Professional Documents

Culture Documents

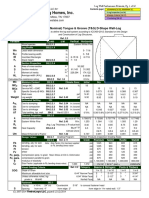

Es 1S71 1K251 Ac+2002 12

Uploaded by

Popescu AlinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Es 1S71 1K251 Ac+2002 12

Uploaded by

Popescu AlinCopyright:

Available Formats

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

SCOPE:

This specification defines the requirements of spot welds used in the fabrication of assemblies

comprising two or more thickness of steel of the same or different gauge.

It is additional information of resistance spot welds on drawings or defined by CAD Data. The

definition excludes items, which are already described in Ford Engineering CAD & Drafting

Standards and/or Manufacturing Standards (U-WX 012).

APPLICATION:

This Engineering Specification applies to steel sheet, strip or plate in the uncoated condition and

also with coatings of zinc, tin, nickel, terne alloy (tin & lead). It also applies to steel coated with

temporary coatings for rust prevention and paint primers providing the coating does not

effectively interfere with the welding process.

It applies to the following categories of steels:

CATEGORY TYPE OF FORD MATERIAL

STEELS SPECIFICATION No.

Category A Mild Steels, Hot & WSS-M1A344-A1/A2

Cold Rolled, Low WSS-M1A345-A1/A2/A3/A4

Carbon

Category B High Strength Low WSS-M1A346-A1/A2/A3

Alloy Steels WSS-M1A347-A1/A2/A3

Category C Dual Phase Steels WSS-M1A348-A1/A2/A3/A4/A5/A6/A7

The text of the referenced Ford Material Specifications is available from the following weblink

http://www.mats.ford.com/mats/scripts/spec_by_mtlCat.html, Metals 1A-99A.

1. WELD IDENTIFICATION

The weld symbols shall be in accordance with Ford Engineering CAD and Drafting Standard

D-3 (Welding Symbols And Specifications) as outlined in the Cadmethods weblink

http://www.cadmethods.ford.com/cad_methods/welding/weld_namnum_eu.html.

2. DEFINITIONS

2.1 Button

Figure 2.1 shows a button that is pulled out of one of the welded components as the result of a

chisel (peel) test as described in Section 7.4. A button typically occurs in those cases where the

chisel tests leads to either a peel fracture or a combination fracture as shown in Figure 2.2 below.

Figure 2.1: Button As A Result Of A Peel Test

Frame 2 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

2.2. Button Diameter dp

In the cases of a peel fracture and a combination fracture, the button diameter dp is the

average of two diameters measured at right angles to each other when one of the diameters is the

apparent minimum. See Figure 2.2, sections a) and c) for a detailed illustration.

Figure 2.2: Button & Fracture Face Diameters dp

2.3 Shear Fracture Face

• Category A- and B-Steels

A shear fracture typically occurs in the case of different gauge combinations and on larger spot

welds.

• Category C-Steels

A shear fracture may also occur on joints made of Category C-sheet steel combinations due to the

metallurgical changes in the metal during the welding process.

Figure 2.2, Section b) illustrates a typical shear fracture face. It is characterized by a lack of a

button. The occurrence of the shear fracture is acceptable provided that there is evidence of good

metal adhesion at the weld i.e. the fracture face is crystalline and there is metal distortion in the

parent metal around the weld.

The shear fracture face diameter (also indexed as dp) is the average diameter of the fractured

surface without the adhesion zone (also called “ring zone” as shown in Figure 2.2, Section b)).

2.4 Nugget

The nugget is the fused metal forming the weld. It is visible in a section cut only.

Figure 2.4: Weld Nugget

Frame 3 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

2.5 Weld Penetration p

The weld penetration p is the depth of the nugget in any one sheet, strip or plate compared with

the thickness of that sheet, strip or plate. Figure 2.5 shows the scheme of a nugget in a section cut

exemplary for a 2-gauge combination.

Nugget

p1

t1

t2

p2

-

Ring Zone

dL

Figure 2.5: Weld Penetration And Nugget Diameter

The acceptance criteria for the weld penetration p are as follows:

p1 p

• 2 - Sheet Combinations: 0.4 ≤ ≤ 0.8 and 0.4 ≤ 2 ≤ 0.8

t1 t2

p1 p p

• 3 - Sheet Combinations: 0.3 ≤ ≤ 0.8 and 0.3 ≤ 2 ≤ 0.8 and 0.3 ≤ 3 ≤ 0.8

t1 t2 t3

2.6 Nugget Diameter dL

The nugget diameter dL in a section cut as shown in Figure 2.5 shall comply with the following

requirements:

Thickness Of Minimum

Thinner Sheet NUGGET DIAMETER dL

as shown in Figure 2.5

[mm] [mm]

0.5 - 0.79 3.1

0.8 - 0,99 3.5

1.0 - 1.24 3.9

1.25 -1.59 4.4

1.60 - 1.99 4.9

2.0 - 2.49 5.5

2.5 - 3.14 6.2

3.15 - 3.54 7.0

3.55 - 3.99 7.4

4.0 - 4.49 7.8

4.5 - 4.99 8.3

5.0 - 5.59 8.7

5.6 - 6.0 9.2

Table 2.6: Minimum Nugget Diameter dL

2.7 Sheet Metal Thickness

Sheet metal thickness as referred to in Table 6.2.

