Professional Documents

Culture Documents

Fabrication Inspection Test Plan: Barwa Commercial Avenue Project

Uploaded by

ROriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Fabrication Inspection Test Plan: Barwa Commercial Avenue Project

Uploaded by

RCopyright:

Available Formats

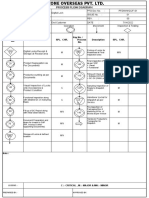

BARWA COMMERCIAL AVENUE PROJECT Ref. No.

: FITP-BCA-02

Rev. No.: 01

FABRICATION INSPECTION TEST PLAN Page No.: 2 of 2

Quality Control Type

MAIN Fabrication of Doors and Action C Document Review DR AQ ALUMCO QATAR

ACTIVITY: Windows Surveillance S Witness W MC HTCQ

Approval A Hold H C/E MAUNSELL I AECOM

Item QCS 2007 Inspection INSPECTION VERIFICATION

Main Activity Check Points Acceptance Criteria Verifying Records Responsibility

No. Section No. Frequency AQ MC C/E

→ Machining tolerance of ±1.5mm. Random Inprocess Inspection Cutting-

1.0 Sec 17, cl 3.1.3 Machining → Surfaces to be free from burrs, indentation and sampling. Doc checklist Machining Team / C S S

waviness RF-QY08002 CL-QY08001 QC Inspector

→ Distance between slots must not exceed 600 mm

and from the edge of frame should not exceed 150mm.

→ Slot size tolerance ± 1mm Drain hole size tolerance Random Inprocess Inspection Cutting-

Drain slots/holes

2.0 Sec 17, cl 3.1.3 ± 1mm. sampling. Doc checklist Machining Team / C S S

Dimension

→ Drain hole to be on the outer side. RF-QY08002 CL-QY08001 QC Inspector

Fabrication of Doors and Windows

→ Dimensions as per Approved drawings / Shuco

fabrication manual.

Inprocess Inspection Assy Team

Corner assembly and T → Hairline joint to be maintained.

3.0 Sec 17, cl 3.1.3 100% checklist Leader / QC C S S

joints → Offset of 1 mm is allowed

CL-QY08001 Inspector

→ Screws ,fasteners and rivets to be as per Schuco

system.

→ Dimensional tolerance ± 1.5mm in length. Final Inspection Assy Team

Frame and shutter

4.0 Sec 17, cl 3.1.3 → Diagonal difference < 4mm. 100% checklist Leader / QC C S S

assembly

→ All openings and gaps in the frame to be sealed by CL-QY08002 Inspector

Silicon around the full perimeter of gasket.

→ Gap between frame and shutter allowed ± 1mm

Final Inspection Assy Team

Accessories/ → As per schuco manual and approved drawings.

5.0 Sec 17, cl 3.1.3 100% checklist Leader / QC C S S

Ironmongery → Functioning to be free and proper

CL-QY08002 Inspector

FO-QY09012/Inspection Test Plan/24-Oct-09/01

BARWA COMMERCIAL AVENUE PROJECT Ref. No.: FITP-BCA-02

Rev. No.: 01

FABRICATION INSPECTION TEST PLAN Page No.: 2 of 2

Quality Control Type

MAIN Fabrication of Doors and Action C Document Review DR AQ ALUMCO QATAR

ACTIVITY: Windows Surveillance S Witness W MC HTCQ

Approval A Hold H C/E MAUNSELL I AECOM

Item QCS 2007 Inspection INSPECTION VERIFICATION

Main Activity Check Points Acceptance Criteria Verifying Records Responsibility

No. Section No. Frequency AQ MC C/E

Prepared by: Benedict Rego Date Prepared: 11-Nov-09 ITP No.: FITP_BCA-02 Rev. No.: 01

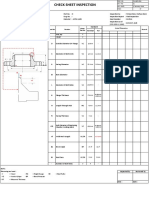

Fabrication of Doors and Windows

→ Setting blocks type as per approved

drawing/Schuco manual.

→ Setting blocks to be placed at quarter points of the

sill. Final Inspection Assy Team

6.0 Sec 17, cl 2.3.2 Dry Glazing → The distance between the outer end of the setting 100% checklist Leader / QC C S S

block should not be closer than 150mm to the corner of CL-QY08002 Inspector

the glass.

