Professional Documents

Culture Documents

Selection Factors for Construction Equipment

Uploaded by

sachin100%(1)100% found this document useful (1 vote)

40 views23 pagesOriginal Title

4. Selection of construction plant and equipment

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

40 views23 pagesSelection Factors for Construction Equipment

Uploaded by

sachinCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 23

Unit 4

Selection of Construction Plant and Equipment

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Introduction

• Proper selection of equipment for a construction project is of vital

importance for its speedy and economical completion.

• Selection of Construction Plant basically involves planning the equipment,

careful selection considerations and the basis for selection.

• Problem of equipment selection has become more complicated because

large variety of equipment are being manufactured now a days.

• Records kept for operation, maintenance and actual output obtained

under comparable conditions of previous projects helps in taking decision

for equipment selection.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Introduction

• There are two principal aspects of equipment selection:

1. Technical aspects governed by the performance, and

2. Economical aspects and commercial aspects mainly concerns the

contractor or the equipment hire organizations from a business

sense.

• Selection carried out purely from a technical point of view is not enough, it

is necessary to test the viability of the selected equipment from a

economic or business point of view.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Planning for equipment selection

• Planning involves working out to get the answer to the following

questions

i. What for is the equipment needed ?

ii. When is the equipment needed and for how long? (the duration of

equipment use)

iii. How big equipment is needed? (the capacity assessment )

iv. Which one is preferred based upon the history of performance of

the equipment ?

• Planning can be described as a function aimed at selection from

alternative course of action which will direct an organization’s human and

material resources for future time spans.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Planning for equipment selection

• While executing projects with mechanized construction, planning plays an

important role and has a big impact on the ultimate cost of the project.

• A construction plan shall ensure and preserve the balance between the

four objectives of the project: time, cost, quality and safety.

• At the planning stage it is necessary to take concrete decisions on the

method of achieving the ultimate target by utilizing resources (Men,

Machinery, Material & Money) in the best possible way.

• This may be done in the pre tender stage by the contractors by studying

the contract documents, plans and the local conditions.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Planning for equipment selection

• Depending on the type of the project, following survey may be required

before equipment selection:

i. Geological conditions

ii. Weather conditions

iii. Site conditions

iv. Transport facilities

v. Availability of fuel

vi. Availability of labour

vii. Availability of services (electricity, water)

viii. Pollution standards

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Planning for equipment selection

• Once the basic concept is formed, it is necessary to take a decision of the

equipment that could be used.

• During the stage it may be necessary to compare alternative methods and

types of equipment which could be economically used.

• It is necessary to be knowledgeable in the following to prepare a basic plan

a. Types of equipment manufactured in the world and available locally or

in the region

b. Selection criteria of equipment

c. Costs of equipment

d. Safety standards of equipment

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Planning for equipment selection

• It is the project manager who takes the overall responsibility for planning

while the equipment manager takes responsibility for the maintenance of

the equipment and its operation.

• At the end of the planning process, detailed documentation consisting of

who will operate, who will maintain, the storage, the equipment record,

use on similar projects (Multi project usage plan) etc. shall be prepared.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Careful selection consideration

• The following have to be carefully considered before selecting any

equipment:

1. Specially designed

2. Performance in fixed

3. The varying need

4. Combination may be needed

5. Match finding

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection

Some of the factors that need to be considered while selecting construction

equipment are as follows:

1. Identification of task

• Any construction project is a summation of construction tasks.

• Project size is determined by the quantity of work involved in each task.

• It is very necessary to identify the task clearly in the Bill of Quantities

(BoQ) and also it is necessary for the contractor to have a clear

understanding of the tasks when submitting a bid.

• For filling an earth embankment, the following are the main construction

tasks:

a) Clear the area to be filled

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

b) Clear the borrow area

c) Cutting the earth from borrow area

d) Transport the earth to fill site

e) Spread the earth on layers

f) Compact the earth

2. Quantity of Material

• The quantity of material guides the size and the capacity of the equipment

that should be selected to carryout the task.

3. Unit weight and size

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

4. Changeable Characteristics

• Earth when disturbed expands as the air enters and fills the voids.

• Same thing happens when the earth is used as a fill material.

