Professional Documents

Culture Documents

TN1021 PDF

Uploaded by

vinay rodeOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TN1021 PDF

Uploaded by

vinay rodeCopyright:

Available Formats

J D Dewar

Consultancy

32 Tolethorpe close

Oakham

Rutland

LE15 6GF

UK

Tel/ Fax 01572 774 338

e-mail joedewar@btopenworld.com

TECHNICAL NOTE 1021

Guidance on the use of MixSim concrete data in place of laboratory trial mix data in

existing company computer systems.

Most ready mixed concrete companies have computer systems for generating batch books,

pricing data, strength lists, mix data sheets etc. These systems rely upon input of data from

laboratory trial mixes which are processed in the computer using curve smoothing techniques

to allow interpolation for all mixtures within the range of data from the trials.

Users of MixSim have the options of:-

A. Immediate use of comprehensive Output data from MixSim for mix selection, costing

and production purposes;

B. Transferring any selected data from MixSim into ‘comma separated’ format or MS

Excel format for further processing automatically or manually within specialised

company systems;

C. As (B) but specifically making only a very limited selection of MixSim data as direct

substitutes for Laboratory trial mix data.

This note is concerned primarily with Option C, which has the advantage of enabling users of

sophisticated and well established systems to continue to use them with minimal visible

disruption, while benefitting from the speed and accuracy of MixSim compared with laboratory

trial mixes.

Method

1. Use MixSim to generate the full range of 17 designs for the particular materials, their

properties and construction conditions particularly cohesion factor, air content and

slump (See Figure1).

2. Transfer the required section(s) of the MixSim Results Table to an MS Excel

Spreadsheet (See Figure 2). This is achieved by placing the cursor within the Table

and right-clicking to display the menu from which Export Data is selected and the

instructions followed to create and save the comma separated file. The file may then

be opened in MS Excel spreadsheet format from the Export data file under MixSim.

The file should then be Saved As an Excel file of the appropriate type before editing.

3. Edit the spreadsheet as necessary to suit the normal input sequence to the company

system. Select a number of rows of data, max 17, min normally 5 to cover the

required range of cement content, usually 100 - 500 kg/m3, in approximately equal

increments (See Figure 2).

4. Check whether the materials conditions and the units are as required to be reported

for laboratory trial mix data in the company system. If not they will need to be

amended in the MS Excel spreadsheet before introducing into the company system.

For MixSim the conditions and units are

Cement and additions (kg/m3)

Water is free water (kg/m3) = (l/m3)

DRAFT

Aggregates are in SSD condition (kg/m3)

Admixtures (l/m3) (kg/m3).

Figure 1 Example of a MixSim Results Table showing 17 mixtures

Pt Cem + Add PC Kemp Water Hey sand 10SS Cam 20 SS Cam Density Per Cent Fines w/c a/c 7 Day Strength

28 Day

N/mm²

Strength

56 Day

N/mm²

Strength N/mm²

A 0 0 288 628 421 782 2119 34.29 0 0 0

31 31 270 701 404 750 2157 37.78 8.61 59.2 0 0 0

72 72 251 772 386 717 2198 41.17 3.5 26.15 0 0 0

122 122 230 841 367 682 2243 44.49 1.89 15.51 1 3 4

B 183 183 209 907 347 645 2291 47.75 1.14 10.4 10 14 18

209 209 205 878 353 656 2301 46.51 0.98 9.01 15 20 25

236 236 201 849 359 667 2312 45.26 0.85 7.95 20 27 32

262 262 197 820 365 678 2322 44 0.75 7.12 26 33 39

C 287 287 193 791 371 689 2332 42.72 0.67 6.45 32 40 46

340 340 192 714 383 711 2341 39.5 0.56 5.31 42 50 57

D 389 389 191 640 395 733 2348 36.23 0.49 4.54 50 59 66

431 431 195 561 406 755 2348 32.58 0.45 3.99 56 65 71

E 467 467 198 487 418 777 2347 28.95 0.42 3.6 60 69 75

571 571 212 340 426 791 2340 21.82 0.37 2.73 66 75 81

656 656 225 210 434 806 2331 14.5 0.34 2.21 69 77 83

723 723 238 97 441 819 2319 7.16 0.33 1.88 70 78 84

F 774 774 251 0 448 833 2306 0 0.32 1.66 70 78 84

Selected mixes

Pt Cem + Add PC Kemp Water Hey sand 10SS Cam 20 SS Cam Density % Fines w/c a/c 7 Day Str 28 Day Str 56 Day Str

