Professional Documents

Culture Documents

Saudi Aramco Inspection Checklist: Pre-Cast Post-Concreting & Final Inspection SAIC-Q-1028 31-Dec-14 Civil

Saudi Aramco Inspection Checklist: Pre-Cast Post-Concreting & Final Inspection SAIC-Q-1028 31-Dec-14 Civil

Uploaded by

RajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Saudi Aramco Inspection Checklist: Pre-Cast Post-Concreting & Final Inspection SAIC-Q-1028 31-Dec-14 Civil

Saudi Aramco Inspection Checklist: Pre-Cast Post-Concreting & Final Inspection SAIC-Q-1028 31-Dec-14 Civil

Uploaded by

RajCopyright:

Available Formats

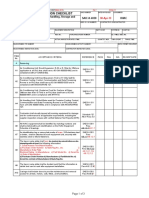

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

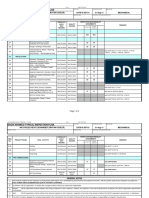

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Cast Post-Concreting & Final Inspection SAIC-Q-1028 31-Dec-14 CIVIL -

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

EQUIPMENT ID NUMBER(S) EQUIPMENT DESCRIPTION EQPT CODE SYSTEM ID. PLANT NO.

LAYOUT DRAWING NUMBER REV. NO. PURCHASE ORDER NUMBER EC / PMCC / MCC NO.

SCHEDULED INSPECTION DATE & TIME ACTUAL INSPECTION DATE & TIME QUANTITY INSP. MH's SPENT TRAVEL TIME

SAUDI ARAMCO USE ONLY

SAUDI ARAMCO TIP NUMBER SAUDI ARAMCO ACTIVITY NUMBER WORK PERMIT REQUIRED?

SAUDI ARAMCO INSPECTION LEVEL CONTRACTOR INSPECTION LEVEL

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

A Demolding and Curing Inspection

The concrete surface shall be protected immediately against

SAES-Q-012

A1 moisture loss following the finisher or finishing machine.(ACI 308,

Sec. 3.2

Sec. 1.4.2.2.4)

Formwork supports shall not be removed until sufficient prestressing

SAES-Q-001

A2 force has been applied to support the dead load, formwork and

Sec. 3.2

construction load. (ACI 301, Sec. 9.3.8.3.b)

Precast members or units are removed from forms only after the

SAES-Q-012

A3 concrete has reached a specified strength, as determined by field-

Sec. 5.14

cured test cylinders or beams. (ACI 347R, Sec. 7.6.5)

When water curing is used, it shall be continuous until the

SAES-Q-001

A4 compressive strength has reached 70% of the specified strength, but

Sec. 10.3

not less than 7 days after placement.

Maximum total dissolved solids in water used for curing shall not SAES-Q-001

A5

exceed 1000 parts per million. Sec. 10.2

Saturated burlaps shall be covered with a plasticized sheet vapor

SAES-Q-001

A6 barrier, minimum 0.15 mm (6 mils) in thickness and shall be kept in

Sec. 10.4

contact with the concrete surface at all times.

When steam curing is used, it shall be in accordance with ACI

SAES-Q-012

A7 517.2R "Accelerated Curing of concrete at Atmospheric Pressure -

Sec. 6.9

State of the Art."

For accelerated curing, heat shall be applied at a controlled rate

following the initial set of concrete in combination with an effective SAES-Q-012

A8

method of supplying or retaining moisture. (PCI-MNL-117, Div. 4, Sec. 3.2

Sec. 4.21.1.3)

The maximum sustained concrete temperature during the

SAES-Q-012

A9 accelerated curing cycle shall be 70 °C. (PCI-MNL-117, Div. 4, Sec.

