Professional Documents

Culture Documents

Small-Hole Drilling Tools

Uploaded by

Subhash KediaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Small-Hole Drilling Tools

Uploaded by

Subhash KediaCopyright:

Available Formats

m

Small-hole Drilling Tools

co

s.

Integral Drill Steels

ll

Integral Drill Steels are a fixed length with a shank

ri

at one end and a bit at the other, and are able to

drill to a depth equivalent to their effective length.

ed

The bit may consist of a single chisel shaped

tungsten carbide insert or four such inserts. This

ac

provides a hexagonal chuck section to provide

leverage for the rotation chuck bushing. It usually

w.

has a forged collar to maintain the proper shank

striking face position in the rock drill and bit end. Holes are typically drilled in 0.4m increments to accommodate

ww

the air-leg feed length. To drill deep holes, the rods are designed to be used in a series where the length of any rod

used is longer than the one used just before it. (The drilled steel is then extracted and followed with a slightly

smaller diameter bit on the next steel length in the sequence). To do this, a series of rods must be produced so that

m

the bit diameter is reduced for each increase in length of rod to prevent jamming of the bit in the hole.

co

Integral Drill Steel is mainly used by a hand held drill machine in stone quarrying, foundation drilling, and

s.

underground mining and so on, and for small-hole drilling, equipped with small power rock drills, like air leg rock

drills, hand held rock drills, etc. It can reduces the expense of impact energy, improves the drilling speed and

ll

efficiency.

ri

Acedrills’ Integral Drill Steels are normally produced from 19mm (3/4”), 22mm (7/8”) or 25mm (1”) Hexagon Drill

Steel, where the dimensions given are measured across the flat of the hexagon, and length from 400mm (1’4”) up to

ed

9,600mm (31’ 6”) with a bit diameter from 23 to 45mm.

ac

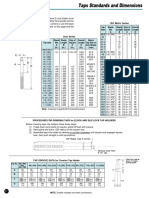

The table shown below indicates some of the most commonly used and produced integral drill steels, for other bit

w.

diameters and lengths please contact us:

ww

Length Head diameter Weight

Hex19 Integral Drill Steels Series Part No.

mm Foot mm Inch Kg Lb

om

400 1’ 4” 29 1 9/64 1.3 2.9 211-0429,21

500 1’ 8” 29 1 9/64 1.5 3.3 211-0529,21

c

800 2’ 7” 28 1 7/64 2.2 4.9 211-0828,21

s.

Hex19 x 108 mm (3/4” x 4 1/4”) Shank, 1000 3’ 3 3/8” 28 1 7/64 2.6 5.7 211-1028,21

Chisel Bit Type 21 1200 3’ 11” 27 1 1/16 3 6.6 211-1227,21

ll

1600 5’ 3” 27 1 1/16 3.9 8.6 211-1627,21

2400 7’ 10” 26 1 1/32 5.7 13 211-2426,21

i

3200 10’ 6” 25 63/64 7.5 17 211-3225,21

dr

4000 13’ 1” 24 5/16 9.2 20 211-4024,21

400 1’ 4” 24 5/16 1.3 2.9 211-0424,22

e

22

800 2’ 7” 23 27/32 2.2 4.9 211-0823,22

ac

1

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

600 1’ 11 5/8” 27 1 1/16 1.7 3.8 211-0627,24

1200 3’ 11” 26 1 1/32 3 6.6 211-1226,24

ll

24 2000 6’ 7” 24 5/16 4.8 11 211-2024,24

2400 7’ 10” 24 5/16 5.7 13 211-2424,24

ri

2700 8'10” 24 5/16 6.3 14 211-2724,24

400 1’ 4” 35 1 3/8 1.3 2.9 211-0435,25

ed

25

800 2’ 7” 34 1 11/32 2.2 4.9 211-0834,25

Length Head diameter Weight

ac

Hex22 Integral Drill Steels Series Part No.

mm Foot mm Inch Kg Lb

800 2’7” 34 1 11/32 2.8 6.2 213-0834,11

w.

1600 5’3” 33 1 19/64 5.2 12 213-1633,11

2400 7’10” 32 1 17/64 7.7 17 213-2432,11

ww

3200 10’6” 31 1 7/32 10 23 213-3231,11

11 4000 13’1” 30 1 3/16 13 28 213-4030,11

m

4800 15’9” 29 1 9/64 15 33 213-4829,11

co

5600 18’4” 28 1 7/64 18 39 213-5628,11

6400 21’ 27 1 1/16 20 44 213-6427,11

s.7200

400

23’6”

1’ 4”

26

41

1 1/32

1 39/64

23

1.6

50

3.5

213-7226,11

213-0441,12

ll

800 2’ 7” 40 1 37/64 3 6.6 213-0840,12

1600 5’3” 39 1 17/32 5.2 12 213-1639,12

ri

2400 7’10” 38 1 1/2 8 18 213-2438,12

Hex22 x 108 mm (7/8” x 4 1/4”) Shank, 12 3200 10’6” 37 1 29/64 10 23 213-3237,12

ed

Chisel Bit Type 4000 13’1” 36 1 27/64 13 28 213-4036,12

4800 15’9” 35 1 3/8 15 33 213-4835,12

ac

5600 18’4” 34 1 11/32 18 39 213-5634,12

6400 21’ 33 1 19/64 20 44 213-6433,12

w.

400 1’4” 34 1 11/32 1.7 3.7 213-0434,13

800 2’7” 33 1 19/64 3 6.6 213-0833,13

ww

13 1200 3’11” 32 1 17/64 4.1 9 213-1232,13

1600 5’3” 31 1 7/32 5.2 12 213-1631,13

om

2000 6’7” 30 1 3/16 6.7 15 213-2030,13

600 1’ 11 5/8” 35 1 3/8 2.4 5.3 213-0635,16

c

1200 3’11” 34 1 11/32 4.3 9.5 213-1234,16

s.

16

1800 5’11” 33 1 19/64 6.2 14 213-1833,16

2400 7’10” 32 1 17/64 8 18 213-2432,16

ll

600 2’ 41 1 39/64 2.4 5.3 213-0641,17

1200 3’11” 40 1 37/64 4.3 9.5 213-1240,17

i

17

1800 5’11” 39 1 17/32 6.2 14 213-1839,17

dr

2400 7’10” 38 1 1/2 8 18 213-2438,17

e

ac

2

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

800 2’7” 29 1 9/64 3 6.6 213-0829,N

ll

800 2’7” 38 1 1/2 3.1 6.8 213-0838,N

1200 3’11” 39 1 17/32 4.3 9.5 213-1239,N

ri

Hex22 x 108 mm (7/8” x 4 1/4”) Shank, 1600 5’3” 36 1 27/64 5.2 12 213-1636,N

Chisel Bit Type 1800 5’11” 36 1 27/64 6 13 213-1836,N

ed

2000 6’7” 32 1 17/64 6.7 15 213-2032,N

2400 7’10” 27 1 1/16 8 18 213-2427,N

ac

3200 10’6” 27 1 1/16 10 23 213-3227,N

3200 10’6” 32 1 17/64 10 23 213-3232,N

w.

