Professional Documents

Culture Documents

University of Kirkuk. Department of Mechanical Enginnering.: Name: Ahmed Qais

Uploaded by

Mostafa HamawandyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

University of Kirkuk. Department of Mechanical Enginnering.: Name: Ahmed Qais

Uploaded by

Mostafa HamawandyCopyright:

Available Formats

u

University Of Kirkuk.

Department of mechanical enginnering.

Date: 6/13/2020 { Saturday}

^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^^

Name: Ahmed Qais.

Under The Supervision:Fouad Ramadan

Introduction

Isothermal transformation diagrams (also known as time-temperature-

transformation (TTT) diagrams) are plots of temperature versus time (usually on a logarthimic

scale). They are generated from percentage transformation-vs time measurements, and are useful

for understanding the transformations of an alloy steel at elevated temperatures.

An isothermal transformation diagram is only valid for one specific composition of material, and only

if the temperature is held constant during the transformation, and strictly with rapid cooling to that

temperature. Though usually used to represent transformation kinetics for steels, they also can be

used to describe the kinetics of crystallization in ceramic or other materials. Time-temperature-

precipitation diagrams and time-temperature-embrittlement diagrams have also been used to

represent kinetic changes in steels.

Isothermal transformation (IT) diagram or the C-curve is associated with mechanical

properties,microconstituents/microstructures, and heat treatments in carbon steels. Diffusional

transformations like austenite transforming to a cementite and ferrite mixture can be explained

using the sigmoidal curve; for example the beginning of pearlitic transformation is represented by the

pearlite start (Ps) curve. This transformation is complete at Pf curve. Nucleation requires an

incubation time. The rate of nucleation increases and the rate of microconstituent growth decreases

as the temperature decreases from the liquidus temperature reaching a maximum at the bay or nose

of the curve. Thereafter, the decrease in diffusion rate due to low temperature offsets the effect of

increased driving force due to greater difference in free energy As a result of the transformation, the

microconstituents, pearlite and bainite form; pearlite forms at higher temperatures and bainite at

lower.

Austenite is slightly undercooled when quenched below Eutectoid temperature. When given more

time, stable microconstituents can form: ferrite and cementite. Coarse pearlite is produced when

atoms diffuse rapidly after phases that form pearlite nucleate. This transformation is complete at the

pearlite finish time (Pf).

However, greater undercooling by rapid quenching results in formation of martensite or bainite

instead of pearlite. This is possible provided the cooling rate is such that the cooling curve intersects

the martensite start temperature or the bainite start curve before intersecting the Ps curve. The

martensite transformation being a diffusionless shear transformation is represented by a straight line

to signify the martensite start temperature.

You might also like

- Fluid Properties: PVT Properties of Crude Oils: 1. Oil Formation Volume Factor, BDocument6 pagesFluid Properties: PVT Properties of Crude Oils: 1. Oil Formation Volume Factor, BAli HijaziNo ratings yet

- TTT DiagramDocument6 pagesTTT DiagramDeepa PujariNo ratings yet

- Time Temperature Transformation (TTT) Diagrams PDFDocument108 pagesTime Temperature Transformation (TTT) Diagrams PDFSerkan Apay100% (1)

- TTT and CCT Continuous Cooling TransformationDocument6 pagesTTT and CCT Continuous Cooling TransformationurcojNo ratings yet

- Ch. 18 Waves & SoundsDocument29 pagesCh. 18 Waves & SoundsNick Andrew Dequilla NiervaNo ratings yet

- Principles of Heat Treating of SteelsDocument30 pagesPrinciples of Heat Treating of Steelssatish_trivediNo ratings yet

- TTT Phase DiagramDocument9 pagesTTT Phase Diagramhari krishnaNo ratings yet

- Steel Plate Bonding MethodDocument29 pagesSteel Plate Bonding MethodSiti Rohani Isdris100% (1)

- Lecture Chapter 4 Phase Transformation and Metal AlloysDocument79 pagesLecture Chapter 4 Phase Transformation and Metal AlloysWinni TanNo ratings yet

