Professional Documents

Culture Documents

Job Safety and Environmental Analysis Worksheet: Leighton International Limited

Uploaded by

leoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job Safety and Environmental Analysis Worksheet: Leighton International Limited

Uploaded by

leoCopyright:

Available Formats

Leighton International Limited

JOB SAFETY AND ENVIRONMENTAL ANALYSIS WORKSHEET

Tools and or Equipment required: JSEA No: ID 204-JSEA-129

Division Office / Project: MHU Coal Mining project

Recvery D8 R tipped over

Unit Exc.Exc 345, Dozer D9R, Sling

2”, Shackle 50 ton, PPE (leather

Job Location & Details: Mining-Jonggon AB Reposisi D8 R TC 607# tipped over hand gloves, full body harness, radio Date Prepared: 18-01-2010

comunicationsafety shoes, helmet,

safety glasses), TAKE 5,

Hetro .s ( Mining Supt),Dikari E(Mining supt) Oktovian L ( H&S

JSEA Participants: Supt), Mujiko S( Mech supt), M.thoha (mech supv) Mining

(foreman)

Approved by PM: Sahala

Aritonang

Responsible Supervisor: Hetro Silvanius(Mining Supt)

Date: 18-01-2010

Mar 2008 Page 1 of 3 LIL-HSE-FM-001B(01)

Leighton International Limited

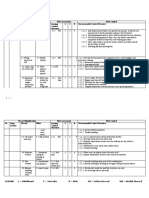

JOB STEP HAZARDS IDENTIFIED CONTROLS REQUIRED (Eg. Remove overhead cable or isolate/sheath ACTION BY/RECORD

(Eg. Set Up Crane) (Eg. Electrocution from 11Kv Cables) overhead or monitor with spotter) Training PPE Needs (Eg. Supervisor)

1. Preparation access 1.1 Not Simper operator 1.1.1 Ensure the operator qualified, have simper and not 1.1.1.1 Supervisor

area for recovery expired

unit 1.2 Tools / unit failure 1.2.1 Ensure have inspection tools/ unit / equipment support 1.1.2.1 Supervisor/ Operator

1.3 Lack of communication 1.31 Ensure to do TAKE 5, brief crews involved this activity, 1.1.3.1 Supervisor and crews

only one person(supervisor involved) to give instruction involved

for this activity, use radio communication,

1.4 Lack of Supervision for 1.4.1 Ensure have supervision and spotter 1.1.4.1 Supervisor

this activity

1.5 People injured caused 1.5.1 Ensure followed procedure ID205-HSE-PI-020 “Personnel 1.1.5.1 Supervisor

hit by unit while Working around Heavy Equipment”, only authorized

activity people working in recovery, and kept safe distance min.

50m unit activity. If need to closed with unit must be

contacted operator and ensure get good feedback or

signal from operator, unit stop activity (parked position). 1.1.6.1 Supervisor/ Operators

Ensure PPE as procedure requirement

1.6 Unit Collide 1.6.1 Ensure each units when working must be kept safe

distance and observe area before moving position

1.7 Spilled oil from unit 1.7.1 Ensure clean up spilled oil from around unit rolled over

rolled over

2. Install sling to 2.1 Pinched injury, slip, fall 2.1.1 Ensure do not put part of body at pinch point, only rigger 2.1.1.1 Workers/ Supervisor

attachment unit down, back injury and worker get training working at height to do this job,

accident and for followed LIL-SAF-PI-005(01) Working at Height, 3 point

recovery contact , followed manual handling procedure, PPE

(leather hand gloves, full body harness, safety shoes,

helmet, glasses)

2.1.2 Ensure use support equipment I;e step ladder/plat form/ 2.1.2.1 Workers

main basket if can’t reach

2.2 People hit by sling 2.2.1 Ensure fitted sling correct placed and tight, do not 2.2.1.1 Workers

working alone,

2.3.1 Ensure use correct lifting gears I;e Shackle, sling, etc

Mar 2008 Page 2 of 3 LIL-HSE-FM-001B(01)