Frame 4 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

2.8. “Weld Joint”

A “Weld Joint” (weld-line) is defined as all of the welds that weld a specific set of parts

which creates a structural unit for providing the specified body strength.

(Ref: http://www.be.ford.com/avt213/procs/03063/weld_strategy.htm)

3. WELD HARDNESS

3.1 Category A- and B- Steels

The material used and the welding techniques employed shall be such that the hardness of the

weld shall not exceed HV 400.

3.2 Category C- Steels

The material used and the welding techniques employed shall be such that the hardness of the

weld shall not exceed HV 460.

4. DISTANCE BETWEEN WELDS

The pitch of the welds shall be considered to be the distance between centres of adjacent spot

welds. For spot welds set with automatic welding machines the general tolerance on the pitch is

+ 10% (unless otherwise specified). The general tolerance on pitch for manual spot welds is

- 40% and the excess number of spot welds allowable, related to this tolerance, is 20 %.

The minimum distance of spot welds is defined in the manufacturing standard U-WX 012.

5. DISTANCE FROM EDGES & FLANGES

The centers of the spot welds shall be in the middle of the flange.

The tolerance will be such that the edge of the weld shall be at least 1/2 dp away from the edge or

the flange radius (dp = button or fracture face diameter as specified in Table 6.2 below). The

minimum flange overlap is defined in the manufacturing standard U-WX 012.

dp

min

dp / 2

Figure 5: Distance From Edges & Flanges

Frame 5 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

6. WELD PROPERTIES & QUALITY

6.1 Button Size

The weld size as specified on the drawing, in the CAD Data file, or in Table 6.2 of this

specification, shall refer to the button or fracture face diameters dp which are revealed as a result

of the chisel test described in Section 7.4. The acceptance criteria for this test are shown in Table

6.2 as it lists the minimum button or fracture face diameter dp relative to the thickness of the

thinner sheet of the combination.

6.2 Shear Strength

Static tensile testing shall be performed in accordance with DIN EN ISO 14273 to determine spot

weld shear strength.

6.2.1 Category A- and B-Steels & Their Combinations

Category A- and B-steels and their combinations have been analyzed in generic tensile testing

with regards to shear strength. The welds shall have the guaranteed minimum shear strength

values given in Table 6.2 below. This table applies to uncoated and zinc-coated material only.

Thickness of Minimum Minimum Shear

Thinner Sheet BUTTON or FRACTURE Strength

FACE DIAMETER dp

as defined in

Sections 2.2 and 2.3

[mm] [mm] [kN]

0.5 - 0.79 3.6 2.5

0.8 - 0,99 4.0 3.2

1.0 - 1.24 4.5 4.0

1.25 -1.59 5.0 5.0

1.60 – 1.99 5.6 6.3

2.0 - 2.49 6.3 8.0

2.5 - 3.14 7.1 11.2

3.15 – 3.54 8.0 16.0

3.55 – 3.99 8.5 19.0

4.0 - 4.49 9.0 22.4

4.5 - 4.99 9.5 26.5

5.0 - 5.59 10.0 31.5

5.6 – 6.0 10.6 35.5

Table 6.2: Minimum Button Or Fracture Face Diameter dp And Shear Strength For

Category And B Steels And Their Combinations (dp˜ 1.15*dL)

6.2.2 Combinations Involving Category C- Steels

Combinations involving Category C-steels shall comply with the minimum button or fracture

diameter requirements as outlined in Table 6.2 above.

6.3 Weld Defects

6.3.1 All Combinations Of Steel Categories With The Exception Of B-C, C-C

The fracture surface of the button or fracture faces shall be metallic bright and free from

evidence of hot cracking. A weld shall be classed as defective if it shows any evidence of burn

through or porosity. No cracks are allowed in any part of the weld.

Frame 6 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

6.3.2 Combinations Of Steel Categories B-C And C-C

The fracture surface of the button or fracture faces shall be metallic bright and free from

evidence of hot cracking. A weld shall be classified as defective if it shows any evidence of burn

through or porosity.

Acceptance Criteria For Weld Defects

Minor cracks and inclusions may occur in combinations of High Strength Low Alloy Steels

(Category B) with Dual Phase Steels (Category C). Joints made of Dual Phase Steel

combinations (Category C-C) are also likely to a show minor occurrence of cracks and

inclusions. These weld defects are only detectable in micro-section cuts that shall be

performed as part of the pre-production welding trials.

During these trials, the acceptance criteria for the weld defect occurrence shall be as follows:

• Cracks

The overall length of one or several cracks shall not exceed 15 % of the nugget diameter

dL in a micro-section cut.

• Inclusions

The overall length of one or several inclusions shall not exceed 15 % of the nugget

diameter dL in a micro-section cut.

• Combined Effect Of Cracks & Inclusions

The overall length of cracks and inclusions shall not exceed 15 % of the button diameter

dL in a micro-section cut.