- Abutment Design ExampleDocument56 pagesAbutment Design Examplezrilek1No ratings yet

- Bottom Roughness Parameter StudyDocument7 pagesBottom Roughness Parameter StudyAlejandro Canul TurrizaNo ratings yet

- Closed-Book Practice-Ch 10 (2017!08!08)Document12 pagesClosed-Book Practice-Ch 10 (2017!08!08)Juan0% (1)

- TTT and CCT DiagramDocument24 pagesTTT and CCT DiagramArun Raj A C100% (2)

- Flow and Heat Transfer in Geothermal Systems: Basic Equations for Describing and Modeling Geothermal Phenomena and TechnologiesFrom EverandFlow and Heat Transfer in Geothermal Systems: Basic Equations for Describing and Modeling Geothermal Phenomena and TechnologiesNo ratings yet

- Phase Transformation in Metals: Dr. Aneela WakeelDocument29 pagesPhase Transformation in Metals: Dr. Aneela WakeelmazharNo ratings yet

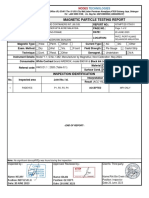

- Test Report For Lab Iso 17025Document6 pagesTest Report For Lab Iso 17025vines7831No ratings yet

- EMAT 10 (2k21)Document41 pagesEMAT 10 (2k21)Kumail AbbasNo ratings yet

- Time Temperature Transformation With ReferncesDocument12 pagesTime Temperature Transformation With ReferncesEllie BrooklynNo ratings yet

- Time Temperature Transformation With ReferncesDocument12 pagesTime Temperature Transformation With ReferncesEllie BrooklynNo ratings yet

- Chapter Outline: Phase Transformations. KineticsDocument23 pagesChapter Outline: Phase Transformations. Kineticsmpcd07No ratings yet

- Heat Treatment 1Document42 pagesHeat Treatment 1Akash TiwariNo ratings yet

- 8.heat TreatmentDocument7 pages8.heat Treatmentrohan_n_desai100% (2)

- TTT 11Document55 pagesTTT 11MrDOTNo ratings yet

- TTT N AvramiDocument40 pagesTTT N AvramiAmirul AminNo ratings yet

- TTT CurvesDocument4 pagesTTT Curvesmanas310jntuhNo ratings yet

- DivaCalista 1806187902 CCT&TTTdiagramsDocument7 pagesDivaCalista 1806187902 CCT&TTTdiagramsAlishia LoshNo ratings yet

- Capili Jefferson 11Document16 pagesCapili Jefferson 11Christian Al EncarnacionNo ratings yet

- Chapter Outline:: Heat Treatment (And Temperature)Document24 pagesChapter Outline:: Heat Treatment (And Temperature)DSGNo ratings yet

- JN Qu 7 HJRR AYog AXWp Qhgakii IO91Document10 pagesJN Qu 7 HJRR AYog AXWp Qhgakii IO91tabibkarimNo ratings yet

- What Is The Difference Between CCT and TTT Curve by An Easy Example? How They Are Plotted?Document5 pagesWhat Is The Difference Between CCT and TTT Curve by An Easy Example? How They Are Plotted?nareshNo ratings yet

- TTT DiagramDocument31 pagesTTT DiagramEducated SmugglerNo ratings yet

- TTT DiagramDocument17 pagesTTT DiagramGAURAV SINGHNo ratings yet

- SM 5th-Sem Meta Heat-Treatment-TechnologyDocument37 pagesSM 5th-Sem Meta Heat-Treatment-TechnologyARINDAM SETTNo ratings yet

- Imp Article - Sph. Annealing Detailed MetallurgyDocument19 pagesImp Article - Sph. Annealing Detailed MetallurgyP I GuddimathNo ratings yet

- Sudipta Nath: Materials EngineeringDocument19 pagesSudipta Nath: Materials EngineeringSudipta NathNo ratings yet

- Publication 4 11889 199Document9 pagesPublication 4 11889 199Mulia AridhoNo ratings yet