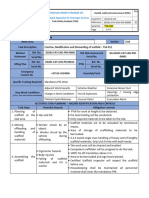

Leighton International Limited

2.3 Incorrect use lifting 2.4.1 Ensure to do TAKE 5, brief crews involved this activity, 2.3.1.1 Riggers

gears/ tools only one person( supervisor involved) to give instruction 2.4.1.1 Supervisor/ Workers

2.4 Lack of communication for this activity, use radio communication,

3. Recovery unit D8 R 3.1. Fire incident 3.1.1 Ensure followed LIL-SAF-PI-004(01) Isolation Procedure 3.1.1.1 Supervisor/ Workers

by unit Exc. 345 ( switch battery off position), no lighting fire on area,

Engine off, available Fire Extinguisher on area, followed

procedure ID205-HSE-PI-018 Emergency Response Plan

3.2 Lifting gears broken 3.2.1 Ensure workers far away (kept safe distance) from area 3.2.1.1 Workers

then hit workers or hit while lifting/recovery unit activity, followed procedure

by unit ID205-HSE-PI-020 “Personnel Working around Heavy

Equipment”, authorized personal only, followed

procedure ID205-HSE-PI-018 Emergency Response Plan

3.3 Unit collide 3.3.1 Ensure each units when working must be kept safe 3.3.1.1 operators

distance and observe area before moving position, and

can moving if get instructed by spotter

3.4 Lack of communication 3.4.1 Ensure only 1 spotter to give signal/ instructed when 3.4.1.1 Supervisor

recovery unit, use radio communication,

4. Recovery end 4.1 Unstable unit position 4.1.1 Ensure unit stabile parked position 4.1.1.1 Supervisor

4.2 not remove isolation 4.2.1 Ensure release isolation tools/ barricade area 4.2.1.1 Workers

4.3 lack of inspection unit 4.3.1 Ensure unit inspected by qualified person 4.3.1.1 Mechanic

4.4 lack of communication 4.4.1 Ensure information to supervisor 4.4.1.1 Workers

4.5 Poor housekeeping 4.5.1 Ensure clean up area and tidy tools 4.5.1.1 Supervisor/ Workers

Mar 2008 Page 3 of 3 LIL-HSE-FM-001B(01)

You might also like

- Techniques and Basic Experiments for the Study of Brain and BehaviorFrom EverandTechniques and Basic Experiments for the Study of Brain and BehaviorNo ratings yet

- The Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerFrom EverandThe Instant Handbook of Boat Handling, Navigation, and Seamanship: A Quick-Reference Guide for Sail and PowerRating: 5 out of 5 stars5/5 (1)

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument3 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument4 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- ID 204-JSEA-WS-003 Remove & Install Stick Cylinder Bucket Exc. 5110BDocument3 pagesID 204-JSEA-WS-003 Remove & Install Stick Cylinder Bucket Exc. 5110BleoNo ratings yet

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument2 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument4 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- 01.work Instruction For Operation of Belt Conveyor-UpdatedDocument6 pages01.work Instruction For Operation of Belt Conveyor-UpdatedRahul VermaNo ratings yet

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument4 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- Jsa Fan Coil Unites MaintenanceDocument5 pagesJsa Fan Coil Unites MaintenanceASLAM MULANINo ratings yet

- Air Jsa ExcavationsDocument13 pagesAir Jsa ExcavationsNIdhinNo ratings yet

- JSA For Cutting, Grinding and Welding in AtmosphereDocument21 pagesJSA For Cutting, Grinding and Welding in AtmosphereThái Đạo Phạm Lê100% (1)

- 001 - Rev.03 Survey Work, Excavation, Backfilling and Compaction (1362)Document13 pages001 - Rev.03 Survey Work, Excavation, Backfilling and Compaction (1362)NIdhinNo ratings yet

- Tsa-001 - Rev 0 - ExcavationDocument2 pagesTsa-001 - Rev 0 - ExcavationMusadiq HussainNo ratings yet

- 01 Loading, Unloading & Transportation of Heavy Equipment (Well Head)Document11 pages01 Loading, Unloading & Transportation of Heavy Equipment (Well Head)Pangky AbasoloNo ratings yet

- 7.removing Fixing Demister.Document7 pages7.removing Fixing Demister.Mohammad Fazal KhanNo ratings yet

- Barbending HirarcDocument2 pagesBarbending HirarcSuraindran ManoharanNo ratings yet