Sec. 3.2

4.21.1.4)

The maximum peak concrete temperature during the accelerated

SAES-Q-012

A10 curing cycle shall be 190°F (88 °C)-180°F. (PCI-MNL-117, Div. 4,

Sec. 3.2

Sec. 4.21.1.5)

The maximum cooling rate from accelerated curing temperature shall

be 50°F per hour (28°C per hour) and cooling at this rate shall

SAES-Q-012

A11 continue until the concrete temperature is no more than 40°F (22°C)

Sec. 3.2

above the ambient temperature outside the enclosure. (PCI-MNL-

117, Div. 4, Sec. 4.21.1.6)

Saudi Aramco: Company General Use

At least one recording thermometer shall be provided per contiguous

form group with a common heat source to monitor the product at SAES-Q-012

A12

appropriate locations (usually coolest position). (PCI-MNL-117, Div. Sec. 3.2

4, Sec. 4.21.1.7)

Saudi Aramco: Company General Use

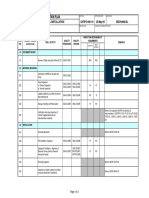

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Cast Post-Concreting & Final Inspection SAIC-Q-1028 31-Dec-14 CIVIL -

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Curing compound shall not be used for curing of precast and SAES-Q-012

A13

prestressed concrete elements. Sec. 6.10.3

B Final Inspection

Each precast member shall be marked to indicate its location and

SAES-Q-012

B1 orientation in the structure and date of manufacture.(ACI

Sec. 3.2

318,Sec16.8.1)

Holes left by tie rods, strand hold-down devices or other temporary

SAES-Q-012

B2 inserts shall be thoroughly cleaned and filled with stiff dry mortar or

Sec. 3.2

non-shrink grout. (PCI-MNL-116, Div. III, Sec. 3.5.4)

All precast members where the reinforcement protrudes the surface

SAES-Q-012

B3 or where shadow lines caused by reinforcement too near the surface

Sec. 6.4

shall be rejected.

Chamfer shall be provided at exposed edges of columns and beams SAES-Q-012

B4

unless shown otherwise.. Sec. 6.6

Dimensional tolerances shall not exceed those recommended in the

SAES-Q-012

B5 PCI Manual of Quality Control (MNL-116, MNL-117, MNL-135) with

Sec. 6.5

exceptions as listed in Items B6, B7 and B8.

Wall panels shall have no camber and differential bowing between

adjacent panels shall not exceed 3mm (1/8 of an inch). Total SAES-Q-012

B6

maximum bowing due to thermal stresses, etc., shall not exceed Sec. 6.5

1/360 of the panel length.

Differential camber between adjacent members other than wall

panels shall not exceed 10 mm (3/8 of an inch). Where the SAES-Q-012

B7

differential camber exceeds this value, a fill shall be installed and Sec. 6.5

feathered out on a 1-in-12 slope.

Differential camber between adjacent members for Prestressed SAES-Q-012

B8

Concrete Double Tees shall not exceed 6mm (1/4 of an inch). Sec. 6.5

Finish of exterior surface shall be in accordance with the Project SAES-Q-012

B9

Specifications and as shown on contract drawings. Sec. 6.8.1

All concrete surfaces in direct contact with earth are coated with two

coats of coal tar or bitumen coating that conforms to APCS-3 or

APCS-10 of SAES-H-101V. Where concrete surface protection is

required, it shall be in accordance with ACI 515.1R. Note: APCS-10 SAES-Q-012

shall not be used where soil is contaminated with hydrocarbons. Sec. 6.4/ SAES-

B10

Dry Film Thickness Requirements: H-101V-APCS-3

APCS-3: 2 or more coats; 300μm max/coat, Total System 400μm & 10

(Min) 600 μm (Max) (SAES-H-101V-APCS-3)

APCS-10: Minimum 2 coats, minimum 750μm Total system.(SAES-H-

101V-APCS-10)

Saudi Aramco: Company General Use

SAUDI ARAMCO ID/PID - 18-MAY-05 - REV 0 (Standards Cutoff - June 2014) Rev 8 30-Jun-14

SAIC NUMBER DATE APPROVED QR NUMBER

SAUDI ARAMCO INSPECTION CHECKLIST

Pre-Cast Post-Concreting & Final Inspection SAIC-Q-1028 31-Dec-14 CIVIL -

PROJECT TITLE WBS / BI / JO NUMBER CONTRACTOR / SUBCONTRACTOR

ITEM

ACCEPTANCE CRITERIA REFERENCE PASS FAIL N/A RE-INSP DATE

No.