→ Width of setting block should be 3mm wider than

the glass thickness

→ When viewed at an oblique angle with normal or

Final Inspection Assy Team

corrected vision, no blisters, or scratches shall be

7.0 Sec 17, cl 3.1.3 Finish Twice in a shift checklist Leader / QC C S S

visible from a distance of 1 mtr.

CL-QY08002 Inspector

→ Color to match with approved samples

FO-QY09012/Inspection Test Plan/24-Oct-09/01

BARWA COMMERCIAL AVENUE PROJECT Ref. No.: FITP-BCA-02

Rev. No.: 01

FABRICATION INSPECTION TEST PLAN Page No.: 2 of 2

Quality Control Type

MAIN Fabrication of Doors and Action C Document Review DR AQ ALUMCO QATAR

ACTIVITY: Windows Surveillance S Witness W MC HTCQ

Approval A Hold H C/E MAUNSELL I AECOM

Item QCS 2007 Inspection INSPECTION VERIFICATION

Main Activity Check Points Acceptance Criteria Verifying Records Responsibility

No. Section No. Frequency AQ MC C/E

Prepared by: Benedict Rego Date Prepared: 11-Nov-09 ITP No.: FITP_BCA-02 Rev. No.: 01

FO-QY09012/Inspection Test Plan/24-Oct-09/01

You might also like

- QA-033 Outgoing Inspection Checklist Rev.GDocument1 pageQA-033 Outgoing Inspection Checklist Rev.GChoo Wei MingNo ratings yet

- Check 3 Điểm MatchingDocument61 pagesCheck 3 Điểm MatchingNgọc Thiện BùiNo ratings yet

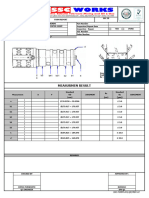

- SSC SA-156 HD 785-7 Retainer BrakeDocument4 pagesSSC SA-156 HD 785-7 Retainer BrakeEngineering ProductionNo ratings yet

- QCP & Report Rev 03Document30 pagesQCP & Report Rev 03Heri FebriyantoNo ratings yet

- ITP For Fabrication & Erection of TanksDocument20 pagesITP For Fabrication & Erection of TanksosersNo ratings yet

- Inspection and Test Plan (ITP) WeldingDocument3 pagesInspection and Test Plan (ITP) WeldingMuhammed Abo-Fandood100% (5)

- Fit-Up TC-2Document1 pageFit-Up TC-2Muhammad Fitransyah Syamsuar Putra100% (2)

- QC Check Sheet Inspection TitleDocument1 pageQC Check Sheet Inspection TitleJovianto PrisilaNo ratings yet

- ELBOW 2 S40 90D LR - OkDocument1 pageELBOW 2 S40 90D LR - OkJovianto PrisilaNo ratings yet

- QC-F29-Rewinding Form-03Document2 pagesQC-F29-Rewinding Form-03Annabella1234No ratings yet

- Routine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeDocument3 pagesRoutine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeFL Technics DFPNo ratings yet

- (Painting Works) : Inspection and Test PlanDocument2 pages(Painting Works) : Inspection and Test Planrize1159No ratings yet

- Fit - Up and Visual Examination Report: Attachment Drawing Joint DetailDocument1 pageFit - Up and Visual Examination Report: Attachment Drawing Joint DetailMuhammad Fitransyah Syamsuar Putra100% (1)

- 28 02 2024 05 RicDocument1 page28 02 2024 05 RicPrabhakaran CHNQualityNo ratings yet

- Dimensional Inspection Report: Rapport de Contrôle DimensionnelDocument3 pagesDimensional Inspection Report: Rapport de Contrôle DimensionnelZouhair BenmabroukNo ratings yet

- 18.9 ITP SUB BASE Rev01Document2 pages18.9 ITP SUB BASE Rev01YEHIA100% (1)

- Measurement of Payment (Steel Structure)Document6 pagesMeasurement of Payment (Steel Structure)Steven JosephNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Ashish Tripathi - Process Flow & Time StudyDocument5 pagesAshish Tripathi - Process Flow & Time StudymanpreetNo ratings yet

- Elbow 2 S80 90D LR - OkDocument1 pageElbow 2 S80 90D LR - OkJovianto PrisilaNo ratings yet