6400 21’ 30 1 3/16 20 44 213-6430,N

7200 23’6” 32 1 17/64 23 50 213-7232,N

ww

8000 26’2” 26 1 1/32 25 55 213-8026,N

Length Head diameter Weight

Hex25 Integral Drill Steels Series Part No.

mm Foot mm Inch Kg Lb

m

600 1’ 11 5/8” 36 1 27/64 3 6.6 214-0636,31

co

1200 3’11” 35 1 3/8’ 5.5 12 214-1235,31

31

s.1800

2400

5’11”

7’10”

34

33

1 11/32

1 19/64

7.8

10

17

23

214-1834,31

214-2433,31

ll

800 2’ 7” 42 1 21/32 3.8 8.4 214-0842,32

1600 5’ 3” 41 1 5/8 6.9 15 214-1641,32

ri

2400 7’ 10’ 40 1 37/64 10 23 214-2440,32

Hex25 x 108 mm (1” x 4 1/4”) Shank,

3200 10’6” 40 1 37/64 14 31 214-3240,32

Chisel Bit Type

ed

3600 11’ 10” 39 1 17/32 15 33 214-3639,32

32

3200 10’ 6” 39 1 17/32 14 31 214-3239,32

ac

4000 13’ 1” 38 1 1/2 16 36 214-4038,32

4800 15’ 9” 37 1 29/64 20 44 214-4837,32

w.

5600 18’ 4” 36 1 27/64 23 50 214-5636,32

6400 21’ 35 1 3/8 26 57 214-6435,32

ww

600 1’ 11 5/8” 45 1 25/32 3.1 6.8 214-0645,N

1200 3’ 11” 44 1 47/64 5.8 13 214-1244,N

om

1800 5’ 11” 43 1 45/64 7.8 17 214-1843,N

2400 7’ 10” 42 1 21/32 10 22 214-2442,N

c

Length Head diameter Weight

Series Part No.

s.

mm Foot mm Inch Kg Lb

Hex25 x 159 mm (1” x 6 1/4”) Shank, 3200 10’6” 40 1 37/64 14 30 215-3240,32

ll

Chisel Bit Type 3200 10’6” 39 1 17/32 18 40 215-3239,32

3600 11’ 10” 39 1 17/32 18 40 215-3639,32

i

32 4000 13’1” 38 1 1/2 17 38 215-4038,32

dr

4800 15’9” 37 1 29/64 20 45 215-4837,32

5600 18’4 36 1 27/64 23 51 215-5636,32

e

6400 21’ 35 1 3/8’ 26 58 215-6435,32

ac

3

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

800 2’ 7” 42 1 21/32 4 8.8 215-0842,N

1600 5’ 3” 41 1 5/8 7.2 16 215-1641,N

ll

2400 7’ 10” 40 1 1/4 10 23 215-2440,N

Hex25 x 159 mm (1” x 6 1/4”) Shank,

2400 7’ 10” 38 1 27/64 10 23 215-2438,N

Chisel Bit Type

ri

2400 7’ 10” 36 1 1/2 10 23 215-2436,N

2400 7’ 10” 32 1 37/64 10 23 215-2432,N

ed

3200 10’ 6” 40 1 19/64 14 30 215-3240,N

3200 10’ 6” 35 1 3/8 14 30 215-3235,N

ac

3200 10’ 6” 33 1 37/64 14 30 215-3233,N

3600 11’ 10” 35 1 3/8 15 34 215-3635,N

w.

4000 13’ 1” 35 1 3/8 17 37 215-4035,N

How to order?

ww

Shank Style + Effective Length + Bit Diameter

m

Guide Tips for Integral Drill Steels

co

To optimize the performance of integral drill steels, attention should be paid to:

s.

1. Choose suitable integral drill steels according to different work condition: cross bit type for hard, abrasive and

easy-stuck rock formation, while chisel bit type for soft formation.

ll

2. Drill stably and turn down the work pressure when open a new hole, then turn up the pressure to normal level

after drill to 150mm deep; or it may lead to carbide damage, due to partially over loaded.

ri

3. When need to drill to more than 2000mm deep holes, using series integral drill steels will be necessary to

improve service life of each, among which the short drill steels are for opening new holes while longer steels for

ed

drilling deeper.

4. Adjust the output of the compressor depend on different rock formation. Keep normal rotary speed and high

ac

penetration, and make sure the drill steel is straight and the flushing is normal.

5. When bulk of premature failure (failure in shank, collar, or rod breakage, etc.) arise, please stop using all the rest

w.

drill steels and then notify us promptly with the following information:

1) Air compressor brand and model, normal and maximum pressure output, storage capacity and quantity of

ww

rock drills that matched with this compressor;

2) Rock drills brand and model, air pressure, air consumption and water pressure;

om

3) Rock formation type and hardness (with uniaxial compressive strength or Protodyakonov hardness scale);

work site condition: surface, underground, tunnel or other); drill-hole depth and drilling methods: down,

c

horizontal, fan and others;

s.

4) Actually average life in using;

5) Drilling life of equivalent drill steels of other brands under same work condition;

ll

6) Premature Failure Statistics:

A, Specified failure part, service life, quantity;

i

B, Carbide condition (left height).

e dr

ac

4

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

Plug-Hole Integral Steels

ll

The plug hole integral drill steel is widely used in stone pit field to drill small holes. Because of the integration of

ri

the drilling rods and drilling bits, it can be matched directly with rock drills without shank adapter or coupling

sleeve, these advantages avoid the wastage of energy, and improve the drilling efficiency remarkably.

ed

Length Head Diameter Turned Length Weight

Plug Hole Integral Steels Part No.

ac

mm Inch mm Inch mm Inch Kg Lb

210 8 1/8 17 21/32 150 6 0.7 1.54 216-2117

w.

210 8 1/8 20 25/32 150 6 0.7 1.54 216-2120

210 8 1/8 22 7/8 150 6 0.7 1.54 216-2122

ww

220 8 43/64 20 25/32 160 6 1/4 0.7 1.54 216-2220

Hex19 x 108 mm (3/4” x 4 1/4”) Shank 220 8 43/64 22 7/8 160 6 1/4 0.7 1.54 216-2222

250 9 27/32 22 7/8 190 7 1/2 0.8 1.76 216-2522

m

260 10 15/64 20 25/32 200 7 7/8 0.8 1.76 216-2620

co

260 10 15/64 22 7/8 200 7 7/8 0.8 1.76 216-2622

300 11 13/16 20 25/32 240 9 29/64 0.8 1.76 216-3020

310

s.