• This swelling of earth when loosened increases volume thereby affecting

the type and size of handling equipment. This has to be taken in

consideration while selecting the equipment.

5. Haul Distance

• Haul distance is an important factor to be considered.

• Guidance is given by the manufactures in selecting equipment depending

on the haul distance.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

6. Trafficability

• Trafficability indicates the ability of the selected equipment to move in a

terrain.

• When considering the trafficability it is necessary to consider the

following:

i. ability of the equipment /vehicle to travel.

ii. ability of the equipment/vehicle to travel once or twice.

iii. ability of the equipment/vehicle to travel many times.

• As the vehicles and equipment engaged in construction work in a cyclic

manner it is necessary that equipment can travel many times at the site.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

7. Manoeuvrability

• Manoeuvrability is the ability of the equipment to work within the site

without difficulty.

• This factor should be considered especially when equipment has to be

utilized in congested sites or at sites with limited access.

8. Output of the equipment

• Output of equipment is the quantity of work (linear, area, volume) the

equipment could accomplish during a specified time period.

• Normally the output is calculated per hour, per shift, or per day.

• In the construction industry, output is the key factor which decides the

ultimate cost of the accomplishment of the construction task.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

• Output of equipment has to be calculated before calculating the unit cost.

• A piece of equipment will not be able to accomplish total volume of work

in the particular construction task in one go. Therefore equipment has to

be used in a cyclic manner when accomplishing construction tasks.

• The output of construction equipment can be calculated using the

following relation:

Q=qxNxE

Q = output per time unit (hour, shift, day): (cu.m. per hour)

q = output per cycle (cu.m. per cycle)

N= Number of cycles per time unit (hour, shift, day)

E= Efficiency factor

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

There are factors which will effect output of construction equipment. They

are:

i. Type of Material

• Output per cycle depends on the capacity of the equipment to accomplish

a task.

• In a wheeled loader it will be equal to the bucket capacity. Loading of

bucket to occupy the maximum volume will depend on the type of

material being loaded into the bucket.

• Therefore depending on the type of material the theoretical volume has

to be calculated.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

ii. Resistance to movement

• When travelling on the flat ground, the equipment has to overcome the

rolling resistance which depends upon coefficient of friction of the road

surface

• When travelling on inclined ground (or grade) it has to overcome the

grade resistance in addition to the rolling resistance.

• Rolling resistance depends on the ground on which the equipment

travels. The grade resistance depends on the inclination of the road

section the machine has to travel.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

iii. Cycle time

• The construction equipment works in a cyclic manner.

• The number of cycles the equipment can accomplish is related to the time

it takes the equipment to complete one cycle. This is known as cycle time

(CT)

• Cycle time consists of following:

1. Loading time (LT)

2. Hauling time, mixing time (HT)

3. Unloading time (UL)

4. Return time (RT)

5. Spot time, delay time etc. (ST)

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

Therefore,

CT= LT+ HT+UL+RT+ST

• Number of cycles (N) per unit time (T) is equal to:

N = T/CT

• The time taken for hauling and return for the mobile equipment depends

on the maximum speeds they could achieve.

iv. Efficiency factor

• The peak output can be achieved if the machine is operated during the

full hour without any stoppages.

• But in practical situation, it is necessary to allow for the human factor.

Normally it is around 50 minutes in a 60 minute hour.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Main basis of selection (contd..)

• The human efficiency will be 50/60 or 0.83.

• In addition to that factor there is a job management factor which will

depend on topography.

• Efficiency factor on various working conditions are:

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Example

Q. A wheel loader with effective bucket capacity of 1.8 cu.m has cycle time 15

seconds while working on a heap of loose earth. Calculate the output of this

machine if it is working in good job site condition and good management

condition. Attached efficiency chart may be used

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Example

Solution:

Here,

Output per cycle (cum per cycle) [q] = 1.8 cum

Cycle Time [CT] = 15 sec.

From the chart,

Efficiency factor [E] = 0.75

Now,

Number of cycles per hour [N]= 3600/15 = 240 cycles/hr.

Therefore, output per unit hour will be,

Q = q x N x E = 1.8 x 240 x 0.75 = 324 cum / hr.

ECM 524 Management of Construction Plant and Equipment Shacheendra K Labh

Thank you!