- Threadolet 0,5 X 3 - 4 3000Document1 pageThreadolet 0,5 X 3 - 4 3000Jovianto PrisilaNo ratings yet

- LQC STDDocument2 pagesLQC STDAstronNo ratings yet

- Cable test reportDocument1 pageCable test reportBadhur ZamanNo ratings yet

- Material Receiving Inspection Report Discipline: Quality Control FormDocument15 pagesMaterial Receiving Inspection Report Discipline: Quality Control FormSREENATH SOMANATHAN NAIRNo ratings yet

- Inspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Document4 pagesInspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Delta akathehuskyNo ratings yet

- CBH-21-079 Flange Nut M4 WZP 8Document1 pageCBH-21-079 Flange Nut M4 WZP 8qualityNo ratings yet

- S-000-1676-0001V - 11 - ITP For Piping WorkDocument47 pagesS-000-1676-0001V - 11 - ITP For Piping WorkVO DINH TRI100% (2)

- Concreting Inspection FormDocument2 pagesConcreting Inspection FormralphNo ratings yet

- Itp-Internals R2Document2 pagesItp-Internals R2Delta akathehuskyNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Elbow 4 s40 90d LR - OkDocument1 pageElbow 4 s40 90d LR - OkJovianto PrisilaNo ratings yet

- Hex Bushing 0,75 X 0,5Document1 pageHex Bushing 0,75 X 0,5Jovianto PrisilaNo ratings yet

- Inspection report for 15 pcs CAP 28Document1 pageInspection report for 15 pcs CAP 28Jovianto PrisilaNo ratings yet

- Check Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportDocument1 pageCheck Sheet Inspection: Customer Part No. Inspection by DWG No. Inspection ReportJovianto PrisilaNo ratings yet

- Elbow 3 s40 90d LR - OkDocument1 pageElbow 3 s40 90d LR - OkJovianto PrisilaNo ratings yet

- 9.WN 2 600 S80 RF - OkDocument1 page9.WN 2 600 S80 RF - OkJovianto PrisilaNo ratings yet

- FF - 01 - Vernier CaliperDocument2 pagesFF - 01 - Vernier CaliperMechtek LabNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- Elbow 2 S40 45D LRDocument1 pageElbow 2 S40 45D LRJovianto PrisilaNo ratings yet

- Request For InspectionDocument2 pagesRequest For InspectionYudhaNo ratings yet

- Inspection Report: 875-4528 Valve 1 in Nominal Brass C223C3-6-3Document1 pageInspection Report: 875-4528 Valve 1 in Nominal Brass C223C3-6-3NAGRAJNo ratings yet

- Itp STR Slpg-Q-0000-24001-032-001-4-ADocument11 pagesItp STR Slpg-Q-0000-24001-032-001-4-AsivagnanamNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- QIP of Boiler For ErectionDocument6 pagesQIP of Boiler For ErectionUmair Awan100% (2)

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- Final Inspection Check SheetDocument2 pagesFinal Inspection Check SheetJovianto PrisilaNo ratings yet

- Work Inspection Request (Wir) : LB2 GRC Corridor Fabricated Additional Column Material Inspection & Release For ErectionDocument2 pagesWork Inspection Request (Wir) : LB2 GRC Corridor Fabricated Additional Column Material Inspection & Release For ErectionRejoy Baby100% (1)

- Elbow 8 STD s40 90d LR - OkDocument1 pageElbow 8 STD s40 90d LR - OkJovianto PrisilaNo ratings yet

- QAR-QD418-5 Rod-Front Susp 797 (191-8043)Document6 pagesQAR-QD418-5 Rod-Front Susp 797 (191-8043)Irwanto ManafNo ratings yet

- Spindle Center JointDocument2 pagesSpindle Center JointIrwanto ManafNo ratings yet

- Cp5-Itp CWC RomanuDocument22 pagesCp5-Itp CWC RomanuherdiansyahNo ratings yet

- 3 - Hdpe - Itp Pipe WeldingDocument2 pages3 - Hdpe - Itp Pipe Weldingasif712100% (6)