7. PRODUCTION VALIDATION & IN-PROCESS TEST REQUIREMENTS

7.1 Definition Of Production Validation (PV) & In-Process (IP) Tests

Production Validation (PV) tests are used to obtain an initial estimate of the process potential to

produce parts that conform to engineering requirements, and to identify causal or predictive

relationships between significant design and process characteristics (to be used for process

control).

The tests must be completed successfully using initial parts from production tooling and

production process before Part Submission Warrant (PSW) approval and authorization of

production parts can be issued. Sampling plans for PV testing must be included in the control

plan.

In-Process (IP) tests are used to further understand the relationship between significant design

and process characteristics and to establish a basis for continuing improvement.

Tests must be completed with production parts on an ongoing basis. Sampling plans for both IP

testing and evaluation of the significant process characteristics must be included in the Control

Plan.

When the process is found to be out of control or the test acceptance criteria are not met, the

reaction plan approved in the Control Plan shall be invoked.

Note:

The table that follows summarizes the various PV- and IP-tests and specifies their respective

applicability. Some tests are specified as mandatory tests (e.g. Visual Inspection).

Recommendations are issued in the case that multiple test choices exist (e.g. in the field of In-

Process Control). The ultimate test method shall then be selected on the basis of an individual

risk and test method capability assessment during PV-phase.

Frame 7 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

Summary Of Production Validation (PV) & In-Process (IP) Tests

Test Test PV, IP Applicability / Limitations

No.

7.2 Visual Inspection PV, IP Mandatory inspection for PV & IP-testing;

Visual inspection must be complemented by

one of the following tests: 7.4 (Destructive

Chisel Test), 7.5 (Non-Destructive Chisel Test)

or 7.6 (Ultrasonic Inspection)

7.3 Macro-/Micro- PV Shall be conducted during PV-testing as a

Section Cuts method for concern root cause analysis

7.4 Destructive Chisel PV, IP Shall be conducted during PV-testing to

Test determine compliance with the min. button/

fracture face diameter requirements as listed in

Table 6.2;

IP-testing: Alternative test procedure in case

that neither 7.5 (Non-Destructive Chisel Test)

nor 7.6 (Ultrasonic Testing) can be applied (risk

& capability assessment)

7.5 Non-Destructive IP It is applicable for IP-testing only. Note: this

Chisel Test test procedure – in contrast to 7.4 (Destructive

Chisel Test) - is not suitable to verify

compliance with the min. nugget /fracture face

diameter requirements.

Limitations:

It applies to steel sheet having a gauge = 1.5

mm and/or Category A & B steels with a yield

strength less than 260 MPa only - with the

following exceptions:

• sheet steel with a hot dip galvanized

coating,

• joints with functional flanges (e.g. door

opening flange carrying the sealing)

• weld-bonded joints

• joints on Class 1surfaces

7.6 Ultrasonic PV Shall be performed during PV-testing alongside

Inspection 7.3 (Macro-/Micro- Section Cuts) and 7.4

Capability & (Destructive Chisel Test) in the case that

Correlation Tests ultrasonic testing is considered to be the suitable

test method for IP-testing

Ultrasonic IP Recommended test procedure for IP-testing

Inspection

Table 7.1: Summary Of Production Validation (PV) & In-Process (IP) Tests

7.2 Visual Inspection

Visual inspection is performed to detect obvious defects such as surface cracks, surface pores,

increased indentation, burn damage and spatter.

7.3 Macroscopic Inspection, Micro-Section Cut

A macroscopic examination at a magnification of 10 - 20 times at the weld surface, or a

microscopic examination on a section through the welds (polished specimen) should be conducted

in cases of doubt.

Frame 8 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

7.4 Destructive Chisel Test

In this test, a tapered drift pin (or equivalent) is used to apply a peeling action between spotwelds

without cutting of the sheet metal or weld nugget at the interface.

7.5 Non-Destructive Chisel Test

In this test, a pry bar should be located near or between the spot welds. The pry bar shall be

driven without cutting sheet metal or weld until the metal adjacent to the weld is distorted. Welds

that hold will be classified as satisfactory welds. Welds that unintentionally pull buttons or

fracture face diameters equal to or larger than the minimum size defined in Table 6.2 shall also be

classified as satisfactory welds. Welds that fail without producing significant distortion of the

surrounding metal shall be classified as defective welds.

7.6 Ultrasonic Testing, Inspection Capability & Correlation Tests

Ultrasonic testing is the recommended test method in the case of Category A- and B- steels

having a gauge > 1.5 mm, Category C-steels and steel sheets with a hot dip galvanized coating.

Ultrasonic inspection capability and correlation shall be determined for individual joints during

production validation testing in conjunction with 7.3 and 7.4.

8. WELD EFFECTIVENESS AND TOLERANCE

8.1 Control Welds

Control welds are individual spot welds or groups of spot welds that are significantly important

for the structural integrity of the vehicle. As such they must be processed for optimum weld

integrity and maximum effectiveness (see Section 8.3.2).

