0% found this document useful (0 votes)

4K views1 pageBrickworks Inspection Checklist

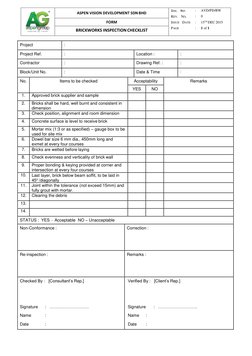

1. This document is a brickworks inspection checklist for a construction project.

2. It lists 14 items to check regarding the brick supplier, brick dimensions, wall alignment, mortar mix, dowel bars, brick laying techniques, bonding, joint sizes, and debris removal.

3. For each item, the inspector indicates whether it is acceptable or unacceptable, and notes any non-conformances, corrections, or remarks.

Uploaded by

Siti Rohani IsdrisCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

4K views1 pageBrickworks Inspection Checklist

1. This document is a brickworks inspection checklist for a construction project.

2. It lists 14 items to check regarding the brick supplier, brick dimensions, wall alignment, mortar mix, dowel bars, brick laying techniques, bonding, joint sizes, and debris removal.

3. For each item, the inspector indicates whether it is acceptable or unacceptable, and notes any non-conformances, corrections, or remarks.

Uploaded by

Siti Rohani IsdrisCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Brickworks Inspection Checklist: A form for inspecting brickwork, including project details, checklist of items, and approval sections.