You might also like

- Lippmann Jawmanual 07 03 08 Locked PDFDocument77 pagesLippmann Jawmanual 07 03 08 Locked PDFMarco Antonio Salcedo100% (7)

- Shopping Mall ImplementationDocument3 pagesShopping Mall ImplementationpapimorokaNo ratings yet

- Planning For Project Layout ReportDocument11 pagesPlanning For Project Layout ReportAko C Rence100% (2)

- 2.CE417-Ch2151CE156Document10 pages2.CE417-Ch2151CE156B BNo ratings yet

- Material & Equipmnt Management 30-9-23Document68 pagesMaterial & Equipmnt Management 30-9-23Sudas DuddeyNo ratings yet

- Construction Equipment Management & Equipment Planning ProcessDocument33 pagesConstruction Equipment Management & Equipment Planning Processdaanial khanNo ratings yet

- (1-4 Slides) Mechanized ConstructionDocument15 pages(1-4 Slides) Mechanized ConstructionnandhiniNo ratings yet

- Chap 1Document34 pagesChap 1MekonenNo ratings yet

- Construction Equipment (Ceng-5193) : College of Engineering Department of Construction Technology and ManagementDocument28 pagesConstruction Equipment (Ceng-5193) : College of Engineering Department of Construction Technology and ManagementMohamed aliNo ratings yet

- Ce CH 01Document29 pagesCe CH 01Bîñïåm ËñdàlåmàwNo ratings yet

- Engineering Faculty Technical Feasibility Studies BylawsDocument21 pagesEngineering Faculty Technical Feasibility Studies BylawsAhmed SalemNo ratings yet

- Pfs Technical AnalysisDocument31 pagesPfs Technical AnalysisNanz11 SerranoNo ratings yet

- Construction Engineering and Management (Chapter 1) by DR B VidivelliDocument75 pagesConstruction Engineering and Management (Chapter 1) by DR B Vidivellirajpkumar292003No ratings yet

- Equipment ManagementDocument7 pagesEquipment ManagementAnushka PatilNo ratings yet

- Plant Layout and Facility Design CourseDocument28 pagesPlant Layout and Facility Design CourseEndashaw YohannesNo ratings yet

- Final DAE 463 notesDocument163 pagesFinal DAE 463 notessafianuharunNo ratings yet

- Building Plant and EquipmentDocument20 pagesBuilding Plant and EquipmentMacdonald MashawiNo ratings yet

- PLANNING FOR HIGH-RISE CONSTRUCTIONDocument21 pagesPLANNING FOR HIGH-RISE CONSTRUCTIONAnil PatelNo ratings yet

- Technical Analysis Chapter SummaryDocument19 pagesTechnical Analysis Chapter SummaryAbu Noyeem ImranNo ratings yet

- Chapter 5 Technical AnalysisDocument19 pagesChapter 5 Technical AnalysisSagar PandeyNo ratings yet

- Selection of Construction Plant & EquipmentDocument4 pagesSelection of Construction Plant & EquipmentUshan Adhikari100% (1)

- Resources, Teams and Stages Guide Construction ProjectsDocument8 pagesResources, Teams and Stages Guide Construction ProjectsMohammad SalmanNo ratings yet

- Grow More Faculty of Engineering: Introduction To Construction EquipmentsDocument56 pagesGrow More Faculty of Engineering: Introduction To Construction EquipmentsPrajapati KrunalNo ratings yet

- October 2019process PlaningstionqueDocument8 pagesOctober 2019process Planingstionquekandasamy sivamuruganNo ratings yet

- MEE1018 Plant Location Factors and Facilities PlanningDocument38 pagesMEE1018 Plant Location Factors and Facilities PlanningShashank PhansikarNo ratings yet

- Construction Project Management: Key ConceptsDocument22 pagesConstruction Project Management: Key ConceptsmcNo ratings yet

- Dr. Najuma Abdul Razack Assistant Professor Department of Chemical Engineering NIT CalicutDocument39 pagesDr. Najuma Abdul Razack Assistant Professor Department of Chemical Engineering NIT CalicutAjeshSurejanNo ratings yet

- Construction Equipment: Amrutha K 4SN16AT006 Sem Viii Sec ADocument25 pagesConstruction Equipment: Amrutha K 4SN16AT006 Sem Viii Sec AAmrutha PavithranNo ratings yet