Control welds shall be identified jointly between Body Engineering (Core & Vehicle Program)

and the Attribute Teams (Crash, Durability and - if applicable – NVH) on the basis of the

relevant Design-FMEAs, CAE-analysis and physical verification testing.

Control welds are identified by the word ’Control’ attached to specific spot welds in the

Metaphase data file. More information relative to the identification of control welds in I-DEAs

can be obtained from Section 5.3.6 of the following Ford Intranet web-link:

(Ref: http://www.cadmethods.ford.com/cad_methods/welding/weld_namnum_eu.html,.

8.2 Satisfactory Welds

Those welds tested and found to be satisfactory to the requirements of this specification.

8.3 Tolerance:

8.3.1 General Tolerance

The general tolerance for all Common Welds on the whole body shall be a minimum acceptance

of 80 % “Satisfactory Welds”. The same tolerance applies to any weld joint on a vehicle (see

Section 2.8 for the definition of a weld joint). Specific requirements apply to groups of 1 to 9 spot

welds as outlined in Table 8.3 below.

Frame 9 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

8.3.2 Tolerance For Control Welds

Tolerance for Control Welds shall be a minimum of 90 % “Satisfactory Welds”. Specific

requirements apply to groups of 1 to 9 spot welds as outlined in Table 8.3 below.

Common Welds Control Welds

Number Of Common / Missing Undersized Missing Undersized

Control Spot Welds In A Welds Welds )*1 Welds Welds )*1

Weld Joint

1 - - - -

2 - 1 - -

3 - 1 - -

4 1 - - 1

5 1 - - 1

6 1 - - 1

7 1 1 1 -

8 2 - 1 1

9 2 - 1 1

)*1

The diameter of an undersized spot weld button must be minimum 50 % of the button or

fracture face diameter specified as “dp” in Table 6.2.

Table 8.3: Number Of Common / Control Welds In A Weld Joint

8.4 Defective Welds

Those welds which fail to meet any one or more of the requirements of this specification are

classified as defective welds (see Table 8.3). Missing welds are also classified as defective welds.

Defective welds will have to be corrected in accordance with appendix A under consideration of

tolerances mentioned in Section 8.3.

8.5 Crucial Welds

The following welds are classified as Crucial Welds:

• Welds that are adjacent.

• Welds that are separated by only one satisfactory spot weld.

• Welds that are common to two lines of welds at their intersection.

• Welds at the extremities of a line of welds (first and last spot of a joint).

Crucial Welds need to be reworked in any case - irrespective of the class and tolerance. Rework

shall be performed according to the components specific repair standard or – if no specific repair

standard exists – according to appendix A of this Engineering Specification.

9. WELD FINISH

The surface appearances after spot welding are classified into the following categories

The class of finish and the actual surface of the component will be identified on the drawing, or in

the CAD Data file, and applies to the visible side if not otherwise specified. On surfaces where no

class of finish is specified, class 3 finish applies.

9.1 Class 1-Finish

This weld finish classification covers sheet metal surfaces that must be free from surface markings

or imperfections after metal finishing to the extent that they are not apparent after painting and

within the limits as described below. Class 1 welds for subsequent metal finish to a class 1 metal

surface should be held to the least possible marking on the surface to be metal finished. Weld

marking must not exceed a depth such as can be removed by metal finishing.

Frame 10 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

Metal finishing shall not remove more than 10 % of the surface thickness, or marking on excess

of 10 % of surface sheet thickness must be filled prior to metal finishing. No surface expulsion of

metal will be acceptable:

Welds on hemmed flanges or doors - decks - hood - glove box doors - tailgates which are

specified Class 1 will be governed by the following exceptions:

Satisfactory welds will have a minimum slug diameter of 2.5 mm. Slug will be pulled from either

the inner panel or turned over flange. Fusion between inner panel and surface sheet is not

required.

9.2 Class 2-Finish

This weld finish classification covers a minimal marked welded surface and shall be used where a

minimum amount of metal displacement is acceptable (a max. 10 % above and a max 15 % below

normal surface). Surface expulsion (weld whiskers) will not be acceptable. .

Outside surface sheet metal assemblies in which Class 2 welds are required, will be governed by

approved “specific” visual samples. “Outside Surface Sheet Metals” are defined as those surfaces

that are visible from the outside of the vehicle in its normal running condition.

9.3 Class 3-Finish

9.3.1 Category A- and B-Steels & Their Combinations

The surface indentation shall not exceed 25 % of the specified thickness of that sheet. Where

metal expulsion or displacement of the metal above the normal surface is unacceptable for safety,

appearance, fit or other reasons on a general finish class of weld, the assembly drawing, or CAD

Data shall specify “flash free” for each weld of this type. This will require that any excess metal

so formed above the surface is removed.

9.3.2 Combinations Involving Category C-Steels

Sheet metal combinations involving Category C-steels are sensitive to joint gap related effects of

indentation, specifically in combinations with Category A- and B-steels. The acceptance criteria

for the indentation in joints involving Category C-steels are as follows:

Ø Scenario A: Part Matching Stays Within Common Production Tolerances.

