Professional Documents

Culture Documents

Review of Shop Drawings - Caltrans PDF

Uploaded by

arunkumar.mgsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Review of Shop Drawings - Caltrans PDF

Uploaded by

arunkumar.mgsCopyright:

Available Formats

Memo to Designers 12-1 • September 2012

LRFD

12-1 Review of Shop Drawings – Steel

Structures

General Information

Introduction

This memo is intended to provide guidelines for the review of Shop Drawings for steel bridges

and other major steel structures. Shop Drawings for other structures such as signs, railings,

bearings and other items are normally reviewed by field personnel and/or design specialists.

Terms and Definitions

The term “Shop Drawings” is used in this memo although “Working Drawings” has

traditionally been used at Caltrans. Shop Drawings are for use by the fabricator in order to

cut, shape, weld, punch, drill, sub-assemble, shop paint, and otherwise produce the pieces

and assemblies which are sent to the project site, and for use in the field and show where steel

components are to be placed and how they are fastened, welded and temporarily supported,

and, if necessary, in what order they are to be assembled or erected.

Purpose of Shop Drawings

Contract plans provide sufficient detail to bid and construct a project by showing material

and dimensional requirements, but fabrication details are not necessarily included. Also,

contract plan details may be generic or typical and not show all locations, some of which

may vary slightly. Additionally, alternative details may be presented on contract plans, from

which the contractor may choose their preferred method.

The contractor, therefore, produces Shop Drawings for two purposes. One is to provide

the fabrication shop with the necessary information to produce the steel components and

assemblies required to complete the project. The other is to provide a plan for use in

the field to properly place and install the fabricated members. The process of producing

Shop Drawings has the added benefit of requiring the contractor to completely familiarize

themselves with the details of a project and identify errors and omissions from the plans

before any fabrication begins, at which point the cost of correcting errors is high.

12-1 Review of Shop Drawings – Steel Structures 1

Memo to Designers 12-1 • September 2012

LRFD

The review of Shop Drawings is important to assure the project will be built in conformance

with the plans and specifications. It is obviously more desirable to identify errors on Shop

Drawings rather than during fabrication or at the project site.

As stated in the Standard Specifications, Section 5-1.23 the authorization of Shop Drawings

does not relieve the contractor of the responsibility to construct the project according to the

plans and specifications.

Format of Shop Drawings

Structural steel Shop Drawings are normally produced by a specialty sub-contractor of the

fabricator, although sometimes the fabricator or contractor will produce their own Shop

Drawings. Since there are hundreds of different companies producing Shop Drawings, format

will vary. Legibility, a logical sequence of sheets, and overall organization are necessary,

but format should not be reviewed or mandated.

Roles and Responsibilities

The responsibility for checking Shop Drawings is shared by the Designer, the Structure

Representative, and a representative from the Materials Engineering and Testing Services

(METS). A representative from the railroad company will also review Shop drawings for

railroad bridges (underpasses). METS and the Structure Representative and, if necessary,

the railroad representative, send their comments to the Designer, making the Designer the

focal point responsible for coordinating, discussing, and resolving problems. After discussion

with the other reviewers, a consensus shall be reached on exactly what comments will be

returned to the contractor. It may be acceptable for the Designer to discuss issues with the

Shop Drawings producer directly, but approval to do so should be obtained from the Structure

Representative. While all reviewers should be thorough in their review, METS generally

is more focused on welding, materials, and painting.

The general procedural requirements for handling Shop Drawings are discussed in detail

in the Standard Specifications, Section 5-1.23. A project may have specific requirements

regarding the submittal and review of Shop Drawings.

2 12-1 Review of Shop Drawings – Steel Structures

Memo to Designers 12-1 • September 2012

LRFD

Review Guidelines

General

These guidelines pertain primarily to Plate Girder bridges, but most items would also apply

to other types of steel bridges and steel bridge retrofits.

It is recommended that the reviewer read the reference material listed at the end of this memo.

These documents are available on-line and provide industry standards on the preparation

and review of structural steel Shop Drawings.

Put simply, the Shop Drawings must conform to the requirements of the Contract Plans,

the Special Provisions, and the Standard Specifications, and they must be internally

consistent. The most important step in the review process is to read and understand all the

contract documents – Contract Plans, Special Provisions, and the Standard Specifications.