- Project ManagemetDocument25 pagesProject ManagemetAmrutha PavithranNo ratings yet

- Questionaire PDFDocument10 pagesQuestionaire PDFKashif KhanNo ratings yet

- chapter5 - 2Document60 pageschapter5 - 2Zewdie Tadesse GebremariamNo ratings yet

- Construction Equipment Management GuideDocument14 pagesConstruction Equipment Management GuidePrasanna KaleNo ratings yet

- Project Management FundamentalsDocument54 pagesProject Management FundamentalsHizb UllahNo ratings yet

- Chapter 5Document14 pagesChapter 5Eyuel SintayehuNo ratings yet

- MGC 110 L3 2024 Man. IntroDocument29 pagesMGC 110 L3 2024 Man. Introkeletsosekome2No ratings yet

- Construction Equipments: Subodh Sharma GautamDocument16 pagesConstruction Equipments: Subodh Sharma GautamKshitizNo ratings yet

- D ProcessunitDocument21 pagesD Processunitaggarwal343No ratings yet

- Technical and Production AspectDocument26 pagesTechnical and Production AspectRuthchell CiriacoNo ratings yet

- Topic 4 - Builder Plants & Machinery - BSR552Document21 pagesTopic 4 - Builder Plants & Machinery - BSR552NURULFARHANA DAUDNo ratings yet

- 03 Construction Project LifecycleDocument18 pages03 Construction Project LifecycleAtiqah Nadiah Mohamad HanafiahNo ratings yet

- Lesson 6 - Construction Equipment, Maintenance and OperationDocument43 pagesLesson 6 - Construction Equipment, Maintenance and OperationJubillee MagsinoNo ratings yet

- Technical AnalysisDocument6 pagesTechnical AnalysisMayank TrivediNo ratings yet

- L05 FactorsDocument6 pagesL05 FactorsMrwan ThabetNo ratings yet

- ppt-1Document18 pagesppt-1Amar Adri Amar AdriNo ratings yet

- Contract Management-I PresentationDocument74 pagesContract Management-I PresentationDevesh KumarNo ratings yet

- Construction Equipments and EIADocument171 pagesConstruction Equipments and EIAivyNo ratings yet

- Construction Engineering ModuleDocument194 pagesConstruction Engineering ModuleSaud Affan100% (3)

- CN4103 _construction eeuipments and managementDocument166 pagesCN4103 _construction eeuipments and managementKIRUTHIKA PALANISAMYNo ratings yet

- Unit V OmDocument18 pagesUnit V Om21BAM025 RENGARAJANNo ratings yet

- Technical Appraisal: Unit 5Document16 pagesTechnical Appraisal: Unit 5DIPAKNo ratings yet

- Subject-Construction Engineering & ManagementDocument12 pagesSubject-Construction Engineering & ManagementAnil Chhotu JhaNo ratings yet

- Machine Design Process and ConsiderationsDocument34 pagesMachine Design Process and ConsiderationsChristian Breth BurgosNo ratings yet

- Case - Pitsburg Project - FINAL PPDocument15 pagesCase - Pitsburg Project - FINAL PPGurjit SNo ratings yet

- Lecture 4 and 5Document23 pagesLecture 4 and 5عبدالرحمن الحازميNo ratings yet

- 15arc 8.6 - Project and Construction Management: (Use of Construction Equipment)Document2 pages15arc 8.6 - Project and Construction Management: (Use of Construction Equipment)Malavika LaxmanNo ratings yet

- Chapter 1: Introduction To Manufacturing Facilities Design and Material HandlingDocument33 pagesChapter 1: Introduction To Manufacturing Facilities Design and Material HandlingPeter GeorgesNo ratings yet

- Construction Cost Estimate GuideDocument20 pagesConstruction Cost Estimate GuideRheymar Dela Rosa DiwaNo ratings yet

- Construction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideFrom EverandConstruction Supervision Qc + Hse Management in Practice: Quality Control, Ohs, and Environmental Performance Reference GuideRating: 5 out of 5 stars5/5 (2)