In this case, the same acceptance criteria as outlined in Section 9.3.1 apply.

Ø Scenario B: Part Matching Exceeds Common Production Tolerances

In this case, deviations from the acceptance criteria outlined in Section 9.3.1

can be granted on a case-by-case basis in a joint effort of Body &

Manufacturing Engineering as well as Craftsmanship. In any case, the

indentation should not exceed 40% of the thickness of the thinnest sheet.

Frame 11 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

This copy is uncontrolled –

Engineering Specification the original resides in SPEED at

http://www.speed.ford.com/

APPENDIX A:

REPAIR OF DEFECTIVE SPOT WELDS:

Spot welds which do not meet the requirements in clauses 8.1 - 8.5 must be repaired by one of the

following methods, agreed by Product Development Engineering. The preferred method will be

method “A“. Specific permission must be obtained to use other methods but agreements may be made

to cover general situations.

A. Resistance Spot Welding

Additional effective spot weld placed as near as possible halfway between the existing spot welds.

B. Plug Welding

A plug weld may be used as a repair for a single spot weld or two plug welds for two adjacent

spot welds. A plug weld involves drilling a hole in the top component which is filled by fusion

welding, preferable MIG or MAG. Only two thicknesses may be permitted to be repaired.

C. Shielded Arc Spot Welding

A single shielded arc spot weld may be used as a repair for a single spot weld, or two shielded

Arc spots may be used for two adjacent defective spot welds. Only two thickness of material may

be permitted to be repaired. The spots must be of at least equal size to those specified and can

only be used in well fitting areas and before painting, MIG or MAG welding preferred.

D. Fusion Fillet Welding

If allowed, details must be agreed with the component Engineer.

E. Gas Brazing

If allowed the details to be agreed by the Product Engineering Development.

F. Gas-Shielded Metal Arc Brazing

If allowed the details to be agreed by the Product Engineering Development.

Frame 12 of 12 Revised 9.12.2002 EBIW E 11446533 000 ES-1S71-1K251-AC

You might also like

- JDM A22 - Rev 06-1987Document8 pagesJDM A22 - Rev 06-1987Reginaldo SantosNo ratings yet

- Resistance Projection Welding Design, Calculation, Process AssuranceDocument20 pagesResistance Projection Welding Design, Calculation, Process AssuranceHemant75% (4)

- Quiz 3 Database Foundation Sesi 1 PDFDocument4 pagesQuiz 3 Database Foundation Sesi 1 PDFfajrul saparsahNo ratings yet

- Ford Spot Weld SpecDocument12 pagesFord Spot Weld SpecJonathan Davies0% (1)

- TAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDocument6 pagesTAYLOR FORGE - SIF CALCS - ES 3.9.2 r0, Design & Forming of Extruded OutletsDDNo ratings yet

- PS 1804 (S)Document19 pagesPS 1804 (S)dzilioNo ratings yet

- Iso 8501Document4 pagesIso 8501cisar0007100% (2)

- Esbm5a-B 1n261-s Aa RSWDocument37 pagesEsbm5a-B 1n261-s Aa RSWChandrajeet Shelke50% (2)

- Aviation Fuel Quality Control PDFDocument69 pagesAviation Fuel Quality Control PDFeduardoquijada100% (1)

- ASTM MNL 47 - Fuel and Fuel System - Microbiology PDFDocument123 pagesASTM MNL 47 - Fuel and Fuel System - Microbiology PDFPopescu Alin100% (1)

- Steelwork Design Chapter 2 - Steelwork Connections HKCodeDocument49 pagesSteelwork Design Chapter 2 - Steelwork Connections HKCodeMa Man KinNo ratings yet

- Duplex Beaune 2010Document10 pagesDuplex Beaune 2010aliNo ratings yet

- Engineering Manual SPD0027EPN: Pipe Thickness Decision Method Under Asme StandardDocument9 pagesEngineering Manual SPD0027EPN: Pipe Thickness Decision Method Under Asme StandardGabbar SinghNo ratings yet

- 7023exq Lecture 3 Bolted Steel ConnectionsDocument17 pages7023exq Lecture 3 Bolted Steel ConnectionsAkhil SurendranNo ratings yet

- TimberLogic Log Wall Estimator 8x8 D Log HALH 2014Document32 pagesTimberLogic Log Wall Estimator 8x8 D Log HALH 2014John BolgerNo ratings yet

- 1 C-HS-DM-003R0 Structural Analysis of Penstocks of ZungeruDocument32 pages1 C-HS-DM-003R0 Structural Analysis of Penstocks of Zungerurotimi olalekan fataiNo ratings yet

- Die Casting Die Parameter - Calculation - GuidelineDocument8 pagesDie Casting Die Parameter - Calculation - GuidelineVenkateswaran venkateswaranNo ratings yet

- Printed in GermanyDocument20 pagesPrinted in GermanyEdson CarvalhoNo ratings yet

- Bms HB 3000-b Brinell-HardheidstesterDocument20 pagesBms HB 3000-b Brinell-HardheidstesterKumara SubramanianNo ratings yet