The reviewer should obtain and read the project correspondence file, which may include

authorized changes to the contract. A working relationship with the Structure Representative

is important in order to be aware of any changes being contemplated to the contract or

special problems. Documentation of conversations regarding the resolution of issues should

be maintained.

An initial cursory review should be made of all submittals to determine completeness and

legibility. Incomplete or illegible submittals should be immediately returned for correction.

The cursory review should verify that each Shop Drawing in the submittal includes the

jobsite name of the structure as shown on the contract plans, bridge number, sheet title,

sheet number, revision number and date, contract number, district/county/route, and a

north arrow on Erection Drawings. Shop Drawings shall be 11 by 17 inches. Any required

supporting documents must be attached, and a transmittal letter listing all attached drawings

should accompany the submittal. Also, submittals should include both erection and shop

drawings together since the proposed erection procedure may not meet the design continuity

assumptions. In this case, the contractor must submit calculations for revised cambers and

stresses, and increased plate thickness or different types of steel may be required. A Shop

Drawing index should be provided also.

Changes from the contract plans or specifications should be discussed with the Structure

Representative and METS before authorization. Revisions may be satisfactory structurally

but create administrative problems.

12-1 Review of Shop Drawings – Steel Structures 3

Memo to Designers 12-1 • September 2012

LRFD

Changes requiring Contract Change Orders as determined by the Structure Representative

need special attention. These change orders could be grouped into two categories:

1. Those involving changes requested by the State and minor changes requested by

the fabricator where there is no question on approval of the change by both parties.

The Shop Drawings can be authorized but the note “Contract Change Order to be

Processed” added to each detail sheet involved.

2. Those involving controversial changes requested by the fabricator. These should be

returned to the fabricator with the note “Request must be made by the Contractor to

the Resident Engineer for Contract Change Order”. The fabricator may ask that the

Shop Drawings be held by design pending such negotiation. The designer should not

hold any plans without such a request.

Establishing general criterion for rejection of Shop Drawings is not practical. Rejection

should be based on the condition of unacceptable or unauthorized non-conformance to the

contract requirements, large numbers of errors, or mistakes that could lead to significant

fabrication errors. With this in mind, Shop Drawings should be authorized, or authorized with

minor corrections, whenever possible to avoid unnecessary re-submittals. If the reviewer is

in doubt, the Project Engineer or Structure Liaison Engineer should be consulted. Deviations

from the contract plans should not be automatically rejected if the structural capacity and

the design concept are maintained. Sheets should be authorized or rejected individually.

Checklist

Review items can be separated into three general categories for convenience. These are

Geometry, Materials, and Details. The following list of items should be considered as a

general guide, but it should not substitute for common sense by the reviewer.

Essential dimensions such as those listed below should be checked, but it is not usually

necessary to do a detailed check of all dimensions. Contract Plans often show only

essential dimensions, usually in the horizontal plane, whereas Shop Drawing detailers use

computational means to establish dimensions dependent on super-elevation, grade, camber,

horizontal and vertical curves, and other specific requirements. Therefore, dimensions will

not match contract plans exactly, and computing them would be difficult. Rough spot

checks of computed dimensions are encouraged. Typically, use of computer aided drafting

programs to check dimensions is unnecessary.

4 12-1 Review of Shop Drawings – Steel Structures

Memo to Designers 12-1 • September 2012

LRFD

Geometry

• Layout Control lines for horizontal and vertical alignment.

• Span Length Girder lengths and center to center dimensions between bearings

or points of support.

• Girder Spacing Transverse girder spacing.

• Elevations Elevation of seats or other supports.

• Camber The amount and method of camber should conform to the contract

plans or values computed to accommodate an authorized erection

procedure. Substantiating camber calculations shall be submitted

with the Shop Drawings.

• Stiffeners Fit, location, and spacing of intermediate stiffeners. Check for

interference with splice locations.

• Field Splices All field splice locations and labels.

• Cross Frames and Spacing and drop (transverse elevation difference) Diaphragms

dimensions and Shop Point locations and labels.

• Member Fracture Critical Members (FCMs), Main Members Designations

(Tension or Compression), Primary Components of Main Members,

and Secondary Members. See Memo to Designers 12-2.

• Temporary Locations of any temporary supports and the vertical alignment of

the Support Locations girder at each stage of erection.