- Barbending HiracDocument2 pagesBarbending HiracSuraindran ManoharanNo ratings yet

- Hiradc ServicingDocument4 pagesHiradc ServicingAyub Abd RahmanNo ratings yet

- JSEA Install Grounding & Stick Earth BuildingDocument6 pagesJSEA Install Grounding & Stick Earth BuildingGus PurNo ratings yet

- Cable TestingDocument1 pageCable Testinglalmani bhusal100% (2)

- Belt Conveyor Bearing InspectionDocument3 pagesBelt Conveyor Bearing InspectionKarthikeyan MNo ratings yet

- JHA - Earthing Lightning Protection & Cable Tray Instalation System - Docx - PCTLDocument8 pagesJHA - Earthing Lightning Protection & Cable Tray Instalation System - Docx - PCTLOmkar MishraNo ratings yet

- Cable TestingDocument2 pagesCable Testinglalmani bhusalNo ratings yet

- Barbending HiracDocument2 pagesBarbending HiracJohn Ha71% (7)

- Expert-Jsa Dewatering WorkDocument6 pagesExpert-Jsa Dewatering WorkMuhammad NadeemNo ratings yet

- JSA-02 For Crane & Hoist PMDocument2 pagesJSA-02 For Crane & Hoist PMNavneet100% (1)

- Duct InstallationDocument2 pagesDuct InstallationKrishna PatilNo ratings yet

- JSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)Document2 pagesJSA - Manual Lifting (Using Chain Block, Sling Belt and Shackle)muiqbal.workNo ratings yet

- 3.1SWP2 - Hand Held GrinderDocument2 pages3.1SWP2 - Hand Held GrinderPackirisamy BaskarNo ratings yet

- 3 Month Maintenance On Hydra RackerDocument2 pages3 Month Maintenance On Hydra Rackermohamed hamedNo ratings yet

- JSA - T8420 Tank Cleaning - docFSPDocument3 pagesJSA - T8420 Tank Cleaning - docFSPavinash100% (2)

- CE06 Use of Power SawDocument3 pagesCE06 Use of Power SawTafireyi TeveraNo ratings yet

- BAWTP1A Project: (Sign Name & Position (Sign Name & PositionDocument6 pagesBAWTP1A Project: (Sign Name & Position (Sign Name & PositionazerNo ratings yet

- 49 Switch Board - Panel ErectionDocument4 pages49 Switch Board - Panel ErectionvasudevanmNo ratings yet

- JSA - Manual Lifting and Installation (Using Chain Block, Sling Belt and Shackle)Document2 pagesJSA - Manual Lifting and Installation (Using Chain Block, Sling Belt and Shackle)muiqbal.workNo ratings yet

- Risk Assessment & Control Measure Worksheet (RA Sheet)Document5 pagesRisk Assessment & Control Measure Worksheet (RA Sheet)alla malikNo ratings yet

- Addendum PLI-EPTCO-JRA-PPP-02 Working at Night Rev01Document4 pagesAddendum PLI-EPTCO-JRA-PPP-02 Working at Night Rev01Alam DooNo ratings yet

- TTEC Fencing RADocument7 pagesTTEC Fencing RAGeml TrinidadNo ratings yet

- RA - MILL RELINING RevisedDocument10 pagesRA - MILL RELINING RevisedRenier DercksenNo ratings yet

- 2.7 Working Near Live SwitchyardDocument3 pages2.7 Working Near Live SwitchyardYusuf Afraz100% (1)

- 010 JSA - Veolia - RO Units Membranes ReplacementDocument5 pages010 JSA - Veolia - RO Units Membranes ReplacementAbdullah AbedNo ratings yet

- HSE - 2017 - 022 - JSA Escort Unit LowboyDocument5 pagesHSE - 2017 - 022 - JSA Escort Unit Lowboyarif ridwanNo ratings yet

- 630-Lubrication of CSR#3Document7 pages630-Lubrication of CSR#3Buddy HartNo ratings yet

- ## JSA - 008 - Hydraulic Rig and Mobile Crane MarchingDocument1 page## JSA - 008 - Hydraulic Rig and Mobile Crane MarchingAbhijit JanaNo ratings yet