- 8 Storey Project Report - FINAL PDFDocument110 pages8 Storey Project Report - FINAL PDFNeil Norman Simon MAnansalaNo ratings yet

- SRM-51-47-00 Fastener Pitch and Edge Distance DataDocument13 pagesSRM-51-47-00 Fastener Pitch and Edge Distance DataJelpi Duvan LariosNo ratings yet

- Presentation of Die DesignDocument33 pagesPresentation of Die DesignIsrar EqubalNo ratings yet

- Norma Jis A5525Document10 pagesNorma Jis A5525Gerardo Emmanuel Romana BrianoNo ratings yet

- Fastener Spacing and Margin DataDocument13 pagesFastener Spacing and Margin DataLONG VUNo ratings yet

- HIRAI LTCC Design GuidelineDocument19 pagesHIRAI LTCC Design GuidelineAkanksha BhutaniNo ratings yet

- 71IJMPERDDEC201871Document9 pages71IJMPERDDEC201871TJPRC PublicationsNo ratings yet

- Strength Design of Structural Masonry - 2017 10 12Document70 pagesStrength Design of Structural Masonry - 2017 10 12Ricardo Muñiz DelgadoNo ratings yet

- ETABS 18.0.2-Report ViewerDocument10 pagesETABS 18.0.2-Report ViewerFady MagdyNo ratings yet

- Metallisches Strahlmittel Gerundetes Stahldrahtkorn Bezeichnung, Güteanforderungen, PrüfungenDocument5 pagesMetallisches Strahlmittel Gerundetes Stahldrahtkorn Bezeichnung, Güteanforderungen, PrüfungenWilmer Quezada MurilloNo ratings yet

- Introduction-Design-Guide 2Document16 pagesIntroduction-Design-Guide 2Sutha100% (1)

- 4 - Column DesignDocument10 pages4 - Column Designlarry0lao0iiiNo ratings yet

- For K 0.156, Compression Steel Required.: Structures & Tall Buildings (CON4338) Data Page 1Document12 pagesFor K 0.156, Compression Steel Required.: Structures & Tall Buildings (CON4338) Data Page 1Ho JamesNo ratings yet

- CEMS A 10 Part II APPXDocument3 pagesCEMS A 10 Part II APPXaldairlopesNo ratings yet

- DIN-48200 Copper Wire SpecificationsDocument45 pagesDIN-48200 Copper Wire SpecificationsAhmed JwdhariNo ratings yet

- Sample WorkDocument135 pagesSample WorkmirceaNo ratings yet

- Is 278 Draft Galvanized Steel Barbed Wire For Fencing - SpecificationDocument7 pagesIs 278 Draft Galvanized Steel Barbed Wire For Fencing - SpecificationAdonis KumNo ratings yet

- Reinforcement Detailing HandbookDocument244 pagesReinforcement Detailing HandbookAhmed Refaey100% (4)

- SSAB - Water Mains - Pipes and Fittings - ENDocument22 pagesSSAB - Water Mains - Pipes and Fittings - ENservice techniqueNo ratings yet

- ER-5861 SSDA Slotted Web Beam-To-Column Steel Moment Frame ConnectionDocument6 pagesER-5861 SSDA Slotted Web Beam-To-Column Steel Moment Frame Connectioncancery0707No ratings yet

- III - D S Bdtw2 5 - S W - P C: ATA Heet X Ocket ELD IN Rocess OnnectionDocument3 pagesIII - D S Bdtw2 5 - S W - P C: ATA Heet X Ocket ELD IN Rocess Onnectionrob.careyNo ratings yet

- Deformation Limit and Ultimate Strength of Welded T-JointsDocument17 pagesDeformation Limit and Ultimate Strength of Welded T-JointsFelipe CoutinhoNo ratings yet

- Suction Hose Couplings For Fire Fighting Purposes - SpecificationDocument9 pagesSuction Hose Couplings For Fire Fighting Purposes - SpecificationRakesh SiempuNo ratings yet

- Guideline For Permissible Internal Misalignment & Root Gap of Piping FabricationDocument2 pagesGuideline For Permissible Internal Misalignment & Root Gap of Piping Fabricationmegastar0604No ratings yet

- ETABS 2013 Beam-Column Connection AnalysisDocument2 pagesETABS 2013 Beam-Column Connection Analysisbenjamin diazNo ratings yet

- CE 314 Design of Steel StructureDocument110 pagesCE 314 Design of Steel StructureMd. Abdullah Al ArafatNo ratings yet

- ISSUE 292 QUIZ - Fix-Tubesheet Heat Exchanger-MDMT of Tubesheet.Document4 pagesISSUE 292 QUIZ - Fix-Tubesheet Heat Exchanger-MDMT of Tubesheet.cpchonburiNo ratings yet

- AISC 360-2010 PinDocument3 pagesAISC 360-2010 PinihpeterNo ratings yet

- Aws d1.5 2020 ChangesDocument40 pagesAws d1.5 2020 ChangesA Aquino MinerosNo ratings yet