Strength tests representing each class of concrete must meet the

following requirements:

1. Every arithmetic average of any three consecutive strength tests

09-SAMSS-97

B11 equals or exceeds f'c; and

Sec. III.B

2. No strength test falls below fc by more than 500 psi when fc is

5000 psi or less; or by more than 0.10fc when fc is more than 5000

psi. (ACI 318-2011, Sec 5.6.3.3)

REMARKS:

REFERENCE DOCUMENTS:

1- SAES-Q-012 -- Criteria for Design and Construction of Precast and Prestressed Concrete Structures, 03 July 2012

2- SAES-Q-001 -- Criteria for Design and Construction of Concrete Structures, 2July 2014

3- 09-SAMSS-97 -- Ready-Mixed Portland Cement Concrete, 30 June 2014

4- SAES-H-101V -- Approved Saudi Aramco Data Sheets - Paints and Coatings, 09 October 2012

Contractor / Third-Party Saudi Aramco

Construction Representative* PMT Representative

Work is Complete and Ready for Inspection:

T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Inspector PID Representative

Performed Inspection Work / Rework May Proceed T&I Witnessed QC Record Reviewed Work Verified

Name, Initials and Date: Name, Initials and Date:

QC Supervisor Proponent and Others

Quality Record Approved:

Name, Organization, T&I Witnessed QC Record Reviewed Work Verified

Name, Sign and Date:

Initials and Date:

Saudi Aramco: Company General Use

You might also like

- Airman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BFrom EverandAirman Certification Standards: Remote Pilot - Small Unmanned Aircraft Systems (2024): FAA-S-ACS-10BNo ratings yet

- Saudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacDocument1 pageSaudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacmohamadNo ratings yet

- Saudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacDocument1 pageSaudi Aramco Inspection Checklist: Duct System Handling, Storage and Preservation SAIC-K-4011 15-Dec-09 HvacmohamadNo ratings yet

- Practical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneFrom EverandPractical, Made Easy Guide To Building, Office And Home Automation Systems - Part OneNo ratings yet

- SAIC-A-2013 Rev 0Document2 pagesSAIC-A-2013 Rev 0philipyapNo ratings yet

- Entertainment IndustryDocument29 pagesEntertainment Industryjohn lexter emberadorNo ratings yet

- Electrical Design Checklist v1.2Document39 pagesElectrical Design Checklist v1.2huangjlNo ratings yet

- AMM 10-30-00-554-804-A - Return To Operation After A Parking PeriodDocument9 pagesAMM 10-30-00-554-804-A - Return To Operation After A Parking PeriodAndres MendezNo ratings yet

- Satip G 005 01Document2 pagesSatip G 005 01Anonymous 4e7GNjzGWNo ratings yet

- Saudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 MechDocument2 pagesSaudi Aramco Inspection Checklist: Installation of Fire Water Isolation Valves SAIC-L-2056 25-May-05 MechphilipyapNo ratings yet

- Saudi Aramco Pre-Commissioning Form: LightingDocument2 pagesSaudi Aramco Pre-Commissioning Form: LightingHaleem Ur Rashid Bangash100% (1)

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- FAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansFrom EverandFAR-AMT 2021: Federal Aviation Regulations for Aviation Maintenance TechniciansRating: 5 out of 5 stars5/5 (2)