- CCT Diagram For Steels PDFDocument33 pagesCCT Diagram For Steels PDFGuru SamyNo ratings yet

- Ch-8 Compatibility ModeDocument58 pagesCh-8 Compatibility Modedreamgurl9011No ratings yet

- Trans FasesDocument6 pagesTrans FasesIveth Carmona GonzalezNo ratings yet

- Trans FasesDocument6 pagesTrans FasesIveth Carmona GonzalezNo ratings yet

- Time-Temperature-Transformation (TTT) DiagramDocument18 pagesTime-Temperature-Transformation (TTT) DiagramGikiTopiNo ratings yet

- MT Ch5Document69 pagesMT Ch5Miras MuratbekovNo ratings yet

- Bantek c.12 No. 66Document2 pagesBantek c.12 No. 66Amirah RashandaryNo ratings yet

- Cooling Curves and The IDocument2 pagesCooling Curves and The IRezki FpNo ratings yet

- TTT DiagramDocument6 pagesTTT DiagramUthaya KumarNo ratings yet

- Time-Temperature-Transformation Diagram Within The Bainitic Temperature Range in A Medium Carbon SteelDocument10 pagesTime-Temperature-Transformation Diagram Within The Bainitic Temperature Range in A Medium Carbon SteelAnonymous Fty6OOHlNo ratings yet

- Kinetics - Heat TreatmentDocument18 pagesKinetics - Heat TreatmentUnknownNo ratings yet

- 42crmo4 PDFDocument10 pages42crmo4 PDFAnuj ShahNo ratings yet

- Group 10: Guided Prof. BP KashyapDocument29 pagesGroup 10: Guided Prof. BP KashyapmohansaiNo ratings yet

- Heat Treatment of 1045 Steel PDFDocument17 pagesHeat Treatment of 1045 Steel PDFH_DEBIANENo ratings yet

- Heat Treatment Part 1Document32 pagesHeat Treatment Part 1Naman DaveNo ratings yet

- TTTDocument13 pagesTTTharitha gorijalaNo ratings yet

- Materiale Dhe Perpunim Termik Chapter11Document48 pagesMateriale Dhe Perpunim Termik Chapter11durimfcbNo ratings yet

- 1 s2.0 1359645496000845 MainDocument11 pages1 s2.0 1359645496000845 MainRaseem AhmedNo ratings yet

- Prelims - PMD - Heat-Treatment-Principles-And-Techniques-Short-No-QDocument36 pagesPrelims - PMD - Heat-Treatment-Principles-And-Techniques-Short-No-Qkitolaw123No ratings yet

- Heat Treatment of SteelsDocument60 pagesHeat Treatment of SteelsGUNJAN MUDGALNo ratings yet

- E45 Laboratory4Document7 pagesE45 Laboratory4nickNo ratings yet

- FeC and TTT DiagramsDocument12 pagesFeC and TTT DiagramsMohamed El-WakilNo ratings yet

- Heat Tretment 18Document8 pagesHeat Tretment 18Qasim SaadNo ratings yet

- TTT DiagramDocument1 pageTTT DiagramaasattiNo ratings yet

- TTT & CCT Diagrams: Dr. K. Devendranath Ramkumar Assistant Professor (Senior)Document22 pagesTTT & CCT Diagrams: Dr. K. Devendranath Ramkumar Assistant Professor (Senior)joel jNo ratings yet

- MEB 1211 QuestionsDocument8 pagesMEB 1211 QuestionsRaj RajendranNo ratings yet

- EMM LectureDocument38 pagesEMM Lecturelatendra kumar srivastavNo ratings yet

- Chapter 8 (Heat Treatment)Document12 pagesChapter 8 (Heat Treatment)Shekinah KanindaNo ratings yet

- Basicsof AustemperingDocument4 pagesBasicsof AustemperingSinan YILDIZNo ratings yet

- Corrosion Resistance Mostafa Qasim % Muhammed DlerDocument14 pagesCorrosion Resistance Mostafa Qasim % Muhammed DlerMostafa HamawandyNo ratings yet