• Anchor Bolt Location, size, embedment, and projection.

Layout

Materials

• Grade of Steel ASTM and/or AASHTO designation.

• Fracture Critical All pieces with Fracture Critical requirements identified.

Requirements

• Charpy V-notch All pieces with Charpy V-notch test requirements identified.

Requirements

• Fasteners Diameter, specification and grade of bolts, nuts, washers, studs,

rods, etc., and coating requirements. Rotational capacity testing

requirements. Quantities are optional.

12-1 Review of Shop Drawings – Steel Structures 5

Memo to Designers 12-1 • September 2012

LRFD

• Non-Destructive The type and extent of Non-Destructive Testing and applicable

Testing specifications listed for Fracture Critical Members.

• Cleaning and Blast cleaning, paint specifications and galvanizing

Painting requirements, including finish paint.

Requirements

Details

• Piece Marks Every element on erection drawings indicated by a unique piece

mark consistent with shop drawings.

• Plate Sizes Length, width, and thickness of all elements (flanges, webs,

stiffeners, splice plates, gussets, fill plates, etc.)

• Shape Sizes Size and weight per unit length of rolled shapes.

• Bolt Holes All hole diameters and slot dimensions shown, and drilling or

reamed in assembly noted. Vertical and horizontal spacing

and edge distance of all bolt holes.

• Formwork / Location and details of brackets, holes, stiffeners, lifting

Attachments attachments, etc. for temporary use during construction.

• Welding Details Location of all welds. Size of all fillet and partial penetration

welds. Configuration of all partial and complete penetration welds.

Fracture Critical welding identified and the authorized Welding

Procedure Specification (WPS) and Non-destructive testing (NDT)

requirements noted.

• Flange Transition Controlling dimensions of bevels and tapers.

Details

• Cover Plates Dimensions and termination details.

• Shear Studs Number and spacing. Shop or field installation.

• Flatness Flatness requirements and tolerances at bearing surfaces.

Requirements

• Rolling Direction Direction of rolling of plates where specific orientation is required.

• Erection Complete list and details of erection sequencing.

Procedure

6 12-1 Review of Shop Drawings – Steel Structures

Memo to Designers 12-1 • September 2012

LRFD

References

AASHTO/NSBA. 2002. Shop Detail Drawings Presentation Guidelines, G1.3-2002,

AASHTO/NSBA Steel Bridge Collaboration, American Association of State Highway and

Transportation Officials, Washington, DC.

AASHTO/NSBA. 2000. Shop Detail Drawings Review/Approval Guidelines, G1.1-2000,

AASHTO/NSBA Steel Bridge Collaboration, American Association of State Highway and

Transportation Officials, Washington, DC.

Original signed by Barton J. Newton

_________________________________

Barton J. Newton

State Bridge Engineer

Deputy Division Chief, Structure Policy & Innovation

Division of Engineering Services

12-1 Review of Shop Drawings – Steel Structures 7

You might also like

- MDOT Shop Drawing Review Process 718756 7Document15 pagesMDOT Shop Drawing Review Process 718756 7Đặng Xuân ViệtNo ratings yet

- Reviewing Shop DrawingsDocument2 pagesReviewing Shop DrawingsAdam JonesNo ratings yet

- Eptar Reinforcement 1 - 2 - User GuideDocument55 pagesEptar Reinforcement 1 - 2 - User GuideericfgNo ratings yet

- Role of consulting engineersDocument2 pagesRole of consulting engineersSuvarnaNo ratings yet

- QA QC by FMIDocument2 pagesQA QC by FMIfreddy.eerstaNo ratings yet

- QCS 2010 Evennes PDFDocument1 pageQCS 2010 Evennes PDFNadine BarghothiNo ratings yet

- SSPCQRCPMDocument3 pagesSSPCQRCPMsarathirv6100% (1)

- Extension of Time in Contracts: Referred ClauseDocument8 pagesExtension of Time in Contracts: Referred ClauseKumud Ranjan JhaNo ratings yet

- Subcontract For ScaffoldingDocument23 pagesSubcontract For ScaffoldingSarin100% (1)

- Construction: Price List - Regional ManagersDocument23 pagesConstruction: Price List - Regional ManagersJoshua Hobson100% (1)

- Associate Assessment Submission Document FinalDocument13 pagesAssociate Assessment Submission Document FinalAshraf MohamedNo ratings yet