- Saic N 2033Document5 pagesSaic N 2033aamirapiNo ratings yet

- PMP-ResourcesDocument71 pagesPMP-ResourcesmohamadNo ratings yet

- SAIC-P-3003 Rev 7 FinalDocument7 pagesSAIC-P-3003 Rev 7 FinalEnginerShahzadGhaffarNo ratings yet

- Satr K 4006Document2 pagesSatr K 4006Jerald SoteloNo ratings yet

- SAIC-K-4001 Rev 7Document3 pagesSAIC-K-4001 Rev 7Rohit BassNo ratings yet

- Saic K 4001Document2 pagesSaic K 4001BilalNo ratings yet

- Saic K 4002Document2 pagesSaic K 4002BilalNo ratings yet

- Saudi Aramco Inspection Checklist: Passively Cooled Shelter Installation Inspection SAIC-K-4035 30-Apr-13 HvacDocument3 pagesSaudi Aramco Inspection Checklist: Passively Cooled Shelter Installation Inspection SAIC-K-4035 30-Apr-13 HvacshahzadaNo ratings yet

- Comsol Multiphysics SimulationDocument14 pagesComsol Multiphysics SimulationNaveen Kumar MadasettyNo ratings yet

- SAIC-K-4038 Rev 7Document3 pagesSAIC-K-4038 Rev 7shahzadaNo ratings yet

- SAIC-K-4044 Rev 7 Pressurized Building HVAC RequirementsDocument6 pagesSAIC-K-4044 Rev 7 Pressurized Building HVAC RequirementsshahzadaNo ratings yet

- SATR - J - 6702 Rev 0 PDFDocument8 pagesSATR - J - 6702 Rev 0 PDFAdel KlkNo ratings yet

- 1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1Document3 pages1 SATIP-D-001-01 Pressure Vessel Installation-Rev 1JithuJohn100% (1)

- SAIC-K-4039 Rev 7 Air-Cooled Condenser InstallationDocument2 pagesSAIC-K-4039 Rev 7 Air-Cooled Condenser InstallationshahzadaNo ratings yet

- SATR-J-6505-Rev 0 PDFDocument5 pagesSATR-J-6505-Rev 0 PDFAdel KlkNo ratings yet

- EDT IMP QuestionsDocument1 pageEDT IMP QuestionsMayur MestryNo ratings yet

- Saudi Aramco Inspection Checklist: Air Filtration Devices Installation SAIC-K-4029 HvacDocument3 pagesSaudi Aramco Inspection Checklist: Air Filtration Devices Installation SAIC-K-4029 HvacshahzadaNo ratings yet

- Saic A 2011Document5 pagesSaic A 2011Anonymous 4e7GNjzGWNo ratings yet

- Saudi Diyar Consultants: Construction Supervision Department Procedures ManualDocument18 pagesSaudi Diyar Consultants: Construction Supervision Department Procedures ManualmohamadNo ratings yet

- 1 SATIP-F-001-04 Boiler - Packaged Type - 1Document4 pages1 SATIP-F-001-04 Boiler - Packaged Type - 1JithuJohnNo ratings yet

- Part - B: (Control and Instrumentation System)Document267 pagesPart - B: (Control and Instrumentation System)joydrathdey100% (1)

- Saic - K-4006Document2 pagesSaic - K-4006Bander Al–kouhlaniNo ratings yet

- Saic K 4010Document3 pagesSaic K 4010mohamadNo ratings yet

- Saic S 4006Document2 pagesSaic S 4006mahdi_gNo ratings yet

- SAIC & SATR - InstrumentationDocument7 pagesSAIC & SATR - InstrumentationAdel KlkNo ratings yet

- Saudi Aramco Inspection ChecklistDocument9 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Satip-X-600-02 Rev 1 For CP SystemDocument4 pagesSatip-X-600-02 Rev 1 For CP SystemSaleem MohammedNo ratings yet

- Saudi Aramco Inspection ChecklistDocument12 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Satip e 007 01Document2 pagesSatip e 007 01Anonymous 4e7GNjzGWNo ratings yet

