Professional Documents

Culture Documents

Padeye Design Cheek

Uploaded by

namasralOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Padeye Design Cheek

Uploaded by

namasralCopyright:

Available Formats

Discipline:

Calc'd by:

TITLE:

LOCATION:

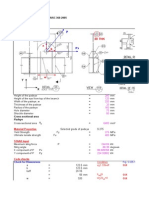

DESIGN OF PADEYE USING CHEEK PLATES

Bottom of Spreader Beam

Reference:

Rev C1

Material Properties:

Yield strength of plate

Material performance factor

Fy

phi

Loads (using factors for Lift Points):

Dynamic Amplification Factor

Skew Load Factor

Contingency Factor

Load applied to padeye

Maximum angle from vertical

Factored Vertical Load

Factored Horizontal Load

DAF

SLF

CF

SWL

Alpha

Pf

Hf

Padeye Geometry:

Diameter of Pin

Diameter of Hole

Diameter of Cheek Pl.

Thickness of Cheek Pl.

Radius of Main Plate

Height to Center of Hole

Length of Main Plate

Thickness of Main Plate

a) Capacity at Base of the Padeye

Case 1: Load acts Vertically

Factored Moment at Base

Moment Resistance at Base

Tension Resistance at Base

Interaction

c) Pullout Capacity in Main Plate

Length in tension (1/4 cheek)

Length in shear

Area for pull out

Direct Tension Resistance

d) Bearing

Bearing Capacity

File: M:\btucker\264161250.xls

1.2

1.4

1.35

1200

5

3314

166

(1.1 for onshore lift, 1.2 for offshore)

(generally 1.4)

(generally 1.35)

kN

degrees

kN

kN

= (1.05 + 1.35 * (DAF*SLF*CF-1))*SWL

= 0.05 * Pf

(see Reference)

Dr

Rm

CHEEK PL.

Dp

Dh

Dc

Tc

Rm

Hh

Lp

Tp

121

126

152.4

50.8

203.2

228.6

914.4

50.8

mm

mm

mm

mm

mm

mm

mm

mm

Mf

Mr

Pr

Mf/Mr

Pf/Pr

48.3

132.7

10452

0.36

0.32

0.68

kN.m

kN.m

kN

289

6898

3302

84

2389

0.36

0.32

0.02

0.03

0.72

kN

kN

kN

kNm

kNm

hv

140

Aw

32410

Fs

165

Vr

4813

Vr >= Pf OK

mm

mm2

MPa

kN

= Rm-Dh/2

Lt

120

Ls

496

At

22725

TFr

5113

Tfr >= Pf OK

mm

mm

mm2

kN

= PI() * Dc * 1/4

= PI() * Dc * 1/4 + 2*SQRT(Rm^2-(Dc/2)^2)

= Tp * (Lt + 0.66*Ls)

= phi*At*Fy * 1e-3

Case 2: Load acts 5 degrees from Vertical

Shear at Base

Vfy

Shear Resistance at Base

Vry

Tension at Base

Pf_2

Moment in Plane of Plate

Mfy

Moment Resistance

Mry

Interaction

Mf/Mr

Pf_2/Pr

0.455 Vfy/Vry

0.727 Mfy/Mry

b) Shear Pullout Capacity of Ring

Tear out height

Area subject to shear

Shear strength

Shear Resistance

250 MPa

0.9

MAIN PLATE

Hh

Dh

Lp

= Hf * (Hh+Dh/2)/1000

= phi * (Lp * Tp^2/4) * Fy * 1e-6

= phi* Lp * Tp * Fy * 1e-3

< 1.0 OK

=Pf*sin(alpha*pi()/180)

= phi * Lp * Tp * 0.66 Fy * 1e-3

= Pf*cos(alpha*pi()/180)

= Vfy * (Hh+Dh/2)/1000

= phi * (Tp*Lp^2/4) *Fy * 0.000001

(Interaction from 13.4.6 of S16.1)

< 1.0 OK

Br

4137 kN

Br >= Pf OK

= 2* (hv * Tp + 2*(Dc-Dh/2)*Tc)

= 0.66*Fy

= phi*Aw*Fs * 1e-3

= phi*Fy*Dp*(Tp+2*Tc)/1000

Page 1 of 3

Printed: 03/20/2015 at 16:33:25

Notes

Discipline:

Calc'd by:

TITLE:

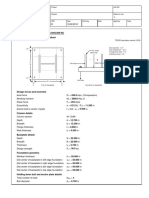

DESIGN OF PADEYE USING CHEEK PLATES

LOCATION: Bottom of Spreader Beam

NOTES RELATING TO PREVIOUS SPREADSHEET PAGE

Check requirements of CM-E-S-P-M00-PH.216

1. Edge distance

Dr - Dh

=

26.4 < Dh = 126 Edge distance insufficient

2.Hole diameter

Recommended hole diameter,

Dh - Dp

Dh = Dp + 3

for D =< 50mm

Dh = Dp + 6

for D > 50mm

5 =< 6, not necessary to check Fhertz

Calc for Fhertz is not correct

3 Pin Diameters for Standard Crosby Shackles

SWL

Dia [in] Dia [mm]

1/2

0.31

8

3/4

0.38

10

1

0.44

11

1 1/2

0.50

13

2

0.63

16

3 1/4

0.75

19

4 3/4

0.88

22

6 1/2

1.00

25

8 1/2

1.13

29

9 1/2

1.25

32

12

1.38

35

13 1/2

1.50

38

17

1.63

41

25

2.00

51

35

2.25

57

55

2.75

70

4. Notes:

- factored moment based on the assumption of Hf acting at the top of the hole

- use a complete penetration weld at the base of the padeye (base metal will therefore govern capacity)

- Use a complete penetration weld between the ring and the main plate (base metal will therefore govern capacity)

- if moment capacity is a problem, consider transverse plates to support out of plane bending

Page 2

Notes

Page 3

You might also like

- 17 Padeye - Spreadsheet Rev ADocument12 pages17 Padeye - Spreadsheet Rev Aoluomo1No ratings yet

- Pad Eye New ReleaseDocument10 pagesPad Eye New ReleaseRaza AidanNo ratings yet

- 03 - Lifting Lug - 2nd Stage Separator (New)Document5 pages03 - Lifting Lug - 2nd Stage Separator (New)Alessio BarboneNo ratings yet

- Padeye Calculation For Lifting AnalysisDocument3 pagesPadeye Calculation For Lifting AnalysisNelson Panjaitan100% (6)

- PADEYE-AISC-360-2005 CalculationDocument6 pagesPADEYE-AISC-360-2005 CalculationsaswattNo ratings yet

- Lifting Sets Calculation - API RP 2ADocument11 pagesLifting Sets Calculation - API RP 2AQuang-derer100% (28)

- Lifting LugsDocument2 pagesLifting LugsAdi Cahyoko82% (11)

- Lifting PadeyeDocument16 pagesLifting PadeyeLưu XuânNo ratings yet

- Spreader BeamDocument7 pagesSpreader BeamAnonymous sfkedkymNo ratings yet

- Lifting Beam CalculationDocument2 pagesLifting Beam Calculationராபர்ட் ஆன்றோ ரெனி100% (4)

- Spreader Beam BLOCK EDocument23 pagesSpreader Beam BLOCK Evaminos85% (13)

- 17 TonsDocument8 pages17 Tonsabuzahrau100% (3)

- CEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveDocument5 pagesCEN TOOL - Standard Padeyes - V4-Rollup Padeye SheaveLaurentiu TeacaNo ratings yet

- Lug Design (XLS)Document4 pagesLug Design (XLS)Bhartendu Patni100% (1)

- Padeye CalculationDocument6 pagesPadeye CalculationKarun DasNo ratings yet

- Padeye Calculation LatestDocument10 pagesPadeye Calculation LatestPavan RayNo ratings yet

- Lifting Lug CalculationDocument2 pagesLifting Lug CalculationDaison Paul63% (8)

- Spreader Bar Plus Free BodyDocument17 pagesSpreader Bar Plus Free BodyMichael HaiseNo ratings yet

- Padeye CalculationDocument11 pagesPadeye CalculationMarvan100% (2)

- Calculation Sheet: Padeye Calculations LoadsDocument28 pagesCalculation Sheet: Padeye Calculations Loadsghoshamit4100% (5)

- Engineering Design of Lifting LugsDocument1 pageEngineering Design of Lifting LugsadammzjinNo ratings yet