- Advertisement For General Scholarship Scheme (GSS), Silver Jubilee Scholarship Scheme (SJSS) and Ayush - (2018-19)Document1 pageAdvertisement For General Scholarship Scheme (GSS), Silver Jubilee Scholarship Scheme (SJSS) and Ayush - (2018-19)sachinNo ratings yet

- Nepal Standard Industrial ClassificationDocument83 pagesNepal Standard Industrial ClassificationsachinNo ratings yet

- DC and AC Machines: Principles, Construction and WorkingDocument36 pagesDC and AC Machines: Principles, Construction and WorkingAkula VeerrajuNo ratings yet

- FEM FundamentalsDocument35 pagesFEM Fundamentalsbibekananda87No ratings yet

- Challenges in ML&DMDocument12 pagesChallenges in ML&DMsachinNo ratings yet

- Fault Detection in Industrial Plant Using - Nearest Neighbors With Random Subspace MethodDocument6 pagesFault Detection in Industrial Plant Using - Nearest Neighbors With Random Subspace MethodsachinNo ratings yet

- Structural Design For Microaccelerometer: SciencedirectDocument12 pagesStructural Design For Microaccelerometer: SciencedirectsachinNo ratings yet

- Chapter 8 Thermal LoadsDocument2 pagesChapter 8 Thermal LoadsCarlo DizonNo ratings yet

- Vacancy PSC PDFDocument6 pagesVacancy PSC PDFtop gunNo ratings yet

- Fault Detection in Industrial Plant Using - Nearest Neighbors With Random Subspace MethodDocument6 pagesFault Detection in Industrial Plant Using - Nearest Neighbors With Random Subspace MethodsachinNo ratings yet

- Plant MaintenanceDocument23 pagesPlant MaintenancesachinNo ratings yet

- Solidworks Tutorial For BeginnerDocument104 pagesSolidworks Tutorial For BeginnerAlexJDM71% (7)

- Cost of EquipmentDocument13 pagesCost of EquipmentsachinNo ratings yet

- 17.064 Machine Learning Techniques For Automatic Sensor Fault Detection in Airborne SHM NetworksDocument7 pages17.064 Machine Learning Techniques For Automatic Sensor Fault Detection in Airborne SHM NetworkssachinNo ratings yet

- Component Fault Diagnosis Using Bayesian Network Model: Original ArticleDocument4 pagesComponent Fault Diagnosis Using Bayesian Network Model: Original ArticlesachinNo ratings yet

- Selection Factors for Construction EquipmentDocument23 pagesSelection Factors for Construction Equipmentsachin100% (1)

- Cost of EquipmentDocument13 pagesCost of EquipmentsachinNo ratings yet

- Mechanical Final Corrected 2016 PDFDocument128 pagesMechanical Final Corrected 2016 PDFiamrabiprakasNo ratings yet

- Classification of Construction EquipmentDocument11 pagesClassification of Construction Equipmentsachin100% (1)

- Tutorial 4Document3 pagesTutorial 4sachinNo ratings yet

- Beam Deflection FormulaeDocument2 pagesBeam Deflection Formulae7575757575100% (6)

- Machine Learning Fault Detection Approach for Power SystemsDocument2 pagesMachine Learning Fault Detection Approach for Power SystemssachinNo ratings yet

- Curriculum of MS ESPM 2016Document16 pagesCurriculum of MS ESPM 2016sachinNo ratings yet

- Stress Tensor Tutorial ProblemsDocument2 pagesStress Tensor Tutorial ProblemsMani BhaiNo ratings yet

- FEM Implement PDFDocument51 pagesFEM Implement PDFsachinNo ratings yet

- Performance of Pelton turbine lab reportDocument1 pagePerformance of Pelton turbine lab reportsachinNo ratings yet

- 2nd-Sem SyllabusDocument12 pages2nd-Sem SyllabusCsit secondshemNo ratings yet

- Thermo ManualDocument17 pagesThermo ManualsachinNo ratings yet

- NumMethChE84 Ch3 BVPforODE FEM PDFDocument30 pagesNumMethChE84 Ch3 BVPforODE FEM PDFsachinNo ratings yet

- Ac 20-141BDocument56 pagesAc 20-141BramchanderNo ratings yet

- D1-NOSPI-22-085: Engr. Lord Patrick S. Rodriguez Meralco - BatangasDocument1 pageD1-NOSPI-22-085: Engr. Lord Patrick S. Rodriguez Meralco - BatangasSenrick MedranoNo ratings yet