- SATR-J-6406 Rev 0 PDFDocument10 pagesSATR-J-6406 Rev 0 PDFAdel KlkNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistmohamadNo ratings yet

- Saic-P-3002 Rev 0Document4 pagesSaic-P-3002 Rev 0jwochNo ratings yet

- Saic - K-4027Document3 pagesSaic - K-4027Bander Al–kouhlaniNo ratings yet

- SAIC-N-2042 Rev 0Document2 pagesSAIC-N-2042 Rev 0philipyapNo ratings yet

- SAIC-S-4012 Rev 7Document5 pagesSAIC-S-4012 Rev 7Muhammad TariqNo ratings yet

- Saudi Aramco Inspection ChecklistDocument10 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingDocument9 pagesSaudi Aramco Test Report: SATR-P-3105 Elect-UPS DC/AC Inverter, Pre-Commissioning & Functional TestingehteshamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument21 pagesSaudi Aramco Inspection Checklistnisha_khanNo ratings yet

- Saudi Aramco Inspection ChecklistDocument6 pagesSaudi Aramco Inspection ChecklistMa.socorro SaballaNo ratings yet

- Saic - K-4017Document2 pagesSaic - K-4017Bander Al–kouhlaniNo ratings yet

- SATR-J - 6802 - Rev 0 PDFDocument3 pagesSATR-J - 6802 - Rev 0 PDFAdel KlkNo ratings yet

- SAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FDocument8 pagesSAIC-G-2012 NMR Verif Visual Insp-Sxs-Rlc-FKirubhakarPooranamNo ratings yet

- Saudi Aramco Inspection ChecklistDocument2 pagesSaudi Aramco Inspection ChecklistphilipyapNo ratings yet

- SAIC-A-2023 Rev 0Document2 pagesSAIC-A-2023 Rev 0philipyapNo ratings yet

- Saudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 ElectDocument3 pagesSaudi Aramco Test Report: UPS Distribution System, Energized Bolted - Fault Test SATR-P-3112 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 MechDocument4 pagesSaudi Aramco Inspection Checklist: Final Insp of Tank Installation (Tanks) SAIC-D-2021 1-Dec-06 Mechரமேஷ் பாலக்காடுNo ratings yet

- Saudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListDocument17 pagesSaudi Aramco Test Report: Final Inspection/Re-Instatement Punch ListnadeemNo ratings yet

- Saudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 ElectDocument8 pagesSaudi Aramco Test Report: Overhead T&D - High-Potential Withstand Testing SATR-P-3220 3-Jul-18 Electkarthi51289No ratings yet

- Saudi Aramco Inspection Checklist: D.C. Power System - Installation Inspection SAIC-T-5118 30-Apr-13 TelecomDocument6 pagesSaudi Aramco Inspection Checklist: D.C. Power System - Installation Inspection SAIC-T-5118 30-Apr-13 TelecomOmer aliNo ratings yet

- Alert Operators Transmission - Aot: Customer Services DirectorateDocument5 pagesAlert Operators Transmission - Aot: Customer Services DirectorateIbrahim KhalilNo ratings yet

- SATIP-K-001-06 - PACKAGED AIR CONDITIONING UNIT SystDocument3 pagesSATIP-K-001-06 - PACKAGED AIR CONDITIONING UNIT SystRAMAKRISHNA100% (1)

- SAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil SystemDocument3 pagesSAIC-G-2017 Rev 0 - Mechanical & Chemical Cleaning of Lube Andor Seal Oil Systemবিপ্লব পালNo ratings yet

- PMP StakeholdersDocument62 pagesPMP StakeholdersmohamadNo ratings yet

- Project Management and Scheduling PDFDocument339 pagesProject Management and Scheduling PDFmohamadNo ratings yet

- Saudi Diyar Consultants: Construction Supervision Department Procedures ManualDocument52 pagesSaudi Diyar Consultants: Construction Supervision Department Procedures ManualmohamadNo ratings yet