122 122 230 841 367 682 2243 44.49 1.89 15.51 1 3 4

236 236 201 849 359 667 2312 45.26 0.85 7.95 20 27 32

340 340 192 714 383 711 2341 39.50 0.56 5.31 42 50 57

E 467 467 198 487 418 777 2347 28.95 0.42 3.60 60 69 75

571 571 212 340 426 791 2340 21.82 0.37 2.73 66 75 81

Figure 2 MS Excel Spreadsheet for the 17 sets of Mixsim results with a selection below

of 5 sets of results for use in company systems.

J D Dewar Consultancy Rev 2 10 October 2003

You might also like

- Daily Production Report Format and ExampleDocument1 pageDaily Production Report Format and ExampleJCS0% (2)

- AdmixtureDocument7 pagesAdmixturevinay rodeNo ratings yet

- Check List Formate DLC & GSBDocument2 pagesCheck List Formate DLC & GSBvinay rode100% (1)

- Remedial Law REVIEWER Atty. Tranquil SalvadorDocument61 pagesRemedial Law REVIEWER Atty. Tranquil SalvadorDPMPascua100% (1)

- Marketing Management Assignment On MelitaDocument17 pagesMarketing Management Assignment On MelitaarjunNo ratings yet

- AL-Yarmouk University Department of Civil Engineering AL-Hijjawi Faculty Highway Laboratory / CE 444Document15 pagesAL-Yarmouk University Department of Civil Engineering AL-Hijjawi Faculty Highway Laboratory / CE 444Mohammed MigdadyNo ratings yet

- Data Pengamatan Dan Hasil Perhitungan HE Revvvvv-1Document16 pagesData Pengamatan Dan Hasil Perhitungan HE Revvvvv-1AhmdMaulanaNo ratings yet

- D12 78 DatasheetDocument2 pagesD12 78 DatasheetAimad LarabiNo ratings yet

- Pressure-Meter Test Analysis Report (ASTM D4719) : Peysanj Geotechnical Engineering SoftwareDocument3 pagesPressure-Meter Test Analysis Report (ASTM D4719) : Peysanj Geotechnical Engineering SoftwaresaidaniNo ratings yet

- Aerasi - AnalysisReportWithMFGResultsDocument13 pagesAerasi - AnalysisReportWithMFGResultseti apriyantiNo ratings yet

- Bbs of All StructureDocument420 pagesBbs of All StructureRitesh kumarNo ratings yet

- Expt 7 - Tesion TestDocument9 pagesExpt 7 - Tesion Testjyoti swaroop repaka100% (1)

- Report#3 Testingthetensilestrengthofmetalsusingtheuniversaltestingmachine Chem1103l Group26Document8 pagesReport#3 Testingthetensilestrengthofmetalsusingtheuniversaltestingmachine Chem1103l Group26MarielleCaindecNo ratings yet

- Compressive and Flexural Test of Mortar PDFDocument9 pagesCompressive and Flexural Test of Mortar PDFHusam RjoubNo ratings yet

- 05 Vega Destiana TRXDocument14 pages05 Vega Destiana TRXvega destianaNo ratings yet

- Design of A Looped Network Using Watercad/Watergems Individual Assignment For Jigjiga StudentsDocument2 pagesDesign of A Looped Network Using Watercad/Watergems Individual Assignment For Jigjiga StudentsARSENo ratings yet

- Agitator Design 5 PDF FreeDocument36 pagesAgitator Design 5 PDF FreeMeisam MomeniNo ratings yet

- Reliable Largo 31-45 compressor designDocument2 pagesReliable Largo 31-45 compressor designBosznay ZoltánNo ratings yet