- Standard Corus Pad EyesDocument1 pageStandard Corus Pad Eyesbureua100% (1)

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- SWI PadeyeDocument11 pagesSWI PadeyeFian ArdiyanaNo ratings yet

- Report of Lifting Beam DesignDocument5 pagesReport of Lifting Beam Designnarutothunderjet216100% (1)

- Padeye8t (Without Cheek Plate)Document2 pagesPadeye8t (Without Cheek Plate)Mohd Khir Johari100% (1)

- Lifting Lug DesignDocument27 pagesLifting Lug Designmramico100% (1)

- Lifting Lug CalculationDocument5 pagesLifting Lug CalculationEm Mar100% (2)

- Mathcad - Spreader Bar FinalDocument4 pagesMathcad - Spreader Bar FinalOkondu Chiedu100% (3)

- Lifting Analysis Report - TemplateDocument31 pagesLifting Analysis Report - TemplateLukman Hakim100% (2)

- Lifting Trunnion AnalysisDocument1 pageLifting Trunnion Analysisprajwal86No ratings yet

- Spreader Bar CalculationDocument2 pagesSpreader Bar Calculationmahhor82_63564383870% (10)

- Padeye DolphinDocument38 pagesPadeye DolphinMuhammad FadelNo ratings yet

- Spreader Beam CalculationDocument2 pagesSpreader Beam Calculationhombre.muerto595977% (13)

- Design of Pad Eye Using Check PlatesDocument3 pagesDesign of Pad Eye Using Check Plateshyoung65No ratings yet

- Padeye Design Cheekxls CompressDocument3 pagesPadeye Design Cheekxls CompressDixon Antonio MaradiagaNo ratings yet

- MOMENT EndplateDocument8 pagesMOMENT Endplatemoseslugtu6324No ratings yet

- Base Plate Design - BS CodeDocument3 pagesBase Plate Design - BS Codemicheleling669667% (3)

- 16147-Shoe With Gusset No RepadDocument5 pages16147-Shoe With Gusset No RepadRamesh Krishnan100% (1)

- ACI Pad Foundation ExampleDocument7 pagesACI Pad Foundation ExampleEm MarNo ratings yet

- Large Moment ExampleDocument5 pagesLarge Moment ExampleAmro Ahmad AliNo ratings yet

- PF2Document4 pagesPF2nhulugallaNo ratings yet

- 14.2.oil Tank FoundationDocument17 pages14.2.oil Tank Foundationnerioalfonso100% (2)

- Beam To Beam Web - Shear ConnectionDocument2 pagesBeam To Beam Web - Shear ConnectionGautam SharmaNo ratings yet

- Padeye Design CheekDocument1 pagePadeye Design CheekPawan ShettyNo ratings yet

- Sfex Pad Eyes Calculations 35T - 32MMDocument1 pageSfex Pad Eyes Calculations 35T - 32MMJohn Rom CabadonggaNo ratings yet

- 3-Pile Cap DesignDocument9 pages3-Pile Cap DesignMitra RampersadNo ratings yet

- Connection Design MomentDocument4 pagesConnection Design MomentAkshit Dhawan100% (1)

- Moment ConnectionsDocument15 pagesMoment ConnectionsHector Aguana100% (1)

- Davit CalcDocument6 pagesDavit Calcrustamriyadi100% (1)

- Base PlateDocument12 pagesBase PlateD SRINIVAS100% (1)

- Four Bolt Unstiffened End PlateDocument7 pagesFour Bolt Unstiffened End PlateRnD2013No ratings yet

- Mathcad - 539900-050-130 Padeye Pulling Skid 9.5 TDocument7 pagesMathcad - 539900-050-130 Padeye Pulling Skid 9.5 TPablo Diego Didoné100% (1)

- Connection Design SheetDocument47 pagesConnection Design SheetStephen James100% (1)

- #754 v-3103 Spreader & Lifting 60 DegreeDocument12 pages#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- Lifting Lug AnalysisDocument3 pagesLifting Lug Analysisராபர்ட் ஆன்றோ ரெனி67% (3)

- Design Calculation RCC Sleeper Type 6Document9 pagesDesign Calculation RCC Sleeper Type 6DrAmit Dutta100% (4)