11 1/4 22 7/8 250 9 27/32 0.9 1.98 216-3122

340 13 25/64 20 25/32 280 11 1/32 1 2.2 216-3420

ll

370 14 9/16 20 7/8 310 11 1/4 1 2.2 216-3720

ri

260 10 15/64 23 27/32 200 7 7/8 0.8 1.8 217-2623

Hex22 x 108 mm (7/8” x 4 1/4”) Shank

320 12 19/32 23 27/32 260 10 15/64 1 2.2 217-3223

ed

360 14 11/64 23 27/32 300 11 13/16 1.2 2.6 217-3623

410 16 9/64 23 27/32 350 13 25/32 1.4 3.1 217-4123

ac

600 23 5/8 26 1 1/32 540 21 17/64 2.1 4.6 217-6026

How to order?

w.

Shank Style + Turned Length + Head Diameter

ww

c om

s.

i ll

e dr

ac

5

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

Taper Drilling Tools

ll

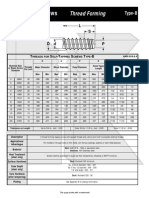

Tapered drill equipment also provides a

ri

hexagonal chuck section to provide leverage

for the rotation chuck bushing, which usually

ed

has a forged collar to maintain the proper

shank striking face position in the rock drill,

ac

and match a tapered bit at the socket end.

With higher faster penetration, straighter

w.

holes, longer service life and lower cost per

meter drilled than integral steel, tapered drill equipment is grabbing market share from integral drill steel,

ww

especially in mining applications and the dimensional stone industry.

Different rock formations and rock drills require different taper angles. When drilling with high impact hydraulic

m

rock drills in medium-hard to hard and abrasive rock formations, a wide taper angle is normally used. Taper angles

co

of 11º and 12º are normally used on modern drill rigs. For low impact rock drills and softer rock formations, a

narrow taper angle of seven degrees is used. A 7º angle can also be used if bit spinning is a problem when using 11

s.

and 12-degree equipment. In addition, a 4.8º (also 4º46’) angle is ideal for soft rock when you're using pneumatic

or hydraulic drill rigs - to prevent bits from spinning or becoming detached.

ll

Acedrills’ tapered steel lengths available from 600mm (2’) to 11,200mm (36’ 8”), (measured from the collar to the

ri

tapered end). Holes are typically drilled in 0.6 m increments to accommodate the air-leg feed length. Besides, we

also offers various cutting structures design configurations, include chisel bits, cross bits and button bits, for an

ed

extensive and diverse selection. These designs can be used in a variety of rock formations for maximum

productivity, high penetration rate and long service life.

ac

w.

The table shown below indicates some of the most commonly used and produced taper drive drill equipments,

including chisel bits, cross bits, button bits and taper drill rods, for those tools of other specifications, please contact

ww

us:

om

Horseshoe Chisel Bit Oblique Chipways Chisel Bits

Taper Chisel Bits

c

s.

Diameter For class Tip size (mm) Weight Weight

Taper Part No. Part No.

ll

mm inch of rock H. × W. Kg Lb Kg Lb

28 1 7/64 10-14 13×8 7° 0.19 0.42 114-0728-32,M

i

30 1 3/16 10-14 13.5×8 7° 0.22 0.49 114-0730-01,M 0.22 0.49 114-0730-33,M

dr

32 1 1/4 8-12 13.5×8 7° 0.24 0.53 114-0732-02,A

32 1 1/4 10-14 13.5×8 7° 0.24 0.53 114-0732-03,M 0.24 0.53 114-0732-34,M

e

33 1 19/64 10-14 13.5×8 7° 0.25 0.55 114-0733-35,M

ac

34 1 11/32 8-12 13.5×8 7° 0.27 0.6 114-0734-04,A

6

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

34 1 11/32 10-14 13.5×8 7° 0.27 0.6 114-0734-05,M 0.27 0.6 114-0734-36,M

36 1 27/64 8-12 13.5×8 7° 0.3 0.66 114-0736-06,A

ll

36 1 27/64 10-14 13.5×8 7° 0.3 0.66 114-0736-07,M 0.29 0.64 114-0736-37,M

38 1 1/2 8-12 13.5×8 7° 0.33 0.73 114-0738-08,A

ri

38 1 1/2 10-14 13.5×8 7° 0.33 0.73 114-0738-09,M 0.34 0.75 114-0738-38,M

38 1 1/2 8-12 15×9 7° 0.33 0.73 114-0738-10,A

ed

38 1 1/2 10-14 15×9 7° 0.33 0.73 114-0738-11,M

40 1 37/64 8-12 13.5×9.2 7° 0.38 0.84 114-0740-12,A

ac

40 1 37/64 10-14 13.5×9.2 7° 0.38 0.84 114-0740-13,M 0.4 0.88 114-0740-39,M

40 1 37/64 14-16 13.5×9.2 7° 0.38 0.84 114-0740-14,N

w.

40 1 37/64 16-18 13.5×9.2 7° 0.38 0.84 114-0740-15,E

40 1 37/64 8-12 15×9.8 7° 0.38 0.84 114-0740-16,A

ww

40 1 37/64 10-14 15×9.8 7° 0.38 0.84 114-0740-17,M

40 1 37/64 14-16 15×9.8 7° 0.38 0.84 114-0740-18,N

40 1 37/64 16-18 15×9.8 7° 0.38 0.84 114-0740-19,E

m

41 1 5/8 10-14 13.5×9.2 7° 0.41 0.9 114-0741-40,M

co

42 1 2/3 8-12 13.5×9.2 7° 0.41 0.9 114-0742-20,A

42 1 21/32 10-14 13.5×9.2 7° 0.41 0.9 114-0742-21,M 0.43 0.95 114-0742-41,M

42

42

1 21/32

1 21/32

14-16

16-18

13.5×9.2

13.5×9.2

7°

7°

0.41

0.41

s. 0.9

0.9

114-0742-22,N

114-0742-23,E

ll

42 1 21/32 8-12 15×9.8 7° 0.41 0.9 114-0742-24,A

42 1 21/32 10-14 15×9.8 7° 0.41 0.9 114-0742-25,M

ri

42 1 21/32 10-14 15×9.8 7° 0.41 0.9 114-0742-26,M

42 1 21/32 16-18 15×9.8 7° 0.41 0.9 114-0742-27,E

ed

43 1 11/16 8-12 13.5×9.2 7° 0.42 0.93 114-0743-28,A

43 1 11/16 10-14 13.5×9.2 7° 0.42 0.93 114-0743-29,M

ac

43 1 11/16 8-12 15×9.8 7° 0.42 0.93 114-0743-30,A

43 1 11/16 10-14 15×9.8 7° 0.42 0.93 114-0743-31,M

w.