- Nomination - External Timber Joinery - Banyan Grove - DMIDocument4 pagesNomination - External Timber Joinery - Banyan Grove - DMIDeepum HalloomanNo ratings yet

- Contract Administration GuideDocument105 pagesContract Administration GuideRajaratnam Tharakan100% (1)

- Extensions of Time to Oppose Trademark ApplicationsDocument44 pagesExtensions of Time to Oppose Trademark ApplicationsPaul ScottNo ratings yet

- Quality Control Procedure For Clearing and Grubbing: Document NoDocument8 pagesQuality Control Procedure For Clearing and Grubbing: Document NoAbhijeetNo ratings yet

- DM GPD P3 F10 Material Approval FormDocument1 pageDM GPD P3 F10 Material Approval FormGeorge GeorgianNo ratings yet

- Request For Inspection (Roads)Document2 pagesRequest For Inspection (Roads)umar babaNo ratings yet

- I Am Looking For Quantity Surveyor Job 1675007885Document2 pagesI Am Looking For Quantity Surveyor Job 1675007885Wiwien Tri AstutiNo ratings yet

- Rebar & BBS Checklist for FootingDocument2 pagesRebar & BBS Checklist for FootingHà VũNo ratings yet

- Method of Statement - FormworkDocument25 pagesMethod of Statement - Formworkabhinav djNo ratings yet

- Method - Statement - For RCC in Beams and SlabsDocument15 pagesMethod - Statement - For RCC in Beams and Slabsirfan khan75% (4)

- Problem Statement Regarding RC StructureDocument6 pagesProblem Statement Regarding RC StructureChockalingamNo ratings yet

- PD-04 Local Assistance Resident Engineer AcademyDocument3 pagesPD-04 Local Assistance Resident Engineer Academytyger089No ratings yet

- Standard Construction Specs for Roads and Pavement MarkingsDocument3 pagesStandard Construction Specs for Roads and Pavement MarkingsRolando de GuzmanNo ratings yet

- Pam Northern Chapter: Delay and Disruption in Construction ContractsDocument37 pagesPam Northern Chapter: Delay and Disruption in Construction ContractscfpyNo ratings yet

- Itp - EifsDocument22 pagesItp - Eifssathiyaprasath100% (1)

- ADSSC Requirements For Issuing NOC OnlineDocument2 pagesADSSC Requirements For Issuing NOC OnlineFenner ElectromechanicalNo ratings yet

- 01-21 QCS 2014Document6 pages01-21 QCS 2014Raja Ahmed Hassan100% (1)

- SpecificationsDocument44 pagesSpecificationsbecpavanNo ratings yet

- Fidic 1992 Risk ClausesDocument8 pagesFidic 1992 Risk ClausesSampath BandaraNo ratings yet

- Project CoordinatorDocument5 pagesProject Coordinatorutw276100% (2)

- Quantity Surveying Letter GuideDocument4 pagesQuantity Surveying Letter GuideZahoor Ahmed MohsanNo ratings yet

- Preventing Formwork Failures PDFDocument2 pagesPreventing Formwork Failures PDFhidayatkamalNo ratings yet

- Structural Desktop and Structural Desktop LT TutorialDocument56 pagesStructural Desktop and Structural Desktop LT TutorialDe Jesus Cerqueira MarcioNo ratings yet

- PWA IAN 048 14 Design Criteria For Drainage StructuresDocument18 pagesPWA IAN 048 14 Design Criteria For Drainage StructureswaquarshaiNo ratings yet

- DLP ContractDocument4 pagesDLP ContractnaurahimanNo ratings yet

- Housing Estate Road Construction Specification Updated May 2014Document112 pagesHousing Estate Road Construction Specification Updated May 2014Chris FindlayNo ratings yet

- Defects in ConstructionDocument2 pagesDefects in ConstructionAyon SenguptaNo ratings yet

- NATIONAL INSTITUTE OF CONSTRUCTION MANAGEMENT AND RESEARCH COURSEDocument5 pagesNATIONAL INSTITUTE OF CONSTRUCTION MANAGEMENT AND RESEARCH COURSEVinod ManiNo ratings yet

- Method Statement (Backfilling Work)Document17 pagesMethod Statement (Backfilling Work)Eng hassan hussienNo ratings yet