- JSA-04 Preventive Maintenance For LT MotorDocument2 pagesJSA-04 Preventive Maintenance For LT MotorNavneetNo ratings yet

- 5.confined Space EntryDocument6 pages5.confined Space EntryMohammad Fazal KhanNo ratings yet

- TSA-011 - Erection, Modification and Dismantling of ScaffoldDocument2 pagesTSA-011 - Erection, Modification and Dismantling of ScaffoldMusadiq HussainNo ratings yet

- Jsa Rig Engine Service 750 HRSDocument1 pageJsa Rig Engine Service 750 HRSAdel AlKhedawyNo ratings yet

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Trial Run of Motor and Panels - 26.04.2019 - FinalDocument7 pagesTrial Run of Motor and Panels - 26.04.2019 - FinalChiranjit BhattacharjeeNo ratings yet

- AHA - Aluminum Windows Installation - 14-3-2019 Revie-2Document6 pagesAHA - Aluminum Windows Installation - 14-3-2019 Revie-2Eyal BabuNo ratings yet

- Job Safety Analysis Record SheetDocument23 pagesJob Safety Analysis Record Sheetza8319712No ratings yet

- Eta-Jsa Piping, Works Bolt Tightening Using Hydraulic ToolsDocument7 pagesEta-Jsa Piping, Works Bolt Tightening Using Hydraulic Toolslelu ojhaNo ratings yet

- 12 Construction of Blowdown LineDocument11 pages12 Construction of Blowdown LinePangky AbasoloNo ratings yet

- 21.removal and Refixing of 02SDV3301C.Document3 pages21.removal and Refixing of 02SDV3301C.Mohammad Fazal KhanNo ratings yet

- JSA For Electrical ActivitiesDocument14 pagesJSA For Electrical Activitiesdrparihary100% (2)

- Adjust Front Suspension Pos 2 DA 433Document4 pagesAdjust Front Suspension Pos 2 DA 433kurniarung oceandaNo ratings yet

- AHA - Asbestos Abatement-11-11-2019Document7 pagesAHA - Asbestos Abatement-11-11-2019Eyal BabuNo ratings yet

- Job Safety Analysis (JSA) - Carpentry Works DateDocument1 pageJob Safety Analysis (JSA) - Carpentry Works DatenabeelNo ratings yet

- Job Safety and Environmental Analysis Worksheet: Leighton International LimitedDocument4 pagesJob Safety and Environmental Analysis Worksheet: Leighton International LimitedleoNo ratings yet

- ID 204-JSEA-WS-042 Remove & Install Bucket, Arm Cylinder Exc. Liebherr 994Document3 pagesID 204-JSEA-WS-042 Remove & Install Bucket, Arm Cylinder Exc. Liebherr 994leoNo ratings yet

- Pipe Fittings PDFDocument164 pagesPipe Fittings PDFjlvega18No ratings yet

- ID 204-JSEA-WS-092 Replace Track Roller Excavator Komatsu PC1250-7Document4 pagesID 204-JSEA-WS-092 Replace Track Roller Excavator Komatsu PC1250-7leoNo ratings yet

- SM PC300-8 SN01983-01Document44 pagesSM PC300-8 SN01983-01aldy yasi77% (13)

- Injector AutolubDocument4 pagesInjector AutolubleoNo ratings yet

- Coalbed Methane Economic BoomDocument5 pagesCoalbed Methane Economic Boommeali513No ratings yet

- Coal and Petroleum Class 8 NotesDocument6 pagesCoal and Petroleum Class 8 NotesYukta SainiNo ratings yet

- Explosive Engineering Lab 3Document12 pagesExplosive Engineering Lab 3mahamNo ratings yet

- NCES Unit-1 - STDocument52 pagesNCES Unit-1 - STpriyanshu MehtaNo ratings yet

- Summer Internship at "G.S.E.C.L. Thermal Power Station Sikka''Document25 pagesSummer Internship at "G.S.E.C.L. Thermal Power Station Sikka''ARJUN SOMAIYANo ratings yet

- Value Chain Track 3Document5 pagesValue Chain Track 3MOHAMMAD NISAR AFROZNo ratings yet

