Professional Documents

Culture Documents

Ashish Tripathi - Process Flow & Time Study

Uploaded by

manpreetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ashish Tripathi - Process Flow & Time Study

Uploaded by

manpreetCopyright:

Available Formats

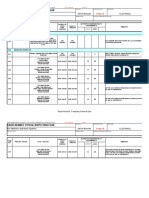

OZONE OVERSEAS PVT. LTD.

PROCESS FLOW DIAGRAM

PFD Doc No. : PFD/WH/QC/F-01

PART NAME :- Digital Lock

ISSUE No. : 01

MATERIAL :- ……………. REV. : 00

CUSTOMER :- End Customer DATE : 7/14/2022

Storage Operation Movement Inspection & Testing

SYMBOLS:

Key No. /

Key No. / Process

Description SPL. CHR. Process Description SPL. CHR.

No.

No.

Picking of Locks for

10 Digital Locks Receipt &

M 90 Readiness at Final MN

Storage at Receipt area Inspection area

Final inspection (PDI)

20 10 Product Segregation as as per SOP

M 100

> Visual

C

Per Documents

> Functional

30 Filling of Check sheet

Products counting as per 110

20 M > Detailed QCS(WH) M

Documents > QC OK (With Lock)

Visual Inspection of Locks Sampling Inspection of

40 only Accessories & C 120 Ready to Dispatch M

Product Condition Locks

Functional Inspection along Handover Locks for

with detailed QC on Sampling C 13 Dispatch as per M

Basis Invoice

0

Re-inspection of

Packaging Box &

60 Fill-up of QC Report along Matching of No. of

with initial observations.

MN 140 M

Boxes as per invoice

Handover Products to

Document Preparation and Transporter for

share for inward in SAP Dispatch

70 (RR, Invoice & other

MN M

supporting Documents)

Storage of Locks at defined

80 location

MN

Note :

LEGEND :- C :- CRITICAL , M :- MAJOR & MN :- MINOR

PREPARED BY:- APPROVED BY:

Digital Lock Handling Process (Receip

S.No. Process Description Department Transportation Inventory Motion

Digital Locks Receipt & Storage at

1 IQC 120 ---- 25

Receipt area

2 Product Segregation as Per Documents Store --- ---- 40

3 Products counting as per Documents IQC --- ---- ----

Visual Inspection of Locks only

4 IQC --- ---- ----

Accessories & Product Condition

Functional Inspection along with detailed QC

5 on Sampling Basis

Testing 5 ---- ----

Fill-up of QC Report along with initial

6 observations.

IQC --- ---- ----

Document Preparation and share for inward

7 in SAP (RR, Invoice & other supporting IQC --- ---- ----

Documents)

8 Storage of Locks at defined location Store --- 3~6 M 40

Picking of Locks for Readiness at Final

9 Inspection area

FQC --- ----

Final inspection (PDI) as per SOP

10 > Visual FQC --- ----

> Functional

Filling of Check sheet

11 > Detailed QCS(WH) FQC --- ----

> QC OK (With Lock)

Sampling Inspection of Ready to Dispatch

12 Locks

FQC --- ----

Handover Locks for Dispatch as per

13 FQC --- ----

Invoice

Re-inspection of Packaging Box & Matching

14 of No. of Boxes as per invoice Dispatch --- ----

Handover Products to Transporter for

15 Dispatch Dispatch --- ----

ocess (Receipt to Dispatch)

Waiting Over Production Over Processing Defects VA NNVA NVA

35 --- ---- ----

---- --- ---- ----

---- ---- ---- 0~2%

---- ---- ---- 0~2%

45 ---- ---- 0~1%

---- ---- ---- ----

15 ---- ---- ----

---- ---- ---- ----

---- ---- ---- 0~1%

---- ---- ---- 0~1%

---- ---- ---- 0~1%

---- ---- ---- 0~1%

---- ---- ---- ----

---- ---- ---- 0~1%

---- ---- ---- ----

Process Capacity Sheet Model No. :

Offline/ Validity/

S.No. Process Process Discription Station No.