- Engg Table PDFDocument102 pagesEngg Table PDFAkd DeshmukhNo ratings yet

- EjerciciosDocument13 pagesEjerciciosJimenez Ayala Alan MichelNo ratings yet

- Smart Management System To Predict The Performance of PV in Accordance With Weather Using IotDocument19 pagesSmart Management System To Predict The Performance of PV in Accordance With Weather Using IotkgmaheswaranNo ratings yet

- Round 0: Software Prediction Cust. Survey Adj. To Cust. Score MKT ShareDocument19 pagesRound 0: Software Prediction Cust. Survey Adj. To Cust. Score MKT ShareJasleen Kaur (Ms)No ratings yet

- Complex Engineering Problem (CEP) : Topics CoveredDocument2 pagesComplex Engineering Problem (CEP) : Topics CoveredMaisam Abbas100% (1)

- Terex-Demag AC500-2 Dimensions and SpecsDocument11 pagesTerex-Demag AC500-2 Dimensions and SpecsYay B. GicoNo ratings yet

- Laboratory of Unit Operations: Packed ColumnDocument18 pagesLaboratory of Unit Operations: Packed ColumnNguyễn ThuNo ratings yet

- Simulation of Melt Flow: 4.1 Experimental ApproachDocument14 pagesSimulation of Melt Flow: 4.1 Experimental ApproachvenkithankamNo ratings yet

- Agitator Design: HP CalculationDocument32 pagesAgitator Design: HP CalculationJose Heli Vallejos CoronadoNo ratings yet

- Financial Statement AnalysisDocument18 pagesFinancial Statement AnalysisSabab ZamanNo ratings yet

- Stainless Steel Hex & Socket Head Screw Torque GuideDocument1 pageStainless Steel Hex & Socket Head Screw Torque GuideOrlando RNNo ratings yet

- Torque-Tension Relationship For Stainless Steel F593 CW and F837 CWDocument1 pageTorque-Tension Relationship For Stainless Steel F593 CW and F837 CWgabriel_127971761No ratings yet

- Assignment 3- ( Heat Exchanger )_subDocument17 pagesAssignment 3- ( Heat Exchanger )_subayoob.mohammedNo ratings yet

- BA Da2 22MBA0168Document7 pagesBA Da2 22MBA0168Jayagokul SaravananNo ratings yet

- Torque-Tension Chart For Metric Fasteners PDFDocument1 pageTorque-Tension Chart For Metric Fasteners PDFmhd abdouNo ratings yet

- Tugass BTADocument26 pagesTugass BTAHabib PijarNo ratings yet

- CE327 Lecture 6 Linear Regression Traffic ModelsDocument5 pagesCE327 Lecture 6 Linear Regression Traffic ModelsReinold NdreuNo ratings yet

- Omc MDD Curve - 407-18Document3 pagesOmc MDD Curve - 407-18Manoj KumarNo ratings yet

- Kapasitas DumptruckDocument1 pageKapasitas Dumptruckadien_miningNo ratings yet

- Multi-year demand forecast and production planning comparisonDocument4 pagesMulti-year demand forecast and production planning comparisonDanny ChristianNo ratings yet

- First Review LBCDocument22 pagesFirst Review LBCReethika SNo ratings yet

- DCP TEST RESULTS FOR EACOP PROJECT LOT 4Document1 pageDCP TEST RESULTS FOR EACOP PROJECT LOT 4inno musiimeNo ratings yet

- Salary of Flight Personnel Dummy T-Test: Two-Sample Assuming Unequal VariancesDocument18 pagesSalary of Flight Personnel Dummy T-Test: Two-Sample Assuming Unequal VariancesSiddhant AggarwalNo ratings yet

- Assignment II Numerical Analysis ENEC20003 Term 1 2020: Full Name Student ID Date of Submission MarkDocument4 pagesAssignment II Numerical Analysis ENEC20003 Term 1 2020: Full Name Student ID Date of Submission MarkImranNo ratings yet

- Optimization of Machining Parameters in EDM Process Using Cast and Sintered Copper ElectrodesDocument11 pagesOptimization of Machining Parameters in EDM Process Using Cast and Sintered Copper Electrodesaji setioNo ratings yet