- G69173-D1001-Y756 - Protocolo SAT CCM Tiastar - REV2Document5 pagesG69173-D1001-Y756 - Protocolo SAT CCM Tiastar - REV2Adriana UstarizNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- Inspection Release Note (General) : Verification of Completion Yes No N/A CommentsDocument2 pagesInspection Release Note (General) : Verification of Completion Yes No N/A CommentsjeswinNo ratings yet

- 000 SA E 50308 - RevBDocument94 pages000 SA E 50308 - RevBDurga Jagan Puppala100% (1)

- Check Sheet Inspection: Pt. DffiDocument2 pagesCheck Sheet Inspection: Pt. DffiJovianto PrisilaNo ratings yet

- Boq 1Document111 pagesBoq 1RNo ratings yet

- All External B.o.q-1Document282 pagesAll External B.o.q-1RNo ratings yet

- 54385753-192326 422606039Document105 pages54385753-192326 422606039RNo ratings yet

- Smart Park Ann BDocument78 pagesSmart Park Ann BAHMEDNo ratings yet

- Bill of Quantities SampleDocument80 pagesBill of Quantities Sampleharicv01967% (3)

- 2 2. BoqDocument113 pages2 2. Boqmian NaveedNo ratings yet

- 02 Aluminium Door Window ManufacturingDocument3 pages02 Aluminium Door Window ManufacturingRNo ratings yet

- Dulux Aus Powders Colour Selector 2016 PDFDocument8 pagesDulux Aus Powders Colour Selector 2016 PDFRNo ratings yet

- Civil & Finishing Work B.O.QDocument32 pagesCivil & Finishing Work B.O.QSagar SharmaNo ratings yet

- Pocket Guide: Glass, Timber or Aluminium Altair Louvre Window SystemsDocument1 pagePocket Guide: Glass, Timber or Aluminium Altair Louvre Window SystemsRNo ratings yet

- Start-Up Sample BPDocument54 pagesStart-Up Sample BPsteven100% (1)

- Real Estate Infographic December 2019Document1 pageReal Estate Infographic December 2019Azhar PatelNo ratings yet

- 213 PDFDocument88 pages213 PDFR100% (1)

- Bushfire Safety: Take A Closer LookDocument4 pagesBushfire Safety: Take A Closer LookRNo ratings yet

- Project Profile On Aluminium FabricationDocument2 pagesProject Profile On Aluminium FabricationRNo ratings yet

- Madhya Pradesh December 2019 PDFDocument46 pagesMadhya Pradesh December 2019 PDFRNo ratings yet

- 3 Part Specification Thermally Improved Aluminum Doors: Specification Begins On The Following PageDocument9 pages3 Part Specification Thermally Improved Aluminum Doors: Specification Begins On The Following PageRNo ratings yet

- Real Estate DecDocument32 pagesReal Estate DecRNo ratings yet

- 02 Aluminium Door Window ManufacturingDocument3 pages02 Aluminium Door Window ManufacturingRNo ratings yet

- Real Estate Infographic December 2019Document1 pageReal Estate Infographic December 2019Azhar PatelNo ratings yet

- Area Openingspecifications Windows 400series Casement PDFDocument2 pagesArea Openingspecifications Windows 400series Casement PDFRNo ratings yet

- Labour ConstantDocument66 pagesLabour ConstantRNo ratings yet

- Akzo Nobel Powder Coat - Prevention, Cleaning Maintenance Guide PDFDocument2 pagesAkzo Nobel Powder Coat - Prevention, Cleaning Maintenance Guide PDFRNo ratings yet

- Confidential: TSWW Glass Quality StandardsDocument2 pagesConfidential: TSWW Glass Quality StandardsRNo ratings yet

- Date Heard From To Country Name of Stationtransmitter Location FreqDocument4 pagesDate Heard From To Country Name of Stationtransmitter Location FreqEdie BlackburnNo ratings yet

- Vehicle Loan Payment Calculator1Document1 pageVehicle Loan Payment Calculator1RNo ratings yet

- What NextDocument10 pagesWhat NextbalajiNo ratings yet

- Material ConstantDocument77 pagesMaterial ConstantRNo ratings yet

- Material ConstantDocument77 pagesMaterial ConstantRNo ratings yet

- 16 - Hasna Jilan A - Xii TGB 1 - GKB Rab - SKPDocument50 pages16 - Hasna Jilan A - Xii TGB 1 - GKB Rab - SKPHASNA JILANNo ratings yet