Online Assy

Mounting BKT &

1 MIG Welding-01

Reinforcement

Offline 01 2.0

2 MIG Welding-02 Base Plate & Ribs Offline 02 2.0

3 MIG Welding-03 Wheel arch & 3 nuts Offline 03 1.0

4 MIG Welding Wheel arch & 3 nuts Offline 03A 1.0

5 MIG +Spot Welding End Floor & 7 Nuts Offline 03B 2.0

6 MIG Welding-Tag-04 X-Member & 8 Nuts Offline 04 1.0

Long Mbr,7 Nuts, 3 Plates &

7 MIG Welding-05

1 Bracket

Online 05 2.0

8 Spot Welding-06 Stn-04 & Gusset Online 06 2.0

9 MIG Welding-07 Stn-06 & Reinforcement Online 07 1.0

Assy Reinforcement & 2

10 MIG Welding

Nuts

Offline 07A 1.0

11 MIG Welding-07.5 Stn-06.5 & Reinforcement Online 07.5 1.0

Assy Reinforcement & 2

12 MIG Welding

Nuts

Offline 07.5A 1.0

13 Trueing Gauging Trueing Online 08 2.0

14 Plug Welding-09 (Stn-07 & Stn-01) LH Online 09 1.0

15 Plug Welding-09.5 (Stn-07.5 & Stn-01)RH Online 09.5 1.0

Stn-09, Wheel arch &

16 MIG Welding-Rotary-LH-10

1 Bracket-LH

Online 10 1.0

Stn-09, Wheel arch &

17 MIG Welding-Rotary-RH-10.5

1 Bracket-RH

Online 10.5 1.0

Stn-10, Stn-10.5, Child Parts

18 Final MIG + Spot Welding-11

& End Floor

Online 11 1.0

New sub assy fixture Z plate sub assy Offline 11A 1.0

Stn-11/11.5 & 2 Assy

19 Final MIG Welding-Rotary-12

Reinforcement

Online 12 1.0

20 Chipping & Grinding-Top-13 Chipping & Grinding-Top Online 13 1.0

21 Chipping & Grinding-Bottom-14 Chipping & Grinding-Bottom Online 14 1.0

Sub Structure Line

Basic Time (Sec) Cycle Time

Station

Loading Processing Unloading Additional Manual Completion Cycle Time

Cycle Time

Time Time Time Time Time Time Actual

Req

25 60 10 25 120 240 190 240

30 55 5 15 105 210 180 210

30 35 5 30 100 100

30 35 5 40 110 110 370 460

35 55 15 20 125 250

120 150 10 40 320 320 280 320

10 160 10 25 205 410 360 410

25 85 20 25 155 310 260 310

15 160 15 30 220 220

255 305

20 35 10 20 85 85

15 160 15 30 220 220

255 305

20 35 10 20 85 85

15 90 15 14 134 267 240 267

30 170 30 15 245 245 230 245

30 170 30 30 260 260 230 260

50 100 20 60 230 230 170 230

50 100 20 60 230 230 170 230

50 285 50 20 405 405 385 405

50 285 50 20 405 405 385 405

45 285 30 35 395 395 360 395

20 340 20 30 410 410 380 410

20 340 20 35 415 415 380 415

735 3190 415 4979

1150 23%

You might also like

- Itp - Refrigerant Pipe & Ac Split InstallationDocument9 pagesItp - Refrigerant Pipe & Ac Split InstallationGultom Juliana LiliesNo ratings yet

- Inspection and Test Plan (ITP) WeldingDocument3 pagesInspection and Test Plan (ITP) WeldingMuhammed Abo-Fandood100% (5)

- ITP - Conduit Metal (GI) & PVC InstallationDocument5 pagesITP - Conduit Metal (GI) & PVC InstallationGultom Juliana LiliesNo ratings yet

- Supply Chain Management Question and AnswerDocument7 pagesSupply Chain Management Question and AnswerJha OdiNo ratings yet

- Itp For Painting - FDocument5 pagesItp For Painting - FMudabbir HussainNo ratings yet

- Supplier Quality Manual TennecoDocument36 pagesSupplier Quality Manual TennecoMohit AggarwalNo ratings yet

- Integrated Business Processes With Erp Systems 1st Edition Magal Test BankDocument25 pagesIntegrated Business Processes With Erp Systems 1st Edition Magal Test BankJenniferWhitebctr98% (57)

- Applied Economic Quarter 2 Module 7 Week7Document14 pagesApplied Economic Quarter 2 Module 7 Week7Jije bere PerezNo ratings yet