- 1.1. Penentuan Nilai C Dan Kadar Air Cake: Bab I Hasil PercobaanDocument1 page1.1. Penentuan Nilai C Dan Kadar Air Cake: Bab I Hasil PercobaanJuventiaLimantoNo ratings yet

- CVT Gearbox Design for 1.5 Tonne Sled PullDocument9 pagesCVT Gearbox Design for 1.5 Tonne Sled PullVinayakNo ratings yet

- BESS CalculationsDocument8 pagesBESS CalculationsPreetham BharadwajNo ratings yet

- Top-Mech TX Serie Eot Cranes Pricelist-30tdg-Fem2mDocument1 pageTop-Mech TX Serie Eot Cranes Pricelist-30tdg-Fem2mfaisal3arainNo ratings yet

- Dextra: System DescriptionDocument10 pagesDextra: System DescriptionHiba SolimanNo ratings yet

- 600r Bridged-T Attenuator CalculationsDocument2 pages600r Bridged-T Attenuator CalculationsFusaty HadNo ratings yet

- Latihan 2 - ContohDocument14 pagesLatihan 2 - ContohCindy NabillahNo ratings yet

- TX To RX ObstructedDocument5 pagesTX To RX ObstructedKamin AgyaoNo ratings yet

- Mix Designs: #106, Mao Tse Tung BLVD, Khan Chamkamorn, Phnom Penh, Cambodia Tel: + (855-23) 958 958, M: + (855-67) 555 721Document1 pageMix Designs: #106, Mao Tse Tung BLVD, Khan Chamkamorn, Phnom Penh, Cambodia Tel: + (855-23) 958 958, M: + (855-67) 555 721Vorn Ra VuthNo ratings yet

- Results of Stokes' Law experiment on sand particle size distributionDocument3 pagesResults of Stokes' Law experiment on sand particle size distributionSubhradip RoychowdhuryNo ratings yet

- NotyetdoneDocument9 pagesNotyetdoneJoshua RamirezNo ratings yet

- Comparative Study Offset PaperDocument4 pagesComparative Study Offset PaperKai FaheemNo ratings yet

- Bored pile capacity design parametersDocument13 pagesBored pile capacity design parametersFrederick TanNo ratings yet

- HDT/GPT/TWP: ApplicationsDocument1 pageHDT/GPT/TWP: Applicationshui luoNo ratings yet

- Autos Buses Camiones: Chart TitleDocument7 pagesAutos Buses Camiones: Chart TitleLuis CarlosNo ratings yet

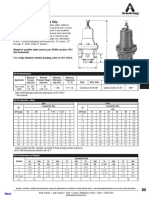

- Armstrong-Reducing Valves GD-24Document1 pageArmstrong-Reducing Valves GD-24Wesley andrade martinsNo ratings yet

- Finite Element Programs in Structural Engineering and Continuum MechanicsFrom EverandFinite Element Programs in Structural Engineering and Continuum MechanicsNo ratings yet

- Technical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionFrom EverandTechnical Tables for Schools and Colleges: The Commonwealth and International Library Mathematics DivisionNo ratings yet

- Profile of the International Pump Industry: Market Prospects to 2010From EverandProfile of the International Pump Industry: Market Prospects to 2010Rating: 1 out of 5 stars1/5 (1)

- Empirical Dynamic Asset Pricing: Model Specification and Econometric AssessmentFrom EverandEmpirical Dynamic Asset Pricing: Model Specification and Econometric AssessmentRating: 4.5 out of 5 stars4.5/5 (3)

- Concrete Repair: Bullivant Arabia LTDDocument5 pagesConcrete Repair: Bullivant Arabia LTDvinay rodeNo ratings yet

- Bomanite Stamped Concrete Presentation Compatibility Mode 2Document9 pagesBomanite Stamped Concrete Presentation Compatibility Mode 2vinay rodeNo ratings yet

- Glenium 7700 Data Sheet 1.08Document2 pagesGlenium 7700 Data Sheet 1.08SivakumarNo ratings yet

- Chapter 16Document12 pagesChapter 16vinay rodeNo ratings yet

- City of Geraldton-Greenough Crossover SpecsDocument8 pagesCity of Geraldton-Greenough Crossover Specsvinay rodeNo ratings yet