- 003 Work Order For Camp ConstructionDocument5 pages003 Work Order For Camp Constructionsunny333100% (1)

- Chapter 9 Design of Composite ConstructionsDocument18 pagesChapter 9 Design of Composite Constructionsapi-2661168786% (7)

- Clause 13: Variations and Adjustments: The Power To Vary and Its LimitationsDocument7 pagesClause 13: Variations and Adjustments: The Power To Vary and Its Limitationssilence_10007No ratings yet

- Action Plan For Close Out - 19122020Document5 pagesAction Plan For Close Out - 19122020jovindhaNo ratings yet

- Fire-Specifications For Fire Free Coatings-Manu Spec FF88Document6 pagesFire-Specifications For Fire Free Coatings-Manu Spec FF88smartman35No ratings yet

- NOC Approval ProcedureDocument9 pagesNOC Approval ProcedureNaseer IsmailNo ratings yet

- Request For Proposal (RFP) : ND STDocument61 pagesRequest For Proposal (RFP) : ND STkavindra singhNo ratings yet

- 5 - SpecificationsDocument69 pages5 - SpecificationsMark Angelo VarillaNo ratings yet

- Post Concrete Placement Inspection Sheet: Yes/Good No/PoorDocument2 pagesPost Concrete Placement Inspection Sheet: Yes/Good No/PoorDawit SolomonNo ratings yet

- 03 Monthly Progress Report May 2022 Rev 00Document38 pages03 Monthly Progress Report May 2022 Rev 00Raj KamatNo ratings yet

- Construction Supervising Site EngineerDocument76 pagesConstruction Supervising Site Engineernashrul_izzuanNo ratings yet

- Sika Igolflex-160 QADocument66 pagesSika Igolflex-160 QAJamsheed Ap KadangodNo ratings yet

- Div 03544 Cement Based ScreedDocument8 pagesDiv 03544 Cement Based ScreedrayNo ratings yet

- SAFCEC SACPCMP CMRegistratioDocument9 pagesSAFCEC SACPCMP CMRegistratioXabiso NdukwanaNo ratings yet

- Demolishing WorkDocument22 pagesDemolishing WorkArifian NugrohoNo ratings yet

- Clause 13: Variations and AssignmentsDocument27 pagesClause 13: Variations and AssignmentsJane PanganibanNo ratings yet

- Civil Works SpecDocument13 pagesCivil Works SpecThilini Thathsarani100% (1)

- Reviewing Steel Shop DrawingsDocument7 pagesReviewing Steel Shop DrawingsDanny NguyenNo ratings yet

- Review of Shop Drawings - Steel StructuresDocument7 pagesReview of Shop Drawings - Steel Structuresعزت عبد المنعمNo ratings yet

- 267 Shop Drawing Submittals: Topic #625-000-002 FDOT Design Manual January 1, 2021Document21 pages267 Shop Drawing Submittals: Topic #625-000-002 FDOT Design Manual January 1, 2021alostooraNo ratings yet

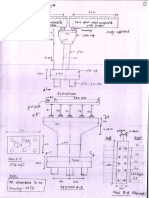

- Design of Substructure & Foundation (As Per IRC 78)Document49 pagesDesign of Substructure & Foundation (As Per IRC 78)arunkumar.mgs100% (1)

- Bending Members: RambollDocument4 pagesBending Members: Rambollarunkumar.mgsNo ratings yet

- Compression Members: Stocky ColumnDocument4 pagesCompression Members: Stocky Columnarunkumar.mgsNo ratings yet

- Bending Members: Euler-Bernoulli Beam Equation/Classical Beam Bending EquationDocument4 pagesBending Members: Euler-Bernoulli Beam Equation/Classical Beam Bending Equationarunkumar.mgsNo ratings yet

- Why Steel For Bridges?: - P 100 KN - L 40M - M Pl/4 1000 KNM - Concrete BeamDocument4 pagesWhy Steel For Bridges?: - P 100 KN - L 40M - M Pl/4 1000 KNM - Concrete Beamarunkumar.mgsNo ratings yet

- Live Load On Road Bridges (As Per IRC 6)Document35 pagesLive Load On Road Bridges (As Per IRC 6)arunkumar.mgsNo ratings yet