How to order?

Bit Diameter + Taper Degree + Socket Diameter

ww

Notes:

om

1. The ordinary connection taper degree is 7º, customized degrees are also available, such as: 4.8º, 6º, 11º, 12º;

2. The ordinary taper diameter is 23mm, 24mm or other dimensions are also available if upon customers’ request;

c

3. Carbide alloy grades: there are usually A, M, N and E types, which should be selected depend on the rock

s.

formation situation, and you could refer to the recommended table in the following:

4. All carbide inserts also come with three designs in height for option: high, medium, short.

i ll

e dr

ac

7

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

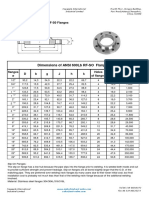

Carbide Alloy Grades Recommended Table

ll

Alloy Protodyakonov

Formation Types Rock Types Recommended Sites

Grade Hardness Scale (f)

ri

soft rock, Limestone, Migmatitic granite, Coal mine, Quarry, some metal mine

A f<13

medium-hard Gneiss etc.

ed

Granite, Magnitite, Poor iron, Gold, Iron, Copper mine, engineering

M Hard to very hard f<16

Quartzite construction etc.

ac

very hard, and Hard quartzite, Hematite, Hard Metal mine and Engineering

N f=16~17

abrasive sandstone construction etc.

w.

Hard rock, very hard Magnitite, Hard quartzite, silicified Gold, Iron, Copper and nonferrous

E f<18

and extremely hard rock, Hard granite etc. metals mine etc.

ww

Taper Cross-Type Bits:

m

co

Diameter

Tip size

Flushing hole

7° Taper

s. 11° Taper 12° Taper

ll

(mm) Weight Weight Weight

Part No. Part No. Part No.

mm inch H. × W. Front Side Kg Lb Kg Lb Kg Lb

ri

29 1 9/64 12×8 1 2 0.25 0.55 113-1129-01 0.25 0.55 113-1229-01

30 1 3/16 12×8 1 2 0.3 0.6 113-0730-01 0.26 0.57 113-1130-02 0.26 0.57 113-1230-02

ed

32 1 1/4 12×8 1 2 0.3 0.7 113-0732-02 0.3 0.66 113-1132-03 0.3 0.66 113-1232-03

33 1 19/64 12×8 1 2 0.3 0.7 113-0733-03 0.32 0.71 113-1133-04 0.32 0.71 113-1233-04

ac

34 1 11/32 12×8 1 2 0.3 0.8 113-0734-04

35 1 3/8 12×8 1 2 0.4 0.8 113-0735-05 0.36 0.79 113-1135-05 0.36 0.79 113-1235-05

w.

36 1 27/64 12×8 1 2 0.4 0.8 113-0736-06 0.39 0.86 113-1136-06 0.39 0.86 113-1236-06

38 1 1/2 12×8 1 2 0.4 1 113-0738-07 0.43 0.95 113-1138-07 0.43 0.95 113-1238-07

ww

40 1 37/64 12×8 1 2 0.5 1 113-0740-08 0.46 1.01 113-1240-08

41 1 5/8 14×8 1 2 0.5 1.1 113-0741-09 0.49 1.08 113-1141-08 0.49 1.08 113-1241-09

42 1 21/32 14×8 1 2 0.5 1.1 113-0742-10

om

43 1 11/16 14×8 1 2 0.5 1.2 113-0743-11

45 1 3/4 14×8 1 2 0.6 1.3 113-0745-12

c

48 1 7/8 14×8 1 2 0.7 1.5 113-0748-13

s.

50 1 31/32 16×8 1 2 0.7 1.6 113-0750-14

How to order?

ll

Bit Diameter + Taper Degree + Socket Diameter

i

Notes:

dr

1. The ordinary connection taper degree is 7º, 11º and 12º, other degrees like 4.8º and 6º are also available;

2. The ordinary taper diameter is 23mm, 24mm or other dimensions are also available if upon customers’ request.

e

ac

8

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

Taper Short Skirt Button Bits:

ll

No. × button diameter

Diameter Flushing hole Weight 7° Taper 11° Taper 12° Taper

ri

(mm)

mm inch Front Gauge Angle Front Side Kg Lb Part No. Part No. Part No.

ed

28 1 7/64 1×7 3×7 20° 1 1 0.2 0.44 111-1228-1301,S

28 1 7/64 1×7 4×7 35° 1 1 0.2 0.44 111-1228-1402,S

ac

29 1 9/64 1×7 3×7 40° 1 1 0.21 0.46 111-1229-1303,S

30 1 3/16 1×7 3×7 40° 1 1 0.22 0.49 111-1230-1304,S

w.

30 1 3/16 1×7 4×7 35° 1 1 0.22 0.49 111-1230-1405,S

32 1 1/4 1×8 3×8 35° 1 1 0.24 0.53 111-0732-1301,S

ww

32 1 1/4 1×8 3×8 35° 1 2 0.24 0.53 111-1132-1301,S

32 1 1/4 2×7 4×7 35° 1 1 0.22 0.49 111-1232-2406,S

32 1 1/4 2×7 5×7 40° 1 1 0.24 0.53 111-1132-2502,S

m

33 1 19/64 2×7 4×7 40° 1 1 0.25 0.55 111-1133-2403,S

co

33 1 19/64 2×7 5×7 35° 2 1 0.26 0.57 111-0733-2502,S 111-1233-2507,S

34 1 11/32 2×7 4×7 40° 1 1 0.29 0.64 111-0734-2403,S 111-1134-2404,S

34 1 11/32 2×7 5×7 35° 1 1 0.33

s.0.73 111-1234-2508,S

35 1 3/8 2×7 5×7 35° 1 1 0.33 0.73 111-1135-2505,S

ll

35 1 3/8 2×7 5×8 35° 1 1 0.33 0.73 111-0735-2504,S 111-1135-2506,S 111-1235-2509,S

35 1 3/8 2×7 5×9 35° 1 1 0.33 0.73 111-1235-2510,S

ri

35 1 3/8 2×7 5×9 35° 2 1 0.33 0.73 111-1235-2511,S

36 1 27/64 1×8 3×9 40° 1 1 0.37 0.82 111-0736-1305,S 111-1136-1307,S

ed

36 1 27/64 2×7 4×7 40° 1 1 0.36 0.79 111-1136-2408,S

ac

36 1 27/64 2×7 5×8 35° 1 1 0.37 0.82 111-0736-2506,S 111-1136-2509,S

36 1 27/64 2×7 5×9 35° 1 1 0.37 0.82 111-1236-2512,S

w.