- MK1600 Electric Concrete Floor Saw PartsDocument32 pagesMK1600 Electric Concrete Floor Saw Partsjmarrero488307No ratings yet

- Malabar 832R User ManualDocument20 pagesMalabar 832R User ManualJivendra KumarNo ratings yet

- Oil Discharge Monitoring and Control SystemDocument1 pageOil Discharge Monitoring and Control SystemcraponzelNo ratings yet

- B&V Elevadores SpiderDocument2 pagesB&V Elevadores SpiderHarzanyi MaldonadoNo ratings yet

- Turret LatheDocument82 pagesTurret LatheReyven ReconNo ratings yet

- Welder Qualification PlanDocument3 pagesWelder Qualification PlanphuyangNo ratings yet

- Juk LH-3128-7 3128Document48 pagesJuk LH-3128-7 3128RHoska100% (1)

- Piping & Instrument Diagrams PDFDocument12 pagesPiping & Instrument Diagrams PDFSuresh KumarNo ratings yet

- Welding Carbon Steel Plates in 2G PositionDocument9 pagesWelding Carbon Steel Plates in 2G PositionJerome A. Gomez67% (3)

- Mechanical Operations Chemical Engineering NotesDocument18 pagesMechanical Operations Chemical Engineering NotesJatin Sharma100% (1)

- Hh7 CatalogDocument1 pageHh7 Catalogjitender kumarNo ratings yet

- Student Log Book: Department of Mechanical Engineering MNS-University of Engineering and Technology, MultanDocument4 pagesStudent Log Book: Department of Mechanical Engineering MNS-University of Engineering and Technology, Multansubhan sibghatNo ratings yet

- PBFB en Us A4Document1 pagePBFB en Us A4operacion hydratekNo ratings yet

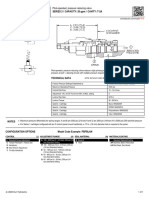

- T 1-2 - 1 - en - 2 Disc Valves LvsDocument6 pagesT 1-2 - 1 - en - 2 Disc Valves LvsIvanNo ratings yet

- Ropes and Wires Construction GuideDocument21 pagesRopes and Wires Construction GuideJames MonishNo ratings yet

- Front Derailleurs X-Gen 3.0: User ManualDocument2 pagesFront Derailleurs X-Gen 3.0: User ManualAlex JonesNo ratings yet

- Lintel and Sunshade DesignDocument17 pagesLintel and Sunshade DesignNikhilNo ratings yet

- 3DMM Cswe 007Document1 page3DMM Cswe 007mlik borhenNo ratings yet

- Coastal Voyager: Shoalbuster 3209Document2 pagesCoastal Voyager: Shoalbuster 3209leokareyxoxoersNo ratings yet

- حساب وزن الصاجDocument2 pagesحساب وزن الصاجm211080% (5)

- Fatiga de MaterialesDocument3 pagesFatiga de MaterialesG1993NCKNo ratings yet

- ITC One Colombo (Sri Lanka) : Project InformationDocument1 pageITC One Colombo (Sri Lanka) : Project InformationMohammed SajidNo ratings yet

- VB 1001 - 0708 - WebDocument6 pagesVB 1001 - 0708 - Webjmech08No ratings yet

- Engineers Guide To Shaft Alignment 1661215823Document192 pagesEngineers Guide To Shaft Alignment 1661215823Michael SanchezNo ratings yet

- The F638 SE/S2 Is An Extreme Heavy Duty Slurry Control Valve, With An Extended Body Style and Replaceable Body SleeveDocument11 pagesThe F638 SE/S2 Is An Extreme Heavy Duty Slurry Control Valve, With An Extended Body Style and Replaceable Body SleeveCapacitacion TodocatNo ratings yet

- Olp-34 & Olp-42Document1 pageOlp-34 & Olp-42sameer bakshiNo ratings yet

- Underpin NotesDocument2 pagesUnderpin Notesanele_amisNo ratings yet

- Exotic Materials Product Bulletin - 1774Document2 pagesExotic Materials Product Bulletin - 1774Govindharj RNo ratings yet

- Armstrong - Manual Sprinkler SystemDocument78 pagesArmstrong - Manual Sprinkler SystemAvinash NathNo ratings yet