- Saic K 4010Document3 pagesSaic K 4010mohamadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument1 pageSaudi Aramco Inspection ChecklistmohamadNo ratings yet

- Saic B 4001Document2 pagesSaic B 4001mohamadNo ratings yet

- Daily TaskDocument36 pagesDaily TaskmohamadNo ratings yet

- Sky13585-679Lf: 1.0 To 6.0 GHZ SPDT Switch: ApplicationsDocument9 pagesSky13585-679Lf: 1.0 To 6.0 GHZ SPDT Switch: ApplicationsrfidguysNo ratings yet

- Datasheet Ocg 118mDocument2 pagesDatasheet Ocg 118mdejan@mailinator.comNo ratings yet

- Technical CemiaDocument4 pagesTechnical CemiaWilsonVargas ChucuChucuNo ratings yet

- Green Laser JERICHO - MultispotDocument12 pagesGreen Laser JERICHO - Multispotderya papuçNo ratings yet

- Manual SENTRON Power Monitoring Device PAC3200Document184 pagesManual SENTRON Power Monitoring Device PAC3200cc_bauNo ratings yet

- BascavrDocument210 pagesBascavretrewtewtNo ratings yet

- What Are The Differences Between Huawei and Cisco WLAN ProductsDocument12 pagesWhat Are The Differences Between Huawei and Cisco WLAN ProductsElizabeth RichNo ratings yet

- Circutor Energy Meter ManualDocument12 pagesCircutor Energy Meter Manualtayyab1965No ratings yet

- Authenticated Key Exchange ProtocolsDocument14 pagesAuthenticated Key Exchange ProtocolsAnonymous lVOTEpkCNo ratings yet

- Manual & Troubleshooting CC3Document161 pagesManual & Troubleshooting CC3Konami BogorNo ratings yet

- 6 Auj 19 UcDocument6 pages6 Auj 19 UcleminhksvlNo ratings yet

- (Uc800 - ZT) BN68 03380a 01L03 0410 PDFDocument192 pages(Uc800 - ZT) BN68 03380a 01L03 0410 PDFfragma84No ratings yet

- Wheatstone Bridge Circuit and Theory of OperationDocument7 pagesWheatstone Bridge Circuit and Theory of OperationAminullah SharifNo ratings yet

- H0400 MODBUS Relay UnitDocument2 pagesH0400 MODBUS Relay UnitkylegazeNo ratings yet

- Datasheet - HK Aoz1013ai09 5271545Document14 pagesDatasheet - HK Aoz1013ai09 5271545BoKi PoKiNo ratings yet

- Assignment 1.solDocument3 pagesAssignment 1.solvanvu123100% (1)

- PLC Traction Temporary Run Manual PDFDocument13 pagesPLC Traction Temporary Run Manual PDFfreddyjoertyNo ratings yet

- Man 4020 PDFDocument98 pagesMan 4020 PDFTeodoro HernándezNo ratings yet

- MBRF20100Document2 pagesMBRF20100Vitaliy ChernovNo ratings yet

- Women Safety AppDocument18 pagesWomen Safety AppVinod BawaneNo ratings yet

- B Tech CivilDocument98 pagesB Tech CivilNaveen GoyalNo ratings yet

- DL4 User Manual - EnglishDocument11 pagesDL4 User Manual - Englishapi-3737343No ratings yet

- MA/MAC6700 Input and Control Connection DiagramDocument2 pagesMA/MAC6700 Input and Control Connection DiagramDanilo Antonio Colombini NetoNo ratings yet

- Service Manual: LCD TVDocument78 pagesService Manual: LCD TVHector SevillaNo ratings yet

- Clever Choice Duo Thermometer Manual 1 1Document14 pagesClever Choice Duo Thermometer Manual 1 1Quoc Tuan Le0% (1)

- Feeder DataDocument108 pagesFeeder DataPrashant TrivediNo ratings yet