37 1 29/64 2×7 5×9 40° 1 1 0.38 0.84 111-1237-2513,S

38 1 1/2 1×8 3×9 35° 1 1 0.38 0.84 111-0738-1307,S

ww

38 1 1/2 1×9 3×9 40° 1 1 0.39 0.86 111-1138-1310,S 111-1238-1314,S

38 1 1/2 2×7 5×8 35° 1 1 0.38 0.84 111-0738-2508,S

38 1 1/2 2×8 3×9 40° 1 1 0.39 0.86 111-1138-2311,S

om

38 1 1/2 2×7 5×9 40° 2 1 0.38 0.84 111-0738-2509,S

38 1 1/2 2×9 5×8 35° 1 1 0.39 0.86 111-1138-2512,S

c

38 1 1/2 2×7 5×9 35° 1 1 0.4 0.88 111-1138-2513,S 111-1238-2515,S

s.

40 1 37/64 1×8 3×9 30° 1 1 0.4 0.88 111-0740-1310,S

40 1 37/64 1×9 3×9 35° 1 1 0.4 0.88 111-0740-1312,S

ll

40 1 37/64 1×9 3×9 40° 1 1 0.4 0.88 111-1140-1314,S

40 1 37/64 1×9 3×10 30° 1 1 0.4 0.88 111-0740-1311,S

i

40 1 37/64 2×8 3×9 40° 1 1 0.4 0.88 111-1140-2315,S

dr

40 1 37/64 2×9 3×9 40° 1 2 0.4 0.88 111-1140-2316,S

40 1 37/64 2×7 5×9 35° 1 1 0.4 0.88 111-0740-2513,S 111-1140-2517,S

e

40 1 37/64 2×8 5×9 35° 1 1 0.4 0.88 111-1140-2518,S

ac

41 1 5/8 2×7 5×9 35° 1 1 0.41 0.9 111-1141-2519,S 111-1241-2516,S

9

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

42 1 21/32 1×8 3×9 30° 1 1 0.43 0.95 111-0742-1314,S

42 1 21/32 1×9 3×10 30° 1 1 0.43 0.95 111-0742-1315,S

ll

42 1 21/32 1×9 3×9 35° 1 1 0.43 0.95 111-0742-1316,S

42 1 21/32 2×8 5×9 35° 1 1 0.43 0.95 111-0742-2517,S

ri

Taper Long Skirt Button Bits

ed

Diameter

No. × button diameter

acFlushing hole Weight 7° Taper 11° Taper 12° Taper

w.

(mm)

Kg Lb

mm inch Front Gauge Angle Front Side Part No. Part No. Part No.

ww

32 1 1/4 2×7 5×7 35° 1 1 0.3 0.66 112-0732-2501,S 112-1132-2501,S

32 1 1/4 2×7 6×7 35° 1 1 0.3 0.66 112-1232-2601,S

m

33 1 19/64 2×7 5×7 35° 1 1 0.31 0.68 112-0733-2502,S 112-1133-2502,S

co

33 1 19/64 2×7 5×7 40° 2 1 0.31 0.68 112-1233-2503,S

33 1 19/64 2×7 6×7 35° 1 1 0.31 0.68 112-1233-2602,S

33

35

1 19/64

1 3/8

2×7

2×7

6×7

5×7

40°

40°

2

2

1

1

0.31

0.35

s.0.68

0.77

112-1133-2603,S

112-1235-2504,S

ll

35 1 3/8 2×7 5×8 35° 1 1 0.36 0.79 112-0735-2503,S

35 1 3/8 2×7 6×7 40° 2 1 0.35 0.77 112-1135-2604,S

ri

38 1 1/2 2×7 5×9 35° 1 1 0.41 0.9 112-0738-2504,S 112-1138-2505,S 112-1238-2505,S

41 1 5/8 2×7 5×9 35° 1 1 0.42 0.93 112-0741-2505,S 112-1141-2506,S 112-1241-2506,S

ed

Heavy Duty (Skirt Enhanced) Taper Long Skirt Button Bits

ac

w.

Diameter No. × button diameter(mm) Flushing hole Weight 11° Taper 12° Taper

ww

mm inch Front Gauge Angle Front Side Kg Lb Part No. Part No.

35 1 3/8 2×7 5×9 35° 1 1 0.38 0.84 112-1135-2507,S 112-1235-2507,S

om

36 1 27/64 2×7 5×9 35° 1 1 0.39 0.86 112-1136-2508,S 112-1236-2508,S

38 1 1/2 2×7 5×9 35° 1 1 0.41 0.9 112-1138-2509,S 112-1238-2509,S

c

41 1 5/8 2×7 5×9 35° 1 1 0.42 0.93 112-1141-2510,S 112-1241-2510,S

s.

How to order?

Bit Diameter + Taper Degree + Socket Diameter + Skirt Length + Insert Configuration

ll

Notes:

i

1. The ordinary connection taper degree is 7º, 11º and 12º, other degrees like 4.8º and 6º are also available;

dr

2. The ordinary taper diameter is 22 mm, other dimensions are also available if upon customers’ request;

3. Optional quantity of inserts: 4, 5, 6, 7 and 8 buttons;

e

4. Skirt length comes with long skirt of 70mm (2 3/4") and short skirt of 50mm (1 31/32") for option.

ac

10

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

Taper Drill Rods:

Length Weight 7° Taper 11° Taper 12° Taper

Hex22 x 108 mm Shank Taper Rods

ll

mm Foot Kg Lb Part No. Part No. Part No.

500 1’ 8” 1.5 3.3 221-0507

ri

600 2’ 1.93 4.3 221-0607

610 2’ 2.2 4.9 221-0611 221-0612

ed

800 2’6” 2.54 5.6 221-0807

1000 3’3” 3.15 6.9 221-1007

ac

1200 3’9” 3.76 8.3 221-1207

1220 4’ 4.1 9 221-1211 221-1212

w.

1500 4’11” 4.68 10.3 221-1507

1600 5’3” 4.98 11 221-1607

ww

1800 5’9” 5.59 12.3 221-1807

1830 6’ 5.9 13 221-1811 221-1812

2000 6’7” 6.4 14.1 221-2007 221-2011 221-2012

m

2200 7’2” 6.81 15 221-2207

co

2300 7’6” 7.12 15.7 221-2307

2400 7’9” 7.42 16.4 221-2407

Hex22 x 108 mm Shank 2435 8’

s. 7.8 17.2 221-2411 221-2412

2500 8’2” 7.73 17 221-2507

ll

2600 8’8” 8.3 18.3 221-2607 221-2611 221-2612

3000 9’10” 9.25 20.4 221-3007

ri

3200 10’ 6” 10.1 22.3 221-3211 221-3212

3500 11’5” 10.78 23.8 221-3507

ed

3655 12’ 11.5 25.4 221-3712

ac

3660 12’ 11.5 25.4 221-3711

4000 13’ 1” 12.6 27.8 221-4007 221-4011 221-4012

w.