- Flow MaterDocument7 pagesFlow MaterMostafa HamawandyNo ratings yet

- Sheet Mumber 1 Mechanical Eng Kirkuk UniversityDocument12 pagesSheet Mumber 1 Mechanical Eng Kirkuk UniversityMostafa HamawandyNo ratings yet

- Lab Report: Tensile TestDocument5 pagesLab Report: Tensile TestMostafa HamawandyNo ratings yet

- LAB (Tensile Test) : Prepared By: Ameena Talib SaedahDocument6 pagesLAB (Tensile Test) : Prepared By: Ameena Talib SaedahMostafa HamawandyNo ratings yet

- Rate Meters Venturi Meter Nozzle Meter Orifice MeterDocument6 pagesRate Meters Venturi Meter Nozzle Meter Orifice MeterMostafa HamawandyNo ratings yet

- Rate Meters Venturi Meter Nozzle Meter Orifice MeterDocument7 pagesRate Meters Venturi Meter Nozzle Meter Orifice MeterMostafa HamawandyNo ratings yet

- ThermodynaDocument14 pagesThermodynaMostafa HamawandyNo ratings yet

- Esra Dhyaa Fluid Report Second StageDocument7 pagesEsra Dhyaa Fluid Report Second StageMostafa HamawandyNo ratings yet

- Pipe Flow Rate MetersDocument6 pagesPipe Flow Rate MetersMostafa HamawandyNo ratings yet

- Computer Science IIDocument4 pagesComputer Science IIMostafa HamawandyNo ratings yet

- Math Emati CS: Partial Derivatives ReportDocument7 pagesMath Emati CS: Partial Derivatives ReportMostafa HamawandyNo ratings yet

- University of Kirkuk College of Pharmacy: Partition CoefficientDocument4 pagesUniversity of Kirkuk College of Pharmacy: Partition CoefficientMostafa HamawandyNo ratings yet

- رياضياتDocument9 pagesرياضياتMostafa HamawandyNo ratings yet

- رياضياتDocument9 pagesرياضياتMostafa HamawandyNo ratings yet

- Partial Derivatives Report: Name: Mostafa Qasim TahrDocument7 pagesPartial Derivatives Report: Name: Mostafa Qasim TahrMostafa HamawandyNo ratings yet

- Fluid: Name: Mostafa Qasim TahrDocument8 pagesFluid: Name: Mostafa Qasim TahrMostafa HamawandyNo ratings yet

- Bahar Salahalden (Fluid)Document7 pagesBahar Salahalden (Fluid)Mostafa HamawandyNo ratings yet

- Name:Mostafa Qasim Tahr.: University of Kirkuk Collage of Engineering Second StageDocument6 pagesName:Mostafa Qasim Tahr.: University of Kirkuk Collage of Engineering Second StageMostafa HamawandyNo ratings yet

- Bahar Salahalden (المختبر)Document5 pagesBahar Salahalden (المختبر)Mostafa HamawandyNo ratings yet

- Matlab: Name:Mo Stafa Qasim TahrDocument16 pagesMatlab: Name:Mo Stafa Qasim TahrMostafa HamawandyNo ratings yet

- Mostafa Qasim Fluid ReportDocument7 pagesMostafa Qasim Fluid ReportMostafa HamawandyNo ratings yet

- ThermodynaDocument14 pagesThermodynaMostafa HamawandyNo ratings yet

- Mostafa Qasim (Lab Report)Document6 pagesMostafa Qasim (Lab Report)Mostafa HamawandyNo ratings yet

- University of Kirkuk Mechanical Engineering Department Second Stage - Morning StudyDocument16 pagesUniversity of Kirkuk Mechanical Engineering Department Second Stage - Morning StudyMostafa HamawandyNo ratings yet

- کالي طيفور (مقاومة المواد)Document6 pagesکالي طيفور (مقاومة المواد)Mostafa HamawandyNo ratings yet

- Mostafa Qasim Fluid ReportDocument7 pagesMostafa Qasim Fluid ReportMostafa HamawandyNo ratings yet