- Column Base Plate (Fixed Type)Document11 pagesColumn Base Plate (Fixed Type)Ernest Navarro100% (2)

- Mathcad - Spreader Beam Design Calculations As Per DNV 5th VerDocument29 pagesMathcad - Spreader Beam Design Calculations As Per DNV 5th VerAbderraoufAffes100% (3)

- Column Base Plate (Hinge Type)Document14 pagesColumn Base Plate (Hinge Type)Tengku Nizarul AslamiNo ratings yet

- Equipment Numeral Calculator For A ShipDocument16 pagesEquipment Numeral Calculator For A ShipBolarinwaNo ratings yet

- 1000 Business IdealsDocument43 pages1000 Business IdealsBolarinwaNo ratings yet

- Ballasting Calculation For The Transportation of PLEMsDocument17 pagesBallasting Calculation For The Transportation of PLEMsBolarinwa100% (1)

- "EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionDocument23 pages"EMBEDPL2" - Embedment Strength of Stud Plate: Program DescriptionBolarinwaNo ratings yet

- ANSYS Manual StudentDocument215 pagesANSYS Manual StudentBolarinwaNo ratings yet

- Crosby Shackles G-2130 PDFDocument2 pagesCrosby Shackles G-2130 PDFBolarinwaNo ratings yet

- BS Civil EngineeringDocument138 pagesBS Civil EngineeringBolarinwaNo ratings yet

- StruCalc 80 ManualDocument124 pagesStruCalc 80 ManualBolarinwaNo ratings yet

- 101 Ways To Make Money in Africa PDFDocument17 pages101 Ways To Make Money in Africa PDFBolarinwaNo ratings yet

- Ffs Su 5221Document12 pagesFfs Su 5221BolarinwaNo ratings yet

- Ffs Su 5218Document33 pagesFfs Su 5218BolarinwaNo ratings yet

- Ffs-su-5216-A - Structural Welding and Inspection For Offshore PlatformsDocument28 pagesFfs-su-5216-A - Structural Welding and Inspection For Offshore PlatformsBolarinwaNo ratings yet

- Ffs-pu-5116-A-transportation of Cargo by Barge or ShipDocument28 pagesFfs-pu-5116-A-transportation of Cargo by Barge or ShipBolarinwaNo ratings yet

- Mac-Su-7.01 - Offshore Lattice Boom Pedestal CranesDocument31 pagesMac-Su-7.01 - Offshore Lattice Boom Pedestal CranesBolarinwaNo ratings yet

- Gen-Su-5227 - Units of MeasurementDocument4 pagesGen-Su-5227 - Units of MeasurementBolarinwaNo ratings yet

- Civ-Su-6001-C - Design of BuildingsDocument37 pagesCiv-Su-6001-C - Design of BuildingsBolarinwaNo ratings yet

- Civ-su-1.10-A Design and Installation of Living QuartersDocument86 pagesCiv-su-1.10-A Design and Installation of Living QuartersBolarinwa100% (1)

- HA and HB LoadingDocument8 pagesHA and HB LoadingBolarinwa100% (2)

- Civ-su-1.28-A Helidecks On Offshore InstallationsDocument12 pagesCiv-su-1.28-A Helidecks On Offshore InstallationsBolarinwaNo ratings yet

- Sketchometry Book enDocument20 pagesSketchometry Book enBolarinwaNo ratings yet

- Equipment Data Sheet Mts Goldhofer - PubDocument1 pageEquipment Data Sheet Mts Goldhofer - PubBolarinwaNo ratings yet

- Python Scripting Tutorial - FreeCAD DocumentationDocument11 pagesPython Scripting Tutorial - FreeCAD DocumentationBolarinwaNo ratings yet

- Civ Du 5009 H Structural Design CriteriaDocument28 pagesCiv Du 5009 H Structural Design CriteriaBolarinwaNo ratings yet

- BS 2X 33 Two Part EpoxyDocument13 pagesBS 2X 33 Two Part EpoxyBolarinwaNo ratings yet

- 101 Ways To Make Money in AfricaDocument17 pages101 Ways To Make Money in AfricaBolarinwa67% (6)

- Top Head Lug & Tail Lug DesignDocument30 pagesTop Head Lug & Tail Lug DesignBolarinwaNo ratings yet