4500 14’8” 13.83 30.5 221-4507

4800 15’ 9” 14.9 32.8 221-4811 221-4812

ww

5000 16’4” 15.35 33.8 221-5007

5500 18’1” 16.88 37.2 221-5507

5600 18’ 4” 17.4 38.4 221-5611 221-5612

om

6000 19’7” 18.3 40.3 221-6007

6400 21’ 19.8 43.7 221-6411 221-6412

c

7000 22’11” 21.2 46.7 221-7007

s.

7200 23’ 6” 22.2 48.9 221-7211 221-7212

8000 26’ 2” 24.6 54.2 221-8007 221-8011 221-8012

i ll

e dr

ac

11

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

Length Weight 7° Taper

Hex25 x 108 mm Shank Taper Rods

mm Foot Kg Lb Part No.

ll

1500 4’11” 5.9 13 222-1507

1600 5’3” 6.3 13.9 222-1607

ri

Hex25 x 108 mm Shank

1800 5’9” 7.1 15.7 222-1807

2000 6’7” 7.9 17.4 222-2007

ed

2500 8’2” 9.9 21.8 222-2507

3000 9’10” 11.9 26.2 222-3007

ac

4000 13’1” 15.8 34.8 222-4007

Length Weight 7° Taper 12° Taper

w.

Hex25 x 159 mm Shank Taper Rods

mm Foot Kg mm Part No. Part No.

1830 6’ 8 17.5 223-1812

ww

2435 8’ 10.4 22.9 223-2412

3050 10’ 12.8 28.3 223-3112

m

3655 12’ 15.3 33.6 223-3712

co

3965 13’ 16.5 36.4 223-4012

4000 13’1” 16.1 35.5 223-4007

Hex25 x 159 mm Shank

4200

4270

13’9”

14’

s. 16.7

17.7

36.8

39.1

223-4207

223-4312

ll

4700 15’4” 18.9 41.7 223-4707

4880 16’ 20.2 44.4 223-4912

ri

5000 16’4” 22.1 48.7 223-5007

5500 18’1” 22.1 48.7 223-5507

ed

5530 18’ 22.8 50.2 223-5512

6000 19’7” 24.1 53.1 223-6007

ac

6095 20’ 25 55.2 223-6112

How to order?

w.

Shank Types + Taper Degree + Rod Length

ww

Notes 1:

1. The ordinary connection taper degree is 7º, 11º and 12º, other degrees like 4.8º and 6º are also available;

2. The ordinary shank is Hex22 × 108mm, Hex25 × 159mm and other styles are also available if upon customers’

om

request;

3. The rod length must be specified in order;

c

4. In order to adapt to different rock conditions, the drill rod is selected by users.

s.

i ll

e dr

ac

12

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

m

Small-hole Drilling Tools

co

s.

Taper Rods Grades Recommended Table:

ll

Grades Types Recommended conditions

1) Rock drills impact energy: ≥76J, typically model: YT28

ri

2) Drilling depth: ≥ 2.5 m (8’ 2 27/64”)

G III 3) Rock formations: very hard, hard, medium hard and soft rock

Superior

ed

KSW Protodyakonov Hardness Scale: f ≥ 15

Uniaxial Compressive Strength: ≥150 Mpa

ac

4) Replacements: G rod, G I rod

1) Rock drills impact energy: < 76 J, typically model: YT24

w.

2) Drilling depth: ≤2.5 m (8’ 2 27/64”)

3) Rock formations: Medium hard and soft rock

Normal GI

ww

Protodyakonov Hardness Scale: f <15

Uniaxial Compressive Strength: <150 Mpa

4) Replacements: G rod

m

1) Rock drills impact energy: < 76 J, typically model: YT24

co

2) Drilling depth: ≤2.5 m (8’ 2 27/64”)

Economy G 3) Rock formations: Medium hard and soft rock

s.

Protodyakonov Hardness Scale: f <10

Uniaxial Compressive Strength: <100 Mpa

ll

ri

Notes 2:

ed

When bulk of premature failure (failure and cracking in shank, rod broken etc.) arise, please stop using all the rest

taper rods and then notify us promptly with the following information:

ac

1) Air compressor brand and model, normal and maximum pressure output, storage capacity and the number of

rock drills that matched with this compressor;

w.

2) Rock drills brand and model, air pressure, air consumption and water pressure.

3) Rock formation type and hardness (with uniaxial compressive strength or Protodyakonov hardness scale);

ww

work site condition: surface, underground, tunnel or other);

drill-hole depth and drilling methods: down, horizontal, fan and others;

4) Actually average life in using;

om

5) Drilling life of equivalent drill steels of other brands under same work condition;

6) Premature Failure Statistics: failure position, service life, quantity.

c

s.

i ll

e dr

ac

13

w.

Tel: 0086-851-85526688 Fax: 0086-851-85515597 Web: www.acedrills.com Email: info@acedrills.com

ww

You might also like

- Metric MSThreadDocument2 pagesMetric MSThreadarvindspakNo ratings yet

- Rock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesFrom EverandRock Blasting: A Practical Treatise on the Means Employed in Blasting Rocks for Industrial PurposesNo ratings yet

- Sandvik DARI SWEDEN PDFDocument138 pagesSandvik DARI SWEDEN PDFsidik marsudi100% (1)

- Hydrema 912C Rep - Man GBDocument174 pagesHydrema 912C Rep - Man GBjanezNo ratings yet

- Charts & ReferenceDocument6 pagesCharts & ReferencegicacosmaNo ratings yet

- Section 04 - GmaDocument6 pagesSection 04 - GmaHunterNo ratings yet

- Bolt & Screw DetailsDocument6 pagesBolt & Screw Detailsjee01No ratings yet

- Containers For Every Need: Maersk Equipment GuideDocument12 pagesContainers For Every Need: Maersk Equipment GuideSharath RadhakrishnanNo ratings yet

- Dimensional TolerancesDocument3 pagesDimensional Tolerancesedo tenseiNo ratings yet

- Zagar 7Document13 pagesZagar 7ratnakarNo ratings yet

- Document Title: Eliminating Screw Failures Used in Determining The Proper Techniques and MachiningDocument3 pagesDocument Title: Eliminating Screw Failures Used in Determining The Proper Techniques and MachiningSIMONENo ratings yet