- PCI - 9.0m-14-2.0kN (TNB)Document17 pagesPCI - 9.0m-14-2.0kN (TNB)Mohd Farmi Izudin Che RosNo ratings yet

- 01ES00002 - Acabamento de Proteção Contra CorrosãoDocument2 pages01ES00002 - Acabamento de Proteção Contra CorrosãoRafah1212No ratings yet

- Molten Metal Flow Analysis of Housing Component: Bodhayana M.R., N RameshaDocument4 pagesMolten Metal Flow Analysis of Housing Component: Bodhayana M.R., N RameshaagungfebryNo ratings yet

- Chapter2 - Manual Metal Arc WeldingDocument14 pagesChapter2 - Manual Metal Arc WeldingAkhil VenugopalNo ratings yet

- Concrete Anchor BlockDocument11 pagesConcrete Anchor BlockKhaled SalemNo ratings yet

- Pedestal Nave 2Document4 pagesPedestal Nave 2Jesús AlvaNo ratings yet

- Manufacturing Wiring Harnesses Amp Cables PDFDocument8 pagesManufacturing Wiring Harnesses Amp Cables PDFarun.nagarkarNo ratings yet

- RepTec-cast IronDocument2 pagesRepTec-cast IronSDS MANINo ratings yet

- ShearWallDesign Manual2016Document82 pagesShearWallDesign Manual2016Alfia BanoNo ratings yet

- CWB FCAW Prequalified SetDocument77 pagesCWB FCAW Prequalified Setרונן לבNo ratings yet

- B31.3 - Reinf Pad CalculationDocument2 pagesB31.3 - Reinf Pad CalculationasafhoxlNo ratings yet

- Single Plate Shear Tabs - VP BuildingsDocument10 pagesSingle Plate Shear Tabs - VP BuildingsAlex ImmanuelNo ratings yet

- Flexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsFrom EverandFlexible Glass: Enabling Thin, Lightweight, and Flexible ElectronicsSean M. GarnerNo ratings yet

- Aluminum Structures: A Guide to Their Specifications and DesignFrom EverandAluminum Structures: A Guide to Their Specifications and DesignRating: 5 out of 5 stars5/5 (2)

- API 653 Tank Inspections, Maintenance, and Causes of FailureDocument43 pagesAPI 653 Tank Inspections, Maintenance, and Causes of FailureAnderson ReyesNo ratings yet

- DIN EN ISO 15614-12 Eng+2004-10 PDFDocument13 pagesDIN EN ISO 15614-12 Eng+2004-10 PDFPopescu AlinNo ratings yet

- Steel Tubes and Fittings For Onshore and Offshore PipelinesDocument48 pagesSteel Tubes and Fittings For Onshore and Offshore PipelinesPopescu Alin0% (1)

- partPG PDFDocument75 pagespartPG PDFJatin SomaiyaNo ratings yet

- GP 04-80-UXO Risk Mitigation Strategy For Projects - DevelopmDocument36 pagesGP 04-80-UXO Risk Mitigation Strategy For Projects - DevelopmPopescu AlinNo ratings yet

- GP 04-30-DRAFT 01-12-2005 - Design of Buildings Subject ToDocument26 pagesGP 04-30-DRAFT 01-12-2005 - Design of Buildings Subject ToPopescu AlinNo ratings yet

- Summary of Changes: Location ChangeDocument3 pagesSummary of Changes: Location ChangePopescu AlinNo ratings yet

- GP 04-81-UXO Risk Mitigation Strategy For Projects - ImplemenDocument40 pagesGP 04-81-UXO Risk Mitigation Strategy For Projects - ImplemenPopescu AlinNo ratings yet

- Part Peb: GeneralDocument5 pagesPart Peb: GeneralPopescu AlinNo ratings yet

- Part PVG: GeneralDocument4 pagesPart PVG: GeneralPopescu AlinNo ratings yet

- Asme1sample PDFDocument5 pagesAsme1sample PDFmatias mancillaNo ratings yet

- Asme1index PDFDocument31 pagesAsme1index PDFPopescu AlinNo ratings yet

- Part PR Requirements For Boilers Fabricated by RivetingDocument1 pagePart PR Requirements For Boilers Fabricated by Rivetingkirandevi1981No ratings yet

- Statement of PolicyDocument2 pagesStatement of Policyapi-26723112No ratings yet

- Asme V Si UnitsDocument3 pagesAsme V Si UnitsvidhisukhadiyaNo ratings yet

- Asme1preamble PDFDocument1 pageAsme1preamble PDFPopescu AlinNo ratings yet

- Asme1pft PDFDocument21 pagesAsme1pft PDFPopescu AlinNo ratings yet

- Part PWT: GeneralDocument5 pagesPart PWT: GeneralPopescu AlinNo ratings yet

- A-370 Guide To Information Appearing On Certificate of Authorization Item DescriptionDocument2 pagesA-370 Guide To Information Appearing On Certificate of Authorization Item DescriptionPopescu AlinNo ratings yet