- Spot Welding Function R30iB Manual Del OperarioDocument130 pagesSpot Welding Function R30iB Manual Del Operariopedro100% (2)

- The Sphere Circumscribing A TetrahedronDocument4 pagesThe Sphere Circumscribing A TetrahedronRaghuveer ChandraNo ratings yet

- Muscular System NotesDocument6 pagesMuscular System NotesZussette Corbita VingcoNo ratings yet

- Examples of Consonant BlendsDocument5 pagesExamples of Consonant BlendsNim Abd MNo ratings yet

- Ventilation WorksheetDocument1 pageVentilation WorksheetIskandar 'muda' AdeNo ratings yet

- Nestle IndiaDocument74 pagesNestle IndiaKiranNo ratings yet

- SPR, RCS-9627CN, NoDocument5 pagesSPR, RCS-9627CN, NoAmaresh NayakNo ratings yet

- Islami Bank Bangladesh Limited: Ibbl Ibanking ServiceDocument2 pagesIslami Bank Bangladesh Limited: Ibbl Ibanking ServiceShaikat AlamNo ratings yet

- HGP Year End Report 2021-2022 NewDocument169 pagesHGP Year End Report 2021-2022 Newangelica sungaNo ratings yet

- Bharat Sanchar Nigam Limited: Invoice For Post Paid ServicesDocument2 pagesBharat Sanchar Nigam Limited: Invoice For Post Paid ServicessuryaNo ratings yet

- Fruit Brearing CropsDocument177 pagesFruit Brearing CropsJoshua G. Sapin100% (1)

- CHAPTER 5 Ground ImprovementDocument47 pagesCHAPTER 5 Ground ImprovementBeman EasyNo ratings yet

- Welcome Speech For Seminar in College 2Document4 pagesWelcome Speech For Seminar in College 2Niño Jay C. GastonesNo ratings yet

- Sari Sari Store in Tabango Leyte The Business Growth and Its Marketing Practices 124 PDF FreeDocument11 pagesSari Sari Store in Tabango Leyte The Business Growth and Its Marketing Practices 124 PDF FreeJim Ashter Laude SalogaolNo ratings yet

- Barclays Personal Savings AccountsDocument10 pagesBarclays Personal Savings AccountsTHNo ratings yet

- Manuall Cryton-Yamaha 2015Document57 pagesManuall Cryton-Yamaha 2015Abel PachecoNo ratings yet

- Caribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Document1 pageCaribbean Career Opportunity - Cayman Island Water Authority - Plant Operator Cayman Brac Plant Operator (Overseas)Cawasa St-LuciaNo ratings yet

- User Manual of CHISON IVis 60 EXPERT PDFDocument164 pagesUser Manual of CHISON IVis 60 EXPERT PDFJuan Carlos GoyzuetaNo ratings yet

- Micron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesDocument92 pagesMicron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesAENo ratings yet

- Keepa ApiDocument55 pagesKeepa ApiQazi Sohail AhmadNo ratings yet

- LAB - Testing Acids & BasesDocument3 pagesLAB - Testing Acids & BasesRita AnyanwuNo ratings yet

- Pressuremeter TestDocument33 pagesPressuremeter TestHo100% (1)

- Airline and Airport Master - OdsDocument333 pagesAirline and Airport Master - OdsGiri KumarNo ratings yet

- Getting Started HANADocument86 pagesGetting Started HANAAr RazaNo ratings yet

- Advertisement For Recruitment of Non-Teaching StaffDocument3 pagesAdvertisement For Recruitment of Non-Teaching StaffGoogle AccountNo ratings yet

- O RTIZDocument2 pagesO RTIZKhimberly Xylem OrtizNo ratings yet

- Monster Energy v. Jing - Counterfeit OpinionDocument9 pagesMonster Energy v. Jing - Counterfeit OpinionMark JaffeNo ratings yet

- Unit One Mathematical EconomicsDocument15 pagesUnit One Mathematical EconomicsSitra AbduNo ratings yet

- Soil ResistivityDocument6 pagesSoil ResistivityAnonymous EP0GKhfNo ratings yet

- Cognitive InfocommunicationsDocument229 pagesCognitive Infocommunicationsradhakodirekka8732No ratings yet