- JIT Inventory Management: EOQ, Reorder Points, and the Theory of ConstraintsDocument15 pagesJIT Inventory Management: EOQ, Reorder Points, and the Theory of ConstraintsReicelle Natividad VejeranoNo ratings yet

- Godrej Product MixDocument10 pagesGodrej Product MixAritra SilNo ratings yet

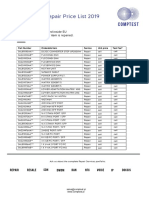

- 1678 MCC Repair Price List 2019Document1 page1678 MCC Repair Price List 2019Comptest Polska Sp z o oNo ratings yet

- Trolley Type: (CG10MPT (Manual Push) CG10CDT (Rope Driven) CG10MT (Motorized)Document3 pagesTrolley Type: (CG10MPT (Manual Push) CG10CDT (Rope Driven) CG10MT (Motorized)Francis BautistaNo ratings yet

- SCJA (Exam 310-019) Questions ExamDocument0 pagesSCJA (Exam 310-019) Questions ExamDexter SouzaNo ratings yet

- Quality Plus Company ProfileDocument36 pagesQuality Plus Company ProfileMartin Carlo Martinez0% (1)

- T-23 BOQ (Katol)Document40 pagesT-23 BOQ (Katol)rajesh kumarNo ratings yet

- Birdair Tensotherm Brochure - 2014Document4 pagesBirdair Tensotherm Brochure - 2014Angel ReyesNo ratings yet

- 1 Chapter 9 Software EvolutionDocument57 pages1 Chapter 9 Software EvolutionHoàng Đá ĐỏNo ratings yet

- Familias de RevitDocument2 pagesFamilias de RevitEdder Ñahui PeñaNo ratings yet

- Numerical, Wind Tunnel, and On Track Study of Monash 2002 Aero PackageDocument13 pagesNumerical, Wind Tunnel, and On Track Study of Monash 2002 Aero PackageZizo StarkNo ratings yet

- Transmission Line and Substation ComponentsDocument72 pagesTransmission Line and Substation ComponentsVictor CiprianNo ratings yet

- iPhoneAppProgrammingGuide PDFDocument118 pagesiPhoneAppProgrammingGuide PDFGeorgios LagiosNo ratings yet

- Pega Foundation Financial ServicesDocument29 pagesPega Foundation Financial ServicesUmangNo ratings yet

- A Good City Has Industry-ResumeDocument1 pageA Good City Has Industry-ResumeIoanaNo ratings yet

- Throttle Controls For Diesel EnginesDocument42 pagesThrottle Controls For Diesel Enginesjonatan arangoNo ratings yet

- DocAve 6 SQL Server Data ManagerDocument2 pagesDocAve 6 SQL Server Data Managerdmr1982No ratings yet

- Data Sheet for Power TransformerDocument3 pagesData Sheet for Power TransformerMuhammad Ibad AlamNo ratings yet

- Branding of Industrial ProductsDocument5 pagesBranding of Industrial ProductsvishwajeetarivastavNo ratings yet

- EASA Form Rule Proposal NPA59 - RFFSDocument14 pagesEASA Form Rule Proposal NPA59 - RFFSAnousack KittilathNo ratings yet

- 1Document9 pages1sureya smileyNo ratings yet

- BMW Situation AnalysisDocument6 pagesBMW Situation AnalysisSnigdha Patnaik0% (1)

- Process Mapping: Robert DamelioDocument74 pagesProcess Mapping: Robert Dameliojose luisNo ratings yet

- Installation Guide: For S-Link Automatic Main SwitchDocument12 pagesInstallation Guide: For S-Link Automatic Main SwitchMarcos EvansNo ratings yet

- CHAPTER 1.3 Prod PLanning SystemDocument5 pagesCHAPTER 1.3 Prod PLanning SystemSyrill CayetanoNo ratings yet

- MANUAL Euroclean-GD930Document2 pagesMANUAL Euroclean-GD930Julio HernandezNo ratings yet

- Supply Chain ManagmentDocument22 pagesSupply Chain ManagmentDesdoHexNo ratings yet