- English Report (Mostafa Qasim)Document5 pagesEnglish Report (Mostafa Qasim)Mostafa HamawandyNo ratings yet

- Matlab: Name:Mo Stafa Qasim TahrDocument16 pagesMatlab: Name:Mo Stafa Qasim TahrMostafa HamawandyNo ratings yet

- Kale Tayfur Aziz (Fetigua Test)Document5 pagesKale Tayfur Aziz (Fetigua Test)Mostafa HamawandyNo ratings yet

- Cooling Tower DamageDocument7 pagesCooling Tower DamageRodrigo Felicio AdrianoNo ratings yet

- Duraikkannu, S. L., Castro-Muñoz, R., & Figoli, A. (2021) - A Review On Phase-Inversion Technique-Based Polymer Microsphere FabricationDocument11 pagesDuraikkannu, S. L., Castro-Muñoz, R., & Figoli, A. (2021) - A Review On Phase-Inversion Technique-Based Polymer Microsphere FabricationCoreyNo ratings yet

- Chemical BondingDocument11 pagesChemical Bondingvenom eNo ratings yet

- Beam Deflection Tables - MechaniCalcqweqdsdDocument9 pagesBeam Deflection Tables - MechaniCalcqweqdsdKenneth LuceroNo ratings yet

- ETABS ColumndesignDocument1 pageETABS ColumndesignPujan NeupaneNo ratings yet

- Crystallization: Instructor: Zafar ShakoorDocument32 pagesCrystallization: Instructor: Zafar ShakoorMALIK ZARYABBABAR100% (1)

- Part1 Static 1 1Document12 pagesPart1 Static 1 1Hemn Rafiq TofiqNo ratings yet

- Light PropertiesDocument10 pagesLight PropertiesUsamakhan009No ratings yet

- Yvoire Contour-ImdadDocument3 pagesYvoire Contour-ImdadWaddah Al-magrabiNo ratings yet

- Annual Vg7076Document2 pagesAnnual Vg7076Emmanuel SanthanasamyNo ratings yet

- Stiffening Effect of Refractory Lined Piping - Carmagen EngineeringDocument1 pageStiffening Effect of Refractory Lined Piping - Carmagen EngineeringnaeandNo ratings yet

- Nanoscience and Nanotechnology Around The WorldDocument15 pagesNanoscience and Nanotechnology Around The WorldWaseem JavedNo ratings yet

- Refractive Index ApplyDocument12 pagesRefractive Index ApplyFadila Uswatun HasanahNo ratings yet

- Relative PermittivityDocument7 pagesRelative PermittivityEthiopia HagereNo ratings yet

- Compositematerials 170302065645Document48 pagesCompositematerials 170302065645Pranay FotedarNo ratings yet

- Post Graduate Diploma IN Bakery Science and TechnologyDocument64 pagesPost Graduate Diploma IN Bakery Science and Technologyakshay_pundeNo ratings yet

- EN1992 2 ManciniDocument138 pagesEN1992 2 Mancinidragos_bogdan1974No ratings yet

- PDF Astm d4402 DDDocument3 pagesPDF Astm d4402 DDKAKA MADAFAKANo ratings yet

- Eurocode 3 Stress Ratio Presentation 5 by Lee CKDocument17 pagesEurocode 3 Stress Ratio Presentation 5 by Lee CKKipodimNo ratings yet

- BEE Tutorial 8Document2 pagesBEE Tutorial 8Atharva NairNo ratings yet

- FMM Question BankDocument6 pagesFMM Question BanktagoreboopathyNo ratings yet

- Zona PanelDocument7 pagesZona PanelrobertNo ratings yet

- 11b WWW - Intact Solutions - Com Scan Solve Comparing FeaturesDocument2 pages11b WWW - Intact Solutions - Com Scan Solve Comparing Featuresmilic_31No ratings yet

- Ce121 Lec5 BuoyancyDocument18 pagesCe121 Lec5 BuoyancyPetForest Ni JohannNo ratings yet