- Flour Industry Petroleum IndustryDocument5 pagesFlour Industry Petroleum IndustryMonica Morales MaañoNo ratings yet

- Taller 1Document2 pagesTaller 1juan camilo montenegro cañonNo ratings yet

- Status Gizi, Aktivitas Fisik Dan Produktivitas Kerja Karyawan Tambang Batu Bara PT. Kaltim Prima CoalDocument8 pagesStatus Gizi, Aktivitas Fisik Dan Produktivitas Kerja Karyawan Tambang Batu Bara PT. Kaltim Prima Coalariesky gdskNo ratings yet

- Manufacturing of Fly Ash Brick and Finding The Optimal Mix of Materials With Replacement of Cement by Lime Sludge and GypsumDocument4 pagesManufacturing of Fly Ash Brick and Finding The Optimal Mix of Materials With Replacement of Cement by Lime Sludge and GypsumshivaNo ratings yet

- Lectura 07 Modern Continuous Smelting and Converting by Bath Smelting TechnologyDocument23 pagesLectura 07 Modern Continuous Smelting and Converting by Bath Smelting Technologycarorodriguezlorca12No ratings yet

- ABRASIVESDocument5 pagesABRASIVES147No ratings yet

- Week 3 - HandoutsDocument3 pagesWeek 3 - HandoutsJanniela BonacheNo ratings yet

- Exercises - N2 - UBC Mining Method SelectionDocument12 pagesExercises - N2 - UBC Mining Method SelectionLuis_Escriba_CNo ratings yet

- Ballu Minor Project Report 2Document30 pagesBallu Minor Project Report 2virendra behraNo ratings yet

- Coal-Fired Power Plant Heat Rate Improvement Options, Part 2 - PowermagDocument11 pagesCoal-Fired Power Plant Heat Rate Improvement Options, Part 2 - PowermagRavi SatyapalNo ratings yet

- TCA - Ex PresentationDocument18 pagesTCA - Ex PresentationDuong NguyenNo ratings yet

- CoalDocument2 pagesCoalBrenda EstradaNo ratings yet

- Safety Pillar Design For Main Galleries in Multi-Slice Longwall Top Coal Caving MethodDocument19 pagesSafety Pillar Design For Main Galleries in Multi-Slice Longwall Top Coal Caving MethodGyempo DorjiNo ratings yet

- Costing and Productivity MonthlyDocument4 pagesCosting and Productivity MonthlyListya AnggrainiNo ratings yet

- Workshop Tips: 28 Track PlansDocument15 pagesWorkshop Tips: 28 Track PlansJackSiedschlagNo ratings yet

- Geology and Mineral Resources of EthiopiaDocument17 pagesGeology and Mineral Resources of Ethiopiaongach othow100% (2)

- 2nd Quarter Science NotesDocument27 pages2nd Quarter Science Notescasey lNo ratings yet

- Hans-Günter Ramke, Dennis Blöhse, Hans-Joachim Lehmann, Joachim FettigDocument16 pagesHans-Günter Ramke, Dennis Blöhse, Hans-Joachim Lehmann, Joachim Fettigrtgersergtgr trghgrwthtrtehNo ratings yet

- Ashrant Coal Handling PlantDocument29 pagesAshrant Coal Handling Plantsexyakshay26230% (1)

- Basic and Advanced English ExercisesDocument160 pagesBasic and Advanced English ExercisesFurtive80% (5)

- Abas, Kalair, Khan - 2015 - Review of Fossil Fuels and Future Energy TechnologiesDocument19 pagesAbas, Kalair, Khan - 2015 - Review of Fossil Fuels and Future Energy TechnologiesLanly RomuelNo ratings yet

- Presentation of Pfeiffer High Quality Products For The Cement IndustryDocument291 pagesPresentation of Pfeiffer High Quality Products For The Cement IndustryDilnesa EjiguNo ratings yet

- The Gazette of India: ExtraordinaryDocument4 pagesThe Gazette of India: ExtraordinaryVajjala HimajaNo ratings yet

- Biomass Co-Firing Experience in NL & Black Pellets Status Update - Michiel CarboDocument60 pagesBiomass Co-Firing Experience in NL & Black Pellets Status Update - Michiel CarbogujunjssNo ratings yet