- Concrete Technology and Durability DesignDocument16 pagesConcrete Technology and Durability DesignAhmed OssamaNo ratings yet

- Chapter 9Document14 pagesChapter 9vinay rodeNo ratings yet

- Concrete PumpsDocument6 pagesConcrete Pumpsvinay rode100% (1)

- Crack & Strength Reinforced Concrete Beams with Carbon FiberDocument7 pagesCrack & Strength Reinforced Concrete Beams with Carbon Fibervinay rodeNo ratings yet

- Concrete TechnologyDocument9 pagesConcrete TechnologyV. ManilalNo ratings yet

- Concrete ManualDocument11 pagesConcrete ManualRhiYo LinkYo SabuaYoNo ratings yet

- Test Method For Flow of Grout Mixtures (Flow Cone Method)Document2 pagesTest Method For Flow of Grout Mixtures (Flow Cone Method)vinay rodeNo ratings yet

- Topic No.: 675-000-000 Materials Manual Superpave Mix Design Manual March 29, 2005Document56 pagesTopic No.: 675-000-000 Materials Manual Superpave Mix Design Manual March 29, 2005vinay rodeNo ratings yet

- Improvement of Concrete Durability by Complex Mineral Super-Fine PowderDocument9 pagesImprovement of Concrete Durability by Complex Mineral Super-Fine Powdervinay rodeNo ratings yet

- Soil Stiffness Gauge For Soil Compaction ControlDocument6 pagesSoil Stiffness Gauge For Soil Compaction Controlvinay rodeNo ratings yet

- Concrete pavement construction basics guideDocument12 pagesConcrete pavement construction basics guideAbhijeet LimayeNo ratings yet

- View File1 PDFDocument15 pagesView File1 PDFvinay rodeNo ratings yet

- Chapter 04Document12 pagesChapter 04April RobinsonNo ratings yet

- HMA Mixture Design: SuperpaveDocument30 pagesHMA Mixture Design: Superpavevinay rodeNo ratings yet

- Subsurface Exploration Guidelines for Barrages and WeirsDocument14 pagesSubsurface Exploration Guidelines for Barrages and Weirsvinay rodeNo ratings yet

- Zuper Cote Bitumen Enmulsion PresentationDocument61 pagesZuper Cote Bitumen Enmulsion Presentationvinay rodeNo ratings yet

- Tip 15 - Chemical Admixtures For ConcreteDocument2 pagesTip 15 - Chemical Admixtures For Concretevinay rodeNo ratings yet

- V1N4Document5 pagesV1N4vinay rodeNo ratings yet

- Flexible Gabion Wall'S Key Role On R61: Geotechnical Engineering Gravity Retaining Walls Ntafufu, Port ST Johns, E. CapeDocument2 pagesFlexible Gabion Wall'S Key Role On R61: Geotechnical Engineering Gravity Retaining Walls Ntafufu, Port ST Johns, E. Capevinay rodeNo ratings yet

- Micro-Surfacing Construction Inspection GuidelinesDocument12 pagesMicro-Surfacing Construction Inspection Guidelinesvinay rodeNo ratings yet

- MTAG Volume II - Rigid Pavement Preservation DefinitionsDocument31 pagesMTAG Volume II - Rigid Pavement Preservation Definitionsvinay rodeNo ratings yet

- EM 1110-2-2102 Chapter 6 QA Testing and Specs for WaterstopsDocument1 pageEM 1110-2-2102 Chapter 6 QA Testing and Specs for Waterstopsvinay rodeNo ratings yet

- T & B Structural Systems Gabion Wire Wall System: General NotesDocument5 pagesT & B Structural Systems Gabion Wire Wall System: General Notesvinay rodeNo ratings yet

- Activity 9 - Invitations Valentina Muñoz AriasDocument2 pagesActivity 9 - Invitations Valentina Muñoz AriasValentina Muñoz0% (1)

- Negotiation Self-Assessment and Vision Report - by Umang DharDocument1 pageNegotiation Self-Assessment and Vision Report - by Umang Dharumangdhar8No ratings yet