- Itp Transfer Tower - Xls (Bvi Comment)Document52 pagesItp Transfer Tower - Xls (Bvi Comment)Alif Rahmat FebriantoNo ratings yet

- Iqms 1 2 PDFDocument149 pagesIqms 1 2 PDFsreelayaNo ratings yet

- Itp For Fitp For Hdpe Pipes InstallationDocument3 pagesItp For Fitp For Hdpe Pipes InstallationBleep NewsNo ratings yet

- Plant Location Company Doc. No. NADocument8 pagesPlant Location Company Doc. No. NAsivaNo ratings yet

- Inspection Test PlanDocument36 pagesInspection Test PlanShahid IqbalNo ratings yet

- Emily-1 Project Fuel Terminal and Jetty Compaction Inspection ReportDocument9 pagesEmily-1 Project Fuel Terminal and Jetty Compaction Inspection Reportmuhammad sauqiNo ratings yet

- ITP - CCTV System InstallationDocument6 pagesITP - CCTV System InstallationGultom Juliana LiliesNo ratings yet

- Presentation of GeneratorDocument18 pagesPresentation of Generatorapi-3834081100% (1)

- ITPDocument7 pagesITPSyed Mahmud Habibur Rahman83% (6)

- Channel Institutions - RetailingDocument27 pagesChannel Institutions - Retailingsumit negi100% (2)

- Inspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Document5 pagesInspection & Test Plan FOR Wrapping / Coating of External Metal Surface (C.S Fire Hydrant Spools)Daniel Martinez50% (2)

- VN01-000-40-95-AA-11017 - Rev D1: Inspection and Testing Plan For Topside StructureDocument8 pagesVN01-000-40-95-AA-11017 - Rev D1: Inspection and Testing Plan For Topside StructureHanLe DuyNo ratings yet

- ITP - Public Address InstallationDocument9 pagesITP - Public Address InstallationGultom Juliana LiliesNo ratings yet

- Inspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak RiauDocument10 pagesInspection Test Plan (Itp) at Shop: Natural Gas Transportation Development Project - Siak Riauanang_priNo ratings yet

- Itp Forabove Grade and Embedded Conduits Rev. 0Document6 pagesItp Forabove Grade and Embedded Conduits Rev. 0sartaj0% (1)

- Standard QAP - 4MWDocument2 pagesStandard QAP - 4MWSAEL SOLAR100% (2)

- OU500764928 - R0 - Quality Assurance-Manufacturing IDSDocument13 pagesOU500764928 - R0 - Quality Assurance-Manufacturing IDSbecemNo ratings yet

- Inspection & Test Plan (Itp) : Mechanical (Machine & Equipment)Document2 pagesInspection & Test Plan (Itp) : Mechanical (Machine & Equipment)ikramNo ratings yet

- ITP Check List HVAC Piping WorksDocument5 pagesITP Check List HVAC Piping WorksResearcherNo ratings yet

- ITP - Data & Telephone InstallationDocument6 pagesITP - Data & Telephone InstallationGultom Juliana LiliesNo ratings yet

- Factors Affecting Data Quality in Private Clinics in UgandaDocument93 pagesFactors Affecting Data Quality in Private Clinics in Ugandakeisha baby100% (1)

- Operational Qualification Document (OQ)Document8 pagesOperational Qualification Document (OQ)Konisbell Alcántara UreñaNo ratings yet

- Inspection and Test Plan (Itp)Document2 pagesInspection and Test Plan (Itp)Abdul Gafoor ShaikhNo ratings yet

- Inspection Test Plan For Fabrication PDF FreeDocument4 pagesInspection Test Plan For Fabrication PDF Freesam paulNo ratings yet

- Mnt-Qa Qc-Itp-001 Inspection and Test PlanDocument3 pagesMnt-Qa Qc-Itp-001 Inspection and Test Plansivagnanam sNo ratings yet

- Fabrication Inspection Test Plan: Barwa Commercial Avenue ProjectDocument3 pagesFabrication Inspection Test Plan: Barwa Commercial Avenue ProjectRNo ratings yet

- Icl Condensate TrapDocument5 pagesIcl Condensate TrapAlberto CamposNo ratings yet

- Plumbing System - Jetty Control Building - Calculation ReportDocument8 pagesPlumbing System - Jetty Control Building - Calculation ReportDaniel NjokuNo ratings yet

