90% found this document useful (10 votes)

19K views2 pagesFinal Checklist-SLAB

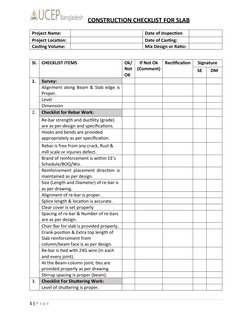

The document is a construction checklist for slab casting that contains items to inspect before pouring concrete. It includes checking that rebar placement, formwork, embedded items, and materials are in accordance with design specifications. The checklist is to be signed off on by the site engineer and deputy manager once inspections are completed and any non-compliant items are rectified.

Uploaded by

Ah RashedCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

90% found this document useful (10 votes)

19K views2 pagesFinal Checklist-SLAB

The document is a construction checklist for slab casting that contains items to inspect before pouring concrete. It includes checking that rebar placement, formwork, embedded items, and materials are in accordance with design specifications. The checklist is to be signed off on by the site engineer and deputy manager once inspections are completed and any non-compliant items are rectified.

Uploaded by

Ah RashedCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOCX, PDF, TXT or read online on Scribd

- Checklist Items