- Solutions: Filler Material ConsumptionDocument2 pagesSolutions: Filler Material ConsumptionAli QureshiNo ratings yet

- Sheet Metal 3&4Document29 pagesSheet Metal 3&4Muhd Shabeeb ANo ratings yet

- Load Chart-Sagar ChiliveriDocument8 pagesLoad Chart-Sagar ChiliveriRajanna NallaNo ratings yet

- Travelingblock 273 1Document4 pagesTravelingblock 273 1kbgwseNo ratings yet

- 7 Grating PDFDocument2 pages7 Grating PDFSathish KumarNo ratings yet

- 7 Grating PDFDocument2 pages7 Grating PDFKomedianTunggalNo ratings yet

- Drillstar Roller ReamerDocument2 pagesDrillstar Roller ReamerLOURIDOMICHELLENo ratings yet

- Tabel MurbautDocument1 pageTabel MurbautPrayoga AriNo ratings yet

- Asme Ansi b16.11 Fittings Dimension PDFDocument38 pagesAsme Ansi b16.11 Fittings Dimension PDFleon057No ratings yet

- Cementing ToolsDocument107 pagesCementing Toolswalter acero orpesaNo ratings yet

- Bridge Deck BrochureDocument2 pagesBridge Deck BrochureClay HogerNo ratings yet

- Wire Ropes and DrillingDocument32 pagesWire Ropes and DrillingNed VasicNo ratings yet

- Pump Installation and Maintenance: Learning OutcomeDocument6 pagesPump Installation and Maintenance: Learning OutcomeMohammed Amin BenharkatNo ratings yet

- Ford We 910 - 2001Document6 pagesFord We 910 - 2001Jason-chungNo ratings yet

- Tuercas MariposaDocument1 pageTuercas MariposaarrancatetasNo ratings yet

- Self Tapping ScrewsDocument1 pageSelf Tapping ScrewsGulfstream Data, IncNo ratings yet

- Sttype BDocument1 pageSttype BSean YangNo ratings yet

- Asme Ansi b16.11 Fittings DimensionDocument23 pagesAsme Ansi b16.11 Fittings DimensionAlvaro Enrique MuñozNo ratings yet

- Asme Ansi b16.11 Fittings DimensionDocument23 pagesAsme Ansi b16.11 Fittings DimensionHarish Chandra Singh0% (1)

- Filtro de Gas - MUELLERDocument2 pagesFiltro de Gas - MUELLERCarlos BaezaNo ratings yet

- SpecificationDocument2 pagesSpecificationToxic ToucanNo ratings yet

- UNifit AccesoriosDocument38 pagesUNifit AccesoriosJorge EduardoNo ratings yet

- Exporter Pipe Fittings Dimensions PDFDocument38 pagesExporter Pipe Fittings Dimensions PDFselva nayagamNo ratings yet

- Asdo Tie Bar Design Capacities: Product DataDocument2 pagesAsdo Tie Bar Design Capacities: Product DatasivakumarNo ratings yet

- ASDO Structural Tie Bars Design CapDocument1 pageASDO Structural Tie Bars Design CapAjiboye MubarakNo ratings yet

- STUD SizesDocument1 pageSTUD SizesGeeNo ratings yet

- Hexagon Nut DrillingDocument1 pageHexagon Nut DrillingMeravigliorso76No ratings yet

- Stok 21 April 2022Document4 pagesStok 21 April 2022QC & Engineering JBI Plant SadangNo ratings yet

- Drilling Reaming Tapping PDFDocument17 pagesDrilling Reaming Tapping PDFPeter ThomasNo ratings yet

- Ansi b16.5 So Flange 600lbDocument1 pageAnsi b16.5 So Flange 600lbdtoxidNo ratings yet

- Screws Nuts Washer SizesDocument5 pagesScrews Nuts Washer SizesNanang RisdiantoNo ratings yet

- The Widest Range of Orbital Welding Equipment in The WorldDocument4 pagesThe Widest Range of Orbital Welding Equipment in The WorldVladimir KarpovNo ratings yet

- Style 400 Steel Coupling: (For 12" and Larger Pipe)Document4 pagesStyle 400 Steel Coupling: (For 12" and Larger Pipe)picottNo ratings yet

- 2 Drilling PipesDocument82 pages2 Drilling Pipesdf_campos3353No ratings yet

- How To Size An IBM MachineDocument1 pageHow To Size An IBM MachineFaisal AftabNo ratings yet

- Atlas Tube Jumbo HSS BrochureDocument6 pagesAtlas Tube Jumbo HSS BrochureOrlando NoguezNo ratings yet

- Flux 9Document1 pageFlux 9SANKET SINGHNo ratings yet

- Manuli Fitting - JIC & NPT MaleDocument5 pagesManuli Fitting - JIC & NPT MaleJasmi Noor SahudinNo ratings yet

- Builders' Metalwork: Ci/Sfb 21.9 Xt6Document32 pagesBuilders' Metalwork: Ci/Sfb 21.9 Xt6JC TsuiNo ratings yet

- Tapping and Drilling ChartDocument3 pagesTapping and Drilling ChartChris HeydenrychNo ratings yet

- Codo 90Document1 pageCodo 90RoLopNo ratings yet

- Threads Part TwoDocument10 pagesThreads Part TwoMaintenance CircleNo ratings yet

- Fabrication: Socket Head Cap ScrewsDocument3 pagesFabrication: Socket Head Cap Screwsnemi90No ratings yet

- StdrillserratedDocument2 pagesStdrillserratedSaul AguilarNo ratings yet

- Starkey 1982Document8 pagesStarkey 1982vasilelucian.diaconuNo ratings yet

- MacomberV-Beam-Catalog-1968 - Open Web Steel JoistsDocument12 pagesMacomberV-Beam-Catalog-1968 - Open Web Steel JoistsFredCreads100% (1)

- Equivalencias ElectromallaDocument2 pagesEquivalencias ElectromallaCésar Aguilar100% (1)

- Rock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesFrom EverandRock Blasting - A Practical Treatise On The Means Employed In Blasting Rocks For Industrial PurposesNo ratings yet

- Electric Cabinet CPL. C46615800 PDFDocument4 pagesElectric Cabinet CPL. C46615800 PDFSubhash KediaNo ratings yet

- C92000200 BSF3609H X-Unit For India PDFDocument368 pagesC92000200 BSF3609H X-Unit For India PDFSubhash KediaNo ratings yet

- MS83 PDFDocument32 pagesMS83 PDFSubhash KediaNo ratings yet

- 2-2. Bench & Long-Hole Drilling Tools PDFDocument15 pages2-2. Bench & Long-Hole Drilling Tools PDFSubhash KediaNo ratings yet