- 8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpDocument5 pages8015-0151-00-Al-Cd 1133-19-Gf-Ogf4-J-Vd-9503-00001 - 00 - ItpRami KsidaNo ratings yet

- PDF Inspection Test Plan For Fabrication - CompressDocument4 pagesPDF Inspection Test Plan For Fabrication - Compressridwan maulanaNo ratings yet

- PDE-EQS-3100-EC-00006 - 00 Technical Specification of Safety VesselDocument9 pagesPDE-EQS-3100-EC-00006 - 00 Technical Specification of Safety Vesselhgag selimNo ratings yet

- Shop Inspection Test and PlanDocument1 pageShop Inspection Test and PlanJeffrey HallNo ratings yet

- Qap - Kongsberg - NabDocument4 pagesQap - Kongsberg - NabDeepak DasNo ratings yet

- Itp Tank-29jan 07Document3 pagesItp Tank-29jan 07Anonymous lv8SNRyNo ratings yet

- Insulation WorksDocument2 pagesInsulation WorksBangkit SamosirNo ratings yet

- Itp: Acidification Vessel: Tag: A-325-02-01-C3Document8 pagesItp: Acidification Vessel: Tag: A-325-02-01-C3Jeroan AyamNo ratings yet

- Routine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeDocument3 pagesRoutine Work Card: ITEM NO: 11659-0016 Project: 9M-Pos-1 Task CodeFL Technics DFPNo ratings yet

- Satip J 903 01Document10 pagesSatip J 903 01javed iqbalNo ratings yet

- Con-Pr-Re-Qual - Obr-11 R1Document29 pagesCon-Pr-Re-Qual - Obr-11 R1carla marangonNo ratings yet

- INSPECTION AND TEST PLAN PipingDocument4 pagesINSPECTION AND TEST PLAN PipingTaofik HidayatullohNo ratings yet

- Kic Itp M 100 13Document1 pageKic Itp M 100 13irasool261No ratings yet

- ITP - Fire Alarm System InstallationDocument7 pagesITP - Fire Alarm System InstallationGultom Juliana LiliesNo ratings yet

- J910 DT03 P0ZEN 040001 SQCP 0010 (Quality Control Procedure Index) - Rev.0Document3 pagesJ910 DT03 P0ZEN 040001 SQCP 0010 (Quality Control Procedure Index) - Rev.0Budi SetiawanNo ratings yet

- Effective Process For Dispatch & Inventory Control PDFDocument17 pagesEffective Process For Dispatch & Inventory Control PDFAnonymous 1LSNg3LdmHNo ratings yet

- Effective Process For Dispatch & Inventory ControlDocument17 pagesEffective Process For Dispatch & Inventory ControlJayant Kumar JhaNo ratings yet

- F-PD-01 Process Flow DiagramDocument1 pageF-PD-01 Process Flow DiagramTrivesh SharmaNo ratings yet

- Schenck Process Australia Pty. LTD.: Project ITPDocument1 pageSchenck Process Australia Pty. LTD.: Project ITPsareluis2727No ratings yet

- M BMF 1F4TS0 Cmac Itp 000001 - 002Document14 pagesM BMF 1F4TS0 Cmac Itp 000001 - 002afsalmechenggNo ratings yet

- Saudi Aramco Typical Inspection Plan: Fire Detection and Alarm Systems SATIP-B-014-01 ElectricalDocument18 pagesSaudi Aramco Typical Inspection Plan: Fire Detection and Alarm Systems SATIP-B-014-01 ElectricalSajid ShaikhNo ratings yet

- 0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxDocument1 page0000100324/17-Civil Inspection and Test Plan: 0000100324/17 03-100000-0000100324 - FTC-CIV-ITP-xxxxxxMeshaal ALBalharithNo ratings yet

- CEL-18663-UK-003-ITP01 - Rev-A1Document10 pagesCEL-18663-UK-003-ITP01 - Rev-A1TASNEEMNo ratings yet

- ITP Service PL 001 RWPDocument1 pageITP Service PL 001 RWPDedi KartiwaNo ratings yet

- QAP1Document2 pagesQAP1akshaymehra2354No ratings yet

- Inspection Test Plan For ElectricalDocument39 pagesInspection Test Plan For Electricalpire.resiNo ratings yet

- Mac-Itpc-039700-001 - Excavation and Backfill Rev. 00 (5750)Document2 pagesMac-Itpc-039700-001 - Excavation and Backfill Rev. 00 (5750)JaseelKanhirathinkalNo ratings yet