- Fundamentals of Procure To PayDocument254 pagesFundamentals of Procure To Paysweetshene100% (3)

- Picasso's Blue Period - WikipediaDocument24 pagesPicasso's Blue Period - WikipediaDinesh RajputNo ratings yet

- Unit 5 - Standard TestDocument5 pagesUnit 5 - Standard Testma rika100% (1)

- Effect of Low Pressure Alkaline Delignification Process On TheDocument15 pagesEffect of Low Pressure Alkaline Delignification Process On Thenurshiyama89No ratings yet

- Noor Ahmed: H.No.4-12-108/2, MM. Pahadi, Rajendra Nagar, Hyderabad-500 049Document2 pagesNoor Ahmed: H.No.4-12-108/2, MM. Pahadi, Rajendra Nagar, Hyderabad-500 049SonuKhaderNo ratings yet

- The Examiner of Alternative MedicineDocument4 pagesThe Examiner of Alternative MedicineLee Ming HinNo ratings yet

- Sex Work in Cyberspace Who Pays The PriceDocument14 pagesSex Work in Cyberspace Who Pays The PriceйцукеячсмNo ratings yet

- Essay Assessment CriteriaDocument1 pageEssay Assessment CriteriaNguyen Quynh AnhNo ratings yet

- U2000 & PRS Operation Introduce V1.0Document25 pagesU2000 & PRS Operation Introduce V1.0Nam PhamNo ratings yet

- NDA Strategic PlanDocument222 pagesNDA Strategic PlanJudith AinembabaziNo ratings yet

- Artificer Infusions: Boots of The Winding PathDocument6 pagesArtificer Infusions: Boots of The Winding PathKylisseNo ratings yet

- C01 Globalisation: The Global Village?Document21 pagesC01 Globalisation: The Global Village?Mat RoyNo ratings yet

- Certificates Search For King and Queen 2019Document13 pagesCertificates Search For King and Queen 2019Kebu YenNo ratings yet

- Chapter 4Document26 pagesChapter 4Kritika JainNo ratings yet

- Ejercicio de Writing Formal EmailsDocument4 pagesEjercicio de Writing Formal EmailsArianna ContrerasNo ratings yet

- ARTS8 Q4 MOD2Document32 pagesARTS8 Q4 MOD2eoghannolascoNo ratings yet

- GSN April Meeting Explores Tasiast Gold Deposit DiscoveryDocument18 pagesGSN April Meeting Explores Tasiast Gold Deposit DiscoveryarisNo ratings yet

- Edexcel Igcse Physics 4ph1 Theory v1Document18 pagesEdexcel Igcse Physics 4ph1 Theory v1farhadmustafa128No ratings yet

- Land Titling and Transfer Legal Services in Trece Martirez and DasmarinasDocument1 pageLand Titling and Transfer Legal Services in Trece Martirez and DasmarinasMark RyeNo ratings yet

- Familymart in China The Divorce of A 20year International PartnershipDocument11 pagesFamilymart in China The Divorce of A 20year International Partnershipsonali mahajan 833No ratings yet

- Meridian Analysis Energy DeviceDocument4 pagesMeridian Analysis Energy Devicehistory APNo ratings yet

- Black Magic v03n04 1967-01.american Art AgencyDocument82 pagesBlack Magic v03n04 1967-01.american Art AgencyJulieta de la HuertaNo ratings yet

- 20 Common Defense Mechanisms for AnxietyDocument8 pages20 Common Defense Mechanisms for AnxietyAbhishek NegiNo ratings yet

- Order Setting Trial - State V Matthew J. Wessels - Fecr012392Document22 pagesOrder Setting Trial - State V Matthew J. Wessels - Fecr012392thesacnewsNo ratings yet

- Catalogo Tecnico Toyota BT Staxio P Series SPE120 200Document4 pagesCatalogo Tecnico Toyota BT Staxio P Series SPE120 200Asesor ComercialNo ratings yet

- Revised Revenue Code of Puerto Galera 2010Document157 pagesRevised Revenue Code of Puerto Galera 2010Jesselle MamintaNo ratings yet