesMaterial Stream: Gas Mainfold: ConditionsMohammed Gad-AllahNo ratings yet

- P8098T 25degcDocument108 pagesP8098T 25degcjulya julyaNo ratings yet

- Material Stream: 3: ConditionsDocument5 pagesMaterial Stream: 3: ConditionsHerrera Jorge AgustínNo ratings yet

- IEA Bioenergy 2 Page Summary Bio Pile Cover - 02032022Document2 pagesIEA Bioenergy 2 Page Summary Bio Pile Cover - 02032022audilioNo ratings yet

- Zinc Guidance NotesDocument10 pagesZinc Guidance NotesaudilioNo ratings yet

- Production Calculator 97 DLDocument3 pagesProduction Calculator 97 DLaudilioNo ratings yet

- Landfill Design and Operation: August 2016Document29 pagesLandfill Design and Operation: August 2016audilioNo ratings yet

- Ea Recycling Brochure 2016Document24 pagesEa Recycling Brochure 2016audilioNo ratings yet

- NRG 43 101 Technical Report Hombre Muerto NorthDocument104 pagesNRG 43 101 Technical Report Hombre Muerto NorthaudilioNo ratings yet

- EIA Review ChecklistDocument8 pagesEIA Review ChecklistaudilioNo ratings yet

- 5a3 16Document90 pages5a3 16audilioNo ratings yet

- Mine Closure FrameworkDocument29 pagesMine Closure FrameworkaudilioNo ratings yet

- Brochure MR300 SeriesDocument2 pagesBrochure MR300 SeriesaudilioNo ratings yet

- Unit-Iv: Fuels and CombustionDocument20 pagesUnit-Iv: Fuels and CombustionporjotonNo ratings yet

- Boiler (A) Boiler Efficiency - :: by Fuel GasDocument4 pagesBoiler (A) Boiler Efficiency - :: by Fuel GasrawadNo ratings yet

- Unit 4-Lecture 2-BOYs Calorimeter and Coal AnalysisDocument30 pagesUnit 4-Lecture 2-BOYs Calorimeter and Coal AnalysisLadliNo ratings yet

- Checal 2 Midterm ExamDocument1 pageChecal 2 Midterm ExamJohn Philip AyoNo ratings yet

- Bomb CalorimeterDocument5 pagesBomb CalorimeterAbhishek SinghNo ratings yet

- AnthraceneDocument142 pagesAnthraceneChengsi WuNo ratings yet

- PublicationDocument390 pagesPublicationJuanSosaNo ratings yet

- 5 Calorimeters PDFDocument11 pages5 Calorimeters PDFFerio ArsyadNo ratings yet

- Basic Notes On Exothermic and EndothermicDocument19 pagesBasic Notes On Exothermic and Endothermicsayma_akhter5074No ratings yet

- Research PaperDocument6 pagesResearch PaperAsnaAfsalNo ratings yet

- Effect of Methanol Addition To Diesel On The Performance and Emission Characteristics of A CI EngineDocument6 pagesEffect of Methanol Addition To Diesel On The Performance and Emission Characteristics of A CI Enginesatheeshsep24No ratings yet

- Fuel and Its CharacteristicsDocument42 pagesFuel and Its CharacteristicsMohammed Al-OdatNo ratings yet

- Conversion of Biomass: Presented By-Gurpreet Singh L-2K16-AE - 178-MDocument86 pagesConversion of Biomass: Presented By-Gurpreet Singh L-2K16-AE - 178-Mkannan000No ratings yet

- Super Sparrow A1 ParametriDocument9 pagesSuper Sparrow A1 ParametriDusanNo ratings yet

- Evs 1Document76 pagesEvs 1AbhishekSinghNo ratings yet

- CAT Engine Specifications: 3508B Offshore Emergency Generator SetDocument6 pagesCAT Engine Specifications: 3508B Offshore Emergency Generator SetGazNo ratings yet

- "H Ehlllllei M Leelhellllle Elhllllllhllll Llllllllmllllu LlllllllhlllluDocument624 pages"H Ehlllllei M Leelhellllle Elhllllllhllll Llllllllmllllu Llllllllhllllushishko106No ratings yet

- Ebook Comprehensive Energy Systems Vol 4A Energy Conversion PDF Full Chapter PDFDocument67 pagesEbook Comprehensive Energy Systems Vol 4A Energy Conversion PDF Full Chapter PDFvictor.vega375100% (31)

- Model C30 PerformanceDocument16 pagesModel C30 PerformanceJlAguirreNo ratings yet

- Applied Thermodynamics IIDocument40 pagesApplied Thermodynamics IIMeka SaimaNo ratings yet

- PT Putra Bintan LestariDocument3 pagesPT Putra Bintan LestariPT. PANDERA KILA MOROWALINo ratings yet

- 4113 9 PDFDocument64 pages4113 9 PDFsimonwonghksar1No ratings yet

- Finals Ice FormatDocument15 pagesFinals Ice FormatBong PadillaNo ratings yet

- JMS 416 GS-N.LDocument4 pagesJMS 416 GS-N.Lemamul613No ratings yet

- Final Exam RETDocument9 pagesFinal Exam RETRajithaSomathilakeNo ratings yet

- Pick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct AnswersDocument6 pagesPick Up The Most Appropriate Statement of The Multiple-Choice Answers by Comment On The Correct Answersأحمد إبراهيم شواربNo ratings yet

- Molino 2016Document16 pagesMolino 2016vitor_alberto_7No ratings yet