- DSQR - RaltechDocument10 pagesDSQR - RaltechHimanshu MishraNo ratings yet

- Inspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Document4 pagesInspection Test Plan: 308200-ITP-ME-15 Rev. 1 Date-08.10.02 Dod/Neat Khuff Condensate Fractionation Project Page 1 of 4Delta akathehuskyNo ratings yet

- RCDR FormatDocument7 pagesRCDR Formatqudrat7khan7devizaiNo ratings yet

- Chat OpenaiDocument1 pageChat OpenaimanpreetNo ratings yet

- Project - 1: - PROJECT TITLE:-To Reduce Bolt Loosening Problem inDocument38 pagesProject - 1: - PROJECT TITLE:-To Reduce Bolt Loosening Problem inmanpreetNo ratings yet

- VSM HWDocument6 pagesVSM HWmanpreetNo ratings yet

- Dashboard ExportDocument30 pagesDashboard ExportmanpreetNo ratings yet

- Deep Drawing Protection FilmsDocument9 pagesDeep Drawing Protection Filmsforough sardarzadehNo ratings yet

- M3 L3 MaterialDocument52 pagesM3 L3 MaterialANALIZA PANIMDIMNo ratings yet

- Master of Business Administration Programme Code: MBA Duration - 2 Years Full TimeDocument162 pagesMaster of Business Administration Programme Code: MBA Duration - 2 Years Full TimeDhaval TahelyaniNo ratings yet

- PSA Peugeot CitroënDocument2 pagesPSA Peugeot CitroënChristopher SanzNo ratings yet

- Marketing ConceptDocument27 pagesMarketing ConceptIrah CabanlitNo ratings yet

- 1 ch01Document69 pages1 ch01Ayush HinsuNo ratings yet

- Inspection of HDGDocument56 pagesInspection of HDGPeter FowlesNo ratings yet

- Marketing Management: Name: Class: DateDocument25 pagesMarketing Management: Name: Class: DateAkash Sonawane Youtuber and vloggerNo ratings yet

- Case Studies LogisticsDocument291 pagesCase Studies LogisticsTooba TariqNo ratings yet

- Decision Sheet of BlitzDocument2 pagesDecision Sheet of BlitzTejaswini BheemaiahNo ratings yet

- Resume OTC PAKDocument3 pagesResume OTC PAKAnum ShaukatNo ratings yet

- Official - Q-SFM Manual Training For Expertise (27 May20) - Eng Ver - Rev1Document52 pagesOfficial - Q-SFM Manual Training For Expertise (27 May20) - Eng Ver - Rev1arshadNo ratings yet

- Sap PLM User Interface Intuitive and FlexibleDocument29 pagesSap PLM User Interface Intuitive and FlexibleAnonymous b3yPOhzNo ratings yet

- Supply Chain BrochureDocument8 pagesSupply Chain BrochureNguyen Hoang AnhNo ratings yet

- E-Logistics (Els 324) : Chapter 2 (Part 1) The E-Business Economic Revolution: The Components and Impact of E-BusinessDocument15 pagesE-Logistics (Els 324) : Chapter 2 (Part 1) The E-Business Economic Revolution: The Components and Impact of E-BusinessHassan MohyNo ratings yet

- Flow Diagram of RR Control SpecificationsDocument1 pageFlow Diagram of RR Control SpecificationsJose nuñezNo ratings yet

- ALSTOM Power ZN 00110Document6 pagesALSTOM Power ZN 00110MarcoNo ratings yet

- A Bright Future For PLCsDocument2 pagesA Bright Future For PLCsBir KhumanthemNo ratings yet

- Justin Devine ResumeDocument3 pagesJustin Devine ResumeJustinDevine100% (2)

- Rural Marketing MOD 3Document33 pagesRural Marketing MOD 3Manjima DileepNo ratings yet

- ExamplessssDocument2 pagesExamplessssJasselle GorreNo ratings yet

- Business-Plan 9213535 PowerpointDocument22 pagesBusiness-Plan 9213535 PowerpointSadi AminNo ratings yet

- Topic 11 Measuring Customer LoyaltyDocument19 pagesTopic 11 Measuring Customer LoyaltyRAGOS Jeffrey Miguel P.No ratings yet