- Asme1pb PDFDocument9 pagesAsme1pb PDFPopescu AlinNo ratings yet

- Asme 1 PMBDocument4 pagesAsme 1 PMBPopescu AlinNo ratings yet

- Appendix I - Mandatory Preparation of Technical Inquiries To TheDocument1 pageAppendix I - Mandatory Preparation of Technical Inquiries To TheJason501No ratings yet

- PersonnelDocument10 pagesPersonnelapi-26723112No ratings yet

- Asme1pfh PDFDocument1 pageAsme1pfh PDFPopescu AlinNo ratings yet

- Asme 1 CodesDocument3 pagesAsme 1 CodesmilesmiconNo ratings yet

- Unit HydrographDocument31 pagesUnit Hydrographg7711637No ratings yet

- Ieee Computer SDN Issue When Open Source Meets Network Control PlanesDocument9 pagesIeee Computer SDN Issue When Open Source Meets Network Control PlanesMysterio KnowerNo ratings yet

- Intro to Alt Bldg Construction SystemsDocument11 pagesIntro to Alt Bldg Construction SystemsPatrisha UretaNo ratings yet

- CO DMA 1042 MetrologyDocument9 pagesCO DMA 1042 MetrologyfarizanNo ratings yet

- Harsh Iit Kanpur CVDocument3 pagesHarsh Iit Kanpur CVapi-293629330No ratings yet

- Technical Guidline On Migration TestingDocument30 pagesTechnical Guidline On Migration Testingchemikas8389No ratings yet

- Water Vapor Transmission of Materials: Standard Test Methods ForDocument12 pagesWater Vapor Transmission of Materials: Standard Test Methods Formailtorubal2573No ratings yet

- Is.1795.1982 Pillar TapDocument20 pagesIs.1795.1982 Pillar Tapkishor150688No ratings yet

- TM 9-1651 Data Transmission System m3, January 1942Document78 pagesTM 9-1651 Data Transmission System m3, January 1942Advocate100% (1)

- PG 1 3 AES2.1 QuarterlyAnnualWetPipe2013 FSCDocument3 pagesPG 1 3 AES2.1 QuarterlyAnnualWetPipe2013 FSCesgarNo ratings yet

- SourceDocument13 pagesSourceEric YiuNo ratings yet

- Ground effects on pressure fluctuations in atmospheric boundary layersDocument21 pagesGround effects on pressure fluctuations in atmospheric boundary layersArchie PapNo ratings yet

- Application Engineering BulletinDocument2 pagesApplication Engineering BulletinCesar G.No ratings yet

- Belanak FPSODocument6 pagesBelanak FPSOabet133No ratings yet

- Object Oriented Programming 3Document18 pagesObject Oriented Programming 3rahul rastogiNo ratings yet

- Catalogue Produits OnanDocument6 pagesCatalogue Produits OnanJohn LarsonNo ratings yet

- RISK ASSESSMENT White Paper: A Harmonious ApproachDocument8 pagesRISK ASSESSMENT White Paper: A Harmonious ApproachMaduroNo ratings yet

- Analysys Mason VNGN OSS Framework Sep2015 RMA16 RMA07Document35 pagesAnalysys Mason VNGN OSS Framework Sep2015 RMA16 RMA07Yousuf_Alqeisi100% (1)

- 18a.security GSM & CDMADocument18 pages18a.security GSM & CDMAwcdma123No ratings yet

- en Actionair Installation Method Smokeshield Kit Web VersionDocument7 pagesen Actionair Installation Method Smokeshield Kit Web VersioniishdpsNo ratings yet

- Gk-Federnshop Data Sheet Compression Springs D-207j-72Document1 pageGk-Federnshop Data Sheet Compression Springs D-207j-72ShaikNo ratings yet

- 20-1-16 LS Dyna - SHPB Analysis FinalDocument7 pages20-1-16 LS Dyna - SHPB Analysis FinalJayDeep KhajureNo ratings yet

- Appendix A8 - Design Competition Brief and SJB Design Jury ReportDocument69 pagesAppendix A8 - Design Competition Brief and SJB Design Jury ReportMahesh GopalakrishnanNo ratings yet

- Aerodynamic Coefficients of The Aircraft, Thrust Model and Geometric and Inertial PropertiesDocument6 pagesAerodynamic Coefficients of The Aircraft, Thrust Model and Geometric and Inertial Propertiesrudey18No ratings yet

- Medium and Long-Term Strategic Skills List (MLTSSL) : So Who Is Bravo Migration?Document1 pageMedium and Long-Term Strategic Skills List (MLTSSL) : So Who Is Bravo Migration?OsniSoiNo ratings yet

- Logic GateDocument3 pagesLogic Gateglobalwarming106No ratings yet

- Replace fan kit for hp Model 211A Square Wave GeneratorDocument1 pageReplace fan kit for hp Model 211A Square Wave GeneratorxibmNo ratings yet

- 2.1.4.6 Packet Tracer - Navigating The IOSDocument5 pages2.1.4.6 Packet Tracer - Navigating The IOSЯрослав Алексеев67% (3)

- Fuji FVR E9 ManualDocument91 pagesFuji FVR E9 Manualsdk00No ratings yet