- 2-1. Drifting & Tunneling Drilling Tools PDFDocument9 pages2-1. Drifting & Tunneling Drilling Tools PDFSubhash KediaNo ratings yet

- 2-4. Thread Drill Bits Slection GuideDocument3 pages2-4. Thread Drill Bits Slection GuideSubhash KediaNo ratings yet

- Small-Hole Drilling ToolsDocument13 pagesSmall-Hole Drilling ToolsSubhash KediaNo ratings yet

- Larsen and Toubro RVNL Bid Document Rock Bolts PDFDocument240 pagesLarsen and Toubro RVNL Bid Document Rock Bolts PDFSubhash Kedia100% (1)

- EmcorDocument1 pageEmcorSubhash KediaNo ratings yet

- 3-2. DTH Button Bits enDocument13 pages3-2. DTH Button Bits enSubhash Kedia0% (1)

- SupFRP ISO Certificate (EN)Document1 pageSupFRP ISO Certificate (EN)Subhash KediaNo ratings yet

- TDS For SupFRP SDA Bolt H32S (SKT)Document1 pageTDS For SupFRP SDA Bolt H32S (SKT)Subhash KediaNo ratings yet

- 2-4. Thread Drill Bits Slection GuideDocument3 pages2-4. Thread Drill Bits Slection GuideSubhash KediaNo ratings yet

- Large Skid Steer LoadersDocument16 pagesLarge Skid Steer LoadersSubhash KediaNo ratings yet

- Larsen and Toubro RVNL Bid Document Rock Bolts PDFDocument240 pagesLarsen and Toubro RVNL Bid Document Rock Bolts PDFSubhash Kedia100% (1)

- Particulars Credit DebitDocument3 pagesParticulars Credit DebitSubhash KediaNo ratings yet

- AMW Parts CatalogueDocument363 pagesAMW Parts CatalogueSubhash KediaNo ratings yet

- Pipe Roofing SolutionsDocument12 pagesPipe Roofing SolutionsSubhash KediaNo ratings yet

- Dramix ZP 305Document1 pageDramix ZP 305Subhash KediaNo ratings yet

- 2-3. Shank AdaptersDocument11 pages2-3. Shank AdaptersSubhash KediaNo ratings yet

- Produced by An Autodesk Educational ProductDocument1 pageProduced by An Autodesk Educational ProductSubhash KediaNo ratings yet

- Maurice Nicoll The Mark PDFDocument4 pagesMaurice Nicoll The Mark PDFErwin KroonNo ratings yet

- Boring 7.1 Boring ToolsDocument4 pagesBoring 7.1 Boring ToolsPuneeth KumarNo ratings yet

- DUSS Katalogus PDFDocument92 pagesDUSS Katalogus PDFRegieNo ratings yet

- DrillingDocument71 pagesDrillingravi upadhyayNo ratings yet

- Owner'S Manual GH-1340W/1440W Lathes: Jet Equipment & Tools, IncDocument24 pagesOwner'S Manual GH-1340W/1440W Lathes: Jet Equipment & Tools, IncNoé MuñozNo ratings yet

- Lab 2 TurningDocument12 pagesLab 2 TurningLuqman HakimNo ratings yet

- Tool HoldersDocument47 pagesTool HolderslucamovNo ratings yet

- Maska Catalog QD BushingDocument1 pageMaska Catalog QD Bushingkman548No ratings yet

- AS+1349-1986-Bourdon Tube and Pressure GaugeDocument27 pagesAS+1349-1986-Bourdon Tube and Pressure GaugeDenzil D'SouzaNo ratings yet

- Annexure - 1: Page 1 of 9Document9 pagesAnnexure - 1: Page 1 of 9Haresh RaisinghaniNo ratings yet

- Manual Operacion Taladro MilwaukeeDocument28 pagesManual Operacion Taladro MilwaukeeNICOLAS ALBERTO ESTRADA SANDOVAL100% (1)

- QJet M GeneralDocument12 pagesQJet M GeneralWalter SantosNo ratings yet

- Lathe MachineDocument9 pagesLathe MachineSteven Josh bernalNo ratings yet

- Aitt Feb 2017 TH Sem IIIDocument6 pagesAitt Feb 2017 TH Sem IIIMadhu KumarNo ratings yet

- KOLee Tool Grinder Owners ManualDocument139 pagesKOLee Tool Grinder Owners ManualJason Bowman100% (4)

- VM-1000 (Ver¡g008)Document170 pagesVM-1000 (Ver¡g008)LeonardusNo ratings yet

- ASME Y14.5-2009, Geometric Boundaries 2Document9 pagesASME Y14.5-2009, Geometric Boundaries 2Keith Admin60% (5)

- Machine Spindle Noses: 6 Bison - Bial S. ADocument2 pagesMachine Spindle Noses: 6 Bison - Bial S. AshanehatfieldNo ratings yet

- LG 3 RT 54 QqbmegtvDocument19 pagesLG 3 RT 54 QqbmegtvChacha MagiboNo ratings yet

- Spindle Deflections in High-Speed Machine ToolsDocument8 pagesSpindle Deflections in High-Speed Machine ToolsFabrizio GrassoNo ratings yet

- Metal Joining Processes: List Types of Welding, Description With Sketches ofDocument19 pagesMetal Joining Processes: List Types of Welding, Description With Sketches ofeldhosekjnitNo ratings yet

- RockwellarmymillDocument82 pagesRockwellarmymillCurt WiseNo ratings yet

- 1946 Rusnok Mill Heads CatDocument25 pages1946 Rusnok Mill Heads CatfgrefeNo ratings yet

- Machinery's Handbook 27th Edition: Tooling and ToolmakingDocument3 pagesMachinery's Handbook 27th Edition: Tooling and ToolmakingOmkar KshirsagarNo ratings yet

- Guerrilla Guide To CNC Machining, Mold Making, and Resin CastingDocument106 pagesGuerrilla Guide To CNC Machining, Mold Making, and Resin CastingancientasmNo ratings yet

- Unit - 6 - Centre Lathe MachineDocument114 pagesUnit - 6 - Centre Lathe MachineSuyogNo ratings yet

- TVET 1 (Info. Sheet 12)Document4 pagesTVET 1 (Info. Sheet 12)zaidoNo ratings yet

- Eco100 4Document14 pagesEco100 4charles cashNo ratings yet

- Turning Fixtures 1Document40 pagesTurning Fixtures 1Appu MukundanNo ratings yet

- PRO-76T: Multifunctional Drilling & Tapping MachineDocument4 pagesPRO-76T: Multifunctional Drilling & Tapping MachineBouraoui Ben AyedNo ratings yet