- Pile Group CalcDocument5 pagesPile Group Calcarunkumar.mgsNo ratings yet

- Bending Members: RambollDocument4 pagesBending Members: Rambollarunkumar.mgsNo ratings yet

- Substructure Load Calculation-Manual CalcDocument18 pagesSubstructure Load Calculation-Manual Calcarunkumar.mgsNo ratings yet

- Live Load On Road Bridges (As Per IRC 6)Document35 pagesLive Load On Road Bridges (As Per IRC 6)arunkumar.mgsNo ratings yet

- General Features of Design - Road Bridges (As Per IRC 5)Document51 pagesGeneral Features of Design - Road Bridges (As Per IRC 5)arunkumar.mgsNo ratings yet

- Loading On Road Bridges (As Per IRC 6) - Excl. LLDocument76 pagesLoading On Road Bridges (As Per IRC 6) - Excl. LLarunkumar.mgsNo ratings yet

- Load Calculation For Substructure DesignDocument39 pagesLoad Calculation For Substructure Designarunkumar.mgsNo ratings yet

- Major Axis Bending Minor Axis BendingDocument26 pagesMajor Axis Bending Minor Axis Bendingarunkumar.mgsNo ratings yet

- Beam Column CheckDocument78 pagesBeam Column Checkarunkumar.mgsNo ratings yet

- Major Axis Bending Minor Axis BendingDocument26 pagesMajor Axis Bending Minor Axis Bendingarunkumar.mgsNo ratings yet

- Loading On Road Bridges (As Per IRC 6) - Excl. LLDocument76 pagesLoading On Road Bridges (As Per IRC 6) - Excl. LLarunkumar.mgsNo ratings yet

- Tubular Truss OptimizationDocument124 pagesTubular Truss Optimizationarunkumar.mgsNo ratings yet

- General Features of Design - Road Bridges (As Per IRC 5)Document51 pagesGeneral Features of Design - Road Bridges (As Per IRC 5)arunkumar.mgsNo ratings yet

- Beam Column CheckDocument2 pagesBeam Column Checkarunkumar.mgsNo ratings yet

- Channels PropertiesDocument3 pagesChannels Propertiesarunkumar.mgsNo ratings yet

- Design of Substructure & Foundation (As Per IRC 78)Document49 pagesDesign of Substructure & Foundation (As Per IRC 78)arunkumar.mgs100% (1)

- Beam Design Formulas With Shear and MomentDocument20 pagesBeam Design Formulas With Shear and MomentMuhammad Saqib Abrar100% (8)

- 10 Pkg-III Gad R2-GaDocument1 page10 Pkg-III Gad R2-Gaarunkumar.mgsNo ratings yet

- 14 2016 December Vol 46 No 4Document80 pages14 2016 December Vol 46 No 4VasanthakumarNo ratings yet

- Thoery Behind Joint Design Formulae PDFDocument28 pagesThoery Behind Joint Design Formulae PDFarunkumar.mgsNo ratings yet

- 2006 Beam Column Joint ICJDocument9 pages2006 Beam Column Joint ICJBrian LamNo ratings yet

- Numerical Evaluation of CHS K Joints by de Silva PDFDocument8 pagesNumerical Evaluation of CHS K Joints by de Silva PDFarunkumar.mgsNo ratings yet

- Gusset Plate Connection To Round HSS Tension MembersDocument7 pagesGusset Plate Connection To Round HSS Tension MembersZhihui HuangNo ratings yet

- Joints Between Plates Ori Sections and A Circular Hollow Section Chord by WardenierDocument8 pagesJoints Between Plates Ori Sections and A Circular Hollow Section Chord by Wardenierarunkumar.mgsNo ratings yet

- Measurement of The Internal Angles of A Loop Traverse: Lab Report AboutDocument13 pagesMeasurement of The Internal Angles of A Loop Traverse: Lab Report AboutMuhammad NuraNo ratings yet

- HDD Crossing Calculation 2Document26 pagesHDD Crossing Calculation 2Denstar Ricardo Silalahi93% (29)

- Demonstration Teaching Lesson Plan in Science 9-CLIMATE-NICKDocument15 pagesDemonstration Teaching Lesson Plan in Science 9-CLIMATE-NICKMarkkenneth ColeyadoNo ratings yet

- (BookRAR - Net) - SolidWorks 2021Document1,586 pages(BookRAR - Net) - SolidWorks 2021Projetos Marimar 001100% (5)

- Applied Maths 2000-2010Document55 pagesApplied Maths 2000-2010Kenura R. GunarathnaNo ratings yet

- Planes of The BodyDocument16 pagesPlanes of The Bodyrowealyn fabreNo ratings yet

- Methodology To Calculate The Effective Reclaiming Capacity of Rail Mounted Boom Type Bucket Wheel Reclaimer and Stacker ReclaimerDocument14 pagesMethodology To Calculate The Effective Reclaiming Capacity of Rail Mounted Boom Type Bucket Wheel Reclaimer and Stacker ReclaimerMatheus SimõesNo ratings yet

- Newtonian Mechanics-2D KinematicsDocument68 pagesNewtonian Mechanics-2D KinematicsSuman K ChoudharyNo ratings yet

- Chapter 3 - Measurement of Horizontal DistancesDocument28 pagesChapter 3 - Measurement of Horizontal DistancesBahaa Abou MjahedNo ratings yet

- The Structural Design of Almas Tower DubaiDocument2 pagesThe Structural Design of Almas Tower Dubaiv pavanNo ratings yet

- Leica Theodolite 100 Series: User Manual T105/T110Document64 pagesLeica Theodolite 100 Series: User Manual T105/T110AksanNo ratings yet

- 3.3 Qualification of Welders, Welding Operators, and Tack WeldersDocument1 page3.3 Qualification of Welders, Welding Operators, and Tack WeldersIbrahim shaikNo ratings yet

- KwaZulu-Natal Physical Sciences Grade 11 Mechanics DocumentDocument68 pagesKwaZulu-Natal Physical Sciences Grade 11 Mechanics DocumentJoyce ChikwaNo ratings yet

- An Improved Method For Computing Directional Surveys, 1992, G, J. WilsonDocument6 pagesAn Improved Method For Computing Directional Surveys, 1992, G, J. WilsonfreezefreezeNo ratings yet

- BAS110 - Chapter 10 - Parametric EquationsDocument31 pagesBAS110 - Chapter 10 - Parametric EquationsAyman ElashmawyNo ratings yet

- PV 2 HP 6 X 9 PJNTDocument75 pagesPV 2 HP 6 X 9 PJNTDIEGO ARMANDO VANEGAS DUQUENo ratings yet

- Dial Indicator Alignment Basics GuideDocument24 pagesDial Indicator Alignment Basics Guidekiki270977100% (2)

- Mach - 1Document4 pagesMach - 1Bernie OrtegaNo ratings yet

- Stress Calculations in Guy WiresDocument2 pagesStress Calculations in Guy WiresMohamed MagdyNo ratings yet

- G. Measurement of Angles and DirectionsDocument3 pagesG. Measurement of Angles and DirectionsJasleneDimarananNo ratings yet

- Gen Physics 1 Module Week 2Document37 pagesGen Physics 1 Module Week 2Aaron Philip DuranNo ratings yet

- Adamas University: End Semester Examination Name of The Program: SemesterDocument5 pagesAdamas University: End Semester Examination Name of The Program: SemesterHritik DuttaNo ratings yet

- Magnetism Sub SheetDocument18 pagesMagnetism Sub SheetVipul VermaNo ratings yet

- Pressure Transient Analysis and Inflow Performance For Horizontal WellsDocument16 pagesPressure Transient Analysis and Inflow Performance For Horizontal WellsednavilodNo ratings yet

- Mast Foundation Software PDFDocument10 pagesMast Foundation Software PDFBarry LibertyNo ratings yet

- Projectile Motion - Problems and SolutionsDocument19 pagesProjectile Motion - Problems and SolutionsSanNo ratings yet

- Using A Rotating Column of Liquid On A Recycled Record Player To Measure The Acceleration of GravityDocument6 pagesUsing A Rotating Column of Liquid On A Recycled Record Player To Measure The Acceleration of GravitykostanNo ratings yet

- Handbook of Magnetic Compass AdjustmentDocument46 pagesHandbook of Magnetic Compass Adjustmentjeyanth100% (1)

- Sciography-Assignment 1Document5 pagesSciography-Assignment 1Shivee SahuNo ratings yet

- Lecture 5& 6sun Orientation PDFDocument29 pagesLecture 5& 6sun Orientation PDFSanchita JhaNo ratings yet